Research on Key Technology of Industrial Artificial Intelligence and Its Application in Predictive Maintenance

-

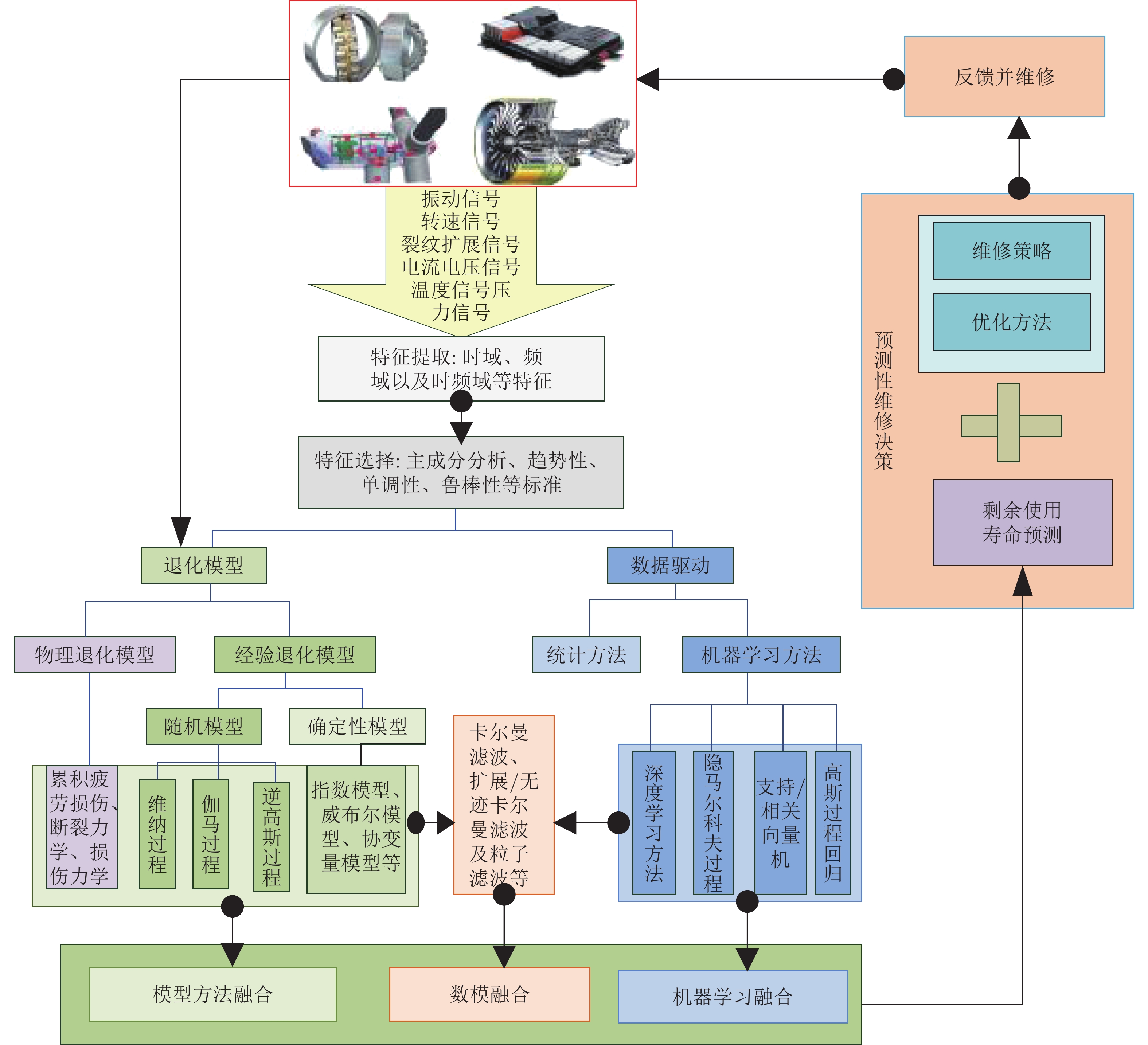

摘要: 随着人工智能技术的快速发展及其在工业系统中卓有成效的应用, 工业智能化成为当前工业生产转型的一个重要趋势. 论文提炼了工业人工智能(Industrial artificial intelligence, IAI)的建模、诊断、预测、优化、决策以及智能芯片等共性关键技术, 总结了生产过程监控与产品质量检测等4个主要应用场景. 同时, 论文选择预测性维护作为工业人工智能的典型应用场景, 以工业设备的闭环智能维护形式, 分别从模型方法、数据方法以及融合方法出发, 系统的总结和分析了设备的寿命预测技术和维护决策理论, 展示了人工智能技术在促进工业生产安全、降本、增效、提质等方面的重要作用. 最后, 探讨了工业人工智能研究所面临的问题以及未来的研究方向.Abstract: With the rapid development of artificial intelligence technology and its effective application in industrial system, industrial intelligentization has become an important trend of current industrial production transformation. In this paper, the general key technologies of industrial artificial intelligence (IAI) such as modeling, diagnosis, prediction, optimization, decision and intelligent chip are extracted, and four main application scenarios including production process monitoring and product quality detection are summarized. Then, predictive maintenance of industrial equipment in this paper is selected as a typical application scenario. Starting from model, data and fusion method, respectively, both remaining useful life prediction and maintenance decision are systematically analyzed and summarized with the form of closed-loop intelligent maintenance. Especially, the important role of artificial intelligence technology in promoting industrial production safety, cost reduction, efficiency enhancement and quality improvement has been verified. Finally, both existing problems and future research direction of IAI is also discussed.

-

表 1 基于模型和数据方法的寿命预测研究总结

Table 1 Research summary of RUL prediction with model and data method

类型 方法 优点 缺点 应用对象 模型 物理

模型1) 刻画了设备退化的实际物理意义.

2) 设备结构简单时预测结果比较精确.1) 建立退化机理模型涉及到多个学科的专业知识, 难以建立准确的物理模型获.

2) 设备复杂时, 预测的实用性较差.1) 累积损伤[29]和裂纹扩展[30]模型等(轴承[34]、IGBT[35]等).

2) 电化学反应机理模型(锂电池[36] 等).

3) 电路元件等效电路模型(锂电池[37]等).经验

模型

(随机)1) 描述设备退化过程中的随机时变性.

2) 获得剩余寿命的解析表达形式.1) 需要利用高深的随机过程理论进行数学推导, 不利于工程应用和推广.

2) 模型参数辨识难, 预测精度有待提高.1) 逆高斯模型(激光设备[38]、励磁绕组[39]等).

2) 维纳过程模型(轴承[42]、高炉炉墙[44]等).

3) 伽马过程模型(半导体制造设备[45]、二极管[46]等).经验

模型

(非随机)1) 利用回归模型(如多项式、指数模型等)来描述设备的退化趋势.

2) 通过外推预测设备的剩余寿命.1) 忽略了设备退化的内部机理.

2) 依靠经验构建退化趋势模型具有随意性和不确定性.

3) 预测结果不准时难以解释退化原理.1) 指数模型(锂电池[47]、轴承[48]等).

2) 威布尔模型(轴承[49] 等).

3) 比例风险模型(电子元件[53]等).数据 深度

学习1) 将数据直接输入到深度网络, 训练预测

模型.

2) 获得较精确的预测结果.1) 需要GPU/CPU、SSD存储、快速和大容量的RAM对数据进行训练.

2) 缺乏严格的理论基础, 超参数和网络设计困难.1) 卷积神经网络(轴承[73—74]等).

2) 深度置信网络(涡轮发动机[75—76]等).

3) 循环神经网络(锂电池[77]、涡轮发动

机[78]等).其他

机器

学习1) 利用特征工程结合机器学习, 获得较好的预测性能.

2) 算法易解释和理解, 调整超参数和更改模型较方便.1) 构建高性能机器学习模型需要特定领域和特定应用的机器学习技术和特征工程.

2) 预测精度不太高, 且通用性不强.1) 支持/相关向量机(锂电池[85]、轴承[87]等).

2) 高斯过程回归(刀具[91]、锂电池[92]等).

3) 隐马尔科夫(刀具[97—98] 等).表 2 基于融合方法的寿命预测和维修决策研究总结

Table 2 Research summary of remaining useful life and maintenance decision based on fusion method

融合对象 融合方式 融合方法 融合效果 寿命预测 数模融合(随机滤波) Exponential model+ GA-SVR+AUKF (锂电池[105]) 基于Rt, Rp, ERUL, ERMSE, EMAE, R2, ERA 等性能标准, 获得比Exponential model加上UKF/AUKF, RVR+UKF, SVR+UKF, GA-SVR+ AEKF等更好的结果. 刀具磨损模型+ BLSTM+PF+SVR (刀具[124]) 基于RMSE, MAE等性能指标, 获得比KNN, RNN, MLP, AE, LR, LSTM, SAE-DNN等方法更好的结果. 机器学习融合 FNN+CNN+LSTM (锂电池[120]) 基于EM性能标准, 获得比UKF+CEEMD, UKF+RVM, SVR+PF, BCT+RVM等方法更好的结果. RNN+CNN (轴承和铣刀[122]) 基于CRA和CPE等性能标准, 获得比SVM, FNN, DBN, CNN, CBL STM等方法更好的结果. 模型融合 PHM+Wiener (汽车发动机[118]) 基于MAE和Bias性能标准, 获得比BPNN, NN更好的预测结果. Inverse Gaussian + Wiener (风力发电机轴承[119]) 基于相对误差和误差时间性能标准, 分别从轴承退化初始阶段、中间阶段、最后阶段展示较好的预测效果. 数模融合(非随机滤波) Dual-Task Deep LSTM+ Weibull (涡轮发动机[125]) 基于RMSE性能标准, 获得比SVR, RVR, CNN, Deep LSTM 等方法更好的结果. SVR+WPHM (轴承[126]) 基于MSE, MAE, MAPE等性能标准, 获得比NAR-NN, BPNN, LSTM, GM, ARMA等方法更好的结果. 维修决策 维修决策 PM+SM (并行系统[132]) 针对具有不确定非周期变化的未来使用应力系统, 基于两阶段随机规划模型, 利用SPM和最小维修策略解决不完全维修和紧急故障时的维修问题. 预测性维修 (退化模型) Wiener+PHM (铅酸电池[146]) 利用PHM 对退化数据和故障时间数据进行联合建模, 采用维纳过程描述退化过程的随机性, 然后通过最小化系统维护成本得到最优的维护计划. 预测性维修 (机器学习) LSTM+DPM (涡轮发动机[151]) 利用LSTM 实现寿命预测, 以平均成本率为目标函数得到动态维护方案, 性能比周期性和理想预测维护策略更好. -

[1] Lee J, Davari H, Singh J, Pandhare V. Industrial artificial intelligence for industry 4.0-based manufacturing systems. Manufacturing Letters, 2018, 18: 20−23 [2] 孟岱. 工业大脑2.0: 直击制造业痛点. 中国工业和信息化, 2019, (9): 18−25 doi: 10.3969/j.issn.1674-9138.2019.09.003Meng Dai. Industrial Brain 2.0: Hit the manufacturing pain point. China Industry & Information Technology, 2019, (9): 18−25 doi: 10.3969/j.issn.1674-9138.2019.09.003 [3] Zhou J, Li P G, Zhou Y H, Wang B C, Zang J Y, Meng L. Toward new-generation intelligent manufacturing. Engineering, 2018, 4(1): 11−20 [4] Chen J H, Hu P C, Zhou H C, Yang J Z, Xie J J, Jiang Y K, et al. Toward intelligent machine tool. Engineering, 2019, 5(4): 679−690 [5] Yuan Y, Tang X C, Zhou W, Pan W, Li X T, Zhang H T, et al. Data driven discovery of cyber physical systems. Nature Communications, 2019, 10: 4894 [6] Yuan Y, Ma G J, Cheng C, Zhou B T, Zhao H, Zhang H T, et al. A general end-to-end diagnosis framework for manufacturing systems. National Science Review, 2020, 7(2): 418−429 [7] 丁进良, 杨翠娥, 陈远东, 柴天佑. 复杂工业过程智能优化决策系统的现状与展望. 自动化学报, 2018, 44(11): 1931−1943Ding Jin-Liang, Yang Cui-E, Chen Yuan-Dong, Chai Tian-You. Research progress and prospects of intelligent optimization decision making in complex industrial process. Acta Automatica Sinica, 2018, 44(11): 1931−1943 [8] 韩栋, 周聖元, 支天, 陈云霁, 陈天石. 智能芯片的评述和展望. 计算机研究与发展, 2019, 56(1): 7−22 doi: 10.7544/issn1000-1239.2019.20180693Han Dong, Zhou Sheng-Yuan, Zhi Tian, Chen Yun-Ji, Chen Tian-Shi. A survey of artificial intelligence chip. Journal of Computer Research and Development, 2019, 56(1): 7−22 doi: 10.7544/issn1000-1239.2019.20180693 [9] Zhang Y, Huang Y, Shao W J, Ming W Y. Research on MCVE piston machining and process parameter optimization. The International Journal of Advanced Manufacturing Technology, 2017, 93(9-12): 3955−3966 [10] Suzuki S. How to detect defects on coating paper-SmartView inspection system technology. Japan Tappi Journal, 2007, 61(2): 151−152 [11] Jeong J H, Kalowitsch M. State-of-the-art surface inspection technology with parsytec 5i. SEAISI Quarterly (South East Asia Iron and Steel Institute), 2007, 36(1): 10−15 [12] 李博, 高志远. 人工智能技术在智能电网中的应用分析和展望. 中国电力, 2017, 50(12): 136−140Li Bo, Gao Zhi-Yuan. Analysis and prospect on the application of artificial intelligence technologies in smart grid. Electric Power, 2017, 50(12): 136−140 [13] 张秀梅, 王海东, 罗永强, 赵涵, 胡翰智. 人工智能在智慧能源管理中的应用研究. 电信工程技术与标准化, 2020, 33(2): 21−24 doi: 10.3969/j.issn.1008-5599.2020.02.005Zhang Xiu-Mei, Wang Hai-Dong, Luo Yong-Qiang, Zhao Han, Hu Han-Zhi. An application research of artificial intelligence in intelligent energy management. Telecom Engineering Technics and Standardization, 2020, 33(2): 21−24 doi: 10.3969/j.issn.1008-5599.2020.02.005 [14] 叶水国, 彭彦卿, 杨永通, 陈李清. 基于人工智能的中央空调能源管理优化控制系统的设计. 化工与医药工程, 2017, 38(1): 48−53Ye Shui-Guo, Peng Yan-Qing, Yang Yong-Tong, Chen Li-Qing. Design of optimum control system based on artificial intelligence for managing central air conditioning system. Chemical and Pharmaceutical Engineering, 2017, 38(1): 48−53 [15] Long N T. Artificial intelligent (AI) and the future of supply chain. Opulence, 2018, 2(1): 1−42 [16] Vachtsevanos G, Lewis F L, Roemer M, Hess A, Wu B Q. Intelligent Fault Diagnosis and Prognosis for Engineering Systems. Hoboken, N.J.: John Wiley & Sons, Inc., 2006. [17] 陈雪峰. 智能运维与健康管理. 北京: 机械工业出版社, 2018.Chen Xue-Feng. Intelligent Maintenance and Health Management. Beijing: Machinery Industry Press, 2018. [18] Jardine A K S, Lin D M, Banjevic D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mechanical Systems and Signal Processing, 2006, 20(7): 1483−510 [19] 王庆锋, 高金吉. 过程工业动态的以可靠性为中心的维修研究及应用. 机械工程学报, 2012, 48(8): 135−143Wang Qing-Feng, Gao Jin-Ji. Research and application of dynamic reliability centered maintenance for process industry. Journal of Mechanical Engineering, 2012, 48(8): 135−143 [20] 周东华, 魏慕恒, 司小胜. 工业过程异常检测、寿命预测与维修决策的研究进展. 自动化学报, 2013, 39(6): 711−722Zhou Dong-Hua, Wei Mu-Heng, Si Xiao-Sheng. A survey on anomaly detection, life prediction and maintenance decision for industrial processes. Acta Automatica Sinica, 2013, 39(6): 711−722 [21] Kordestani M, Saif M, Orchard M E, Razavi-Far R, Khorasani K. Failure prognosis and applications-a survey of recent literature. IEEE Transactions on Reliability, to be published [22] 司小胜, 胡昌华. 数据驱动的设备剩余寿命预测理论及应用. 北京: 国防工业出版社, 2016.Si Xiao-Sheng, Hu Chang-Hua. Data-Driven Remaining Useful Life Prediction Theory and Applications for Equipment. Beijing: National Defense Industry Press, 2016. [23] Pecht M G. Prognostics and Health Management of Electronics. Hoboken, NJ, USA: John Wiley & Sons, Inc., 2008. [24] Liao L X, Kottig F. Review of hybrid prognostics approaches for remaining useful life prediction of engineered systems, and an application to battery life prediction. IEEE Transactions on Reliability, 2014, 63: 191−207 [25] 国家技术监督局. 可靠性、维修性术语, GB/T 3187-94, 1994.The State Bureau of Quality and Technical Supervision. Reliability and maintainability terms, GB/T 3187-94, 1994. [26] 陈学楚. 现代维修理论. 北京: 国防工业出版社, 2003.Chen Xue-Chu. Modern Maintenance Theory. Beijing: National Defense Industry Press, 2003. [27] Ahmad R, Kamaruddin S. An overview of time-based and condition-based maintenance in industrial application. Computers and Industrial Engineering, 2012, 63(1): 135−149 [28] 张小丽, 陈雪峰, 李兵, 何正嘉. 机械重大装备寿命预测综述. 机械工程学报, 2011, 47(11): 100−116Zhang Xiao-Li, Chen Xue-Feng, Li Bing, He Zheng-Jia. Review of life prediction for mechanical major equipments. Journal of Mechanical Engineering, 2011, 47(11): 100−116 [29] Fatemi A, Yang L. Cumulative fatigue damage and life prediction theories: A survey of the state of the art for homogeneous materials. International Journal of Fatigue, 1998, 20(1): 9−34 [30] Machniewicz T. Fatigue crack growth prediction models for metallic materials. Part I: Overview of prediction concepts. Fatigue & Fracture of Engineering Materials & Structures, 2013, 36(4): 293−307 [31] 袁熙, 李舜酩. 疲劳寿命预测方法的研究现状与发展. 航空制造技术, 2005, (12): 80−84 doi: 10.3969/j.issn.1671-833X.2005.12.016Yuan Xi, Li Shun-Ming. Research status and development of forecast method of fatigue life. Aeronautical Manufacturing Technology, 2005, (12): 80−84 doi: 10.3969/j.issn.1671-833X.2005.12.016 [32] Paris P, Erdogan F. A critical analysis of crack propagation laws. Journal of Basic Engineering, 1963, 85: 528−533 [33] Forman R G. Study of fatigue crack initiation from flaws using fracture mechanics theory. Engineering Fracture Mechanics, 1972, 4(2): 333−345 [34] Qian Y N, Yan R Q, Gao R X. A multi-time scale approach to remaining useful life prediction in rolling bearing. Mechanical Systems and Signal Processing, 2017, 83: 549−567 [35] Lu Y Z, Christou A. Prognostics of IGBT modules based on the approach of particle filtering. Microelectronics Reliability, 2019, 92: 96−105 [36] Panchal S, Mathew M, Fraser R, Fowler M. Electrochemical thermal modeling and experimental measurements of 18650 cylindrical lithium-ion battery during discharge cycle for an EV. Applied Thermal Engineering, 2018, 135: 123−132 [37] Liu G M, Ouyang M G, Lu L G, Li J Q, Hu J F. A highly accurate predictive-adaptive method for lithium-ion battery remaining discharge energy prediction in electric vehicle applications. Applied Energy, 2015, 149: 297−314 [38] Ye Z S, Chen N. The inverse Gaussian process as a degradation model. Technometrics, 2014, 56(3): 302−311 [39] Wen X L, Wang Z H, Fu H M, Wu Q, Liu C R. Blues and reliability analysis for general censored data subject to inverse Gaussian distribution. IEEE Transactions on Reliability, 2019, 68(4): 1257−1271 [40] 金光. 基于退化的可靠性技术——模型、方法及应用. 北京: 国防工业出版社, 2014.Jin Guang. Reliability Techniques based on Degradation-Models, Methods and Applications. Beijing: National Defense Industry Press, 2014. [41] Wang X L, Guo B, Cheng Z J. Residual life estimation based on bivariate wiener degradation process with time-scale transformations. Journal of Statistical Computation and Simulation, 2014, 84(3): 545−563 [42] Li N P, Lei Y G, Lin J, Ding S X. An improved exponential model for predicting remaining useful life of rolling element bearings. IEEE Transactions on Industrial Electronics, 2015, 62(12): 7762−7773 [43] Si X S, Wang W B, Hu C H, Zhou D H. Estimating remaining useful life with three-source variability in degradation modeling. IEEE Transactions on Reliability, 2014, 63(1): 167−190 [44] Zhang H W, Zhou D H, Chen M Y, Shang J. FBM-based remaining useful life prediction for degradation processes with long-range dependence and multiple modes. IEEE Transactions on Reliability, 2019, 68(3): 1021−1033 [45] Nguyen T B L, Djeziri M, Ananou B, Ouladsine M, Pinaton J. Fault prognosis for batch production based on percentile measure and gamma process: Application to semiconductor manufacturing. Journal of Process Control, 2016, 48: 72−80 [46] Ling M H, Ng H K T, Tsui K L. Bayesian and likelihood inferences on remaining useful life in two-phase degradation models under gamma process. Reliability Engineering & System Safety, 2019, 184: 77−85 [47] Xing Y J, Ma E W M, Tsui K L, Pecht M. An ensemble model for predicting the remaining useful performance of lithium-ion batteries. Microelectronics Reliability, 2013, 53(6): 811−820 [48] Ahmad W, Khan S A, Islam M M M, Kim J M. A reliable technique for remaining useful life estimation of rolling element bearings using dynamic regression models. Reliability Engineering & System Safety, 2019, 184: 67−76 [49] Ali J B, Chebel-Morello B, Saidi L, Malinowski S, Fnaiech F. Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network. Mechanical Systems and Signal Processing, 2015, 56-57: 150−172 [50] Kumar D, Klefsjo B. Proportional hazards model: A review. Reliability Engineering & System Safety, 1994, 44(2): 177−188 [51] 喻勇, 司小胜, 胡昌华, 崔忠马, 李洪鹏. 数据驱动的可靠性评估与寿命预测研究进展: 基于协变量的方法. 自动化学报, 2018, 44(2): 216−227Yu Yong, Si Xiao-Sheng, Hu Chang-Hua, Cui Zhong-Ma, Li Hong-Peng. Data driven reliability assessment and life-time prognostics: A review on covariate models. Acta Automatica Sinica, 2018, 44(2): 216−227 [52] Cox D R. Regression models and life-tables. Journal of the Royal Statistical Society: Series B (Methodological), 1972, 34(2): 187−202 [53] Zhao S A, Makis V, Chen S W, Li Y. Health assessment method for electronic components subject to condition monitoring and hard failure. IEEE Transactions on Instrumentation and Measurement, 2019, 68: 138−150 [54] Sun Y, Ma L, Mathew J, Wang W Y, Zhang S. Mechanical systems hazard estimation using condition monitoring. Mechanical Systems and Signal Processing, 2006, 20(5): 1189−1201 [55] Ding H, Gao R X, Isaksson A J, Landers R G, Parisini T, Yuan Y. State of AI-based monitoring in smart manufacturing and introduction to focused section. IEEE/ASME Transactions on Mechatronics, 2020, 25(5): 2143—2154 [56] Lei Y G, Li N P, Guo L, Li N B, Yan T, Lin J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mechanical Systems and Signal Processing, 2018, 104: 799−834 [57] Zheng Y, Mao S M, Liu S J, Wong D S H, Wang Y W. Normalized relative RBC-based minimum risk Bayesian decision approach for fault diagnosis of industrial process. IEEE Transactions on Industrial Electronics, 2016, 63(12): 7723−7732 [58] Yan L, Zhang H T, Goncalves J, Xiao Y, Wang M L, Guo Y Q, et al. An interpretable mortality prediction model for COVID-19 patients. Nature Machine Intelligence, 2020, 2: 283−288 [59] Yuan Y, Zhang H T, Wu Y, Zhu T, Ding H. Bayesian learning-based model-predictive vibration control for thin-walled workpiece machining processes. IEEE/ASME Transactions on Mechatronics, 2017, 22(1): 509−520 [60] Zhu J L, Ge Z Q, Song Z H, Gao F R. Review and big data perspectives on robust data mining approaches for industrial process modeling with outliers and missing data. Annual Reviews in Control, 2018, 46: 107−133 [61] Yu J B. Local and nonlocal preserving projection for bearing defect classification and performance assessment. IEEE Transactions on Industrial Electronics, 2012, 59(5): 2363−2376 [62] 裴洪, 胡昌华, 司小胜, 张建勋, 庞哲楠, 张鹏. 基于机器学习的设备剩余寿命预测方法综述. 机械工程学报, 2019, 55(8): 1−13Pei Hong, Hu Chang-Hua, Si Xiao-Sheng, Zhang Jian-Xun, Pang Zhe-Nan, Zhang Peng. Review of machine learning based remaining useful life prediction methods for equipment. Journal of Mechanical Engineering, 2019, 55(8): 1−13 [63] Patil M A, Tagade P, Hariharan K S, Kolake S M, Dong T, Yeo T, et al. A novel multistage support vector machine based approach for Li ion battery remaining useful life estimation. Applied Energy, 2015, 159: 285−297 [64] Javed K, Gouriveau R, Zerhouni N. A new multivariate approach for prognostics based on extreme learning machine and fuzzy clustering. IEEE Transactions on Cybernetics, 2015, 45(2): 2626−2639 [65] Liu Z, Cheng Y H, Wang P, Yu Y L, Long Y W. A method for remaining useful life prediction of crystal oscillators using the Bayesian approach and extreme learning machine under uncertainty. Neurocomputing, 2018, 305: 27−38 [66] Li Z X, Wu D Z, Hu C, Terpenny J. An ensemble learning-based prognostic approach with degradation-dependent weights for remaining useful life prediction. Reliability Engineering & System Safety, 2019, 184: 110−122 [67] Guo L, Lei Y G, Li N P, Yan T, Li N B. Machinery health indicator construction based on convolutional neural networks considering trend burr. Neurocomputing, 2018, 292: 142−150 [68] Javed K, Gouriveau R, Zerhouni N, Nectoux P. Enabling health monitoring approach based on vibration data for accurate prognostics. IEEE Transactions on Industrial Electronics, 2015, 62(1): 647−656 [69] Zhao S, Zhang Y, Wang S, Zhou B T, Cheng C. A recurrent neural network approach for remaining useful life prediction utilizing a novel trend features construction method. Measurement, 2019, 146: 279−288 [70] Shao H D, Jiang H K, Li X Q, Wu S P. Intelligent fault diagnosis of rolling bearing using deep wavelet auto-encoder with extreme learning machine. Knowledge-Based Systems, 2018, 140: 1−14 [71] Hong S, Zhou Z, Zio E, Hong K. Condition assessment for the performance degradation of bearing based on a combinatorial feature extraction method. Digital Signal Processing, 2014, 27: 159−166 [72] Zhu J, Chen N, Peng W W. Estimation of bearing remaining useful life based on multiscale convolutional neural network. IEEE Transactions on Industrial Electronics, 2019, 66(4): 3208−3216 [73] Cheng C, Ma G J, Zhang Y, Sun M Y, Teng F, Ding H, et al. A deep learning-based remaining useful life prediction approach for bearings. IEEE/ASME Transactions on Mechatronics, 2020, 25(3): 1243−1254 [74] Yang B Y, Liu R N, Zio E. Remaining useful life prediction based on a double-convolutional neural network architecture. IEEE Transactions on Industrial Electronics, 2019, 66(12): 9521−9530 [75] Zhang C, Lim P, Qin A K, Tan K C. Multiobjective deep belief networks ensemble for remaining useful life estimation in prognostics. IEEE Transactions on Neural Networks and Learning Systems, 2017, 28: 2306−2318 [76] Peng K X, Jiao R H, Dong J, Pi Y T. A deep belief network based health indicator construction and remaining useful life prediction using improved particle filter. Neurocomputing, 2019, 361: 19−28 [77] Zhang Y Z, Xiong R, He H W, Pecht M G. Long short-term memory recurrent neural network for remaining useful life prediction of Lithium-Ion batteries. IEEE Transactions on Vehicular Technology, 2018, 67(7): 5695−5705 [78] Chen J L, Jing H J, Chang Y H, Liu Q. Gated recurrent unit based recurrent neural network for remaining useful life prediction of nonlinear deterioration process. Reliability Engineering & System Safety, 2019, 185: 372−382 [79] Cheng Y W, Zhu H P, Wu J, Shao X Y. Machine health monitoring using adaptive kernel spectral clustering and deep long short-term memory recurrent neural networks. IEEE Transactions on Industrial Informatics, 2019, 15(2): 987−997 [80] Sun C, Ma M, Zhao Z B, Tian S H, Yan R Q, Chen X F. Deep transfer learning based on sparse autoencoder for remaining useful life prediction of tool in manufacturing. IEEE Transactions on Industrial Informatics, 2019, 15(4): 2416−2425 [81] Mao W T, He J L, Zuo M J. Predicting remaining useful life of rolling bearings based on deep feature representation and transfer learning. IEEE Transactions on Instrumentation and Measurement, 2020, 69(4): 1594−1608 [82] 林景栋, 吴欣怡, 柴毅, 尹宏鹏. 卷积神经网络结构优化综述. 自动化学报, 2020, 46(1): 24−37Lin Jing-Dong, Wu Xin-Yi, Chai Yi, Yin Hong-Peng. Structure optimization of convolutional neural networks: A survey. Acta Automatica Sinica, 2020, 46(1): 24−37 [83] Xiao L, Liu Z X, Zhang Y, Zheng Y, Cheng C. Degradation assessment of bearings with trend-reconstruct-based features selection and gated recurrent unit network. Measurement, 2020, 165: 108064 [84] Wei J W, Dong G Z, Chen Z H. Remaining useful life prediction and state of health diagnosis for lithium-ion batteries using particle filter and support vector regression. IEEE Transactions on Industrial Electronics, 2018, 65(7): 5634−5643 [85] 雷亚国, 陈吴, 李乃鹏, 林京. 自适应多核组合相关向量机预测方法及其在机械设备剩余寿命预测中的应用. 机械工程学报, 2016, 52(1): 87−93Lei Ya-Guo, Chen Wu, Li Nai-Peng, Lin Jing. A relevance vector machine prediction method based on adaptive multi-kernel combination and its application to remaining useful life prediction of machinery. Journal of Mechanical Engineering, 2016, 52(1): 87−93 [86] 刘月峰, 赵光权, 彭喜元. 多核相关向量机优化模型的锂电池剩余寿命预测方法. 电子学报, 2019, 47(6): 1285−1292 doi: 10.3969/j.issn.0372-2112.2019.06.015Liu Yue-Feng, Zhao Guang-Quan, Peng Xi-Yuan. A lithium-ion battery remaining using life prediction method based on multi-kernel relevance vector machine optimized model. Acta Electronica Sinica, 2019, 47(6): 1285−1292 doi: 10.3969/j.issn.0372-2112.2019.06.015 [87] Yan M M, Wang X G, Wang B X, Chang M X, Muhammad I. Bearing remaining useful life prediction using support vector machine and hybrid degradation tracking model. ISA Transactions, 2020, 98: 471−482 [88] Boskoski P, Gasperin M, Petelin D, Juricic D. Bearing fault prognostics using Renyi entropy based features and Gaussian process models. Mechanical Systems and Signal Processing, 2015, 52-53: 327−337 [89] Wang Z P, Ma J, Zhang L. State-of-health estimation for Lithium-ion batteries based on the multi-island genetic algorithm and the Gaussian process regression. IEEE Access, 2017, 5: 21286−21295 [90] Yu J B. State of health prediction of lithium-ion batteries: Multiscale logic regression and Gaussian process regression ensemble. Reliability Engineering & System Safety, 2018, 174: 82−95 [91] Kong D D, Chen Y J, Li N. Gaussian process regression for tool wear prediction. Mechanical Systems and Signal Processing, 2018, 104: 556−574 [92] Li X Y, Wang Z P, Yan J Y. Prognostic health condition for lithium battery using the partial incremental capacity and Gaussian process regression. Journal of Power Sources, 2019, 421: 56−67 [93] Geramifard O, Xu J X, Zhou J H, Li X. A physically segmented hidden Markov model approach for continuous tool condition monitoring: Diagnostics and prognostics. IEEE Transactions on Industrial Informatics, 2012, 8(4): 964−973 [94] Yu J S, Liang S, Tang D Y, Liu H. A weighted hidden Markov model approach for continuous-state tool wear monitoring and tool life prediction. The International Journal of Advanced Manufacturing Technology, 2017, 91(1): 201−211 [95] Liu Q M, Dong M, Lv W Y, Geng X L, Li Y P. A novel method using adaptive hidden semi-Markov model for multi-sensor monitoring equipment health prognosis. Mechanical Systems and Signal Processing, 2015, 64-65: 217−232 [96] Zhu K P, Liu T S. Online tool wear monitoring via hidden semi-Markov model with dependent durations. IEEE Transactions on Industrial Informatics, 2018, 14(1): 69−78 [97] Li W J, Liu T S. Time varying and condition adaptive hidden Markov model for tool wear state estimation and remaining useful life prediction in micro-milling. Mechanical Systems and Signal Processing, 2019, 131: 689−702 [98] Liu T S, Zhu K P, Zeng L C. Diagnosis and prognosis of degradation process via hidden semi-Markov model. IEEE/ASME Transactions on Mechatronics, 2018, 23(3): 1456−1466 [99] Singleton R K, Strangas E G, Aviyente S. Extended kalman filtering for remaining-useful-life estimation of bearings. IEEE Transactions on Industrial Electronics, 2015, 62(3): 1781−1790 [100] Zheng X J, Fang H J. An integrated unscented kalman filter and relevance vector regression approach for lithium-ion battery remaining useful life and short-term capacity prediction. Reliability Engineering & System Safety, 2015, 144: 74−82 [101] Jin X H, Sun Y, Que Z J, Wang Y, Chow T W S. Anomaly detection and fault prognosis for bearings. IEEE Transactions on Instrumentation and Measurement, 2016, 65(9): 2046−2054 [102] Chang Y, Fang H J, Zhang Y. A new hybrid method for the prediction of the remaining useful life of a lithium-ion battery. Applied Energy, 2017, 206: 1564−1578 [103] Jin X H, Que Z J, Sun Y, Guo Y J, Qiao W. A data-driven approach for bearing fault prognostics. IEEE Transactions on Industry Applications, 2019, 55(4): 3394−3401 [104] Cui L L, Wang X, Wang H Q, Ma J F. Research on remaining useful life prediction of rolling element bearings based on time-varying kalman filter. IEEE Transactions on Instrumentation and Measurement, 2020, 69(6): 2858−2867 [105] Xue Z W, Zhang Y, Cheng C, Ma G J. Remaining useful life prediction of lithium-ion batteries with adaptive unscented kalman filter and optimized support vector regression. Neurocomputing, 2020, 376: 95−102 [106] Jouin M, Gouriveau R, Hissel D, Pera M C, Zerhouni N. Particle filter-based prognostics: Review, discussion and perspectives. Mechanical Systems and Signal Processing, 2016, 72-73: 2−31 [107] Li T, Sun S, Sattar T P. Adapting sample size in particle filters through KLD-resampling. Electronics Letters, 2013, 49(12): 740−742 [108] Zhang H, Miao Q, Zhang X, Liu Z W. An improved unscented particle filter approach for lithium-ion battery remaining useful life prediction. Microelectronics Reliability, 2018, 81: 288−289 [109] Duong P L T, Raghavan N. Heuristic Kalman optimized particle filter for remaining useful life prediction of lithium-ion battery. Microelectronics Reliability, 2018, 81: 232−243 [110] Jiao R H, Peng K X, Dong J. Remaining useful life prediction of lithium-ion batteries based on conditional variational autoencoders-particle filter. IEEE Transactions on Instrumentation and Measurement, to be published [111] Chang Y, Fang H J. A hybrid prognostic method for system degradation based on particle filter and relevance vector machine. Reliability Engineering & System Safety, 2019, 186: 51−63 [112] Huang C G, Yin X H, Huang H Z, Li Y F. An enhanced deep learning-based fusion prognostic method for RUL prediction. IEEE Transactions on Reliability, 2020, 69(3): 1097−1109 [113] Cheng F Z, Qu L Y, Qiao W. Fault prognosis and remaining useful life prediction of wind turbine gearboxes using current signal analysis. IEEE Transactions on Sustainable Energy, 2018, 9(1): 157−167 [114] Cheng F Z, Qu L Y, Qiao W, Hao L W. Enhanced particle filtering for bearing remaining useful life prediction of wind turbine drivetrain gearboxes. IEEE Transactions on Industrial Electronics, 2019, 66(6): 4738−4748 [115] Yin S, Zhu X P. Intelligent particle filter and its application to fault detection of nonlinear system. IEEE Transactions on Industrial Electronics, 2015, 62(6): 3852−3861 [116] 张英波, 贾云献, 冯添乐, 邱国栋. 基于Gamma退化过程的直升机主减速器行星架剩余寿命预测模型. 振动与冲击, 2012, 31(14): 47−51 doi: 10.3969/j.issn.1000-3835.2012.14.010Zhang Ying-Bo, Jia Yun-Xian, Feng Tian-Le, Qiu Guo-Dong. Remaining useful life prediction model of planetary carrier in helicopter main gear-box based on Gamma degradation process. Journal of Vibration and Shock, 2012, 31(14): 47−51 doi: 10.3969/j.issn.1000-3835.2012.14.010 [117] 郑建飞, 胡昌华, 司小胜, 张正新, 张鑫. 考虑不确定测量和个体差异的非线性随机退化系统剩余寿命估计. 自动化学报, 2017, 43(2): 259−270Zheng Jian-Fei, Hu Chang-Hua, Si Xiao-Sheng, Zhang Zheng-Xin, Zhang Xin. Remaining useful life estimation for nonlinear stochastic degrading systems with uncertain measurement and unit-to-unit variability. Acta Automatica Sinica, 2017, 43(2): 259−270 [118] Man J N, Zhou Q. Prediction of hard failures with stochastic degradation signals using wiener process and proportional hazards model. Computers & Industrial Engineering, 2018, 125: 480−489 [119] Hu Y G, Li H, Shi P P, Chai Z S, Wang K, Xie X J, et al. A prediction method for the real-time remaining useful life of wind turbine bearings based on the wiener process. Renewable Energy, 2018, 127: 452−460 [120] Ma G J, Zhang Y, Cheng C, Zhou B T, Hu P C, Yuan Y. Remaining useful life prediction of lithium-ion batteries based on false nearest neighbors and a hybrid neural network. Applied Energy, 2019, 253: 113626 [121] Loutas T, Eleftheroglou N, Georgoulas G, Loukopoulos P, Mba D, Bennett I. Valve failure prognostics in reciprocating compressors utilizing temperature measurements, PCA-based data fusion, and probabilistic algorithms. IEEE Transactions on Industrial Electronics, 2020, 67(6): 5022−5029 [122] Wang B, Lei Y G, Yan T, Li N P, Guo L. Recurrent convolutional neural network: A new framework for remaining useful life prediction of machinery. Neurocomputing, 2020, 379: 117−129 [123] Ali J B, Chebel-Morello B, Saidi L, Malinowski S, Fnaiech F. Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network. Mechanical Systems and Signal Processing, 2015, 56—57: 150−172 [124] Guo L, Li N P, Jia F, Lei Y G, Lin J. A recurrent neural network based health indicator for remaining useful life prediction of bearings. Neurocomputing, 2017, 240: 98−109 [125] Miao H H, Li B, Sun C, Liu J. Joint learning of degradation assessment and RUL prediction for aeroengines via dual-task deep LSTM networks. IEEE Transactions on Industrial Informatics, 2019, 15(9): 5023−5032 [126] Qiu G Q, Gu Y K, Chen J J. Selective health indicator for bearings ensemble remaining useful life prediction with genetic algorithm and Weibull proportional hazards model. Measurement, 2020, 150: 107097 [127] Barlow R, Hunter L. Optimum preventive maintenance policies. Operations Research, 1960, 8(1): 90−100 [128] Pham H, Wang H Z. Imperfect maintenance. European Journal of Operational Research, 1996, 94(3): 425−438 [129] Mercier S, Castro I T. Stochastic comparisons of imperfect maintenance models for a gamma deteriorating system. European Journal of Operational Research, 2019, 273(1): 237−248 [130] Scarf P A, Cavalcante C A V, Dwight R A, Gordon P. An age-based inspection and replacement policy for heterogeneous components. IEEE Transactions on Reliability, 2009, 58(4): 641−648 [131] Dong W J, Liu S F, Du Y Y. Optimal periodic maintenance policies for a parallel redundant system with component dependencies. Computers & Industrial Engineering, 2019, 138: 106133 [132] Zhu X Y, Bei X Q, Chatwattanasiri N, Coit D W. Optimal system design and sequential preventive maintenance under uncertain aperiodic-changing stresses. IEEE Transactions on Reliability, 2018, 67(3): 907−919 [133] Yeh R H, Kao K C, Chang W L. Optimal preventive maintenance policy for leased equipment using failure rate reduction. Computers & Industrial Engineering, 2009, 57(1): 304−309 [134] Lin J, Pulido J, Asplund M. Reliability analysis for preventive maintenance based on classical and Bayesian semi-parametric degradation approaches using locomotive wheel-sets as a case study. Reliability Engineering & System Safety, 2015, 134: 143−156 [135] Carvalho T P, Soares F A A M N, Vita R, Francisco R P, Basto J P, Alcala S G S. A systematic literature review of machine learning methods applied to predictive maintenance. Computers & Industrial Engineering, 2019, 137: 106024 [136] Van Horenbeek A, Pintelon L. A dynamic predictive maintenance policy for complex multi-component systems. Reliability Engineering & System Safety, 2013, 120: 39−50 [137] Martinod R M, Bistorin O, Castaneda L F, Rezg N. Maintenance policy optimisation for multi-component systems considering degradation of components and imperfect maintenance actions. Computers & Industrial Engineering, 2018, 124: 100−112 [138] Tsai Y T, Wang K S, Tsai L C. A study of availability-centered preventive maintenance for multi-component systems. Reliability Engineering & System Safety, 2004, 84(3): 261−270 [139] You M Y. Predictive component availability optimization with degradation correlated maintainability. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2013, 227(4): 243−253 [140] 杨建华, 韩梦莹. 基于延迟时间理论的备件维修多目标优化模型. 系统工程与电子技术, 2019, 41(8): 1903−1912 doi: 10.3969/j.issn.1001-506X.2019.08.31Yang Jian-Hua, Han Meng-Ying. Multi-objective optimization model for spare parts maintenance based on delay-time theory. Systems Engineering and Electronics, 2019, 41(8): 1903−1912 doi: 10.3969/j.issn.1001-506X.2019.08.31 [141] 王金贺, 张晓红, 曾建潮. 非完美维修模型下的风电机组最优维修决策. 计算机集成制造系统, 2019, 25(5): 1151−1160Wang Jin-He, Zhang Xiao-Hong, Zeng Jian-Chao. Optimal maintenance decision for wind turbines based on imperfect maintenance model. Computer Integrated Manufacturing Systems, 2019, 25(5): 1151−1160 [142] De Smidt-Destombes K S, Van der Heijden M C, Van Harten A. Joint optimisation of spare part inventory, maintenance frequency and repair capacity for k-out-of-N systems. International Journal of Production Economics, 2009, 118(1): 260−268 [143] Wang W B. A joint spare part and maintenance inspection optimisation model using the delay-time concept. Reliability Engineering & System Safety, 2011, 96(11): 1535−1541 [144] Poppe J, Boute R N, Lambrecht M R. A hybrid condition-based maintenance policy for continuously monitored components with two degradation thresholds. European Journal of Operational Research, 2018, 268(2): 515−532 [145] Huynh K T, Grall A, Berenguer C. A parametric predictive maintenance decision-making framework considering improved system health prognosis precision. IEEE Transactions on Reliability, 2019, 68(1): 375−396 [146] Hu J W, Chen P. Predictive maintenance of systems subject to hard failure based on proportional hazards model. Reliability Engineering & System Safety, 2020, 196: 106707 [147] Liu B, Do P, Iung B, Xie M. Stochastic filtering approach for condition-based maintenance considering sensor degradation. IEEE Transactions on Automation Science and Engineering, 2020, 17(1): 177−190 [148] Susto G A, Schirru A, Pampuri S, McLoone S, Beghi A. Machine learning for predictive maintenance: A multiple classifier approach. IEEE Transactions on Industrial Informatics, 2015, 11(3): 812−820 [149] Yildirim M, Gebraeel N Z, Sun X A. Integrated predictive analytics and optimization for opportunistic maintenance and operations in wind farms. IEEE Transactions on Power Systems, 2017, 32(6): 4319−4328 [150] Carvalho T P, Soares F A A M N, Vita R, Francisco R P, Basto J P, Alcala S G S. A systematic literature review of machine learning methods applied to predictive maintenance. Computers & Industrial Engineering, 2019, 137: 106024 [151] Nguyen K T P, Medjaher K. A new dynamic predictive maintenance framework using deep learning for failure prognostics. Reliability Engineering & System Safety, 2019, 188: 251−262 -

下载:

下载: