|

[1]

|

宋贺达, 周平, 王宏, 柴天佑. 高炉炼铁过程多元铁水质量非线性子空间建模及应用. 自动化学报, 2016, 42(11): 1664−1679Song He-Da, Zhou Ping, Wang Hong, Chai Tian-You. Nonlinear subspace modeling of multivariate molten iron quality in blast furnace ironmaking and its application. Acta Automatica Sinica, 2006, 42(11): 1664−1679

|

|

[2]

|

Zhou P, Lv Y B, Wang H, Chai T Y. Data-driven robust RVFLNs modeling of blast furnace ironmaking process using Cauchy distribution weighted M-estimation. IEEE Transactions on Industrial Electronics, 2017, 64(9): 7141−7151 doi: 10.1109/TIE.2017.2686369

|

|

[3]

|

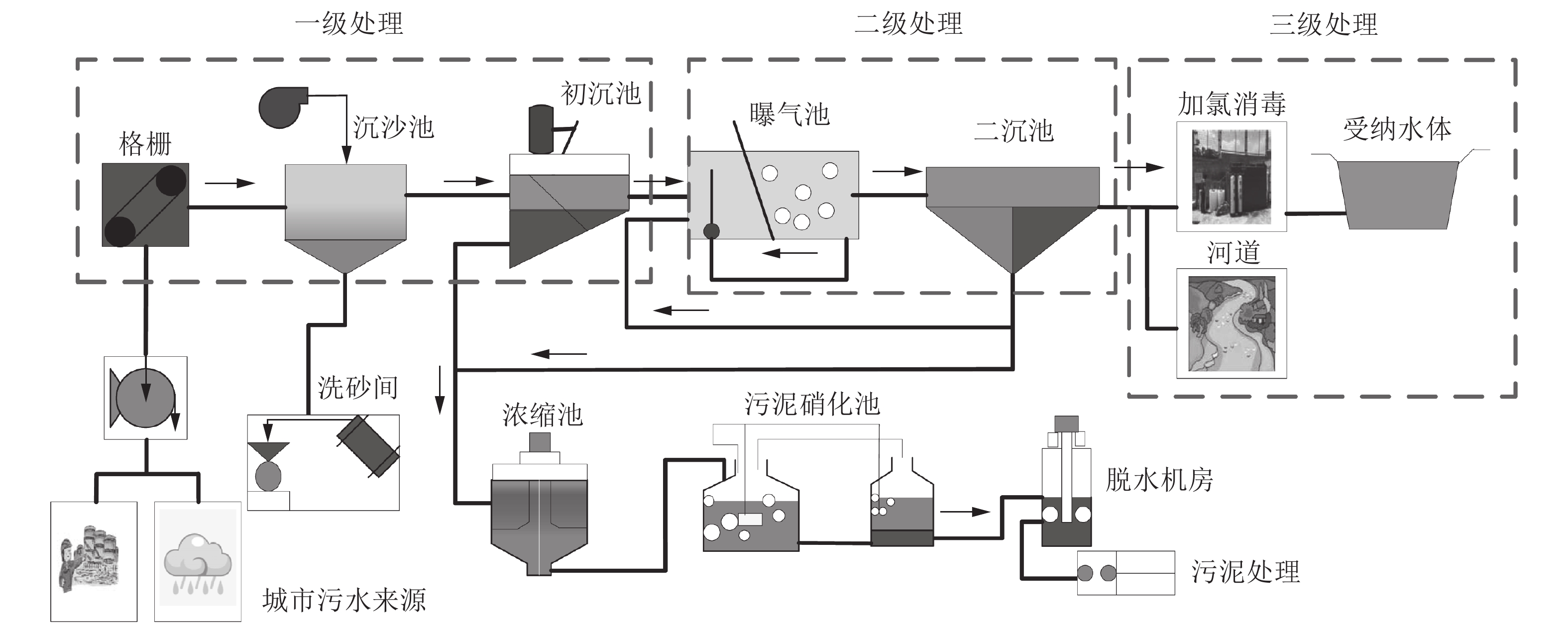

Han H G, Qiao J F. Nonlinear model-predictive control for industrial processes: an application to wastewater treatment process. IEEE Transactions on Industrial Electronics, 2014, 61(4): 1970−1982 doi: 10.1109/TIE.2013.2266086

|

|

[4]

|

Zhou P, Lu S W, Chai T Y.Data-driven soft-sensor modeling for product quality estimation using case-based reasoning and fuzzy-similarity rough sets. IEEE Transactions on Automation Science and Engineering, 2014. 11(4): 992−1003. doi: 10.1109/TASE.2013.2288279

|

|

[5]

|

Janssens P, Pipeleers G, Swevers J. A data-driven constrained norm-optimal iterative learning control framework for LTI systems. IEEE Transactions on Control Systems Technology, 2013, 21(2): 546−551. doi: 10.1109/TCST.2012.2185699

|

|

[6]

|

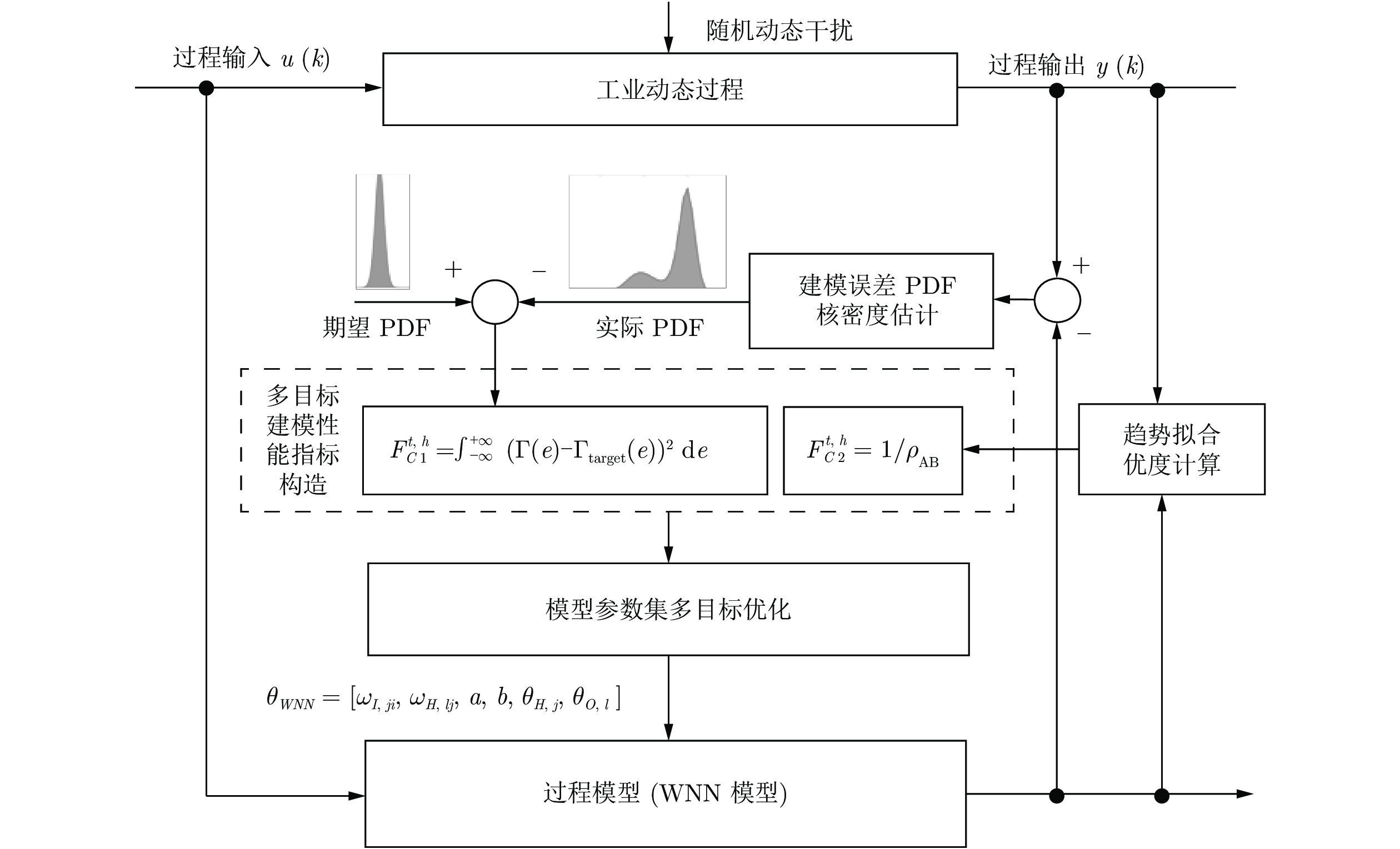

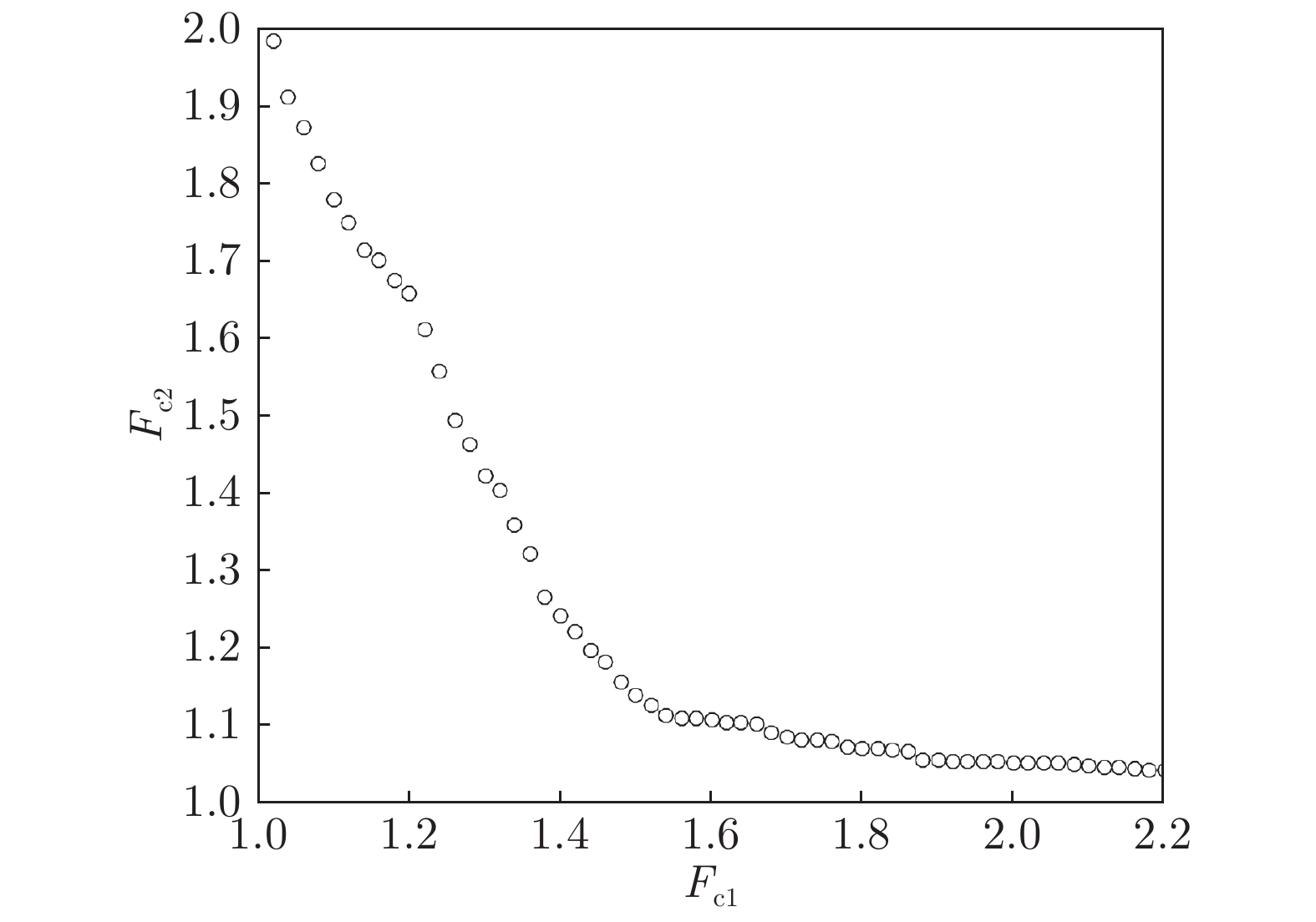

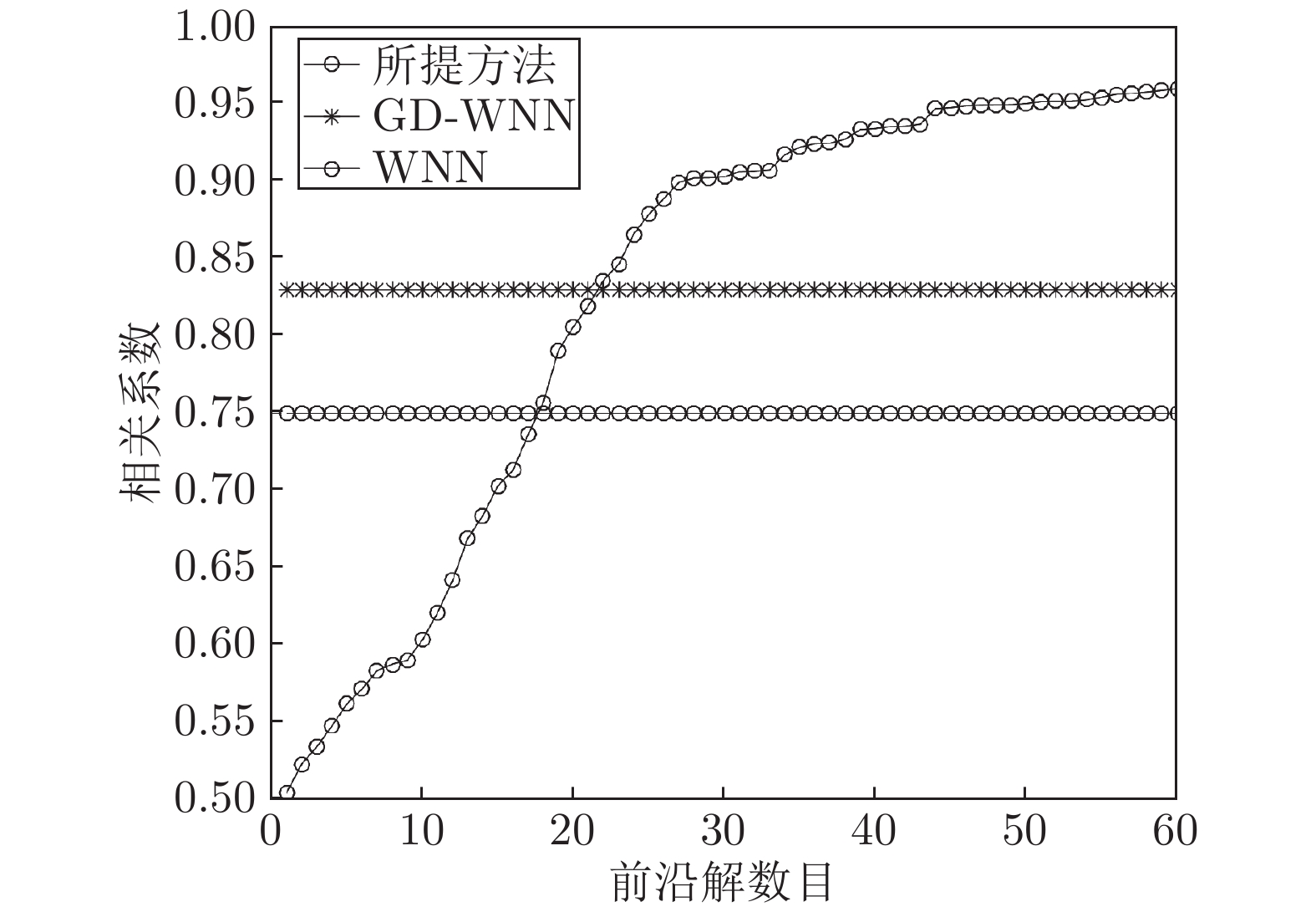

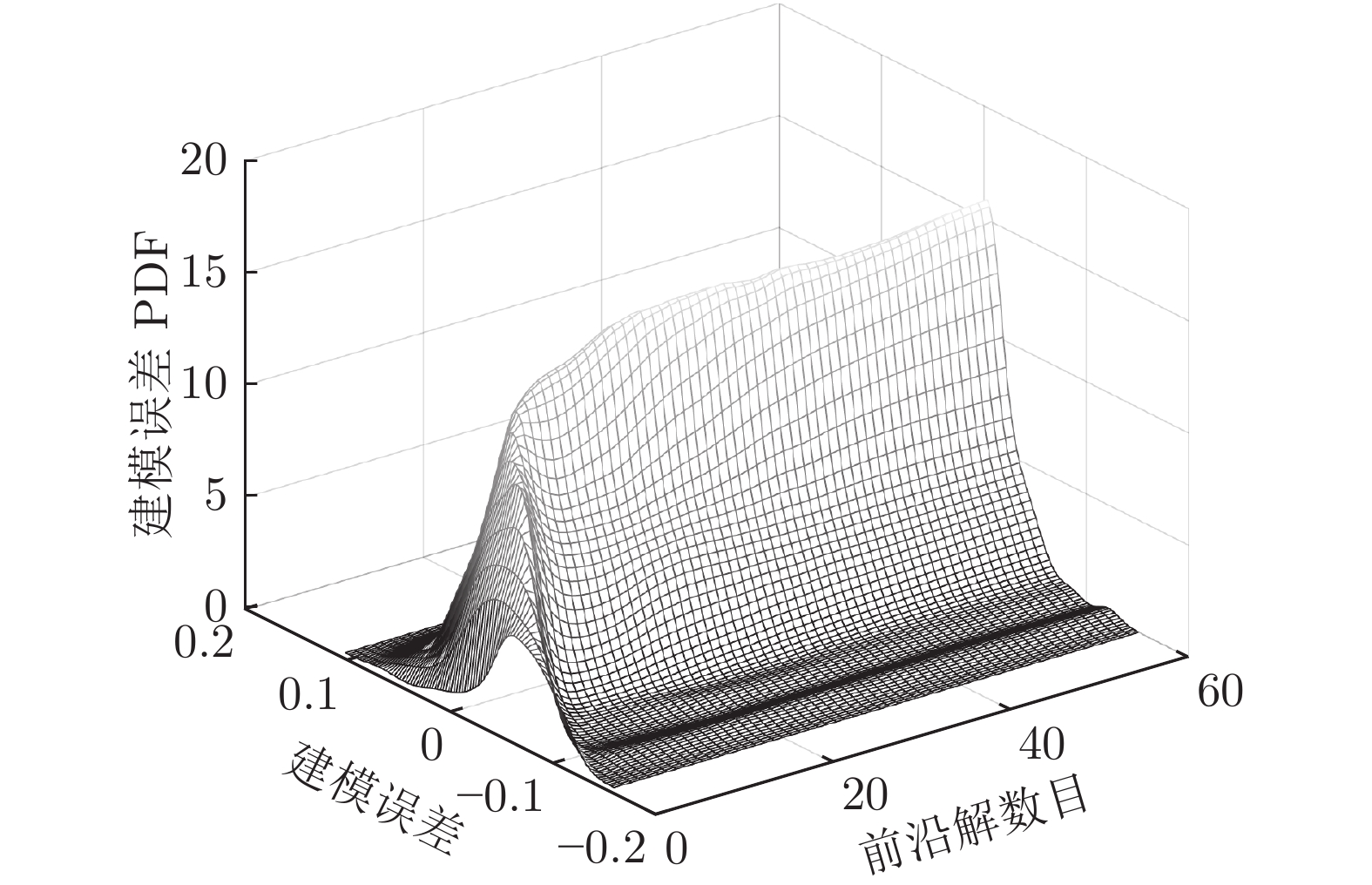

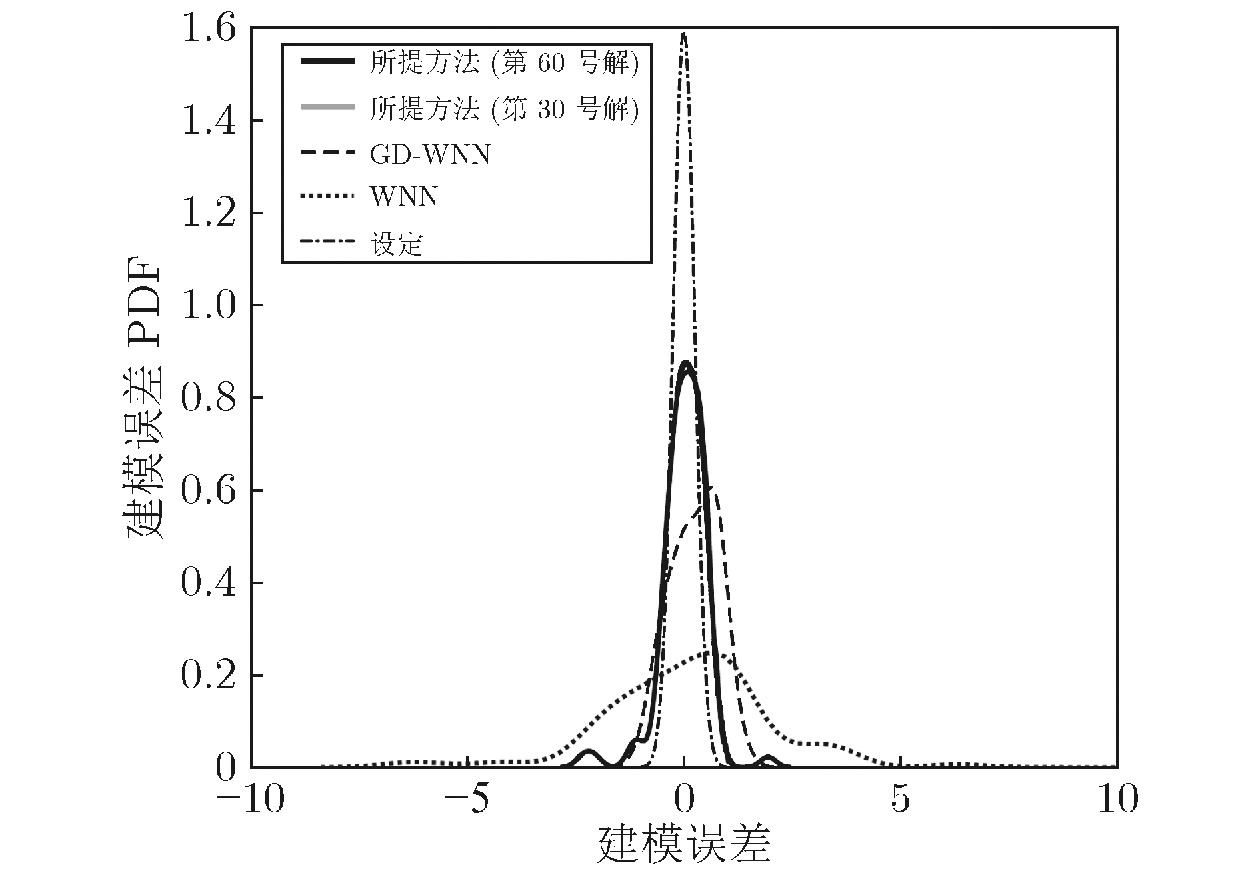

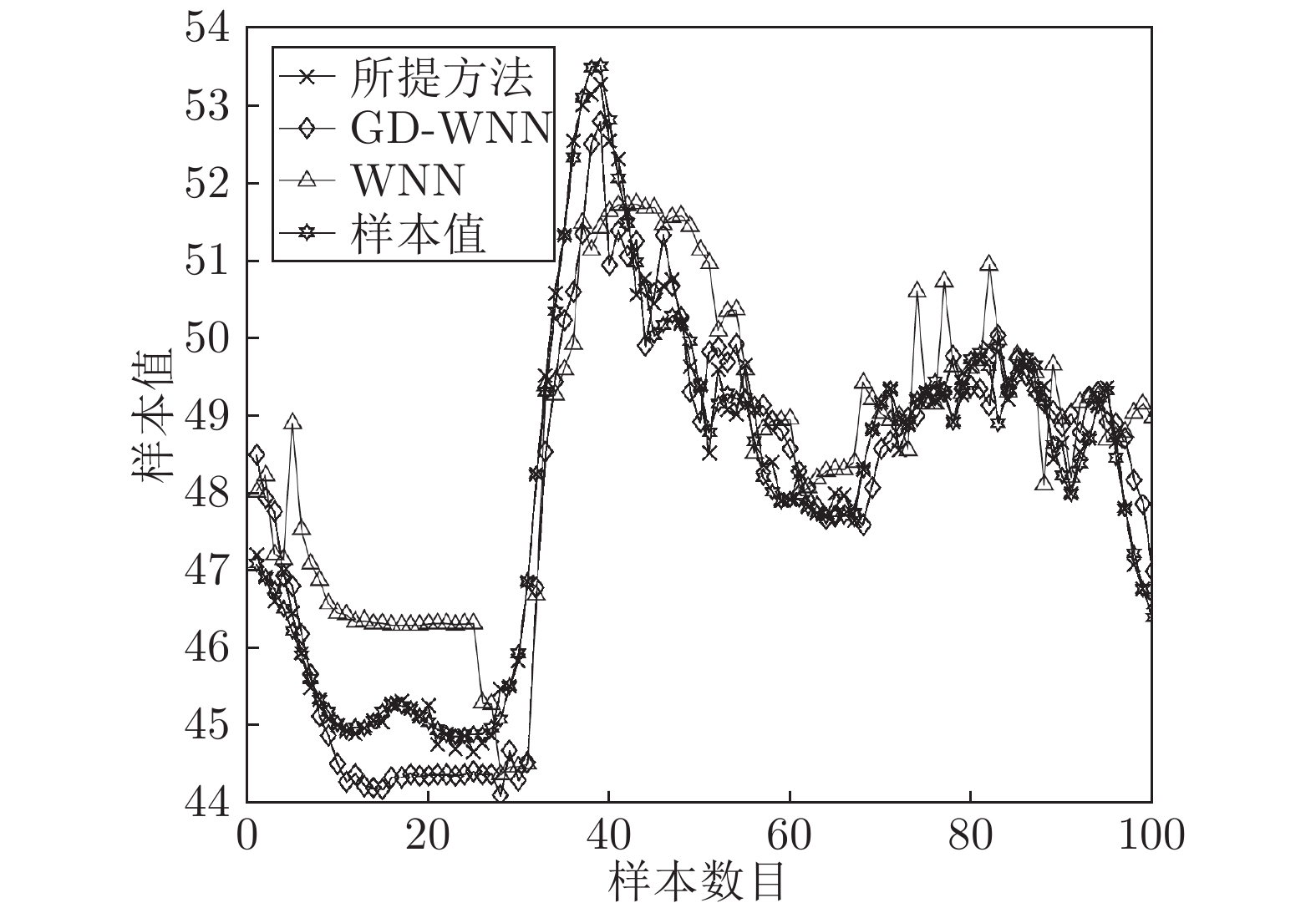

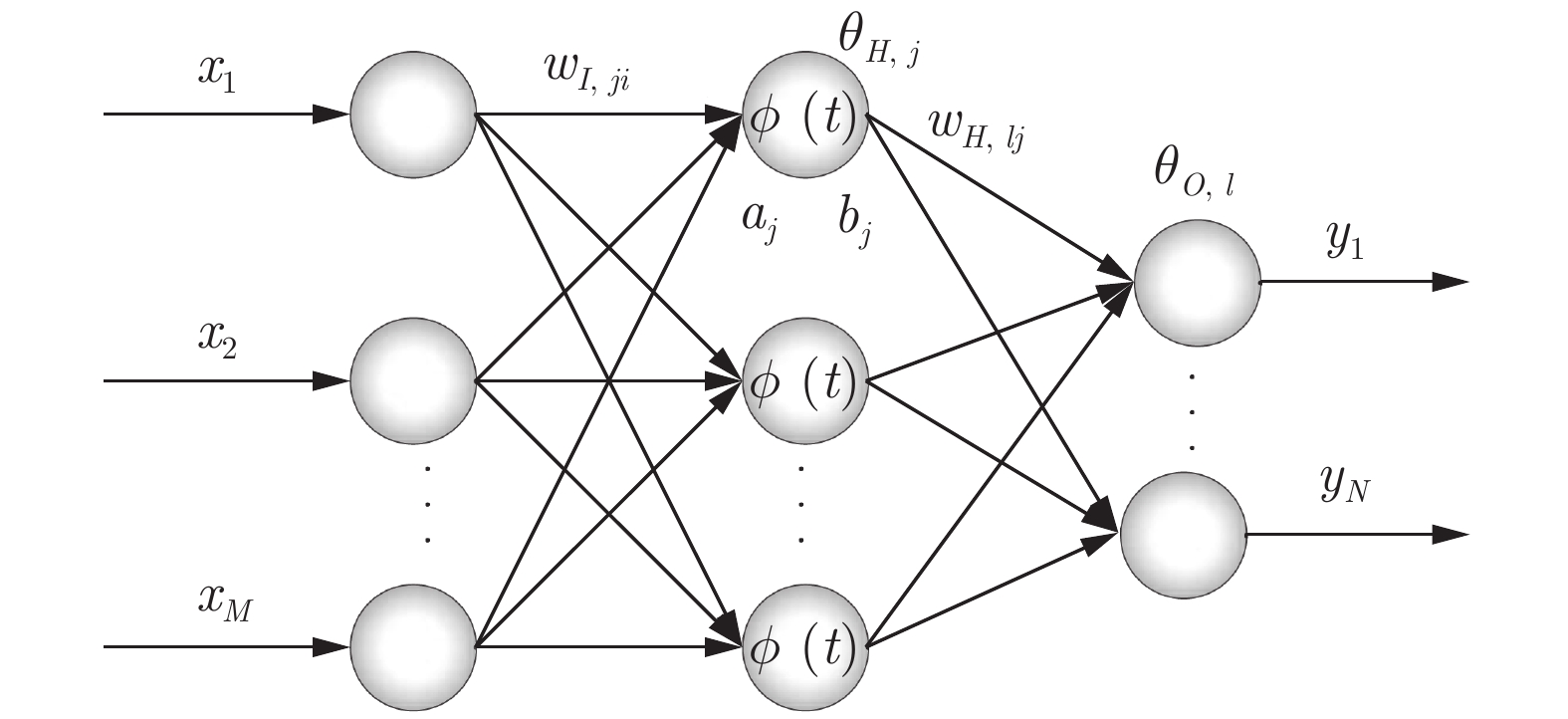

Zhou P, Wang C Y, Li M J, et al. Modeling error PDF optimization based wavelet neural network modeling of dynamic system and its application in blast furnace ironmaking. IEEE Neurocomputing, 2018, 285: 167−175. doi: 10.1016/j.neucom.2018.01.040

|

|

[7]

|

Wang H. Bounded Dynamic Stochastic Systems: Modeling and control. London: Springer-Verlag Ltd, 2000.

|

|

[8]

|

Zhou Y Y, Wang A P, Zhou P, Wang H, and Chai T Y. Dynamic performance enhancement for nonlinear stochastic systems using RBF driven nonlinear compensation with extended Kalman filter. Automatica, DOI: 10.1016/j.automatica.2019.108693

|

|

[9]

|

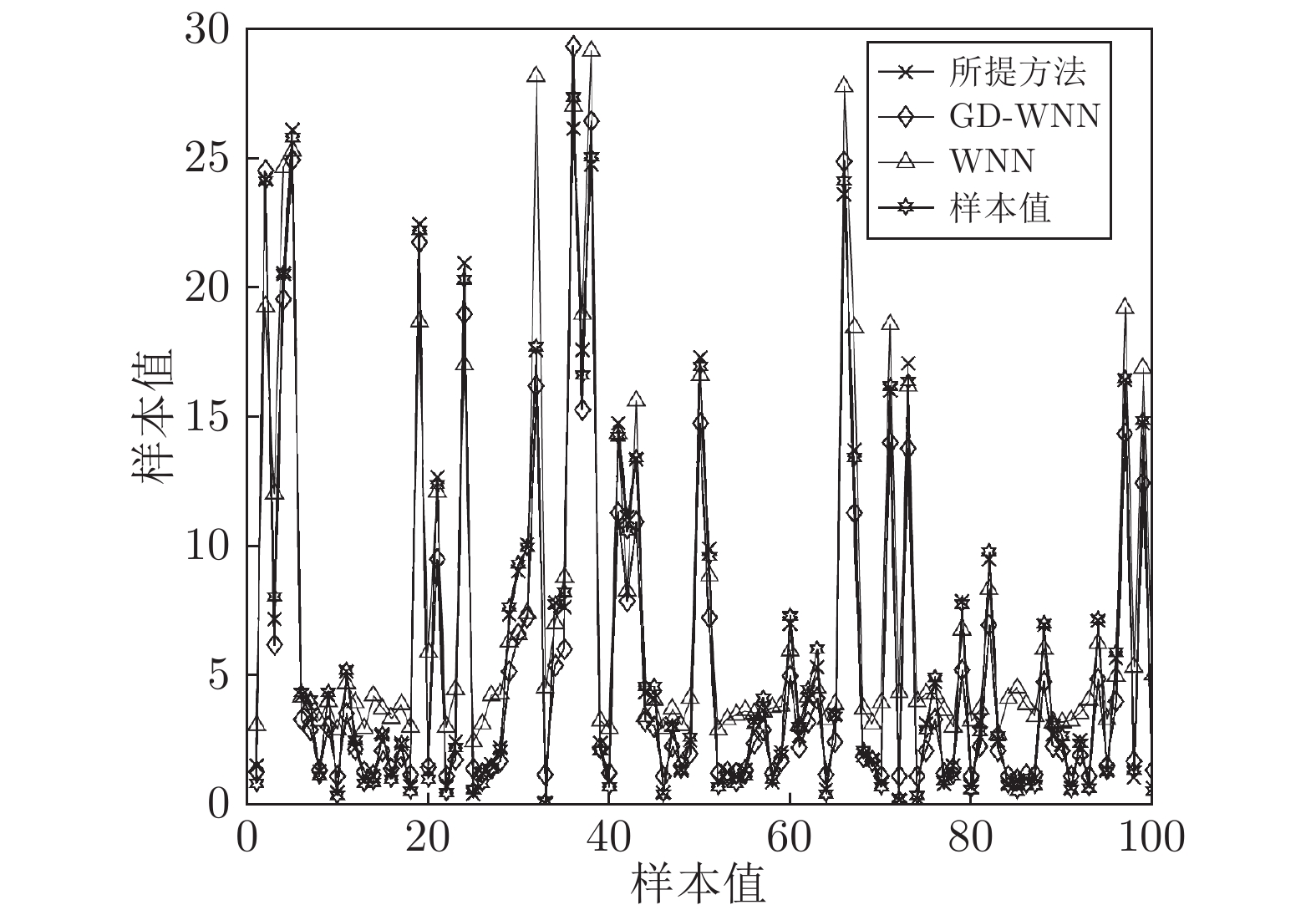

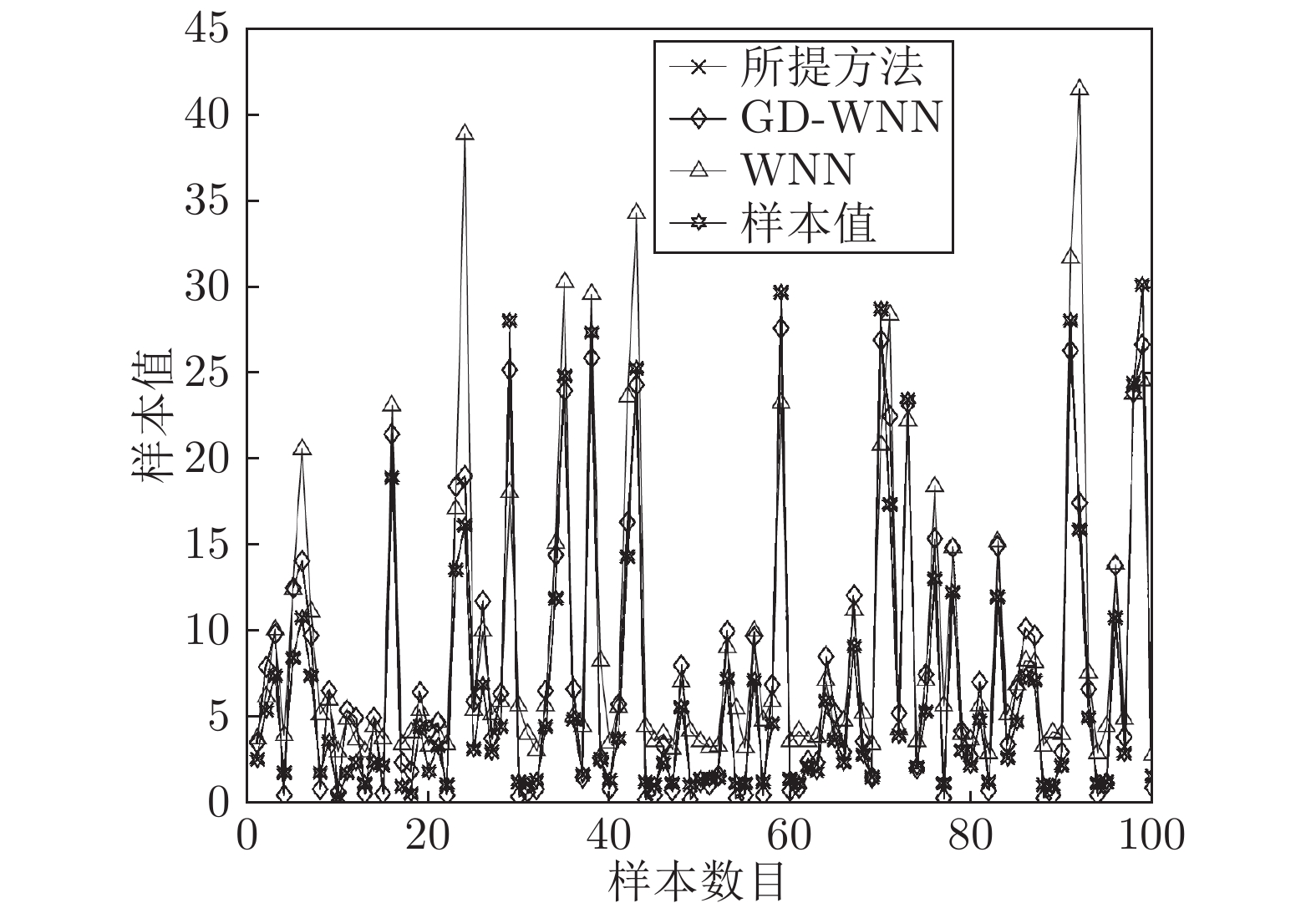

Ding J, Chai T, Wang H. Offline modeling for product quality prediction of mineral processing using modeling error PDF shaping and entropy minimization. IEEE Transactions on Neural Networks, 2011, 22(3):408−419. doi: 10.1109/TNN.2010.2102362

|

|

[10]

|

Jia L, Cao L M, Chui M S. Modeling error PDF shape based data-driven model for batch processes. Chin. J. Sci. Instrum, 2012, 33(7): 1505−1512.

|

|

[11]

|

Zhou P, Guo D W, Wang H, Chai T Y. Data-driven robust M-LS-SVR-based NARX modeling for estimation and control of molten iron quality indices in blast furnace ironmaking. IEEE Trans. Neural Netw. Learn. Syst, 2018, 29(9): 4007−4021. doi: 10.1109/TNNLS.2017.2749412

|

|

[12]

|

李换琴, 万百五. 基于填充函数算法的工业产品小波网络质量模型[J]. 自动化学报, 2004, 30(2): 283−287Li Huan-Qin, Wan Bai-Wu. A wavelet neural network model for industrial product quality based on filled function algorithm. Acta Automatica Sinica, 2004, 30(2): 283−287.

|

|

[13]

|

Rana M, Koprinska I. Forecasting electricity load with advanced wavelet neural networks. Neurocomputing, 2016, 182(3): 118−132.

|

|

[14]

|

Wu M, Xu C H, She J H,Yokoyama R. Intelligent integrated optimization and control system for lead-zinc sintering process. Control Engineering Practice, 2009, 17(2): 280−290 doi: 10.1016/j.conengprac.2008.07.007

|

|

[15]

|

Parzen E. On estimation of a probability density function and mode. Ann. Math. Stat., 1962, 33(3):1065−1076. doi: 10.1214/aoms/1177704472

|

|

[16]

|

Jones M C, Marron J S, Sheather S J. A brief survey of bandwidth selection for density estimation. J. Am. Stat. Assoc, 1996, 91(433): 401−407. doi: 10.1080/01621459.1996.10476701

|

|

[17]

|

Buch-larsen T, Nielsen J P, Guillén M. Kernel density estimation for heavy–tailed distributions using the champernowne transformation. Social Science Electronic Publishing, 2005, 39(6):503−516.

|

|

[18]

|

Deb K, Pratap A, Agarwal S and Meyarivan T. A fast and elitist multi-objective genetic algorithm: NSGA II. IEEE Trans. Evol. Comput., 2002, 6(2): 182−197. doi: 10.1109/4235.996017

|

|

[19]

|

张帅, 周平. 污水处理过程递推双线性子空间建模及无模型自适应控制. 自动化学报, DOI: 10.16383/j.aas.c190514Zhang Shuai, Zhou Ping. Recursive bilinear subspace modeling and model-free adaptive control of wastewater treatment. Acta Automatica Sinica, DOI: 10.16383/j.aas.c190514

|

|

[20]

|

Han H G, Zhang L, Qiao J F. Data-based predictive control for wastewater treatment process. IEEE Access, 2018, 6: 1498−1512. doi: 10.1109/ACCESS.2017.2779175

|

|

[21]

|

Qiao J F, Zhou H B. Modeling of energy consumption and effluent quality using density peaks-based adaptive fuzzy neural network. IEEE/CAA Journal of Automatica Sinica, 2018, 5(5): 968−976. doi: 10.1109/JAS.2018.7511168

|

|

[22]

|

乔俊飞, 薄迎春, 韩广. 基于ESN 的多指标DHP控制策略在污水处理过程中的应用. 自动化学报, 2013, 39(7): 146–1151.Qiao Jun-Fei, Bo Ying-Chun, Han Guang. Application of ESN-based multi indices dual heuristic dynamic programming on wastewater treatment process. Acta Automatica Sinica, 2013, 39(7): 1146−1151.

|

下载:

下载: