Hierarchical Granular Contrastive Network-based Knowledge Acquisition and Modeling for Gas Scheduling of Steel Industry

-

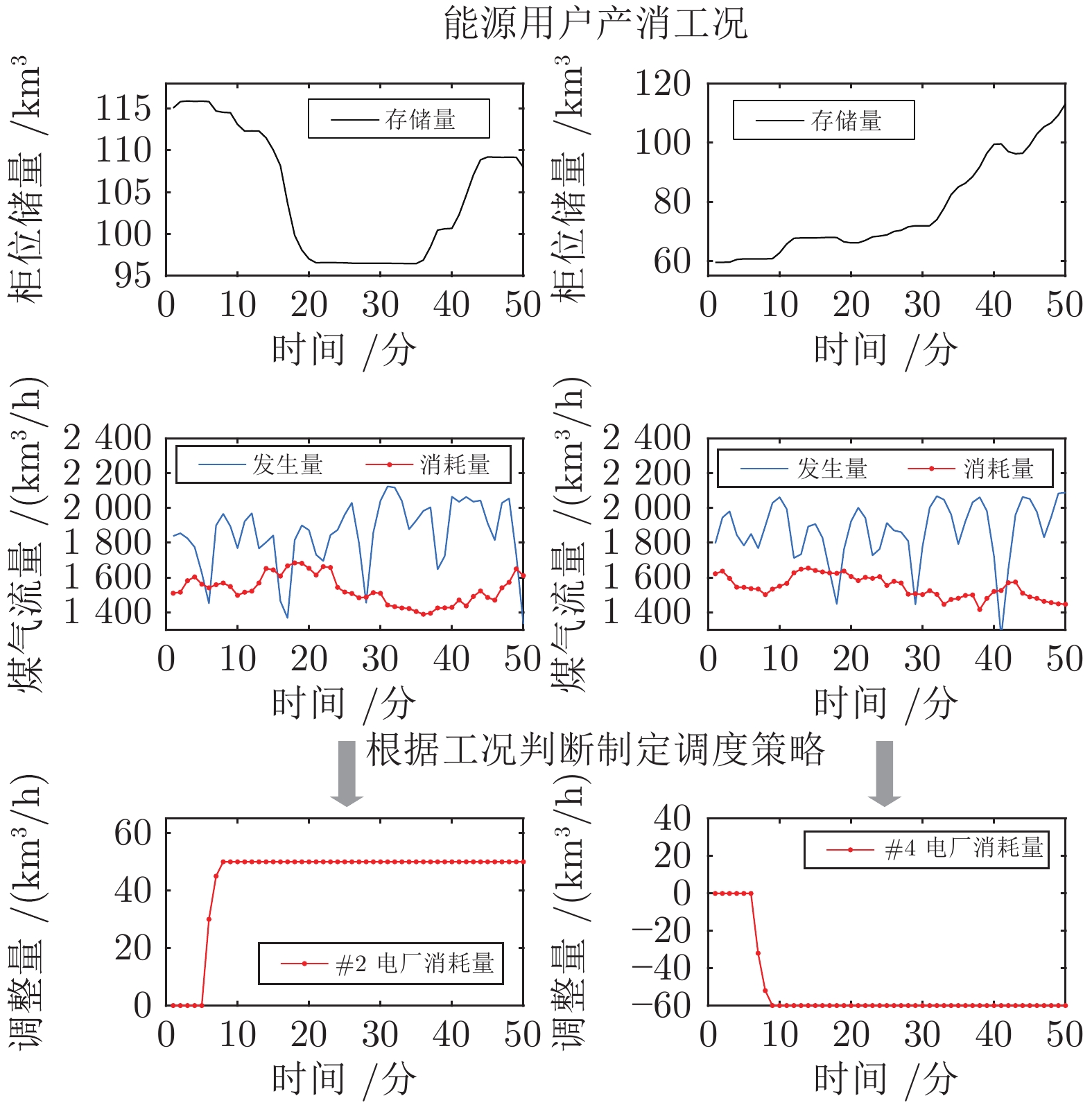

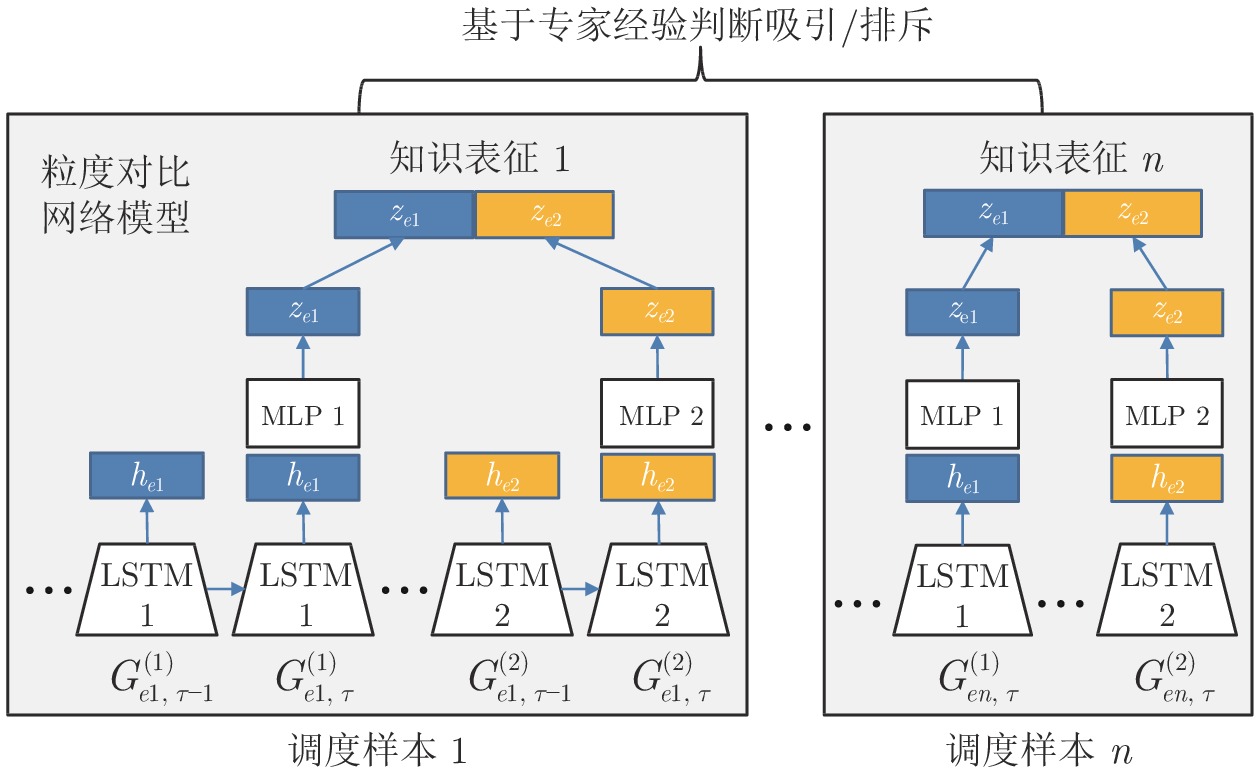

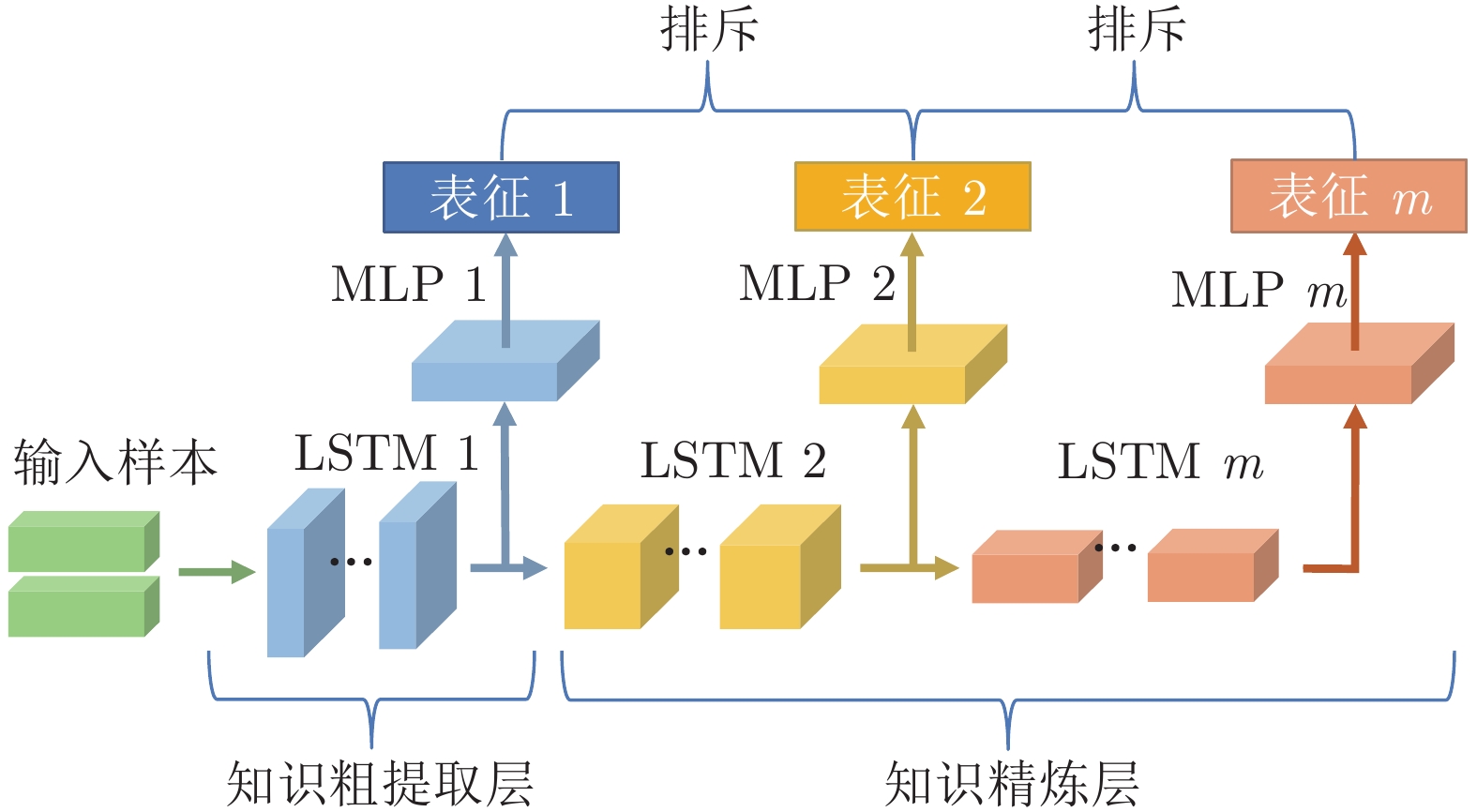

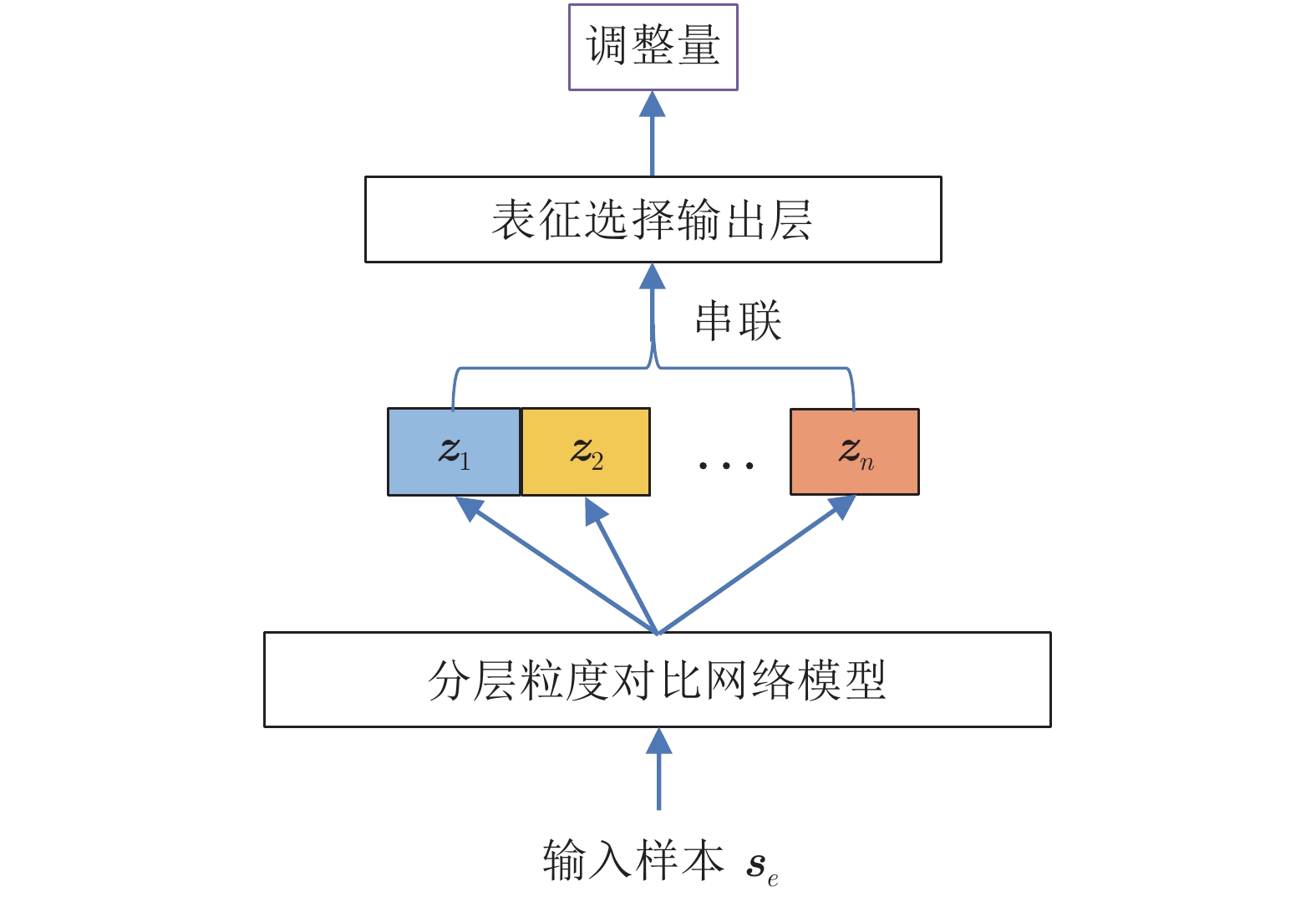

摘要: 对于钢铁燃气系统的实时有效调度是实现企业节能降耗的关键. 考虑燃气产消过程所包含的多工况特征, 提出了一种基于分层粒度对比网络的调度知识获取与建模方法. 鉴于深度对比学习对于语义信息的处理能力, 定义和描述了一系列信息粒度, 以建立能源数据的语义表示. 为初步提取多工况调度知识, 采用长短时记忆(Long and short-term memory, LSTM)网络学习具有时变特性的粒度变量特征. 在此基础上, 利用专家经验知识定性地划分对比学习样本, 建立基于粒度对比学习的知识表征网络. 为挖掘调度数据中所包含的深层次知识, 进一步提出了基于反馈机制的分层对比网络模型, 并通过网络输出层实现调度建模任务. 实验部分采用了国内某钢铁厂高炉煤气系统的实际数据进行了多组对比实验, 结果表明所提方法获得的知识表示能够有效提高燃气系统的建模精度, 帮助实现专家级别的调度表现.Abstract: A real-time effective scheduling for gas system of steel industry is important for achieving energy saving and consumption reduction. Considering that the gas generation and consumption processes are characterized by multiple operating conditions, a knowledge acquisition and modeling algorithm based on hierarchical granular contrastive network is proposed. In view of the capabilities of deep contrast learning for processing semantic information, a series of information granularities are defined and described to establish a semantic representation of the energy data. To extract multi-condition scheduling knowledge, a long and short-term memory (LSTM) network is used to learn the time-varying characteristics of granular variables. On top of this, a knowledge representation network based on granular contrastive learning is established, which takes advantage of the expert knowledge to partition the contrastive samples. For digging out deep-level knowledge involved in the scheduling data, a hierarchical contrastive network is further proposed by employing a closed-loop feedback mechanism, and then scheduling modeling tasks can be addressed with output layers. The practical operation data coming from the blast furnace gas system of a domestic steel plant are utilized to perform our experiments. The results show that the multi-condition knowledge representation obtained by the proposed method would help improve the modeling accuracy of the gas system and realize human-level scheduling performance.

-

Key words:

- Steel industry /

- gas system /

- knowledge acquisition /

- information granularity /

- contrastive learning

-

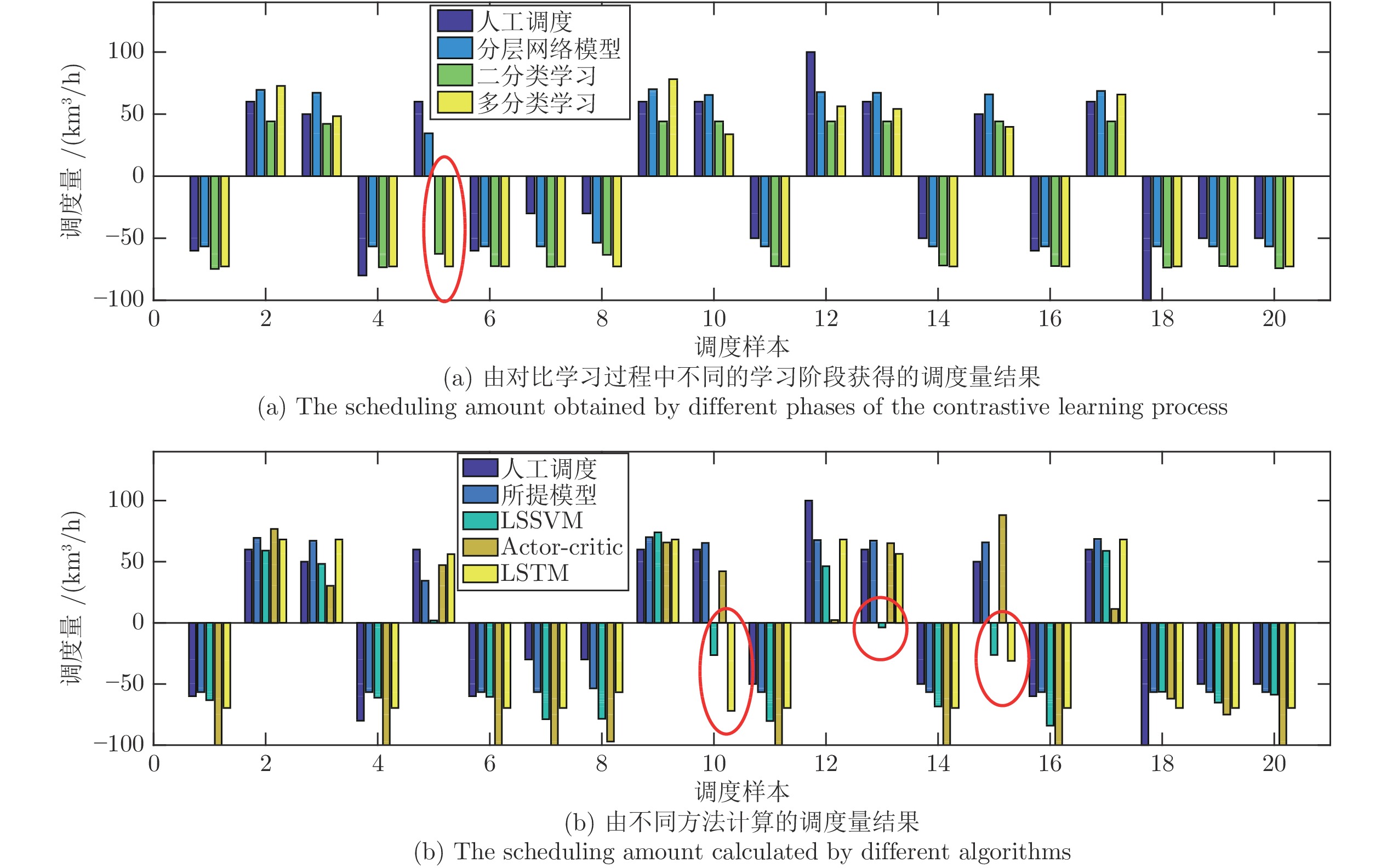

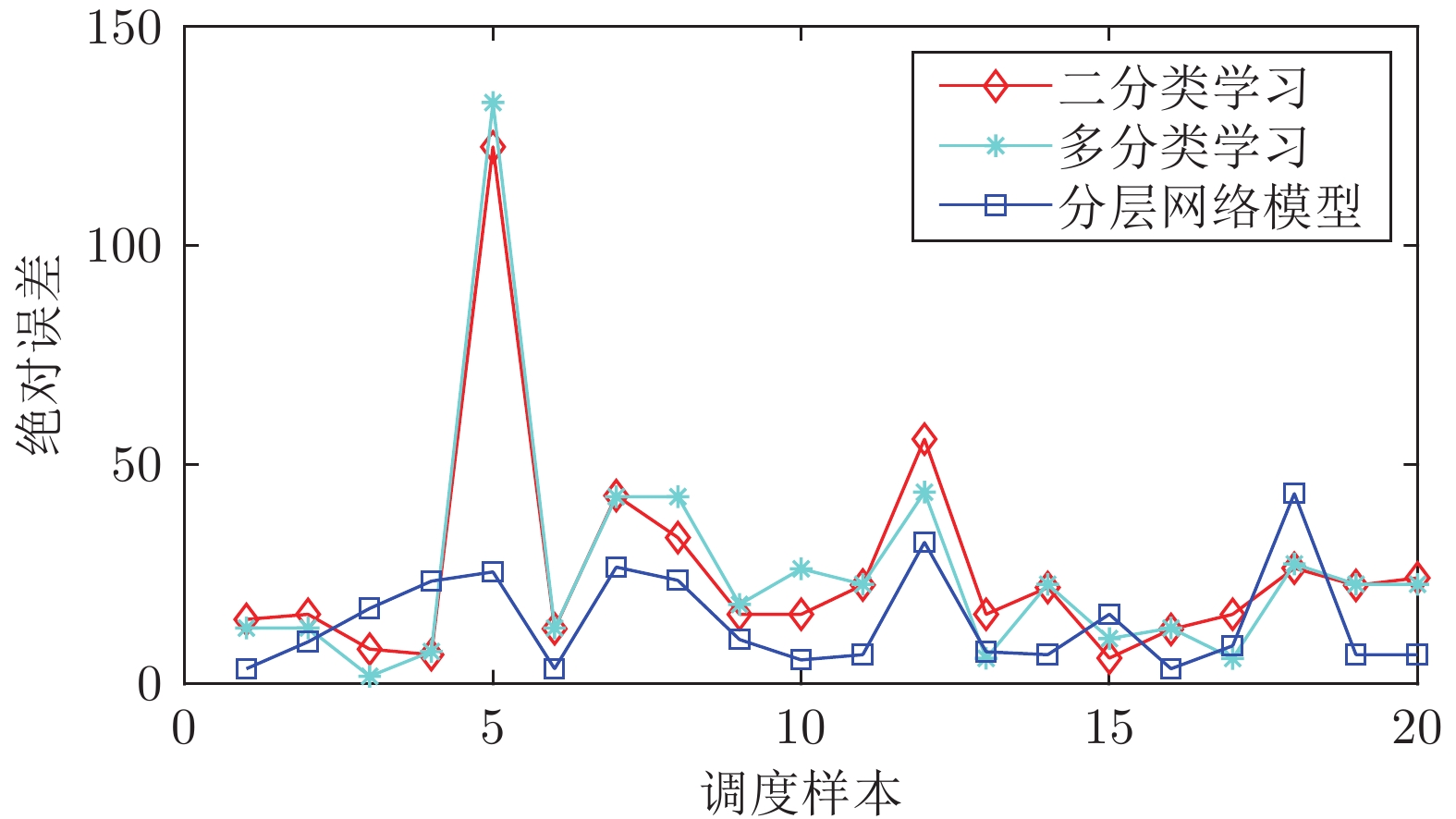

表 1 各对比学习阶段的误差统计

Table 1 Error statistical results of different contrastive learning phases

模型 MAE RMSE MAPE 二分类知识学习 25.5538 35.9038 47.8148 多分类知识学习 25.2805 37.3146 48.4387 分层次对比网络 (本文方法) 14.2621 18.0120 25.9330 表 2 各对比方法的误差及耗时统计

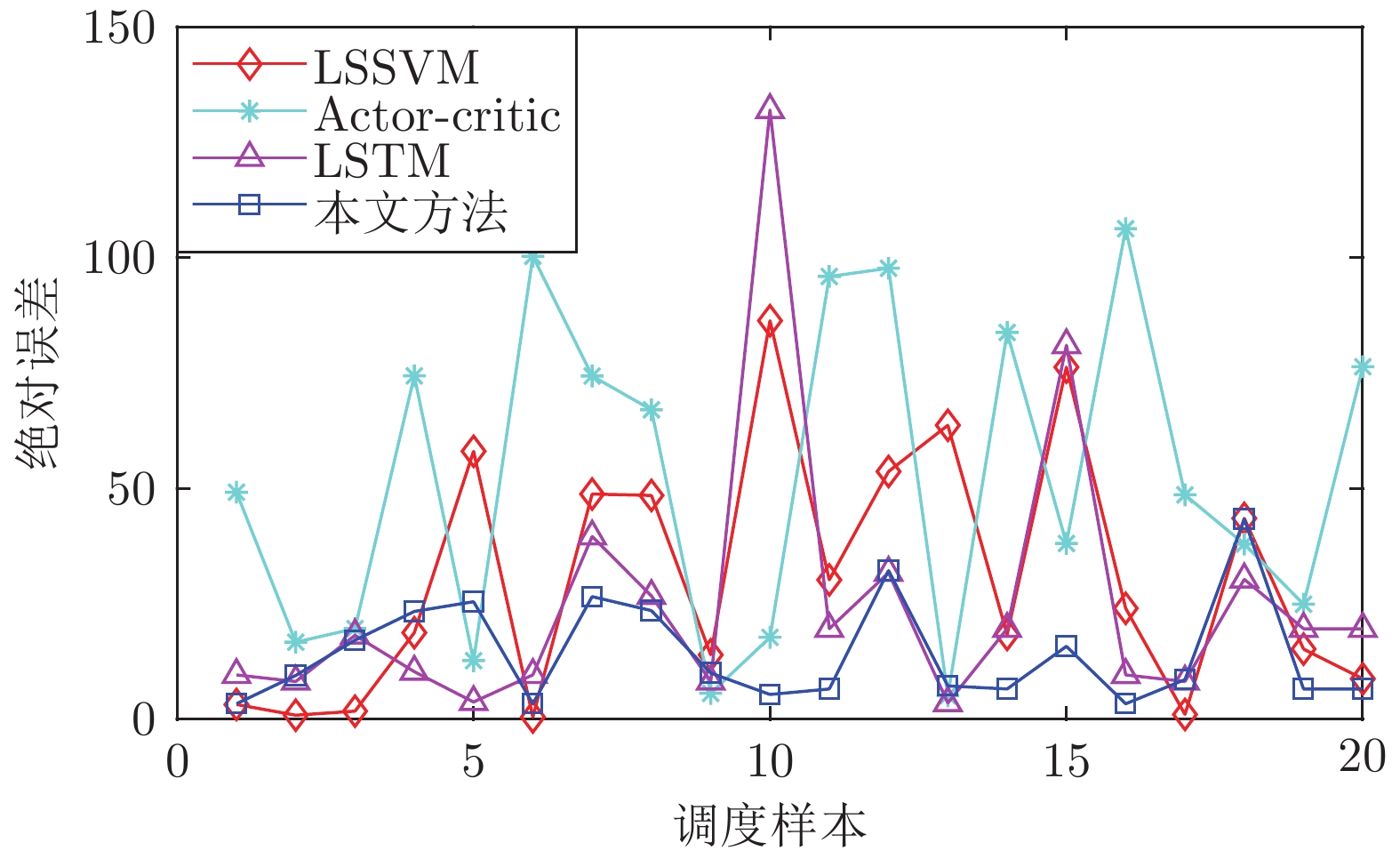

Table 2 Statistical results of error and time consumption of the comparative algorithms

模型 MAE RMSE MAPE TC (s) LSSVM 30.8112 40.5874 58.3436 1.8990 Actor-critic 52.6542 62.4786 99.1213 195.1375 LSTM 25.4867 38.1860 48.6895 11.7582 本文方法 14.2621 18.0120 25.9330 39.0892 表 3 不同场景下的煤气柜位预测误差统计

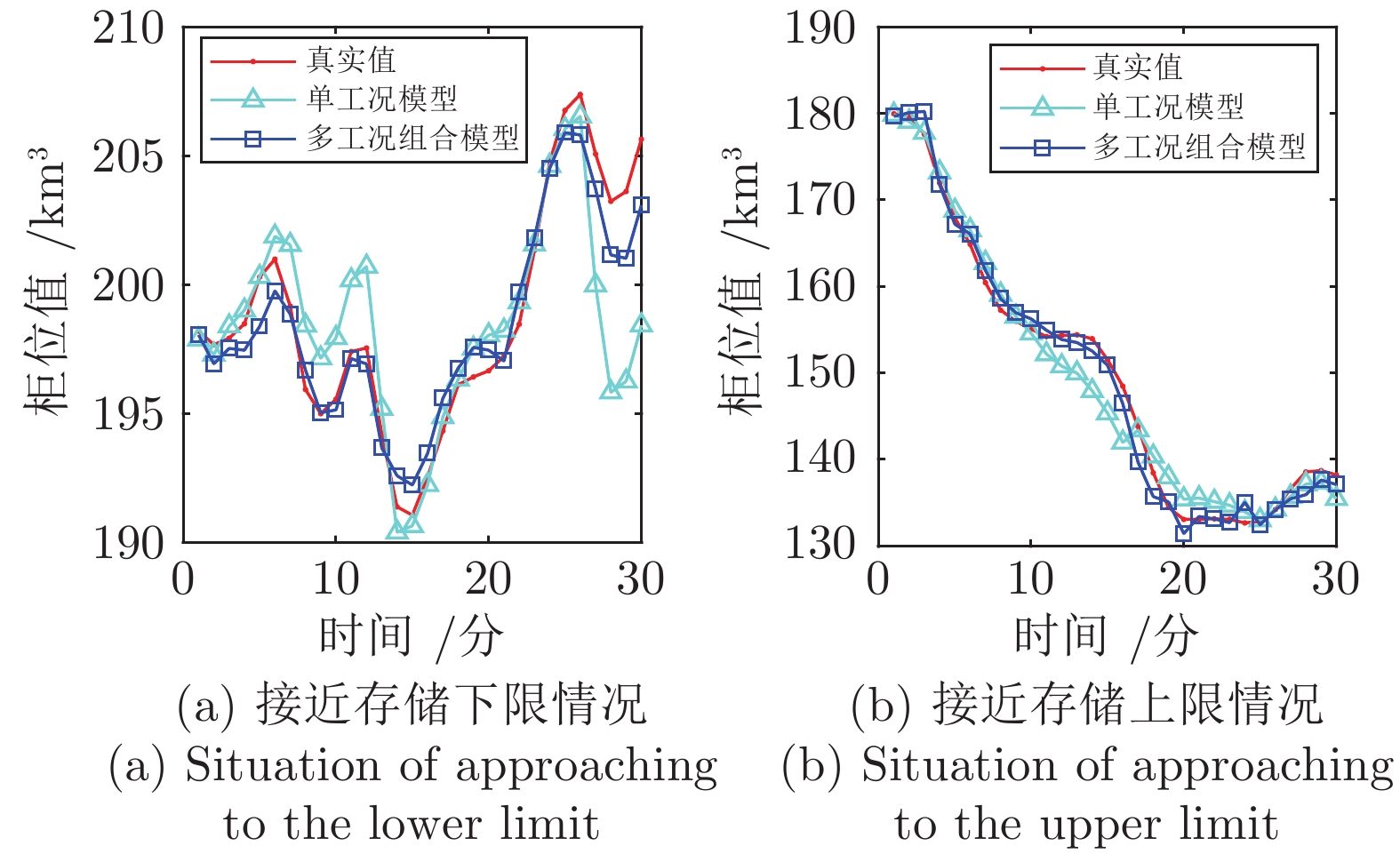

Table 3 The error statistics of the gas tank level prediction under different situations

统计误差 MAE RMSE MAPE 接近柜位存储上限 单工况 1.8248 2.8128 0.9093 多工况 0.9576 1.1646 0.4794 接近柜位存储下限 单工况 2.0187 2.6831 1.3711 多工况 1.1772 1.5033 0.7981 -

[1] Wang T Y, Zhao J, Liu Q L, Wang W. Granular-based multi-layer spatiotemporal network with control gates for energy prediction of steel industry. IEEE Transactions on Instrumentation and Measurement, DOI: 10.1109/TIM.2021.3122173 [2] Wang T Y, Zhao J, Xu Q S, Pedrycz W, Wang W. A dynamic scheduling framework for byproduct gas system combining expert knowledge and production plan. IEEE Transactions on Automation Science and Engineering, DOI: 10.1109/TASE.2022.3162653 [3] Jiang S L, Peng G, Bogle I D L. A two-stage robust optimization approach for oxygen flexible distribution under uncertainty in iron and steel plants. arXiv preprint arXiv: 2106.11635, 2021. [4] . Yang J H, Cai J J, Sun W Q, Huang J. Optimal allocation of surplus gas and suitable capacity for buffer users in steel plant. Applied Thermal Engineering, 2017, 115: 586-596 doi: 10.1016/j.applthermaleng.2016.12.096 [5] . Zhai Y W, Lv Z, Zhao J, Wang W, Leung H. Data-driven inference modeling based on an on-line Wang-Mendel fuzzy approach. Information Sciences, 2021, 551: 113-127 doi: 10.1016/j.ins.2020.10.018 [6] . Jin F, Wang L Q, Zhao J, Wang W, Liu Q L. Granular-causality-based byproduct energy scheduling for energy-intensive enterprise. IEEE Transactions on Automation Science and Engineering, 2020, 17(4): 1662-1673 doi: 10.1109/TASE.2020.2969436 [7] . Wang D, Ha M M, Zhao M M. The intelligent critic framework for advanced optimal control. Artificial Intelligence Review, 2022, 55: 1-22 doi: 10.1007/s10462-021-10118-9 [8] 王鼎, 赵明明, 哈明鸣, 乔俊飞. 基于折扣广义值迭代的智能最优跟踪及应用验证. 自动化学报, 2022, 48(1): 182-193 doi: 10.16383/j.aas.c210658. Wang Ding, Zhao Ming-Ming, Ha Ming-Ming, Qiao Jun-Fei. Intelligent optimal tracking with application verifications via discounted generalized value iteration. Acta Automatica Sinica, 2022, 48(1): 182−193 doi: 10.16383/j.aas.c210658 [9] . Wang D, Zhao M M, Ha M M, Ren J. Neural optimal tracking control of constrained nonaffine systems with a wastewater treatment application. Neural Networks, 2021, 143: 121-132 doi: 10.1016/j.neunet.2021.05.027 [10] . Zhao C H, Chen J H, Jing H. Condition-driven data analytics and monitoring for wide-range nonstationary and transient continuous processes. IEEE Transactions on Automation Science and Engineering, 2020, 18(4): 1563-1574 [11] Chen X, Zhao C H. Conditional discriminative autoencoder and condition-driven immediate representation of soft transition for monitoring complex nonstationary processes. Control Engineering Practice, 2022, 122: Article No. 105090 [12] . Chen J H, Zhao C H. Exponential stationary subspace analysis for stationary feature analytics and adaptive nonstationary process monitoring. IEEE Transactions on Industrial Informatics, 2021, 17(12): 8345-8356 doi: 10.1109/TII.2021.3053308 [13] Chen T, Kornblith S, Swersky K, Norouzi M, Hinton G E. Big self-supervised models are strong semi-supervised learners. arXiv preprint arXiv: 2006.10029, 2020. [14] Chen X C, Yao L, Zhou T, Dong J M, Zhang Y. Momentum contrastive learning for few-shot COVID-19 diagnosis from chest CT images. Pattern Recognition, 2021, 113: Article No. 107826 [15] Marcheggiani D, Titov I. Encoding sentences with graph convolutional networks for semantic role labeling. arXiv preprint arXiv: 1703.04826, 2017. [16] Wu S, Tang Y Y, Zhu Y Q, Wang L, Xie X, Tan T N. Session-based recommendation with graph neural networks. In: Proceedings of the 2019 AAAI Conference on Artificial Intelligence. Palo Alto, USA: AAAI Press, 2019. [17] . Chen T, Kornblith S, Norouzi M, Hinton G. A simple framework for contrastive learning of visual representations. International Conference on Machine Learning, 2020, 119: 1597-1607 [18] . Pedrycz W. Granular computing for data analytics: A manifesto of human-centric computing. IEEE/CAA Journal of Automatica Sinica, 2018, 5(6): 1025-1034 doi: 10.1109/JAS.2018.7511213 [19] . Wang T Y, Han Z Y, Zhao J, Wang W. Adaptive granulation-based prediction for energy system of steel industry. IEEE Transactions on Cybernetics, 2018, 48(1): 127-138 doi: 10.1109/TCYB.2016.2626480 [20] Han Z Y, Pedrycz W, Zhao J, Wang W. Hierarchical granular computing-based model and its reinforcement structural learning for construction of long-term prediction intervals. IEEE Transactions on Cybernetics, DOI: 10.1109/TCYB.2020.2964011 [21] . Wang T Y, Zhao J, Sheng C Y, Wang W, Wang L Q. Multi-layer encoding genetic algorithm-based granular fuzzy inference for blast furnace gas scheduling. IFAC-PapersOnLine, 2016, 49(20): 132-137 doi: 10.1016/j.ifacol.2016.10.109 [22] Zhao J, Wang T Y, Pedrycz W, Wang W. Granular prediction and dynamic scheduling based on adaptive dynamic programming for the blast furnace gas system. IEEE Transactions on Cybernetics, DOI: 10.1109/TCYB.2019.2901268 [23] 桂卫华, 陈晓方, 阳春华, 谢永芳. 知识自动化及工业应用. 中国科学: 信息科学, 2016, 46(8): 1016-1034 doi: 10.1360/N112016-00065. Gui Wei-Hua, Chen Xiao-Fang, Yang Chun-Hua, Xie Yong-Fang. Knowledge automation and industrial application. Scientia Sinica informationis, 2016, 46(8): 1016-1034 doi: 10.1360/N112016-00065 [24] . Hochreiter S, Schmidhuber J. Long short-term memory. Neural Computation, 1997, 9(8): 1735-1780 doi: 10.1162/neco.1997.9.8.1735 [25] . Liu J, Shahroudy A, Xu D, Kot A C, Wang G. Skeleton-based action recognition using spatiotemporal LSTM network with trust gates. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2017, 40(12): 3007-3021 [26] . Wang T Y, Leung H, Zhao J, Wang W. Multiseries featural LSTM for partial periodic time-Series prediction: A case study for steel industry. IEEE Transactions on Instrumentation and Measurement, 2020, 69(9): 5994-6003 doi: 10.1109/TIM.2020.2967247 [27] . Han Z Y, Liu Y, Zhao J, Wang W. Real time prediction for converter gas tank levels based on multi-output least square support vector regressor. Control Engineering Practice, 2012, 20(12): 1400-1409 doi: 10.1016/j.conengprac.2012.08.006 -

下载:

下载: