-

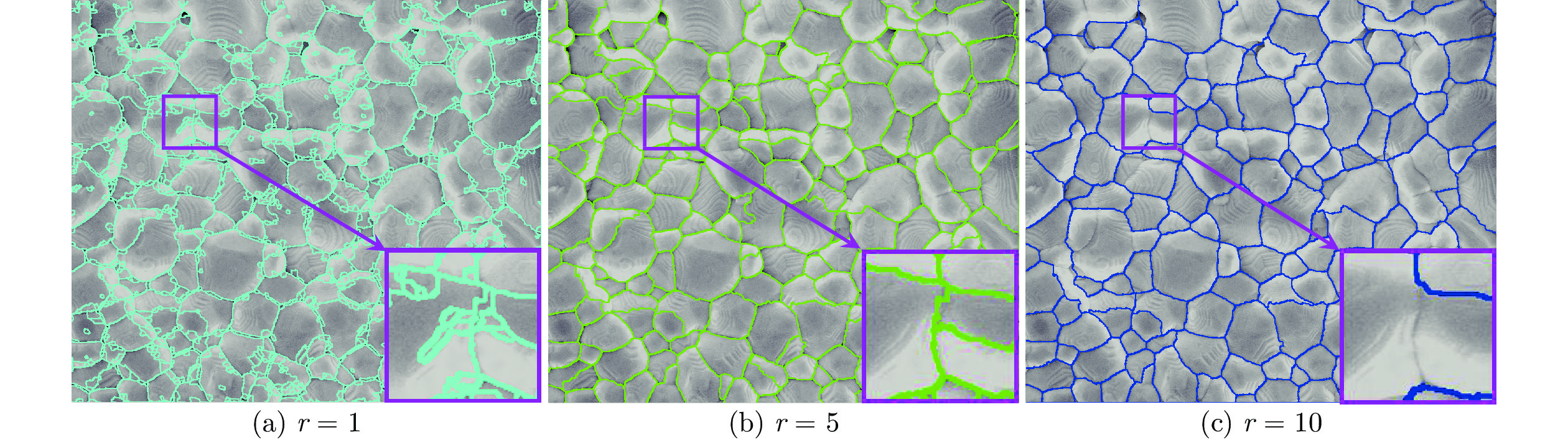

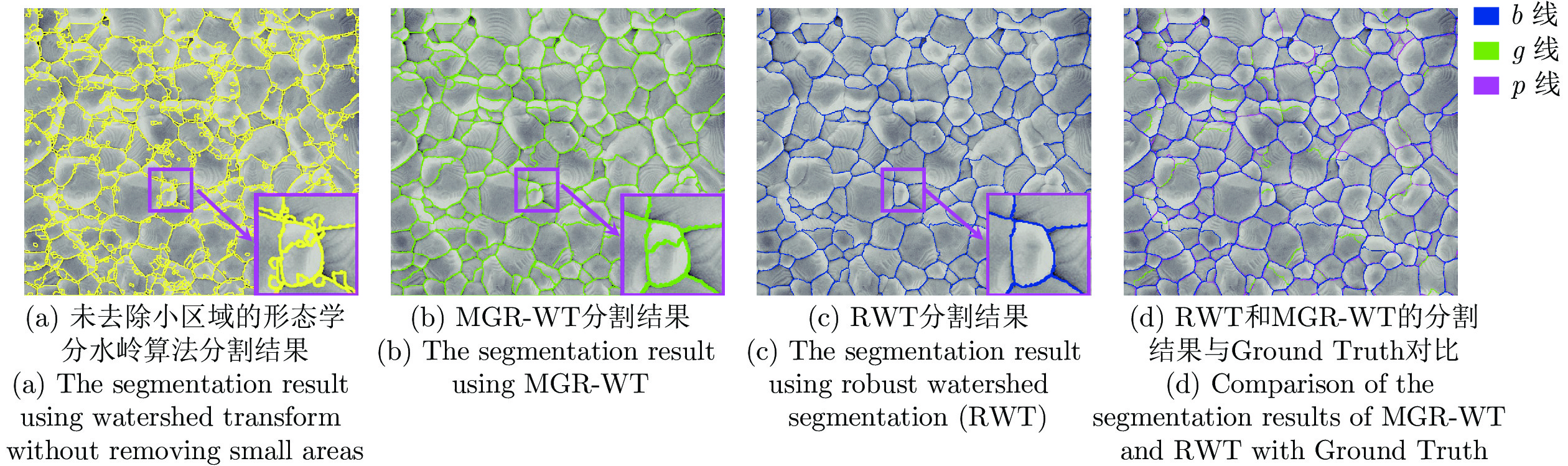

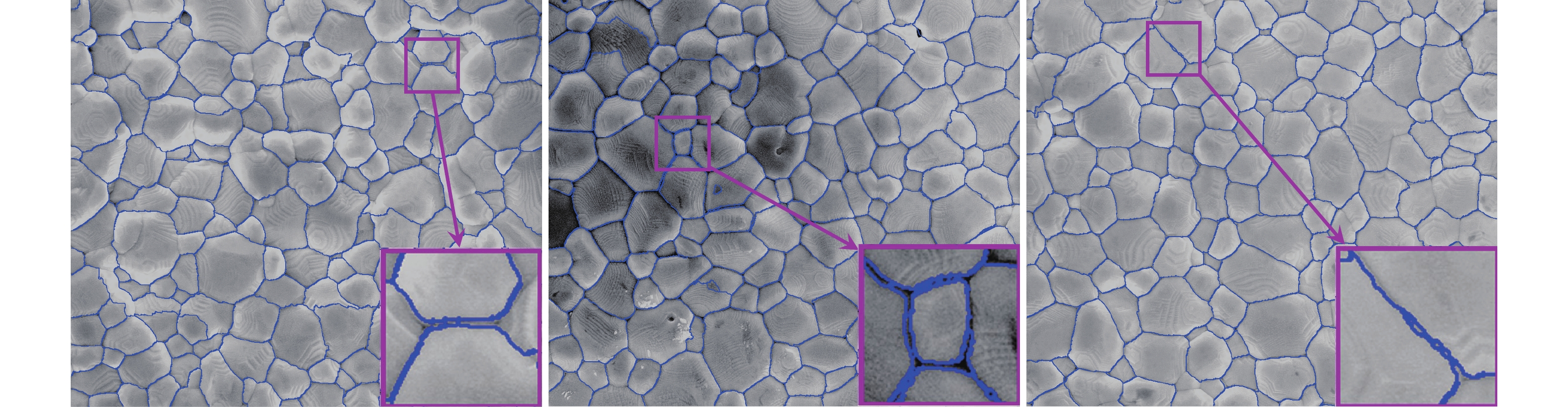

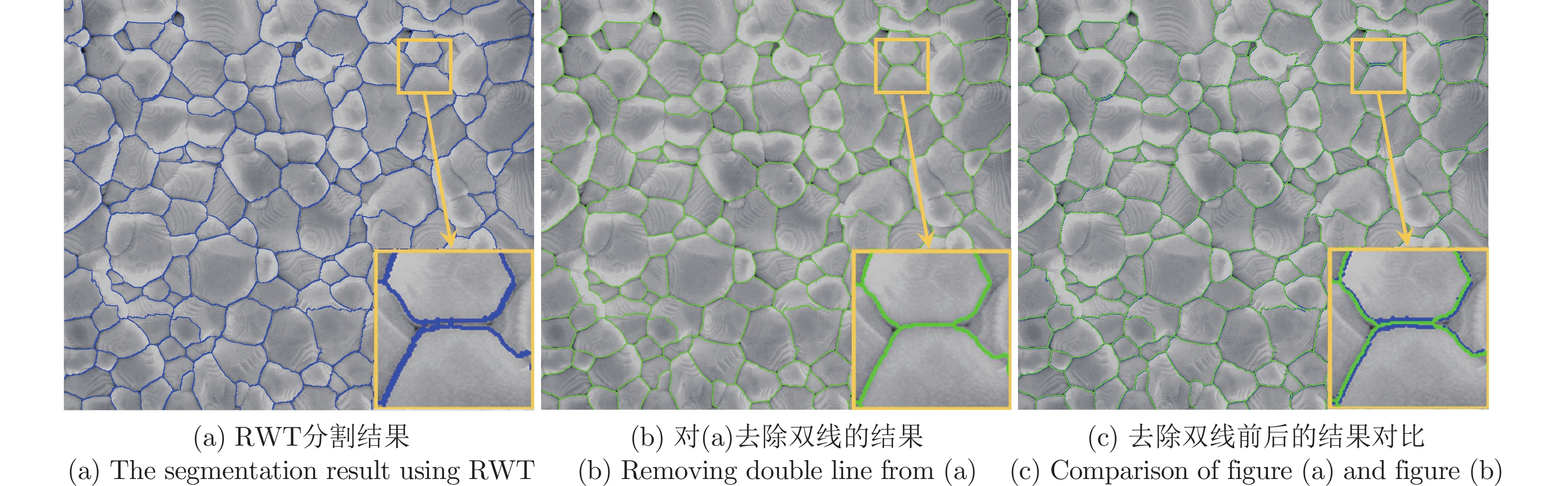

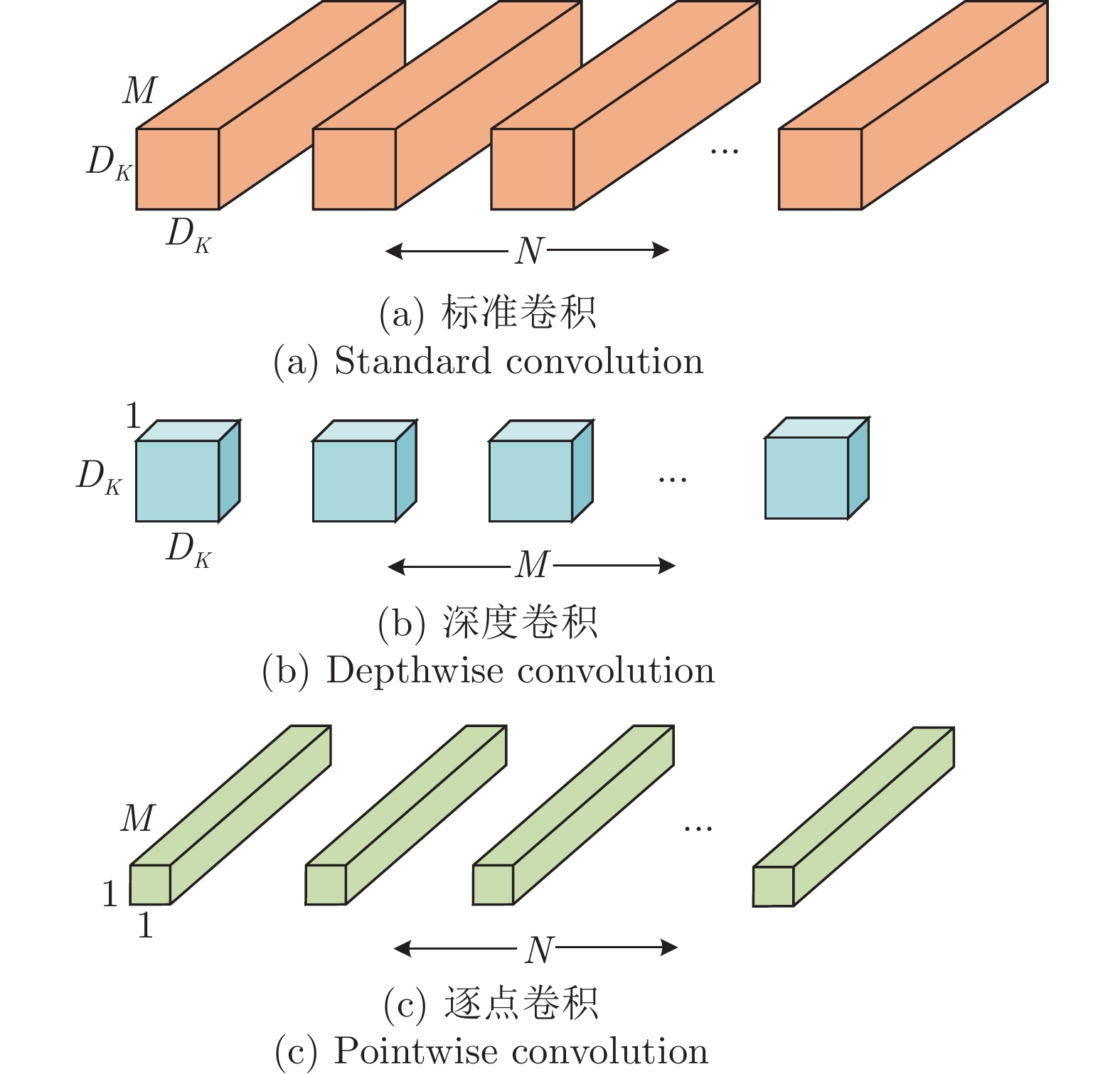

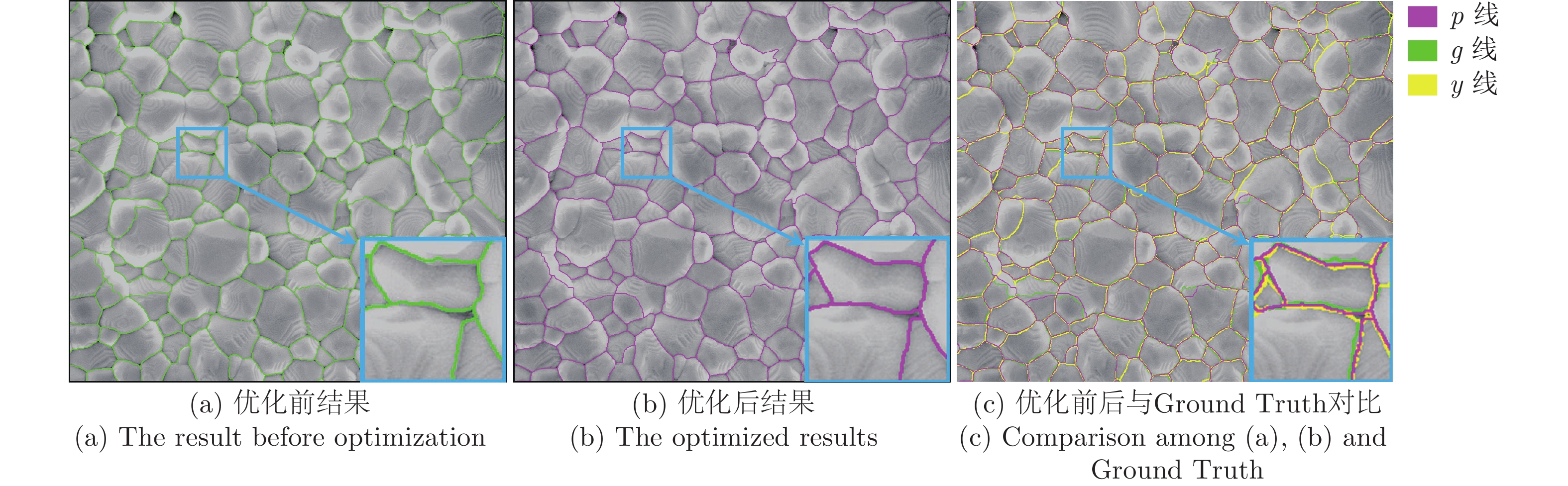

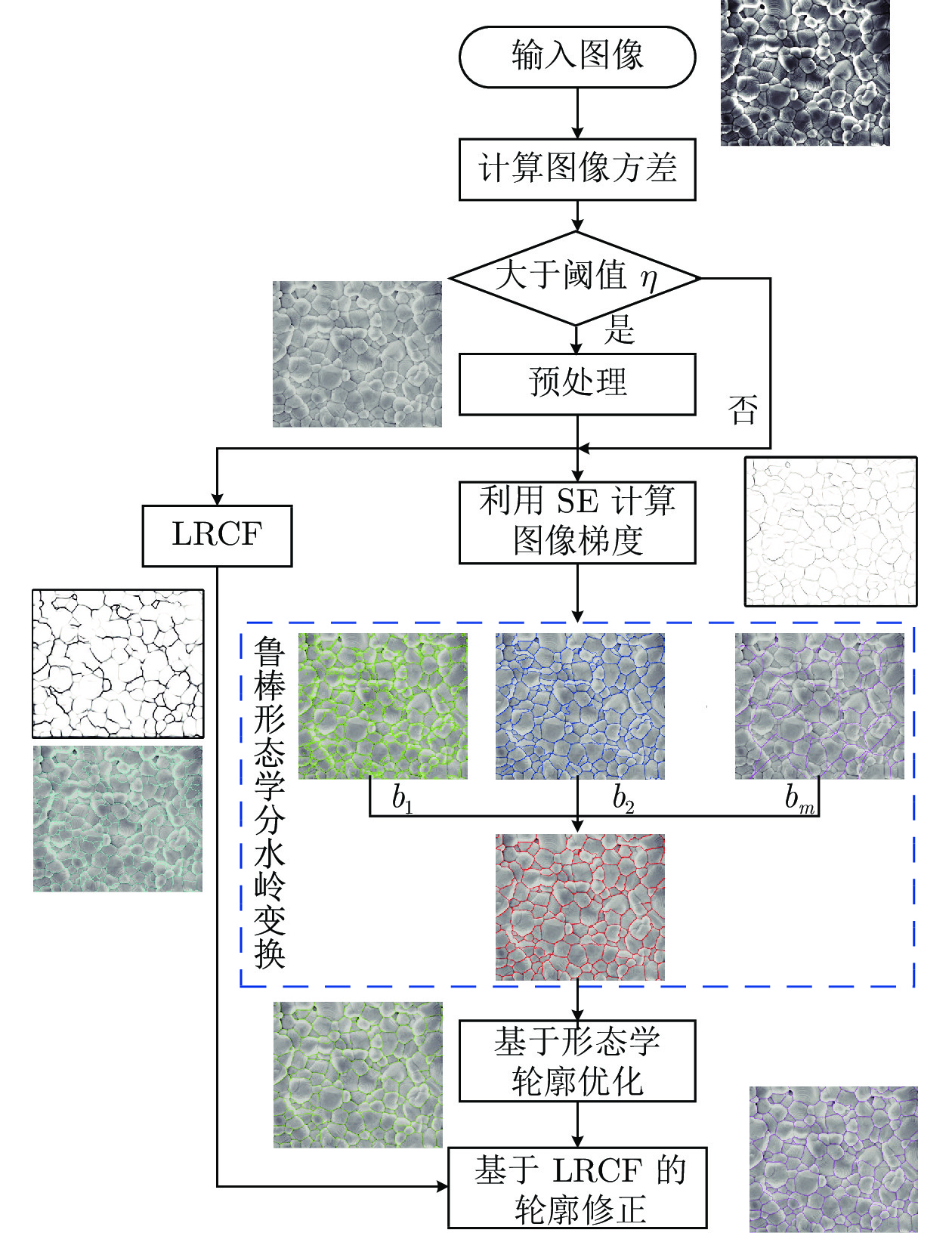

摘要: 研究陶瓷晶粒尺寸分布对估计陶瓷样品的物理属性具有重要意义, 当前主要依赖人工方法测量晶粒尺寸, 由于晶粒形状不规则且大小不一, 因此人工方法测量效率低、误差大. 针对该问题, 提出一种数据与模型联合驱动的陶瓷材料晶粒分割算法. 该算法首先通过图像预处理解决材料表面反光导致的灰度不均匀问题; 其次利用本文提出的鲁棒分水岭变换实现图像中晶粒的预分割, 解决传统分水岭算法存在的过分割以及分割区域个数与轮廓精度难以平衡的问题; 最后提出轻量级富卷积特征网络输出晶粒轮廓, 并利用该轮廓对预分割结果进行优化. 与主流图像分割算法相比, 该算法一方面利用鲁棒分水岭变换实现了更为准确的晶粒区域定位, 另一方面利用图像的低层与高层特征融合获取了更为精准的晶粒轮廓. 实验结果表明, 该算法不仅能够实现陶瓷材料晶粒尺寸的精准计算, 而且具有较高的计算效率, 为分析陶瓷材料物理属性提供了客观准确的数据.Abstract: The research of the distribution of ceramic grain sizes is significant for estimating physical properties of ceramic materials. At present, researchers mainly use manual methods to measure ceramic grains, which leads to low efficiency and large error due to the irregular shape and different sizes of grains in ceramic images. To solve this issue, a new algorithm used for grain segmentation of ceramic materials is proposed in this paper. This algorithm first performs image pre-processing to solve the problem of intensity inhomogeneity caused by surface reflection of materials in the imaging process. Secondly, a robust watershed transform (RWT) is presented and used for pre-segmentation of grains in scanning electron microscope images, which solves two problems existing in traditional watershed transform, one is over-segmentation and the other is the difficulty of balancing the number of segmentation regions and the accuracy of boundaries. Finally, we present a lightweight and richer convolutional features network (LRCF) used for grain contour prediction, and use the results generated by LRCF to optimize the pre-segmentation result. Compared with popular image segmentation algorithms, the proposed algorithm shows two advantages. On one hand, it achieves more accurate grain region segmentation due to the employment of RWT; on the other hand, it provides more accurate grain boundaries due to the optimization of LRCF. Experimental results show that the proposed algorithm not only provides accurate grain sizes of ceramic materials, but also shows high calculation efficiency, which is significant for property analysis of ceramic materials.1) 收稿日期 2020-05-06 录用日期 2020-09-07 Manuscript received May 6, 2020; accepted September 7, 2020 国家自然科学基金(61871259, 61861024), 陕西省杰出青年科学基金(2021JC-47), 陕西省重点研发计划(2022GY-436, 2021ZDLGY08-07), 陕西省创新能力支撑计划(2020SS-03)资助 Supported by National Natural Science Foundation of China (61871259, 61861024), Natural Science Basic Research Program of Shaanxi (2021JC-47), Key Research and Development Program of Shaanxi (2022GY-436, 2021ZDLGY08-07), Shaanxi Joint Laboratory of Artificial Intelligence (2020SS-03) 本文责任编委 胡清华 Recommended by Associate Editor HU Qing-Hua 1. 陕西科技大学电子信息与人工智能学院 西安 710021 2. 陕西科技大学电气与控制工程学院 西安 710021 3. 陕西科技大学2) 材料科学与工程学院 西安 710021 4. 陕西科技大学文理学院 西安 710021 1. School of Electronic Information and Artificial Intelligence, Shaanxi University of Science and Technology, Xi'an 710021 2. School of Electrical and Control Engineering, Shaanxi University of Science and Technology, Xi'an 710021 3. School of Material Science and Engineering, Shaanxi University of Science and Technology, Xi'an 710021 4. School of Arts and Sciences, Shaanxi University of Science and Technology, Xi'an 710021

-

表 1 不同方法对陶瓷晶粒分割的性能指标对比(第1组实验, 未镀金的图像)

Table 1 Performance comparison of different approaches for ceramic grain segmentation (the first group of experiments for unplated image)

Methods CV↑ VI↓ GCE↓ BDE↓ Liu's-MGR[38] 0.2889 3.4270 0.4742 7.3230 Random Walker[39] 0.3556 2.9003 0.1407 13.2147 SLIC[14] 0.3547 3.0524 0.4396 10.1678 LSC[15] 0.3455 2.8820 0.3563 7.5911 Banerjee's[30] 0.5959 2.1992 0.2031 3.9182 SE-MGR-WT[32] 0.4680 2.3887 0.1364 5.0346 SE-AMR-WT[40] 0.8287 1.1280 0.1122 1.6261 RCF-MGR-WT[23] 0.6636 1.4952 0.0955 3.5651 LRCF-RWT 0.8697 0.8710 0.0763 1.6262 表 2 不同方法对陶瓷晶粒分割的性能指标对比(第2组实验, 镀金的图像)

Table 2 Performance comparison of different approaches for ceramic grain segmentation (the second group of experiments for gilded image)

Methods CV↑ VI↓ GCE↓ BDE↓ Liu's-MGR[38] 0.2622 3.8053 0.3565 6.9440 Random Walker[39] 0.3823 2.9517 0.2202 16.4378 SLIC[14] 0.3279 3.0962 0.4070 11.3350 LSC[15] 0.3347 2.8418 0.3265 8.0651 Banerjee's[30] 0.7035 1.7175 0.1052 2.7484 SE-MGR-WT[32] 0.7979 1.2031 0.1033 2.0565 SE-AMR-WT[40] 0.8757 0.9909 0.1110 1.2623 RCF-MGR-WT[23] 0.5771 1.7691 0.0895 4.8813 LRCF-RWT 0.9217 0.6699 0.0628 1.0201 表 3 人工测量晶粒尺寸结果(像素)

Table 3 Grain sizes using manual method (pixels)

测量者 1 测量者 2 测量者 3 测量者 4 测量者 5 1 94.55 89.17 93.39 94.22 88.51 2 90.92 100.33 105.38 91.48 99.91 3 107.50 100.91 102.09 96.49 89.91 4 101.61 89.91 92.08 94.42 93.38 5 108.31 103.88 95.16 102.45 93.52 6 112.51 108.21 112.34 109.70 107.84 7 101.85 104.13 102.80 94.40 89.73 表 4 不同方法对陶瓷晶粒尺寸的计算结果对比(像素)

Table 4 Comparison of ceramic grain sizes using different approaches (pixels)

人工测量 Ground Truth Liu's-MGR[38] RW[39] SLI[14] LSC[15] [30] SE-MGR-WT[32] SE-AMR-WT[40] RCF-MGR-WT[23] LRCF-RWT 1 92.26 97.80 88.00 195.16 74.33 63.95 92.58 48.88 83.73 63.07 98.56 2 97.24 98.00 85.60 161.54 74.48 63.66 86.59 55.09 94.34 75.08 99.15 3 99.83 92.33 82.81 175.15 76.66 62.39 105.29 50.92 90.52 63.08 92.47 4 93.29 93.34 65.97 206.96 75.72 62.73 86.45 53.17 87.70 65.21 92.48 5 100.50 96.09 74.38 192.80 75.99 68.04 102.02 67.25 93.87 59.95 96.76 6 110.08 98.93 69.83 177.56 76.48 70.01 104.08 76.38 96.00 59.31 100.65 7 99.68 96.61 78.18 183.03 75.50 71.71 114.28 85.29 93.98 53.59 97.67 表 5 不同方法计算陶瓷晶粒尺寸结果的误差(像素)

Table 5 Error comparison of different approaches on ceramic grain size computation (pixels)

Liu's-MGR[38] RW[39] SLIC[14] LSC[15] [30] SE-MGR-WT[32] SE-AMR-WT[40] RCF-MGR-WT[23] LRCF-RWT 1 −9.80 +97.36 −23.47 −33.85 −5.22 −48.92 −14.07 −34.73 −0.76 2 −12.40 +63.54 −23.52 −34.34 −11.41 −42.91 −3.66 −22.92 +1.15 3 −9.52 +82.82 −15.67 −29.94 −12.96 −41.41 −1.81 −29.25 −0.14 4 −27.37 +113.62 −17.62 −30.61 −6.89 −40.17 −5.64 −28.13 −0.86 5 −21.71 +96.71 −20.1 −28.05 +6.07 −28.84 −2.22 −36.14 −0.67 6 −29.10 +18.63 −22.45 −28.92 +5.15 −19.55 −2.93 −39.62 +1.72 7 −18.43 +86.42 −21.11 −24.90 +17.67 −11.32 −2.63 −43.02 −1.06 -

[1] Viola G, Chong K B, Eriksson M, Shen Z, Zeng J, Yin Q, et al. Effect of grain size on domain structures, dielectric and thermal depoling of Nd-substituted bismuth titanate ceramics. Applied Physics Letters, 2013, 103(18): 182903. [2] Yuan Q, Yao F, Wang Y, Ma R, Wang H. Relaxor ferroelectric 0.9 BaTiO3–0.1 Bi (Zn0.5Zr0.5) O3 ceramic capacitors with high energy density and temperature stable energy storage properties. Journal of Materials Chemistry C, 2017, 5(37): 9552-9558. [3] Yang Z, Gao F, Du H, Jin L, Yan L, Hu Q, et al. Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties. Nano Energy, 2019, 58: 768-777. [4] 邹耀斌, 雷帮军, 臧兆祥, 王俊英, 胡泽海, 董方敏. 归一化互信息量最大化导向的自动阈值选择方法. 自动化学报, 2019, 45(7): 1373-1385.Zou Yao-Bin, Lei Bang-Jun, Zang Zhao-Xiang, Wang Jun-Ying, Hu Ze-Hai, Dong Fang-Min. Automatic threshold selection guided by maximizing normalized mutual information. Acta Electronica Sinica, 2019, 45(7): 1373-1385. [5] Yang M, Liu S, Chen K, Zhang H, Zhao E, Zhao T. A hierarchical clustering approach to fuzzy semantic representation of rare words in neural machine translation. IEEE Transactions on Fuzzy Systems, 2020, 28(5): 992-1002. [6] Lei T, Jia X, Zhang Y, He L, Meng H, Nandi A K. Significantly fast and robust fuzzy c-means clustering algorithms based on morphological reconstruction and membership filtering. IEEE Transactions on Fuzzy Systems, 2018, 26(5): 3027-3041. [7] 陶新民, 王若彤, 常瑞, 李晨曦, 刘艳超. 基于低密度分割密度敏感距离的谱聚类算法. 自动化学报, 2020, 46(7): 1479-1495.Tao Xin-Min, Wang Ruo-Tong, Chang Rui, Li Chen-Xi, Liu Yan-Chao. Low density separation density sensitive distance-based spectral clustering algorithm. Acta Electronica Sinica, 2020, 46(7): 1479-1495. [8] 雷涛, 张肖, 加小红, 刘侍刚, 张艳宁. 基于模糊聚类的图像分割研究进展. 电子学报, 2019, 47(08): 1776-1791. doi: 10.3969/j.issn.0372-2112.2019.08.023Lei Tao, Zhang Xiao, Jia Xiao-Hong, Liu Shi-Gang, Zhang Yan-Ning. Research progress on image segmentation based on fuzzy clustering. Acta Electronica Sinica, 2019, 47(8): 1776-1791. doi: 10.3969/j.issn.0372-2112.2019.08.023 [9] 马超, 刘亚淑, 骆功宁, 王宽全. 基于级联随机森林与活动轮廓的3D MR图像分割. 自动化学报, 2019, 45(5): 1004-1014.Ma Chao, Liu Ya-Shu, Luo Gong-Ning, Wang Kuan-Quan. Combining concatenated random forests and active contour for the 3D MR images segmentation. Acta Electronica Sinica, 2019, 45(5): 1004-1014. [10] Zhang L, Wu K T, Li P. An improved adaptive level set method for image segmentation. International Journal of Pattern Recognition & Artificial Intelligence, 2017, 32(5): 1854013. [11] Liu X, Guo S, Yang B, Ma S, Fu Y. Automatic organ segmentation for CT scans based on super-pixel and convolutional neural networks. Journal of Digital Imaging, 2018, 31(6): 748-760. [12] Zhang Z, Pan X, Cheng L, Zhan S, Zhou H, Chen R, et al. SAR image segmentation using hierarchical region merging with orientated edge strength weighted Kuiper’s distance. IEEE Access, 2019, 7: 84479-84496. doi: 10.1109/ACCESS.2019.2910735 [13] Ghosh P, Mali K, Das S K. Use of spectral clustering combined with normalized cuts (N-Cuts) in an iterative k-means clustering framework (NKSC) for superpixel segmentation with contour adherence. Pattern Recognition and Image Analysis, 2018, 28(3): 400-409. [14] Achanta R, Shaji A, Smith K, Lucchi A, Fua P, Süsstrunk, S. SLIC superpixels compared to state-of-the-art superpixel methods. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2012, 34(11): 2274-2282. [15] Li Z, Chen J. Superpixel segmentation using linear spectral clustering. IEEE Transactions on Image Processing, 2017, 26(7): 3317-3330. doi: 10.1109/TIP.2017.2651389 [16] Liu M Y, Tuzel O, Ramalingam S, Chellappa R. Entropy rate superpixel segmentation. In: Proceedings of IEEE Computer Vision and Pattern Recognition, CO, USA: IEEE, 2011. 2097-2104 [17] Zhao Z Q, Zheng P, Xu S, Wu X. Object detection with deep learning: A review. IEEE transactions on neural networks and learning systems, 2019, 30(11): 3212-3232. doi: 10.1109/TNNLS.2018.2876865 [18] Wang K, Liew J H, Zou Y, Zhou D, Feng J. Panet: Few-shot image semantic segmentation with prototype alignment. In: Proceedings of International Conference on Computer Vision. Seoul, Korea: IEEE, 2019. 9197−9206 [19] Long J, Shelhamer E, Darrell T. Fully convolutional networks for semantic segmentation. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2014, 39(4): 640-651. [20] He K, Zhang X, Ren S, Sun J. Spatial pyramid pooling in deep convolutional networks for visual recognition. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2015, 37(9): 1904-1916. doi: 10.1109/TPAMI.2015.2389824 [21] Zhao H, Shi J, Qi X, Wang X, Jia J. Pyramid scene parsing network. In: Proceedings of IEEE Computer Vision and Pattern Recognition, Honolulu, USA: IEEE, 2017. 6230−6239 [22] Chen L C, Papandreou G, Kokkinos I, Murphy K, Yuille A L. DeepLab: Semantic image segmentation with deep convolutional nets, atrous convolution, and fully connected CRFs. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2018, 40(4): 834-848.. doi: 10.1109/TPAMI.2017.2699184 [23] Liu Y, Cheng M M, Hu X, Wang K, Bai X. Richer convolutional features for edge detection. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2019, 41(8): 1939-1946. doi: 10.1109/TPAMI.2018.2878849 [24] Gao S, Cheng M M, Zhao K, Zhang X Y, Yang M H, Philip H S T. Res2net: A new multi-scale backbone architecture. IEEE transactions on pattern analysis and machine intelligence, 2019. doi: 10.1109/TPAMI.2019.2938758. [25] Li H, Xiong P, Fan H, Sun J. DFANet: Deep feature aggregation for real-time semantic segmentation. In: Proceedings of IEEE Computer Vision and Pattern Recognition, LA, USA: IEEE, 2019. 9522−9531 [26] Ding H, Jiang X, Shuai B, Liu A Q, Wang G. Semantic segmentation with context encoding and multi-path decoding. IEEE Transactions on Image Processing, 2020, 29: 3520-3533. doi: 10.1109/TIP.2019.2962685 [27] Andrew M. A quantified study of segmentation techniques on synthetic geological XRM and FIB-SEM images. Computational Geosciences, 2018, 22(6): 1503-1512. doi: 10.1007/s10596-018-9768-y [28] 薛维华, 王浩, 刘国权, 冯敏楠, 齐琳, 陈展鹏. 基于图像序列间相似性的晶粒组织图像分割方法. 中国体视学与图像分析, 2015, 20(04): 400-407.Xue Wei-Hua, Wang Hao, Liu Guo-Quan, Feng Min-Nan, Qi Lin, Chen Zhan-Peng. Segmentation method of grain microstructure based on similarity among image sequence. Chinese Journal of Stereology and Image Analysis, 2015, 20(04): 400-407. [29] Jiang F, Gu Q, Hao H, Li N, Wang B, Hu X. A method for automatic grain segmentation of multi-angle cross-polarized microscopic images of sandstone. Computers & Geosciences, 2018, 115: 143-153. [30] Banerjee S, Chakraborti P C, Saha S K. An automated methodology for grain segmentation and grain size measurement from optical micrographs. Measurement, 2019, 140: 142-150. doi: 10.1016/j.measurement.2019.03.046 [31] Vincent L, Soille P. Watersheds in digital spaces: An efficient algorithm based on immersion simulations. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1991, 13(6): 583-598. doi: 10.1109/34.87344 [32] Dollár P, Zitnick C L. Fast edge detection using structured forests. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2015, 37(8): 1558-1570. doi: 10.1109/TPAMI.2014.2377715 [33] Jobson D J, Rahman Z, Woodell G A. Properties and performance of a center/surround retinex. IEEE transactions on image processing, 1997, 6(3): 451-462. doi: 10.1109/83.557356 [34] Jobson D J, Rahman Z, Woodell G A. A multiscale retinex for bridging the gap between color images and the human observation of scenes. IEEE Transactions on Image Processing, 1997, 6(7): 965-976. doi: 10.1109/83.597272 [35] Jackway P T. Gradient watersheds in morphological scale-space. IEEE Transactions on Image Processing, 1996, 5(6): 913-921. doi: 10.1109/83.503908 [36] Yu Z, Feng C, Liu M Y, Ramalingam S. Casenet: Deep category-aware semantic edge detection. In: Proceedings of IEEE Computer Vision and Pattern Recognition, Honolulu, USA: IEEE, 2017. 5964−5973 [37] Liu Y, Lew M S. Learning relaxed deep supervision for better edge detection. In: Proceedings of IEEE Computer Vision and Pattern Recognition, NV, USA: IEEE, 2016. 231−240 [38] Liu G, Zhang Y, Wang A. Incorporating adaptive local onformation onto fuzzy clustering for image segmentation. IEEE Transactions on Image Processing, 2015, 24(11): 3990-4000. doi: 10.1109/TIP.2015.2456505 [39] Grady L. Random walks for image segmentation. IEEE Transactions on Pattern Analysis & Machine Intelligence, 2006, 28(11): 1768-1783. [40] Lei T, Jia X, Liu T, Liu S, Meng H, Nandi A K. Adaptive morphological reconstruction for seeded image segmentation. IEEE Transactions on Image Processing, 2019, 28(11): 5510-5523. doi: 10.1109/TIP.2019.2920514 [41] Arbelaez P, Maire M, Fowlkes C, Malik J. Contour detection and hierarchical image segmentation. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2011, 33(5): 898-916. doi: 10.1109/TPAMI.2010.161 [42] Meila M. Comparing clusterings: An axiomatic view. In: Proceedings of the International Conference on Machine Learning, Bonn, Germany: IMLS, 2005. 577−584 [43] Martin D, Fowlkes C, Tal D, Malik J. A database of human segmented natural images and its application to evaluating segmentation algorithms and measuring ecological statistics. In: Proceedings of International Conference on Computer Vision. BC, Canada: IEEE, 2001. 416−423 [44] Freixenet J, Muñoz X, Raba D, Martí J, Cufí X. Yet another survey on image segmentation: Region and boundary information integration. In: Proceedings of the European Conference on Computer Vision, Copenhagen, Denmark: IEEE, 2002. 408−422 -

下载:

下载: