Prediction Method of Hot Metal Silicon Content in Blast Furnace Based on Optimal Smelting Condition Migration

-

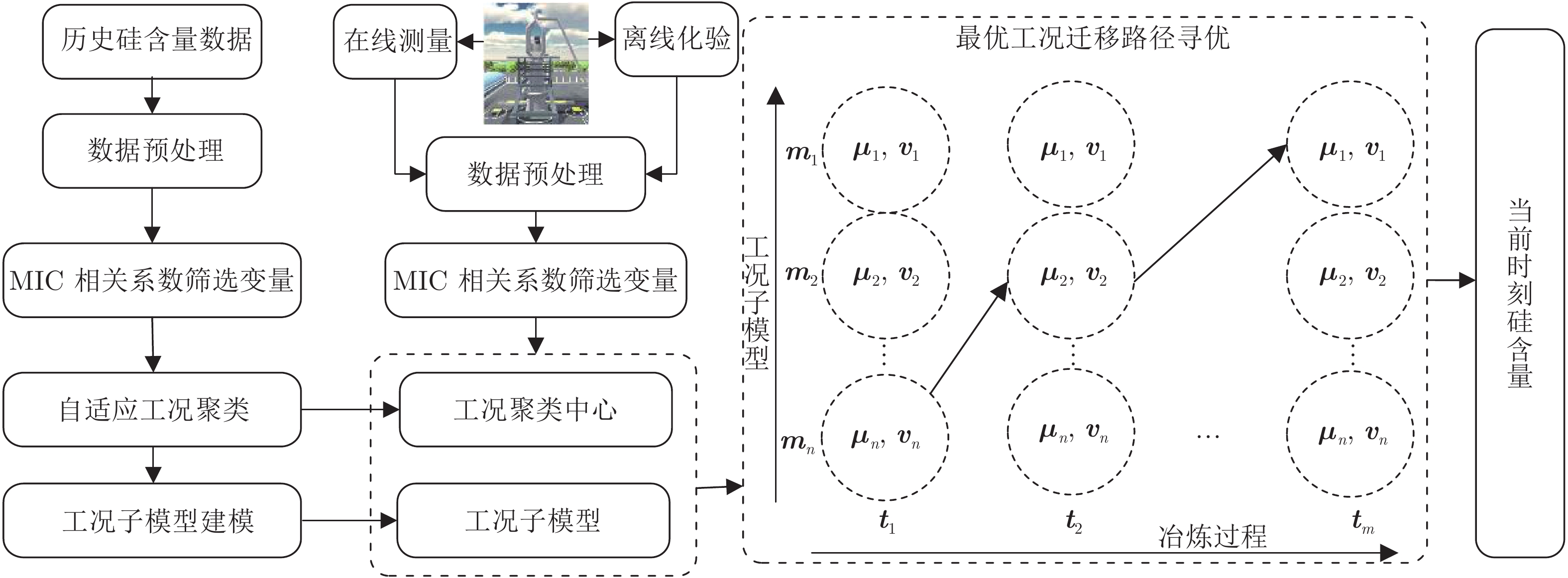

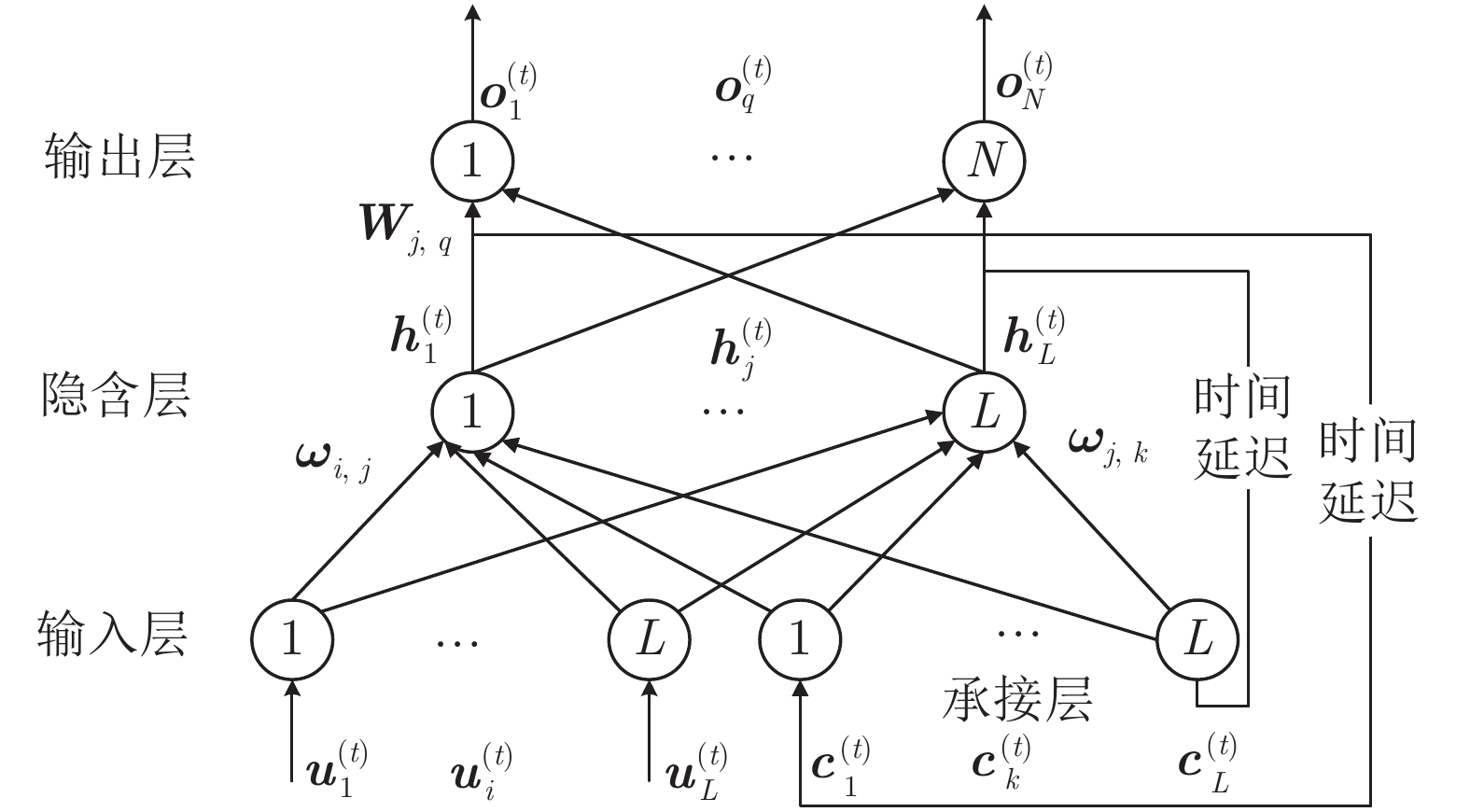

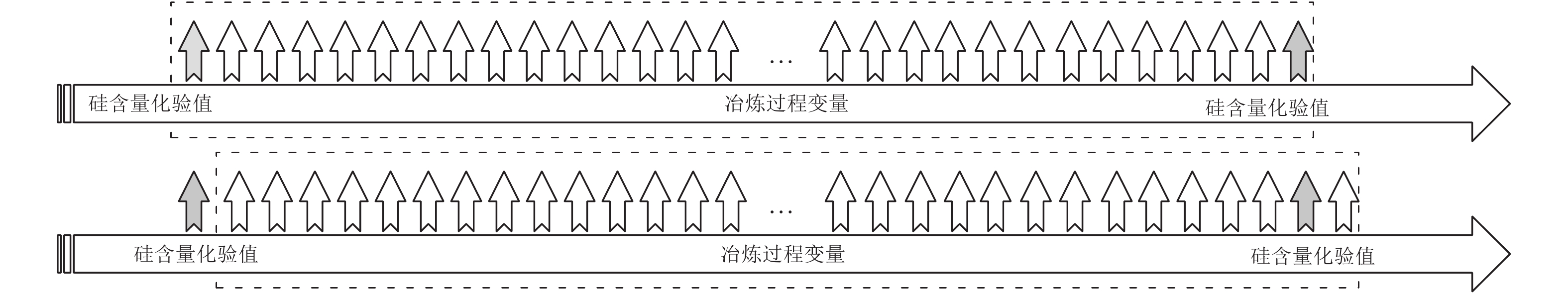

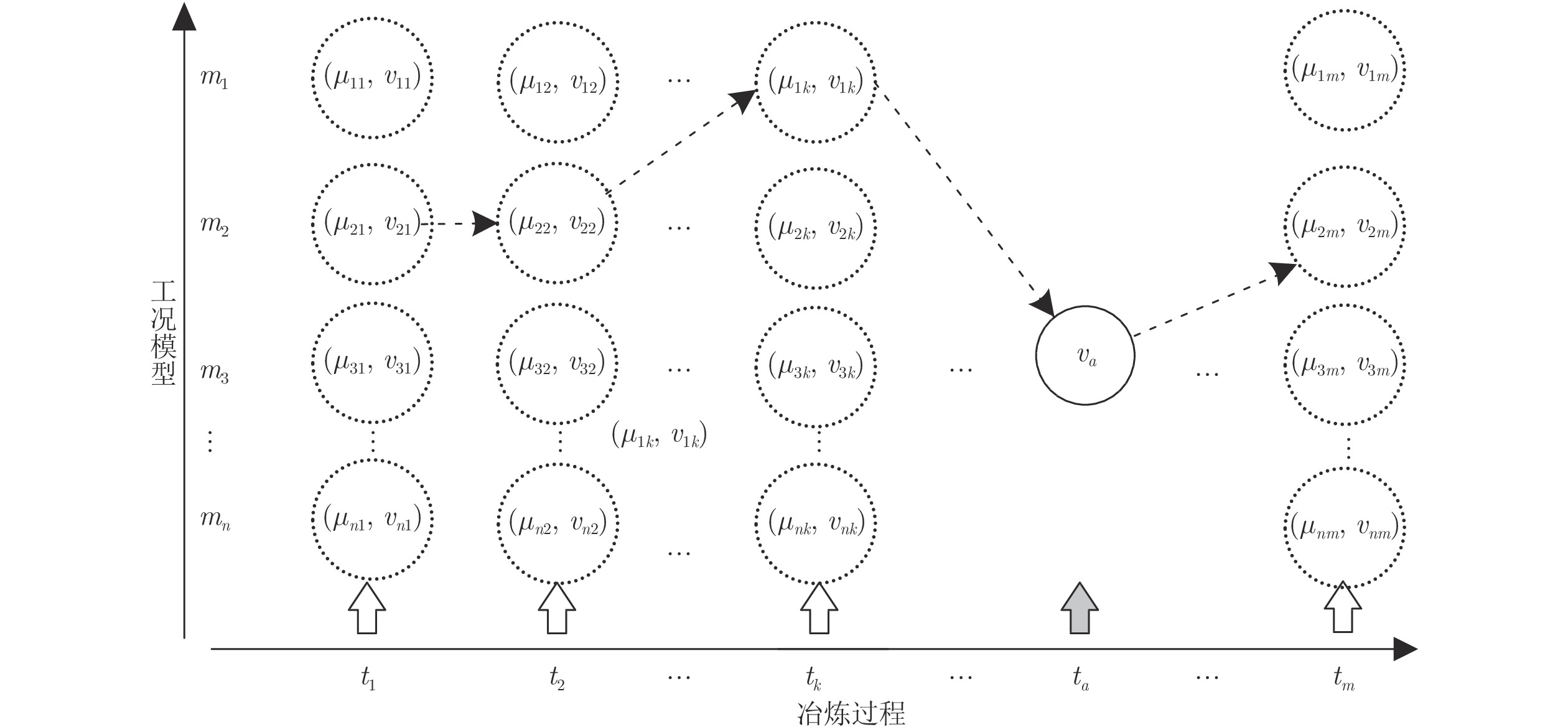

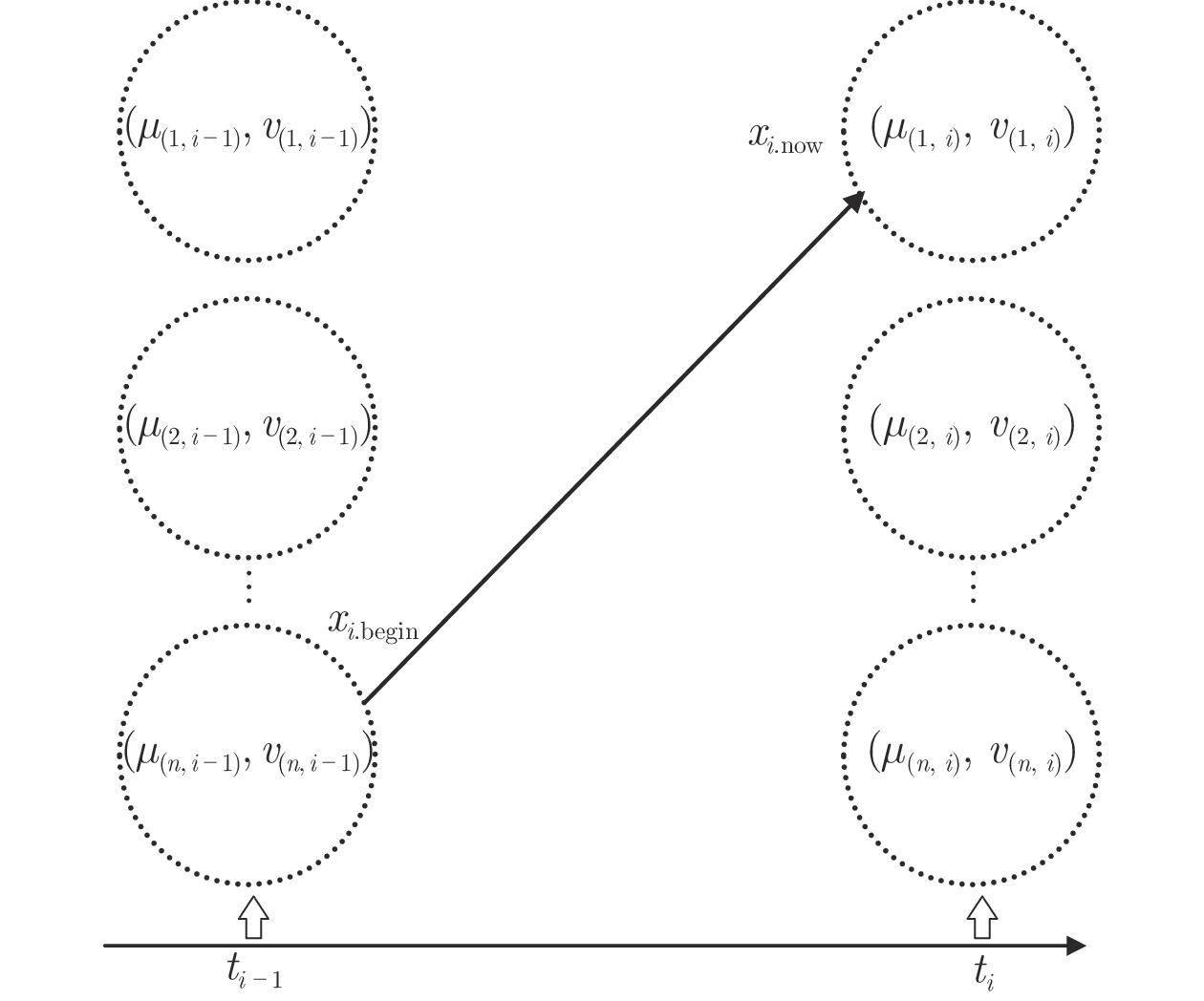

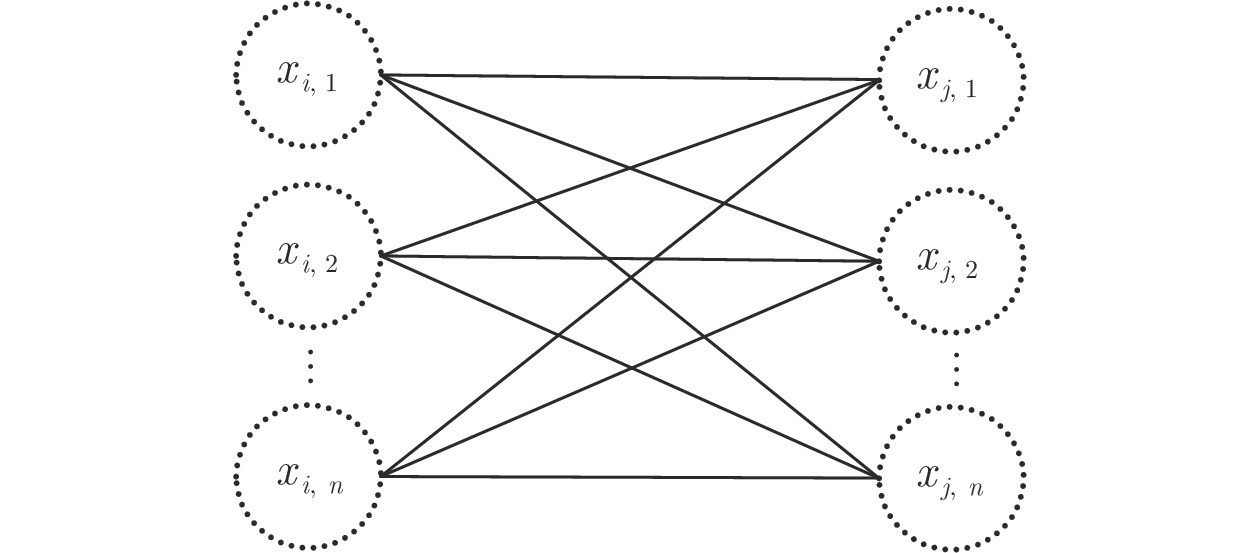

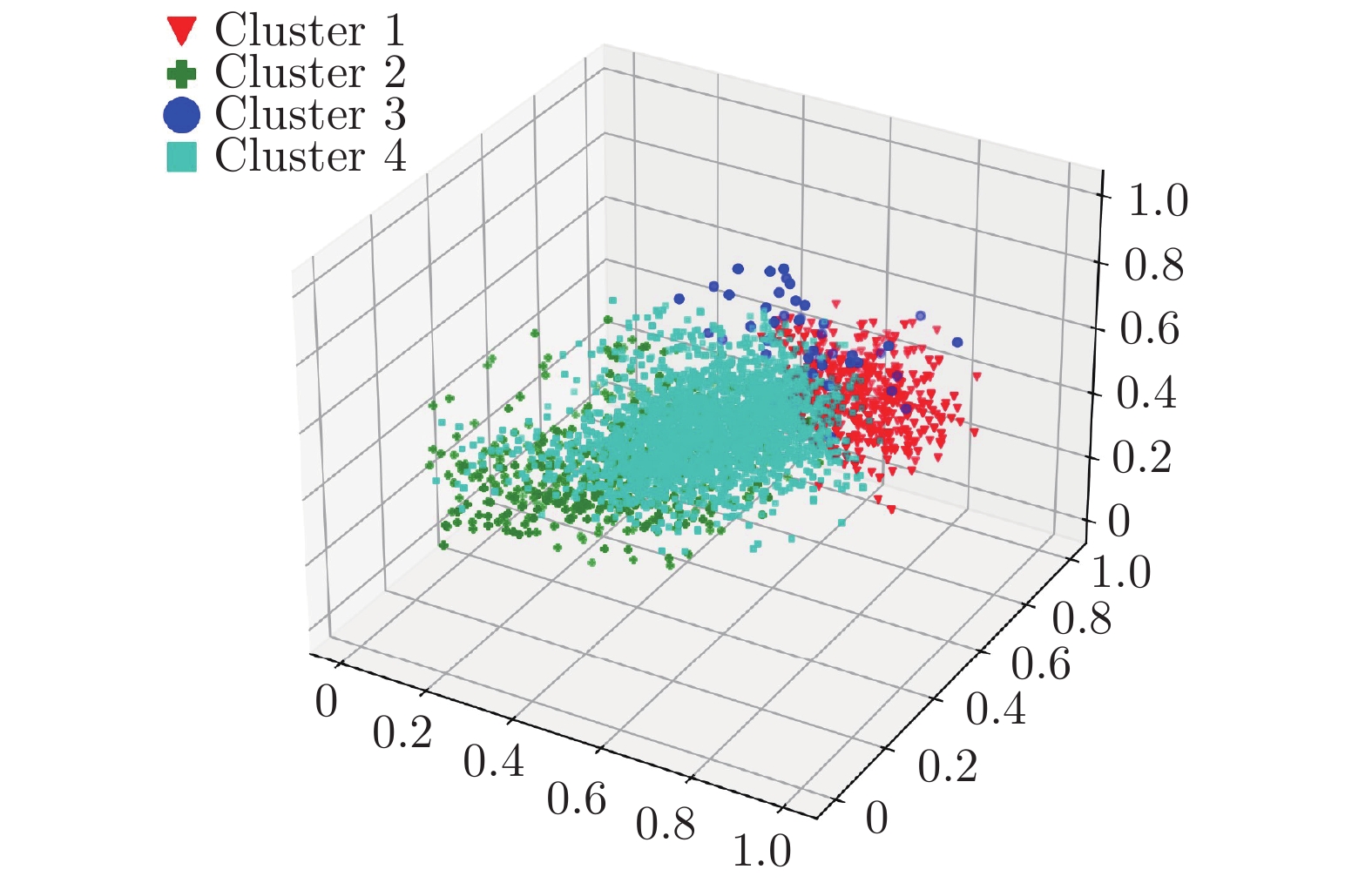

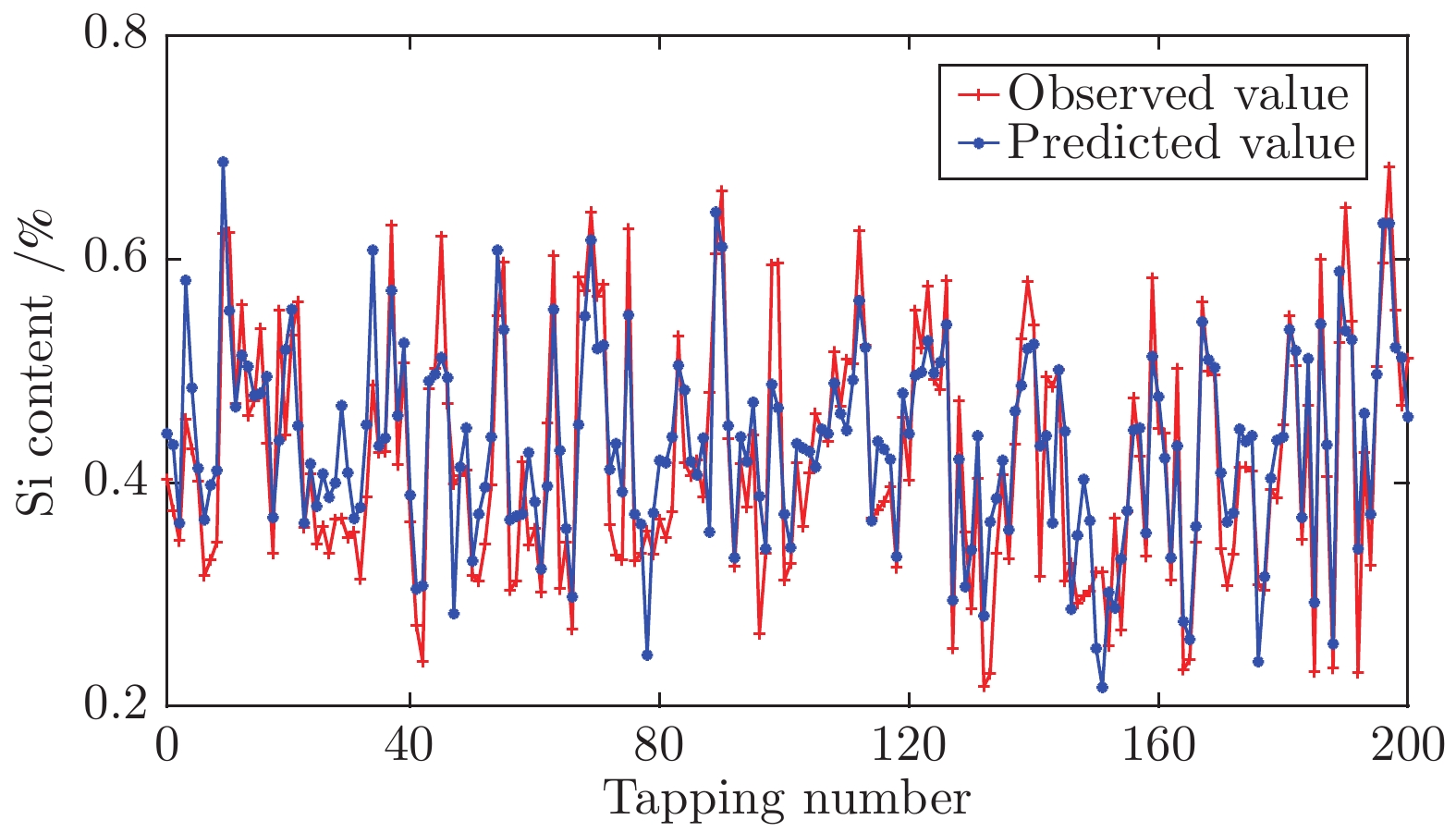

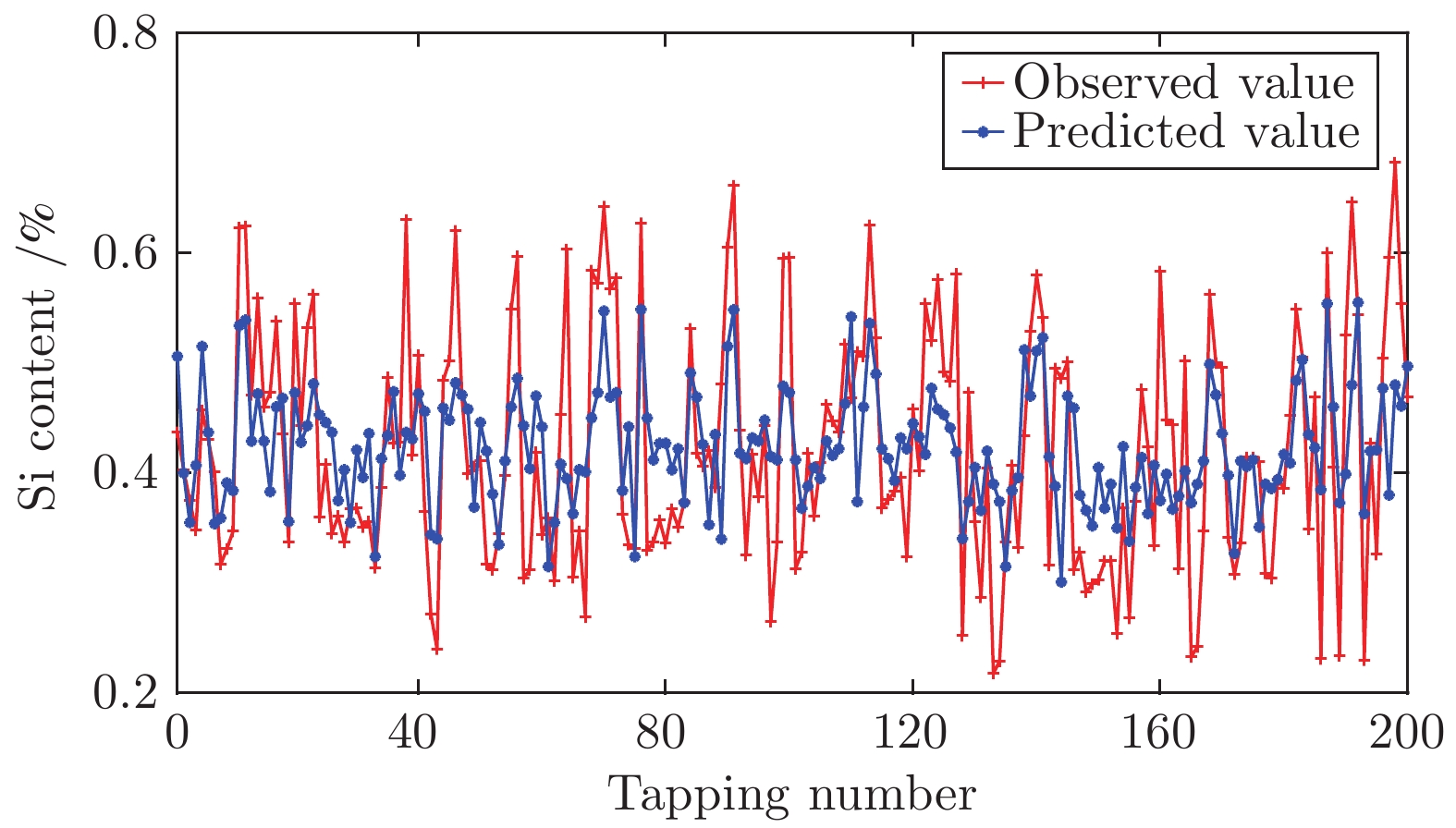

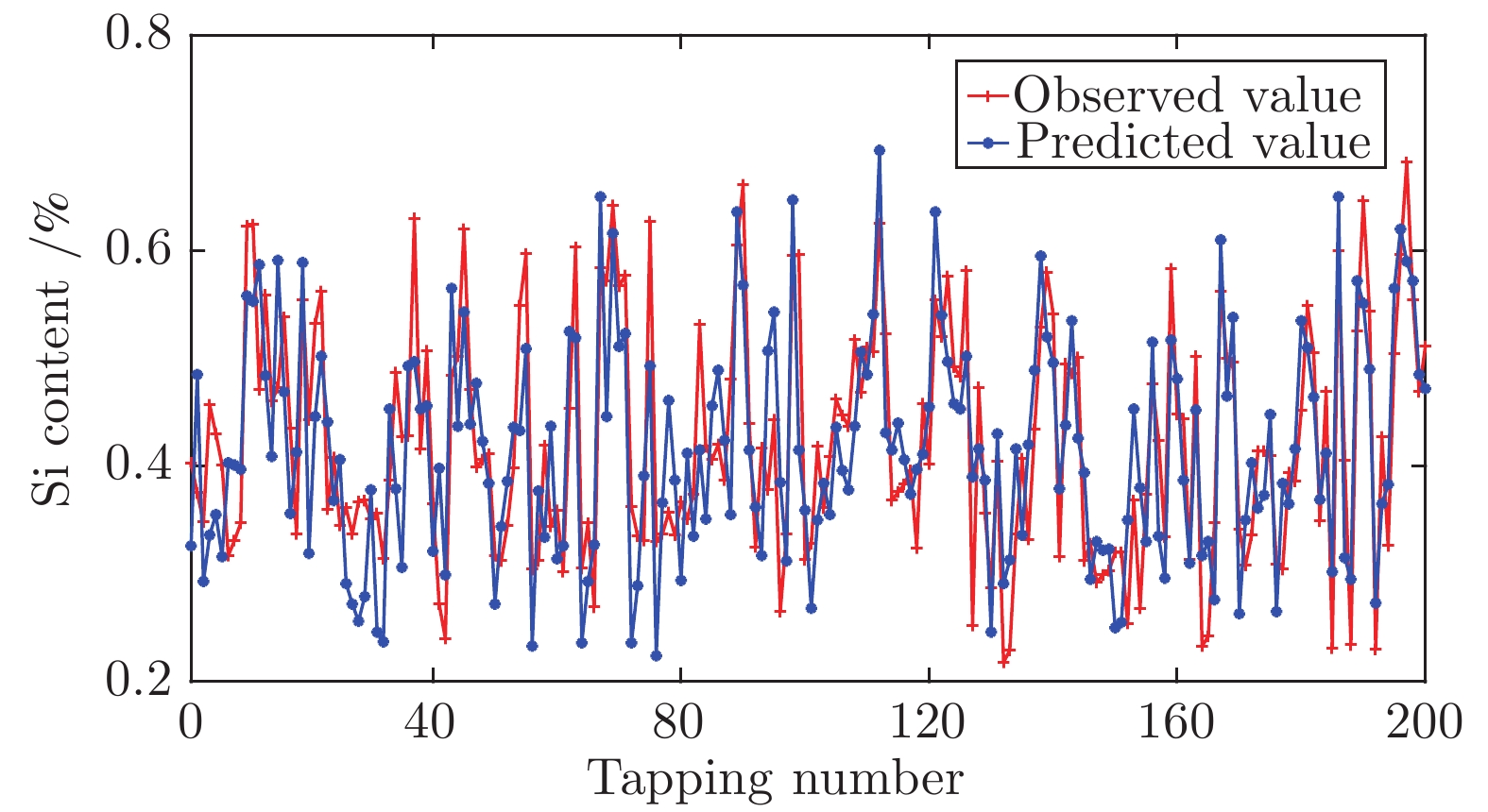

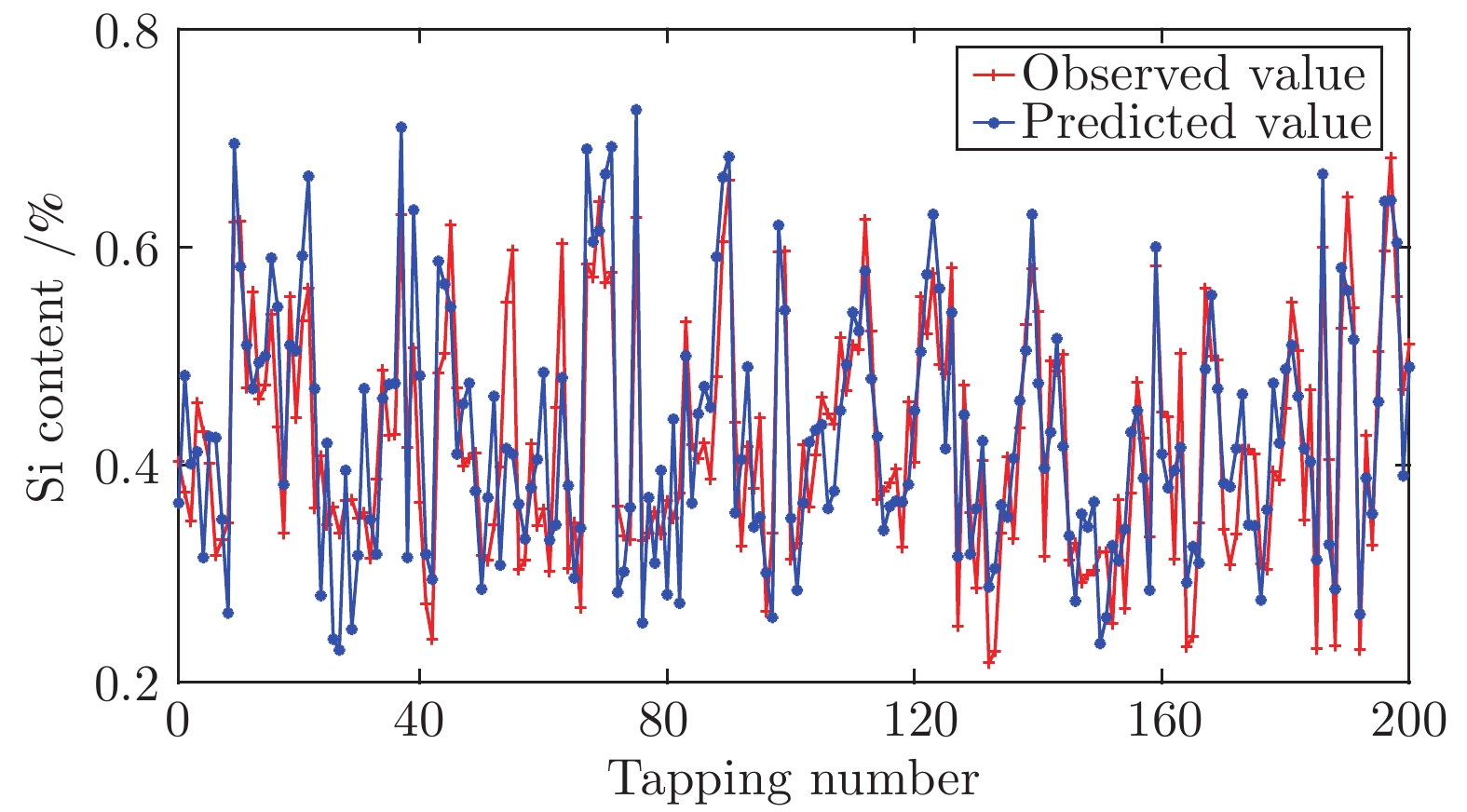

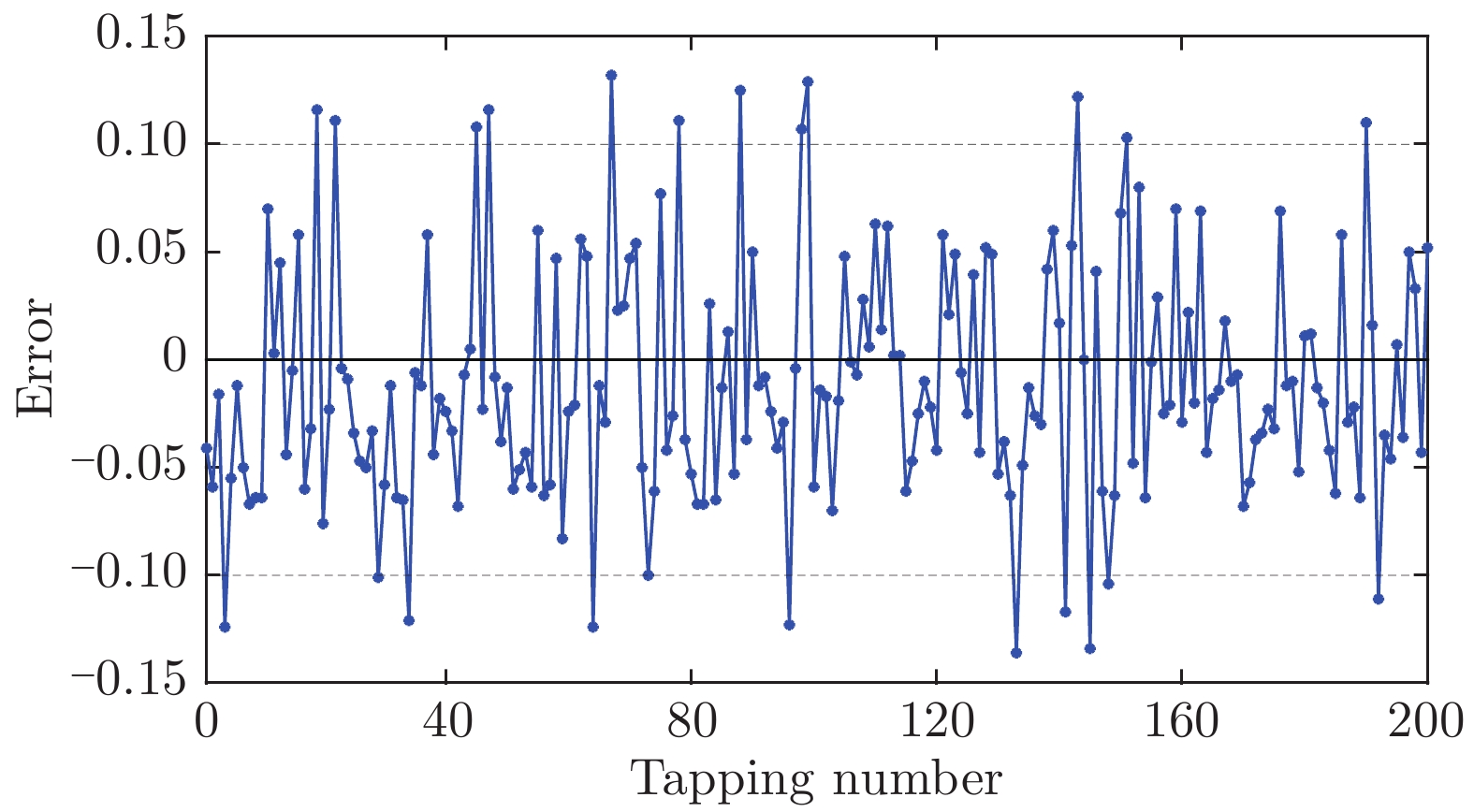

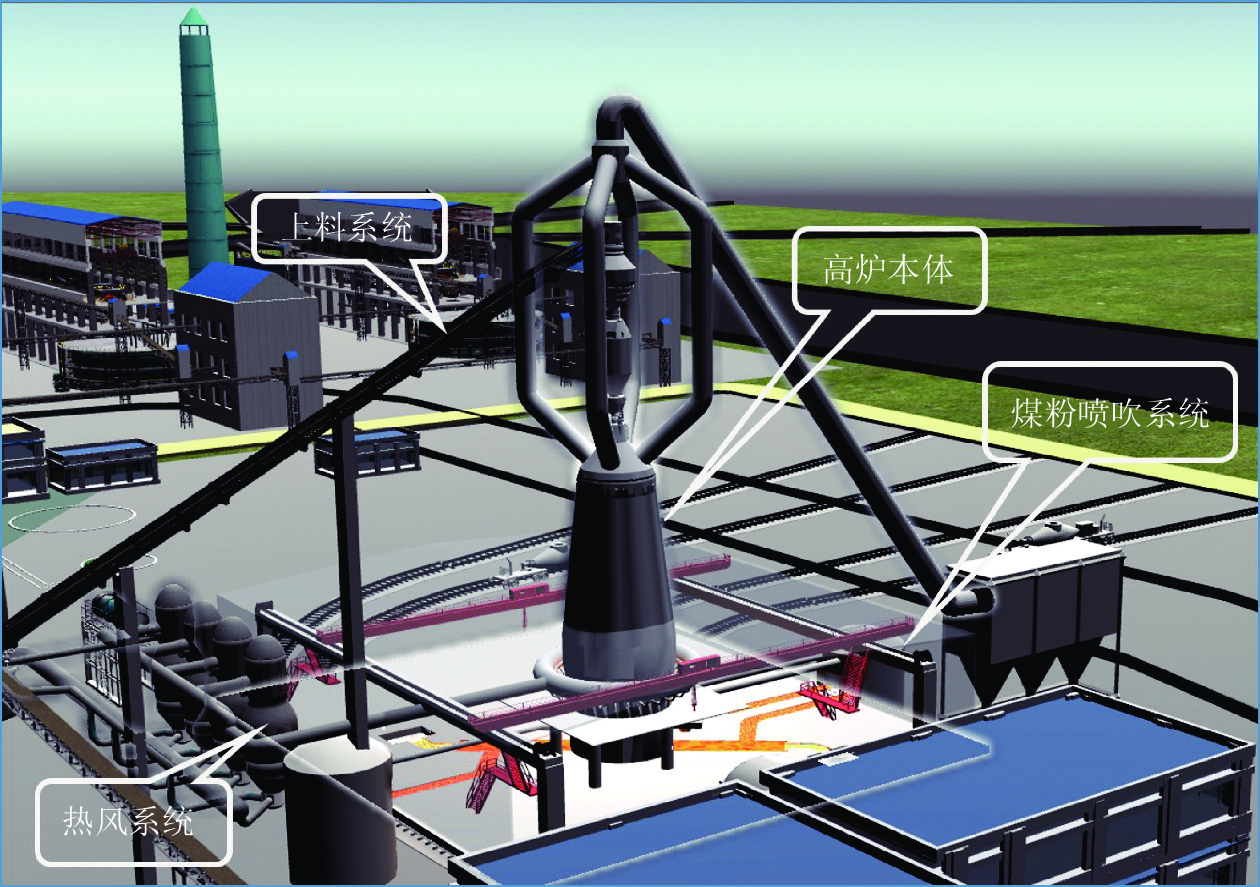

摘要: 高炉铁水硅含量是铁水品质与炉况的重要表征, 冶炼过程关键参数频繁波动及大时滞特性给高炉铁水硅含量预测带来了巨大挑战. 提出一种基于最优工况迁移的高炉铁水硅含量预测方法. 首先, 针对过程变量频繁波动问题, 提出基于邦费罗尼指数的自适应密度峰值聚类算法, 实现对高炉冶炼过程变量的工况划分, 并建立不同工况硅含量预测子模型. 其次, 针对冶炼过程的大时滞特性, 定义相邻时间节点间的硅含量工况迁移代价函数, 并提出多源路径寻优算法, 实现冶炼过程中硅含量最优工况迁移路径及当前时刻硅含量最优预测值的求解. 最后, 基于工业现场数据验证了所提方法的有效性与准确性.Abstract: The hot metal silicon content in blast furnace can characterize the hot metal quality and the condition of blast furnace. It poses a great challenge to the online prediction of silicon content because of the frequent fluctuation of smelting parameters and the existence of large time delay during the ironmaking process. This paper proposes an algorithm for predicting the hot metal silicon content in blast furnace based on optimal smelting condition migration. Firstly, arming at the frequent fluctuation of smelting process variables, an adaptive density peak clustering algorithm based on the Bonferroni index to dynamically cluster the process variables of blast furnace ironmaking process is proposed, which can obtain clusters of different smelting conditions, and establish sub-models for different smelting conditions. Secondly, to mitigate the large time delay of blast furnace ironmaking process, this paper defines the silicon content migration cost function between adjacent time nodes, and proposes a multi-source path optimization algorithm to solve the optimal migration path of silicon content during the smelting process and the optimal prediction value of silicon content at the current time. Finally, the effectiveness and accuracy of the proposed method are verified based on the industrial field data.

-

表 1 过程变量MIC相关性系数

Table 1 MIC correlation coefficient of process variables

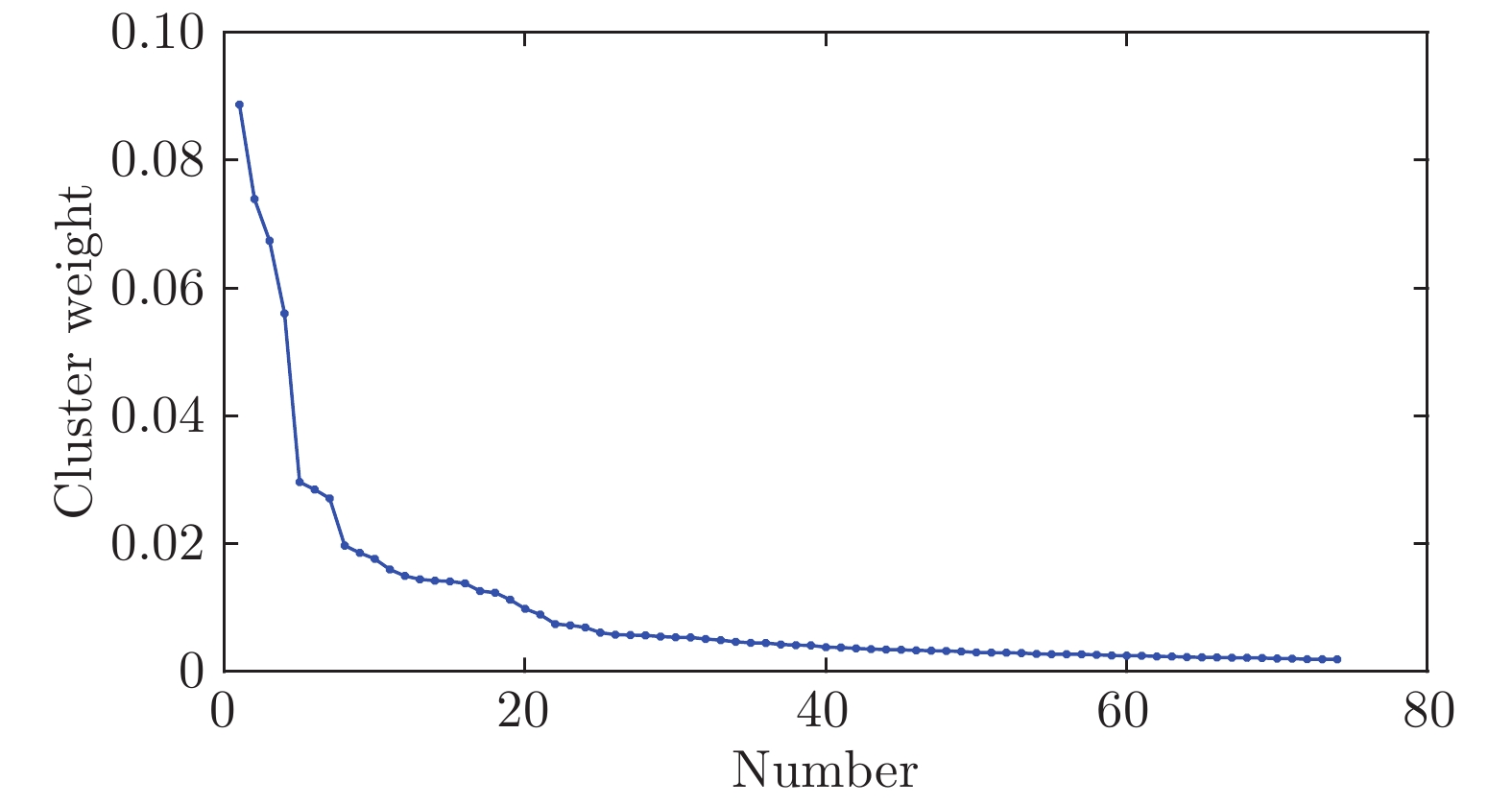

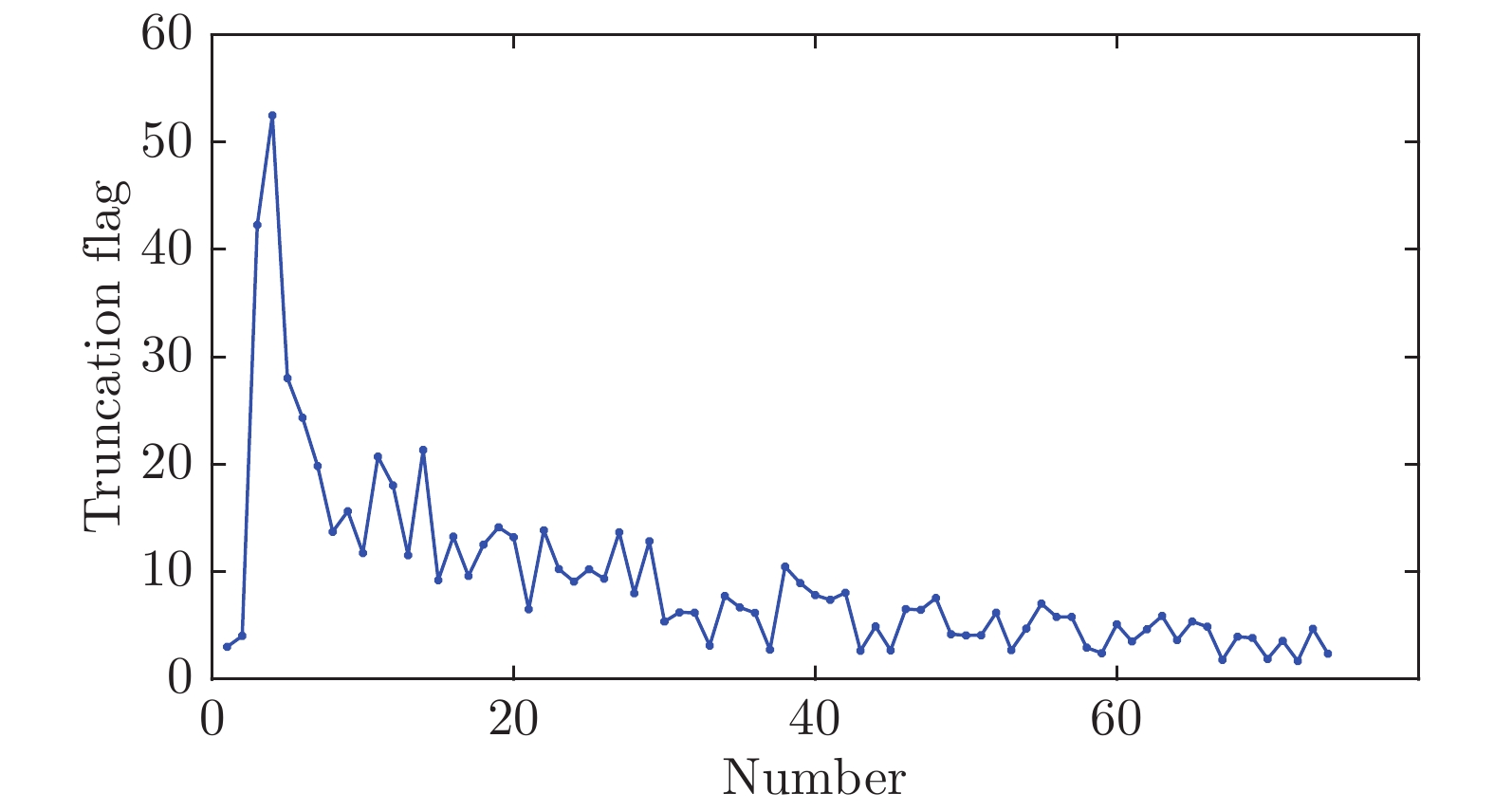

过程变量 MIC 系数 过程变量 MIC 系数 富氧率 0.291 总压差 0.204 透气性指数 0.270 炉腹煤气指数 0.278 标准风速 0.275 热风压力 0.268 富氧流量 0.218 实际风速 0.173 冷风流量 0.264 冷风温度 0.209 鼓风动能 0.204 热风温度 0.213 设定喷煤量 0.241 顶温下降管 0.209 理论燃烧温度 0.248 铁水红外温度 0.291 顶压 0.195 顶温 0.292 富氧压力 0.229 鼓风湿度 0.179 冷风压力 0.197 阻力系数 0.204 表 2 聚类中心截断标志

Table 2 Cluster center truncation flag

序号 1 2 3 4 5 6 截断系数 3.00 4.02 42.30 52.50 28.02 24.34 表 3 寻优算法耗时对比

Table 3 Comparison of the time consumption of optimization algorithms

寻优算法 节点数 40 80 120 160 200 Floyd 算法

耗时 (ms)3.20 × 104 2.72 × 105 8.96 × 105 2.09 × 106 4.05 × 106 本文算法

耗时(ms)3 8 11 13 18 表 4 模型性能对比

Table 4 Model performance comparison

模型类别 性能指标 数值预测

命中率 (%)趋势预测

准确率 (%)预测均方误差 工况迁移预测模型 88 82 0.0043 Elman 网络 79 69 0.0069 Elman-Adaboost 85 71 0.0054 FEEMD-Adaboost-Elman 86 74 0.0049 -

[1] Biswas A K. Principles of Blast Furnace Ironmaking —— Theory and Practice. Brisbane: Cootha Publishing House, 1981. 1−12 [2] Zhou Ping, Zhang Shuai, Dai Peng. Recursive Learning Based Bilinear Subspace Identification for Online Modeling and Predictive Control of a Complicated Industrial Process. IEEE Access, 2020, 8: 6253-62541. [3] Saxén H, Gao Chuan-Hou, Gao Zhi-Wei. Data-driven time discrete models for dynamic prediction of the hot metal silicon content in the blast furnace—A review. IEEE Transactions on Industrial Informatics, 2012, 9(4): 2213-2225. [4] Onorin O P, Spirin N A. Features of blast furnace transient processes. Metallurgist, 2017, 61(1): 121-126. [5] Spirin N A, Onorin O P, Istomin A S, Lavrov V V, Gurin I A. Study of transition processes of blast-furnace smelting by the mathematical model method. In: Proceedings of the 2018 IOP Conference Series, Materials Science and Engineering. Novokuznetsk, Russia: Institute of Physics Publishing, 2018. 012−073 [6] Spirin N, Onorin O, Alexander I. Prediction of blast furnace thermal state in real-time operation. Solid State Phenomena, 2020, 299: 518-523. doi: 10.4028/www.scientific.net/SSP.299.518 [7] Spirin N. A, Polinov A A, Gurin I A, Pishnograev SN. Information System for Real-Time Prediction of the Silicon Content of Iron in a Blast Furnace. Metallurgist, 2020, 63(9): 898-905. [8] Östermark R, Saxen H. VARMAX-modelling of blast furnace process variables. European Journal of Operational Research, 1996, 90(1): 85-101. doi: 10.1016/0377-2217(94)00304-1 [9] Saxen H, Östermark R. State realization with exogenous variables-A test on blast furnace data. European journal of operational research, 1996, 89(1): 34-52. doi: 10.1016/S0377-2217(96)90050-8 [10] Bhattacharya T. Prediction of silicon content in blast furnace hot metal using partial least squares. ISIJ international, 2005, 45(12): 1943-1945. doi: 10.2355/isijinternational.45.1943 [11] Li Jun-Peng, Hua Chang-Chun, Yang Yan-Na, Guan Xin-Ping. Bayesian block structure sparse based T–S fuzzy modeling for dynamic prediction of hot metal silicon content in the blast furnace. IEEE Transactions on Industrial Electronics, 2017, 65(6): 4933-4942. [12] Xu Xia, Hua Chang-Chun, Tang Ying-Gan, Guan Xing-Ping. Modeling of the hot metal silicon content in blast furnace using support vector machine optimized by an improved particle swarm optimizer. Neural Computing and Applications, 2016, 27(6): 1451-1461. doi: 10.1007/s00521-015-1951-7 [13] Han Y, Li J, Yang X L, Liu W X, Zhang Y Z. Dynamic prediction research of silicon content in hot metal driven by big data in blast furnace smelting process under hadoop cloud platform. Complexity, DOI: 10.1155/2018/8079697 [14] Xu X, Hua C C, Tang Y G, Guan X P. Wiener model identification of blast furnace ironmaking process based on laguerre filter and linear programming support vector regression. In: Proceedings of the 2014 International Joint Conference on Neural Networks. Beijing, China: IEEE Press, 2014. 2198−2204 [15] Zhou Ping, Li Wen-Peng, Wang Hong. Robust Online Sequential RVFLNs for Data Modeling of Dynamic Time-Varying Systems With Application of an Ironmaking Blast Furnace. IEEE Transactions on Cybernetics, 2020, 50(11): 4783-4795. doi: 10.1109/TCYB.2019.2920483 [16] 郜传厚, 渐令, 陈积明, 孙优贤. 复杂高炉炼铁过程的数据驱动建模及预测算法. 自动化学报, 2009, 35(06): 725-730. doi: 10.3724/SP.J.1004.2009.00725Gao Chuan-Hou, Jian Ling, Chen Ji-Ming, Sun You-Xian. Data-driven modeling and prediction algorithm for complex blast furnace ironmaking process. Acta Automatica Sinica, 2009, 35(06): 725-730. doi: 10.3724/SP.J.1004.2009.00725 [17] David S F, David F F, Machado M L P. Artificial neural network model for predict of silicon content in hot metal blast furnace. Materials Science Forum, 2016, 869: 572-577. doi: 10.4028/www.scientific.net/MSF.869.572 [18] 宋菁华, 杨春节, 周哲. 改进型 EMD-Elman 神经网络在铁水硅含量预测中的应用. 化工学报, 2016, 67(3): 729-735.Song Jing-Hua, Yang Chun-Jie, Zhou Zhe. Application of improved EMD-Elman neural network in prediction of silicon content in molten iron. CIESC Journal, 2016, 67(3): 729-735. [19] Jiang Ke, Jiang Zhao-Hui, Xie Yon-Fang, Chen Zhi-Peng. Classification of silicon content variation trend based on fusion of multilevel features in blast furnace ironmaking. Information Sciences, 2020, 521: 32-45. doi: 10.1016/j.ins.2020.02.039 [20] 周平, 张丽, 李温鹏, 戴鹏, 柴天佑. 集成自编码与PCA的高炉多元铁水质量随机权神经网络建模. 自动化学报, 2018, 44(10): 1799-1811.Zhou Ping, Zhang Li, Li Wen-Peng, Dai Peng, Chai Tian-You. Modeling of blast furnace multi-element molten iron quality with random weight neural network based on self-encoding and PCA. Acta Automatica Sinica, 2018, 44(10): 1799-1811. [21] Jian Ling, Song Yun-Quan, Shen Shu-Qian, Wang Yan, Yin Hai-Qing. Adaptive least squares support vector machine predictor for blast furnace ironmaking process. ISIJ International, 2015, 55(4): 845-850. doi: 10.2355/isijinternational.55.845 [22] Zeng Jiu-Sun, Liu Xiang-Guan, Gao Chuan-Hou, Luo Shi-Hua, Jian Ling. Wiener model identification of blast furnace ironmaking process. ISIJ International, 2008, 48(12): 1734-1738. doi: 10.2355/isijinternational.48.1734 [23] 蒋朝辉, 董梦林, 桂卫华, 阳春华, 谢永芳. 基于Bootstrap的高炉铁水硅含量二维预报. 自动化学报, 2016, 42(05): 715-723.Jiang Zhao-Hui, Dong Meng-Lin, Gui Wei-Hua, Yang Chun-Hua, Xie Yon-Fang. Two-dimensional prediction for silicon content of hot metal of blast furnace based on bootstrap. Acta Automatica Sinica, 2016, 42 (5): 715-723. [24] 李温鹏, 周平. 高炉铁水质量鲁棒正则化随机权神经网络建模. 自动化学报, 2020, 46(04): 721-733.Li Wen-Peng, Zhou Ping. Wen Liang. Blast furnace hot metal quality robust regularization random weight neural network modeling. Acta Automatica Sinica, 2020, 46(04): 721-733. [25] 温亮, 周平. 基于多参数灵敏度分析与遗传优化的铁水质量无模型自适应控制. 自动化学报.Wen Liang, Zhou Ping. Model-free adaptive control of molten iron quality based on multi-parameter sensitivity analysis and genetic optimization. Acta Automatica Sinica, to be published. [26] Rodriguez, A, Laio A. Clustering by fast search and find of density peaks. Science, 2014, 344(6191): 1492-1496. doi: 10.1126/science.1242072 [27] Martin B, Elena, Silber J. The Bonferroni index and the measurement of distributional change. Metron, 2017, 75(1): 1-16. doi: 10.1007/s40300-016-0105-8 [28] 孙甜, 凌卫新. 基于模拟退火的 Levenberg-Marquardt 算法在神经网络中的应用. 科学技术与工程, 2008(18): 5189−5192Sun Tian, Ling Wei-Xin. Application of Levenberg-Marquardt algorithm based on simulated annealing in neural network. Science Technology and Engineering, 2008(18): 5189−5192 [29] Reshef, D N, Reshef Y A. Detecting novel associations in large data sets. Science, 2011, 334(6062): 1518-1524. doi: 10.1126/science.1205438 [30] Pan Dong, Jiang Zhao-Hui, Chen Zhi-Peng. Temperature measurement and compensation method of blast furnace molten iron based on infrared computer vision. IEEE Transactions on Instrumentation and Measurement, 2018, 68(10): 3576-3588. [31] 庄田, 杨春节. 基于Elman-Adaboost强预测器的铁水硅含量预测方法. 冶金自动化, 2017, 41(04): 1-6+17.Zhuang Tian, Yang Chun-Jie. Prediction method of silicon content in molten iron based on Elman-Adaboost strong predictor. Metallurgical Automation, 2017, 41(04): 1-6+17. [32] 王凯, 毕贵红, 高晗, 蒲娴怡, 陈仕龙. 基于改进快速集合经验模态分解和Elman-Adaboost的短期风速预测方法. 电力科学与工程, 2020, 36(05): 32-39. doi: 10.3969/j.ISSN.1672-0792.2020.05.005Wang Kai, Bi Gui-Gong, Gao Han, Pu Xian-Yi, Chen Shi-Long. Short-term Wind Speed Prediction Method Based on Improved Fast Ensemble Empirical Mode Decomposition and Elman-Adaboost. Electric Power Science and Engineering, 2020, 36(05): 32-39. doi: 10.3969/j.ISSN.1672-0792.2020.05.005 [33] 蒋珂, 蒋朝辉, 谢永芳, 潘冬, 桂卫华. 大型高炉铁水硅含量变化趋势的智能预报. 控制工程, 2020, 27(03): 540-546.Jiang Ke, Jiang Zhao-Hui, Xie Yon-Fang, Pan Dong, Gui Wei-Hua. Intelligent prediction of silicon content change trend in molten iron of large blast furnace. Control Engineering, 2020, 27 (03): 540-546. -

下载:

下载: