-

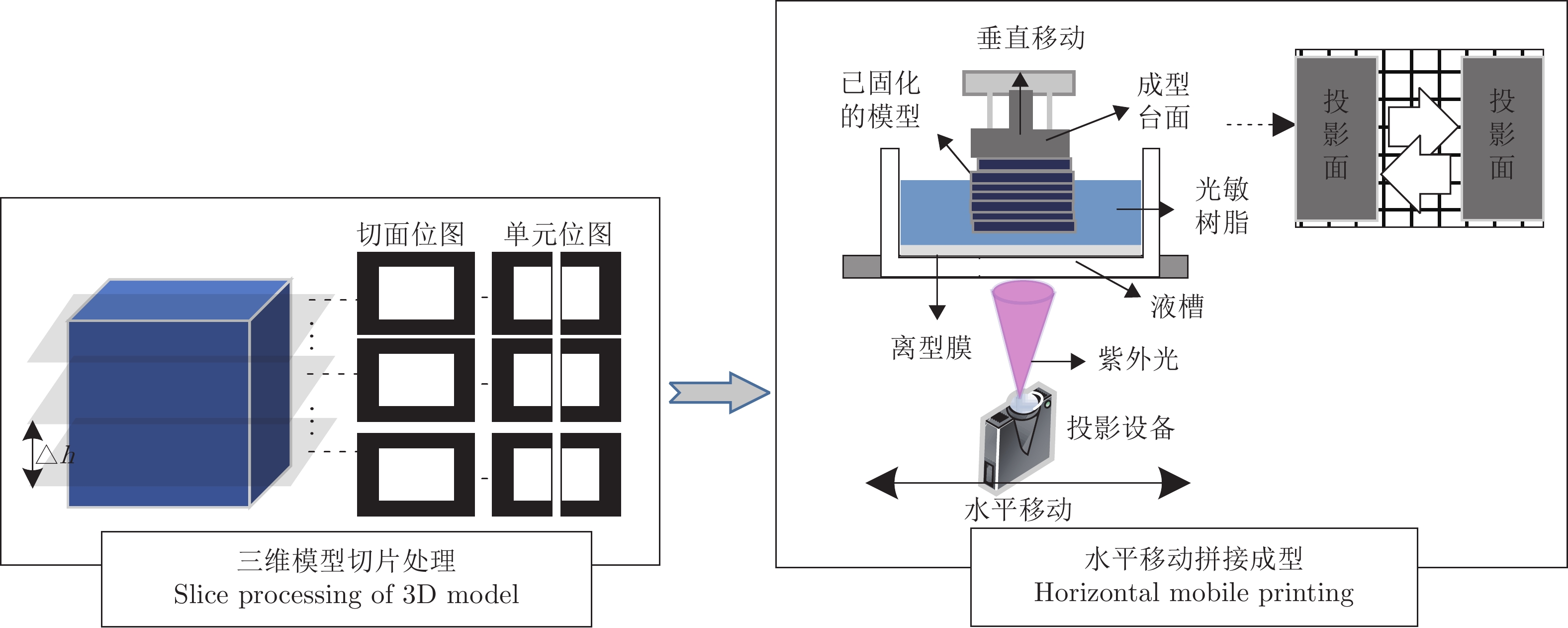

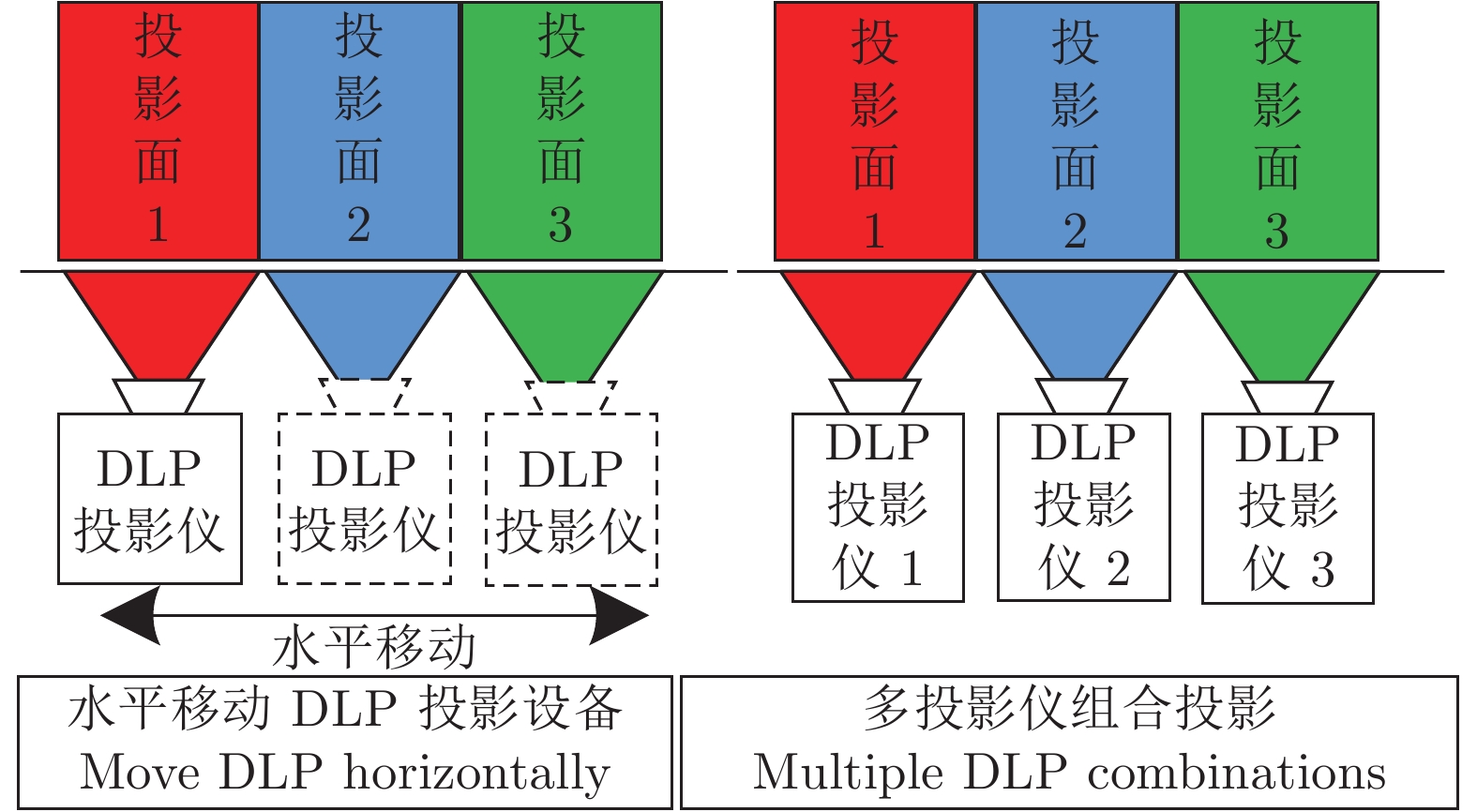

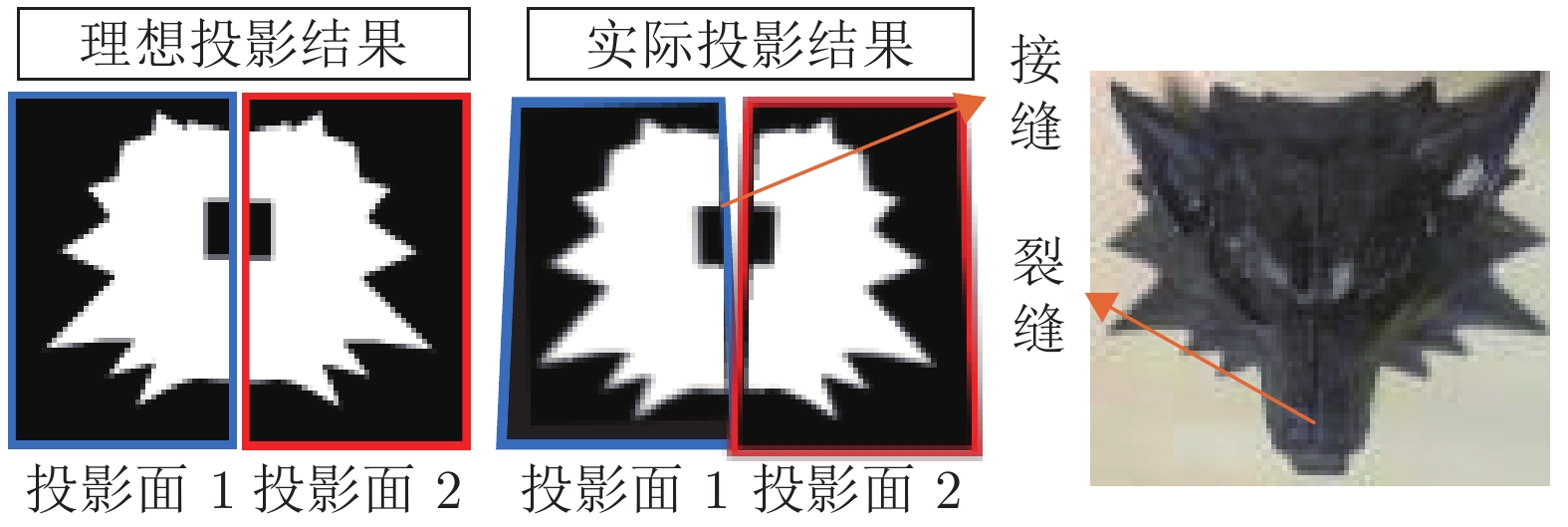

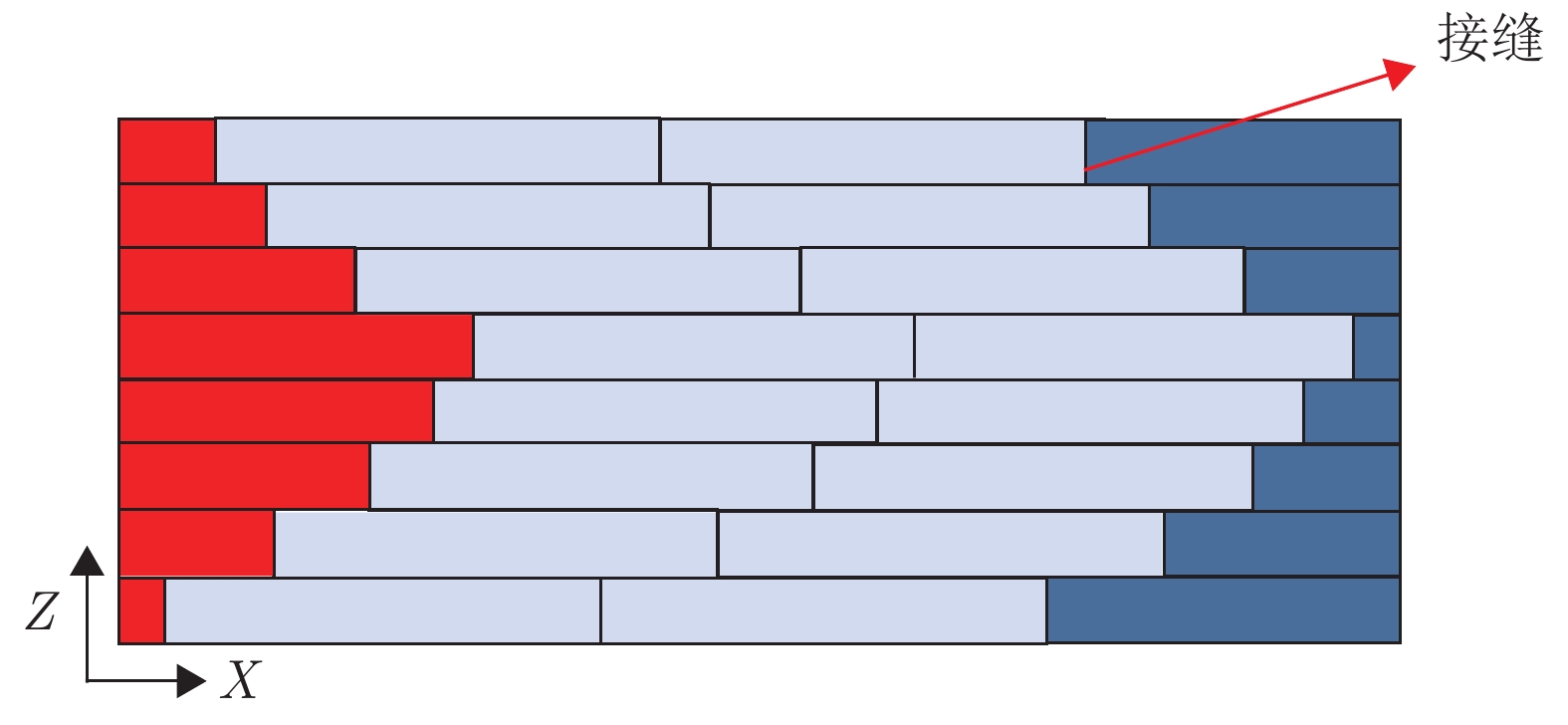

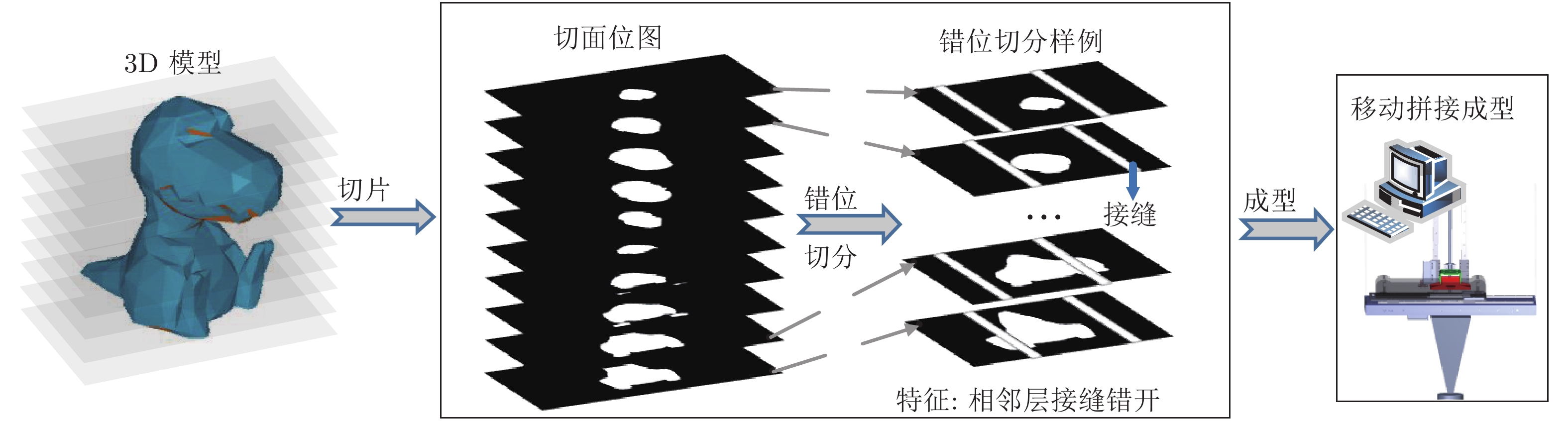

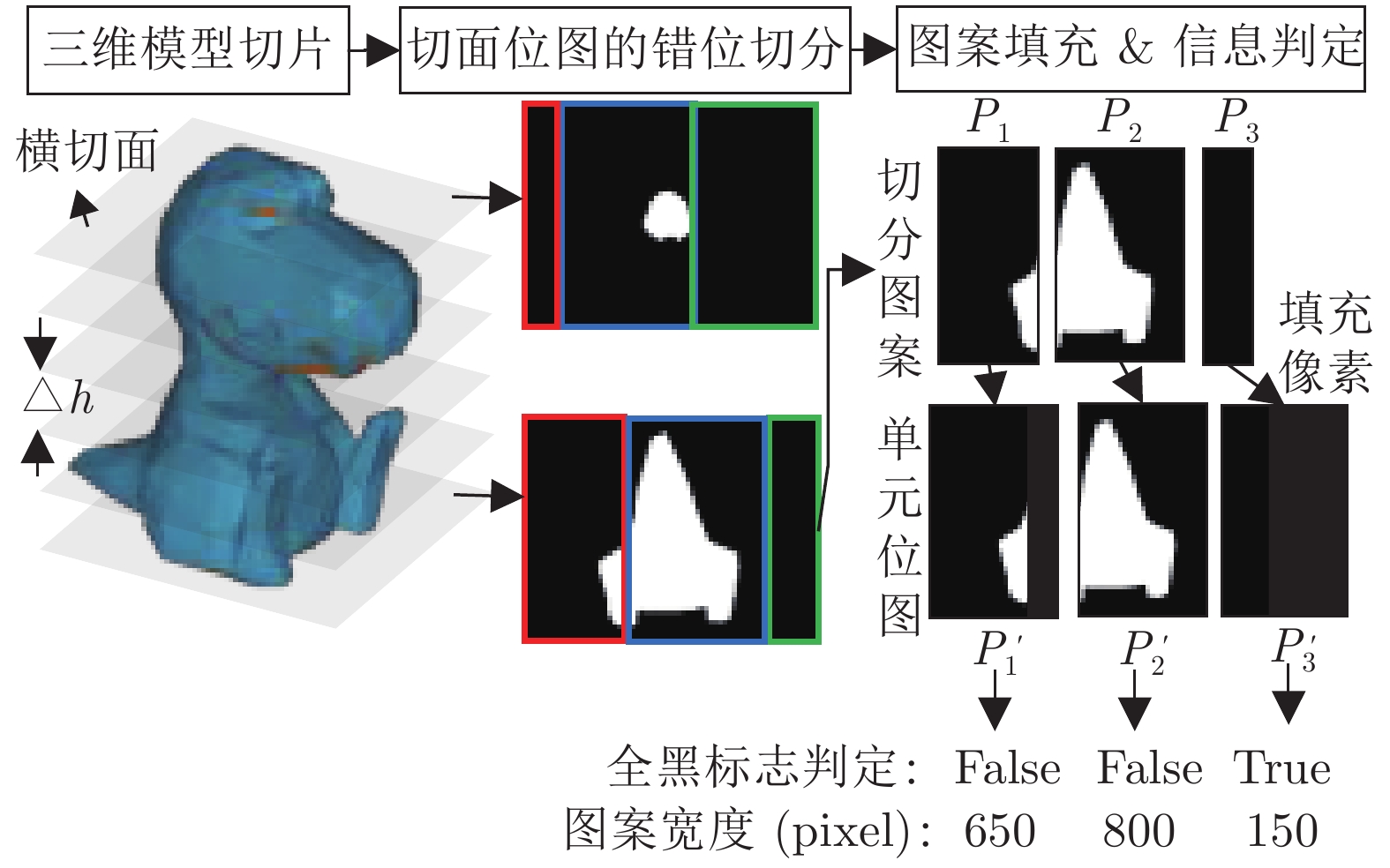

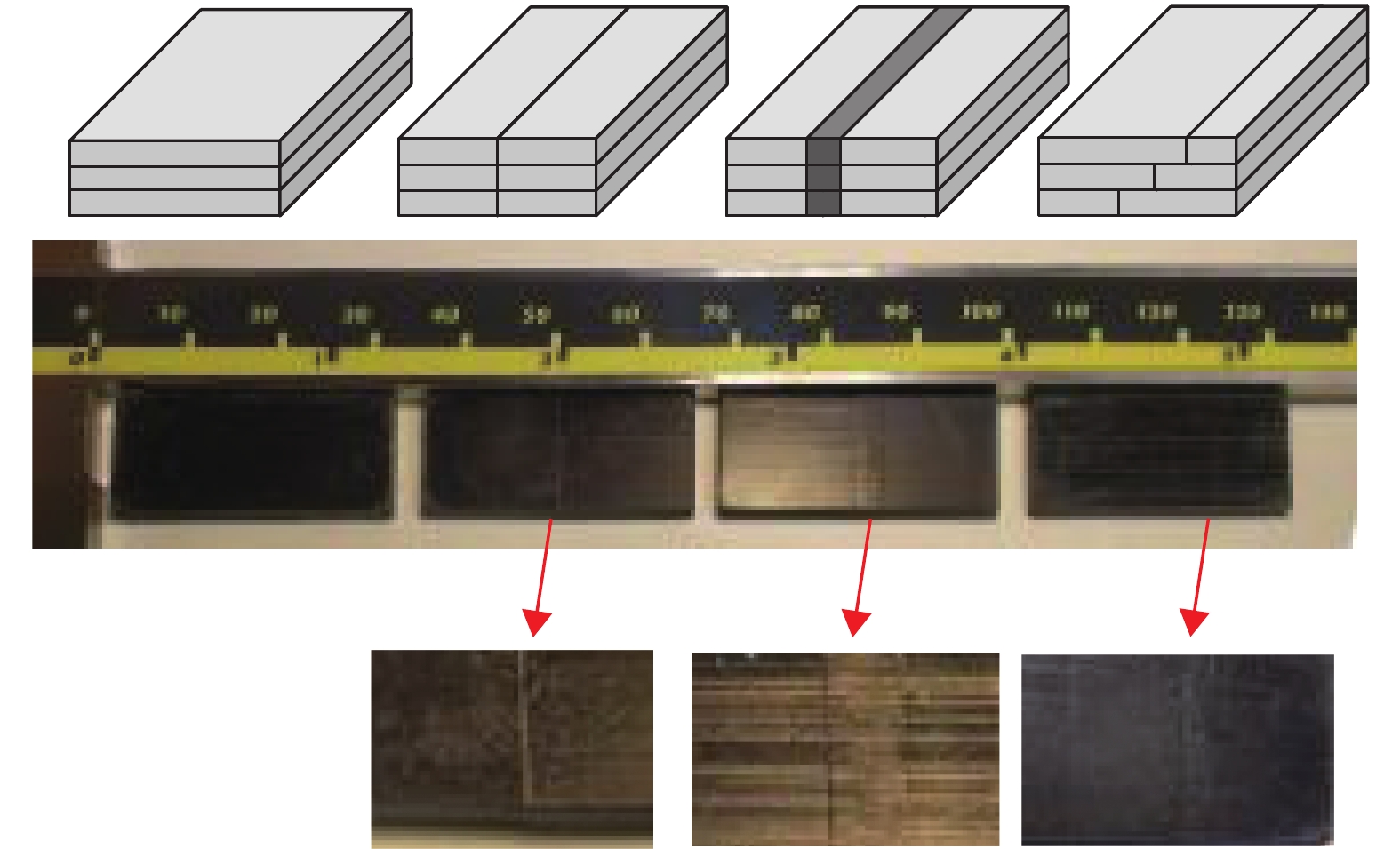

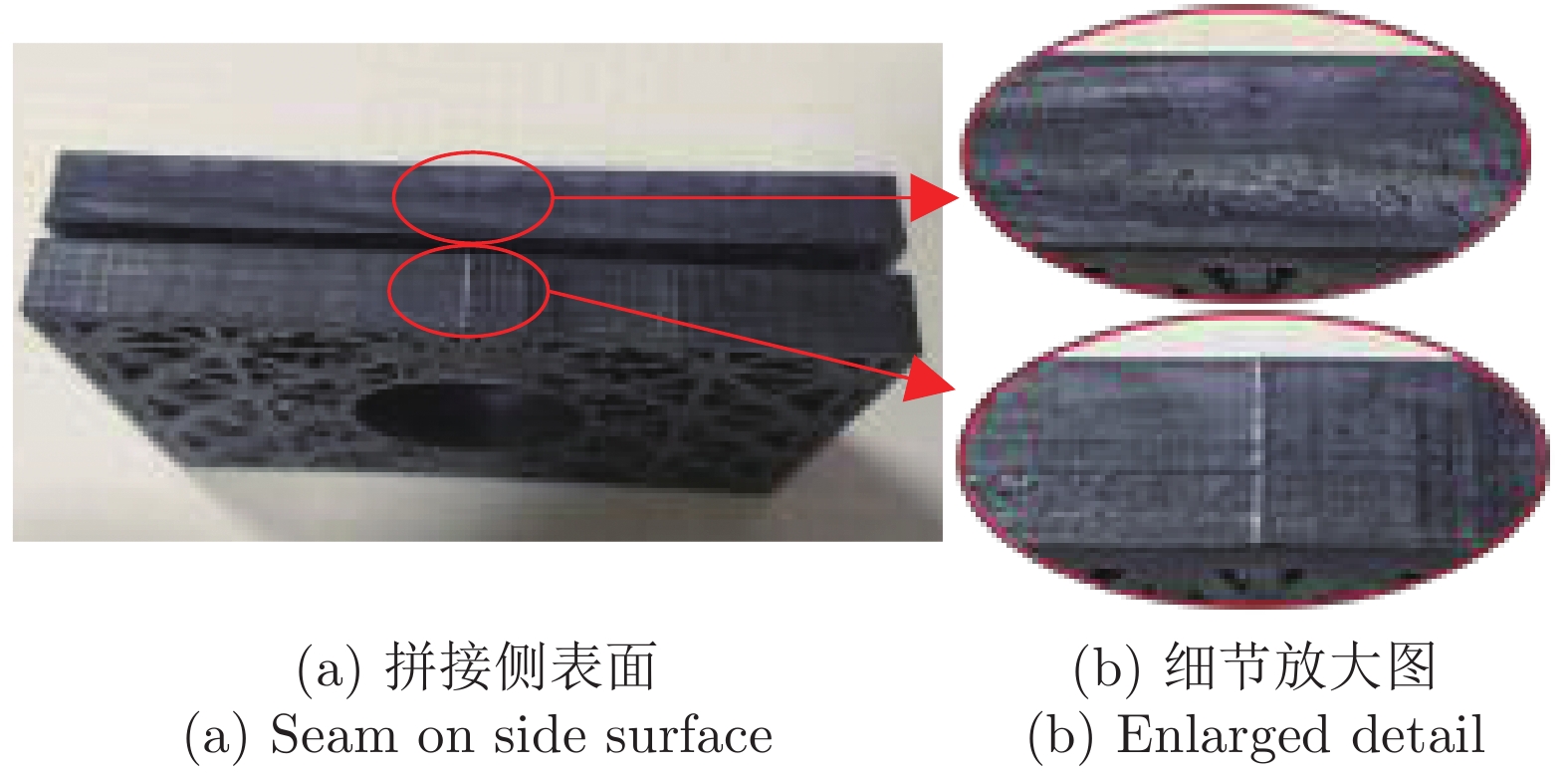

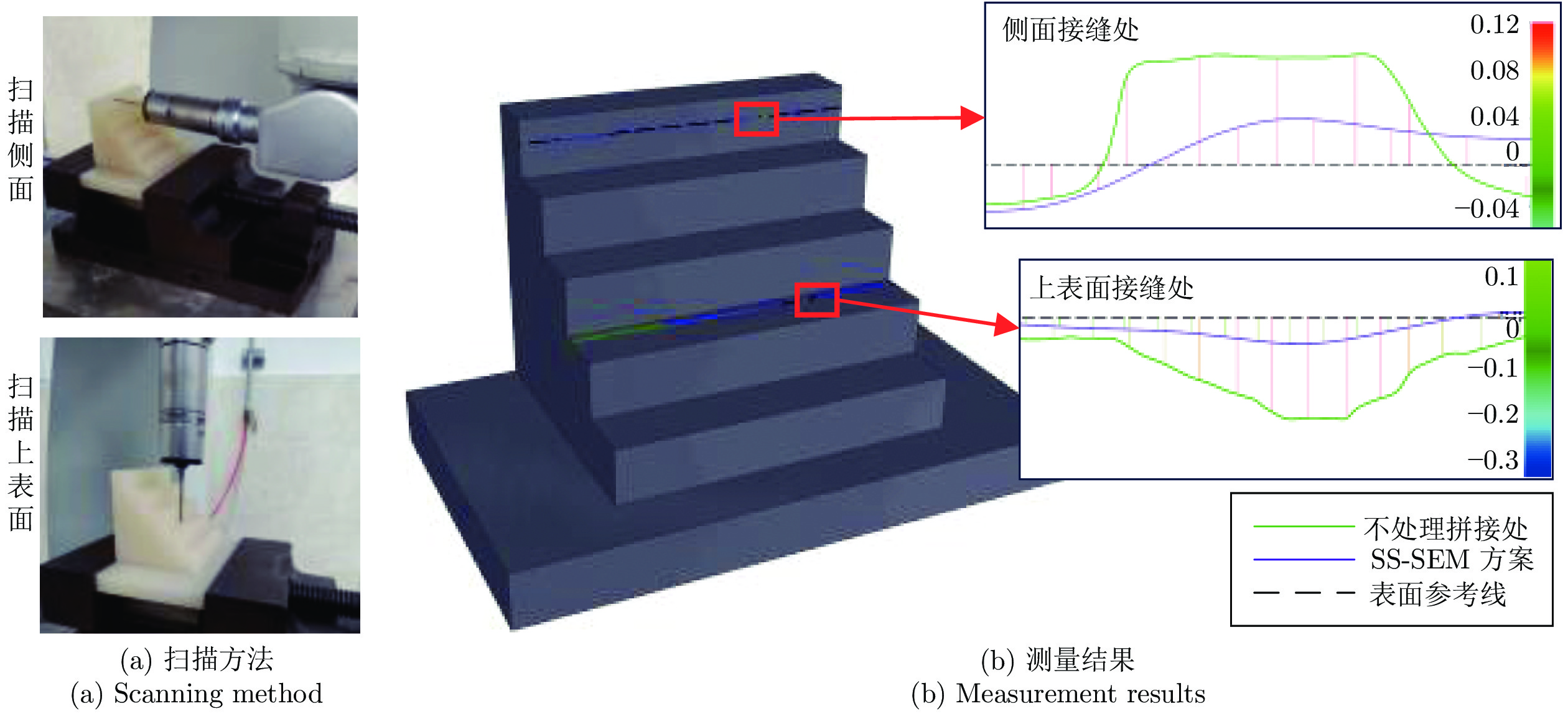

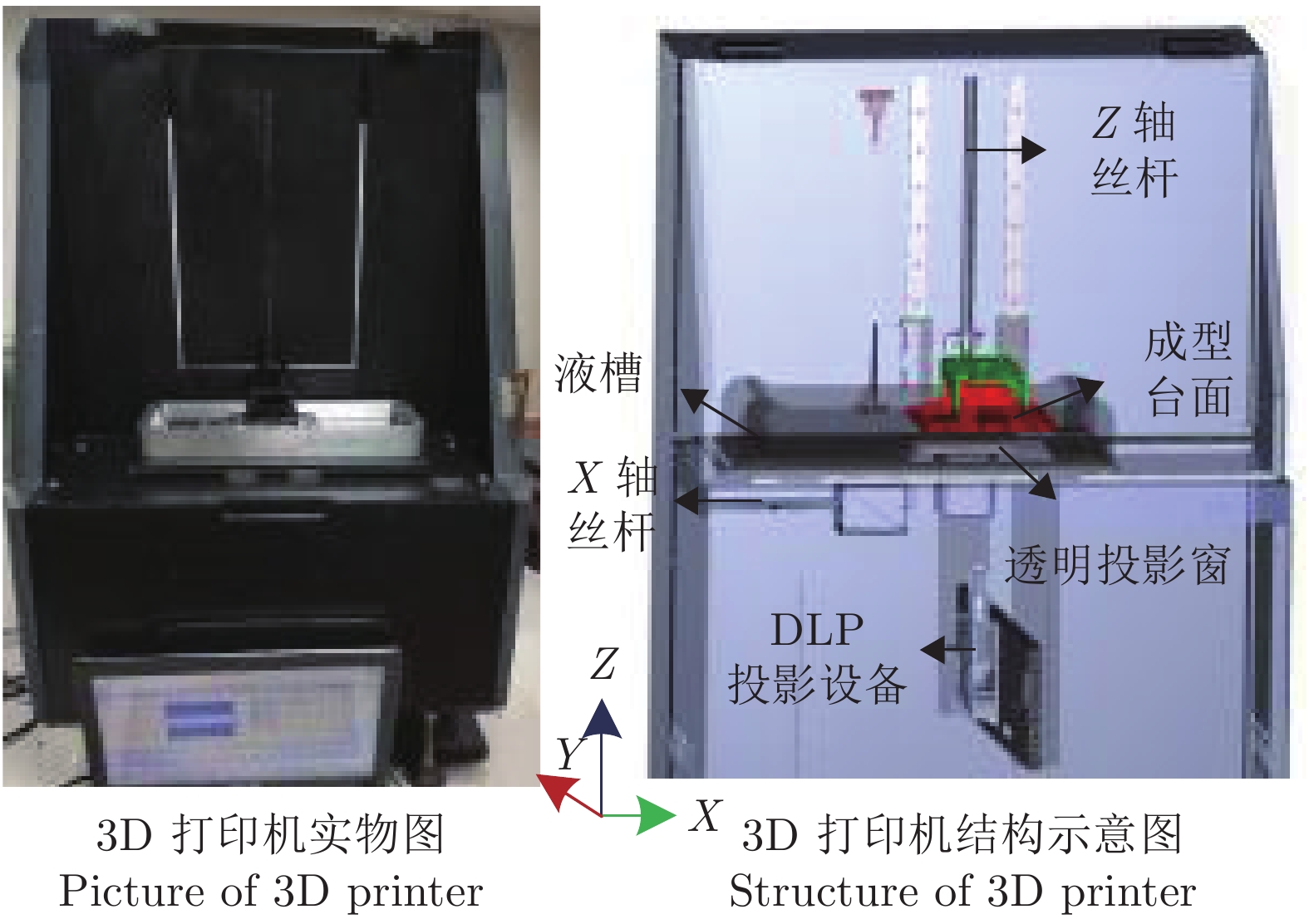

摘要: 针对面曝光模式的数字光处理(Digital light processing, DLP)型3D打印机成型幅面较小问题, 提出一种移动拼接与错位均摊消除接缝痕迹相结合的大幅面技术方案. 该方案首先对三维模型进行均匀切片形成N层切面, 再对切面位图进行错位切分, 使得相邻层的拼接位置错开, 每张切面位图形成M张单元位图, 构成3D打印的数据源; 其次根据错位参数沿着X轴移动投影仪到达对应曝光位, 每层成型M张单元位图, 拼接构成一层切面薄片, 切面薄片的拼接位置逐层错开, 叠加生成三维模型实体. 实际打印结果表明, 该方案能够以较小的附加成本扩大成型尺寸, 提高模型整体质量.Abstract: In order to solve the problem that the forming area of digital light processing (DLP) type 3D printer with surface exposure mode is limited and small, a technical scheme combining mobile splicing and dislocation equalization to eliminate seam marks is proposed. Firstly, the three-dimensional model is sliced evenly to form N-layer slices, then the slices are divided by a staggered method, which makes the splicing positions of adjacent layers staggered. Each slice is divided into M sliced bitmaps, which constitute the data source of 3D printing. Secondly, according to the parameters, the projector is moved along the X-axis to reach the corresponding exposure position. Each layer solidifies M bitmaps and splices them together to form a layer of slices. The splicing positions of slices are staggered layer by layer, and three-dimensional model entities are generated by superposition. The actual printing results show that the scheme can enlarge the forming size and improve the quality of the model with a small additional cost.

-

Key words:

- Digital light processing (DLP) /

- 3D printing /

- large-scale /

- staggered splicing /

- seam elimination

-

表 1 拉力破坏实验结果

Table 1 Results of destructive tensile tests

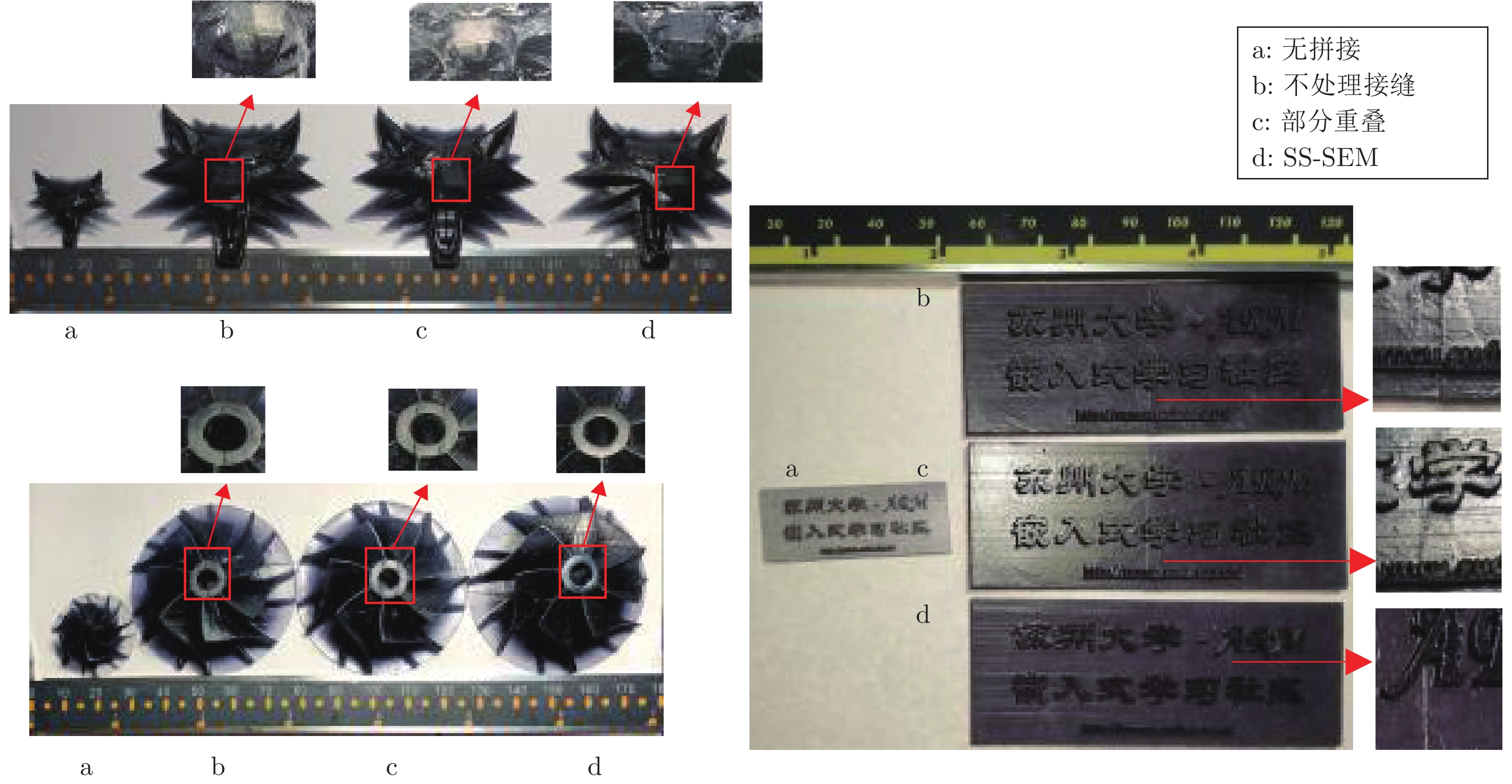

方案 模型 单层固化时间 后固化时间 次数 平均拉力 a 哑铃模型 1.5 s 2 h 8 280.7 N b 1.5 s 2 h 8 215.3 N d 1.5 s 2 h 8 273.9 N 表 2 打印成品结果比较表

Table 2 Comparison of printing results

模型 小狼头

涡轮

文字浮雕

三角形数量 2282 307732 827148 方案 a b c d a b c d a b c d 尺寸 ${{{\boldsymbol{V}}_1}} $ $2{{{\boldsymbol{V}}_1}} $ $2{{{\boldsymbol{V}}_1}} $ $2{{{\boldsymbol{V}}_1}} $ ${{{\boldsymbol{V}}_2}} $ $2{{{\boldsymbol{V}}_2}} $ $2{{{\boldsymbol{V}}_2}} $ $2{{{\boldsymbol{V}}_2}} $ ${{{\boldsymbol{V}}_3}} $ $2{{{\boldsymbol{V}}_3}} $ $2{{{\boldsymbol{V}}_3}} $ $2{{{\boldsymbol{V}}_3}} $ 切片层数 190 380 380 380 208 417 417 417 30 60 60 60 切片时间 (min) 0.1 0.4 3.1 0.6 0.2 0.6 4.1 0.9 0.1 0.2 0.8 0.2 打印时间 (min) 18 54 57 58 21 59 64 66 3 9 11 11 总时间 (min) 18.1 54.4 60.1 58.6 21.2 59.6 68.1 66.9 3.1 9.2 11.8 11.2 -

[1] Steuben J C, Iliopoulos A P, Michopoulos J G. Implicit slicing for functionally tailored additive manufacturing. Computer-Aided Design, 2016, 77:107-119 doi: 10.1016/j.cad.2016.04.003 [2] Ngo T D, Kashani A, Imbalzano G, et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B Engineering, 2018, 143:172-196 doi: 10.1016/j.compositesb.2018.02.012 [3] Dizon J R C, Espera A H, Chen Q, et al. Mechanical characterization of 3D-printed polymers. Additive Manufacturing, 2018, 20:44-67 doi: 10.1016/j.addma.2017.12.002 [4] Brajlih T, Valentan B, Balic J, et al. Speed and accuracy evaluation of additive manufacturing machines. Rapid Prototyping Journal, 2011, 17(1):64-75 doi: 10.1108/13552541111098644 [5] Ahn D, Kim H, Lee S. Fabrication direction optimization to minimize post-machining in layered manufacturing. International Journal of Machine Tools & Manufacture, 2007, 47(3-4):593-606 [6] 刘利刚, 徐文鹏, 王伟明, et al. 3D打印中的几何计算研究进展. 计算机学报, 2015, 38(6):1243-1267Liu Li-Gang, Xu Wen-Peng, Wang Wei-Ming, et al. Survey on geometric computing in 3D printing. Chinese Journal of Computers, 2015, 38(6):1243-1267 [7] 吴芬芬, 刘利刚. 3D打印物体的稳定平衡优化. 计算机研究与发展, 2017, 54(3):549-556Wu Fen-Fen, Liu Li-Gang. Stable equilibrium optimization for 3D printed objects, Journal of Computer Research and Development, 2017, 54(3):549-556 [8] Oropallo W, Piegl L A. Ten challenges in 3D printing. Engineering with Computers, 2016, 32(1):135-148 doi: 10.1007/s00366-015-0407-0 [9] 李轩, 莫红, 李双双, 王飞跃. 3D打印技术过程控制问题研究进展. 自动化学报, 2016, 42(7): 983−1003Li Xuan, Mo Hong, Li Shuang-Shuang, Wang Fei-Yue. Research progress on 3D printing technology process control problem. Acta Automatica Sinica, 2016, 42(7): 983−1003 [10] 邱志惠, 陈号, 黄祺, 等. 面曝光3D打印机光强检测补偿系统研究与实现. 西安交通大学学报, 2017, 51(8):77-83Qiu Zhi-Hui, Chen Hao, Huang Qi, et al. Measurement and compensation of DLP projector light intensity for mask projection stereolithography. Journal of Xi'an Jiaotong University, 2017, 51(8):77-83 [11] 方浩博, 陈继民. 基于数字光处理技术的3D打印技术. 北京工业大学学报, 2015, 41(12):1775-1782Fang Hao-Bo, Chen Ji-Min. 3D printing based on digital light processing technology. Journal of Beijing University of Technology, 2015, 41(12):1775-1782 [12] Smith J M. Method and Apparatus for Creating Three-dimensional Objects by Cross-sectional Lithography, U.S. Patent 6500378B1, December 2002 [13] Wu C, Yi R, Liu Y J, He Y, Wang C L. Delta DLP 3D printing with large size. In: Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems. Daejeon, South Korea: IEEE, 2016. 2155−2160 [14] Wu L, Zhao L, Jian M, et al. EHMP-DLP: multi-projector DLP with energy homogenization for large-size 3D printing. Rapid Prototyping Journal, 2018, 24(9):1500-1510 doi: 10.1108/RPJ-04-2017-0060 [15] Bertsch A, Zissi S, J. Y. Jézéquel, et al. Microstereophotolithography using a liquid crystal display as dynamic mask-generator. Microsystem Technologies, 1997, 3(2):42-47 doi: 10.1007/s005420050053 [16] 沈震, 唐迪, 熊刚, 王飞跃. 3D 打印系统, 中国 201480000261.1, 2014. 10Shen Zhen, Tang Di, Xiong Gang, Wang Fei-Yue. 3D Printing System, China 201480000261.1, October 2014 [17] Kumar V, Debasish D. An assessment of data formats for layered manufacturing. Advances in Engineering Software, 1997, 28(3):151-164 doi: 10.1016/S0965-9978(96)00050-6 -

下载:

下载: