High Precision Pose Measurement of Microsphere-hole Based on Active Movements of Two Microscopic Cameras

-

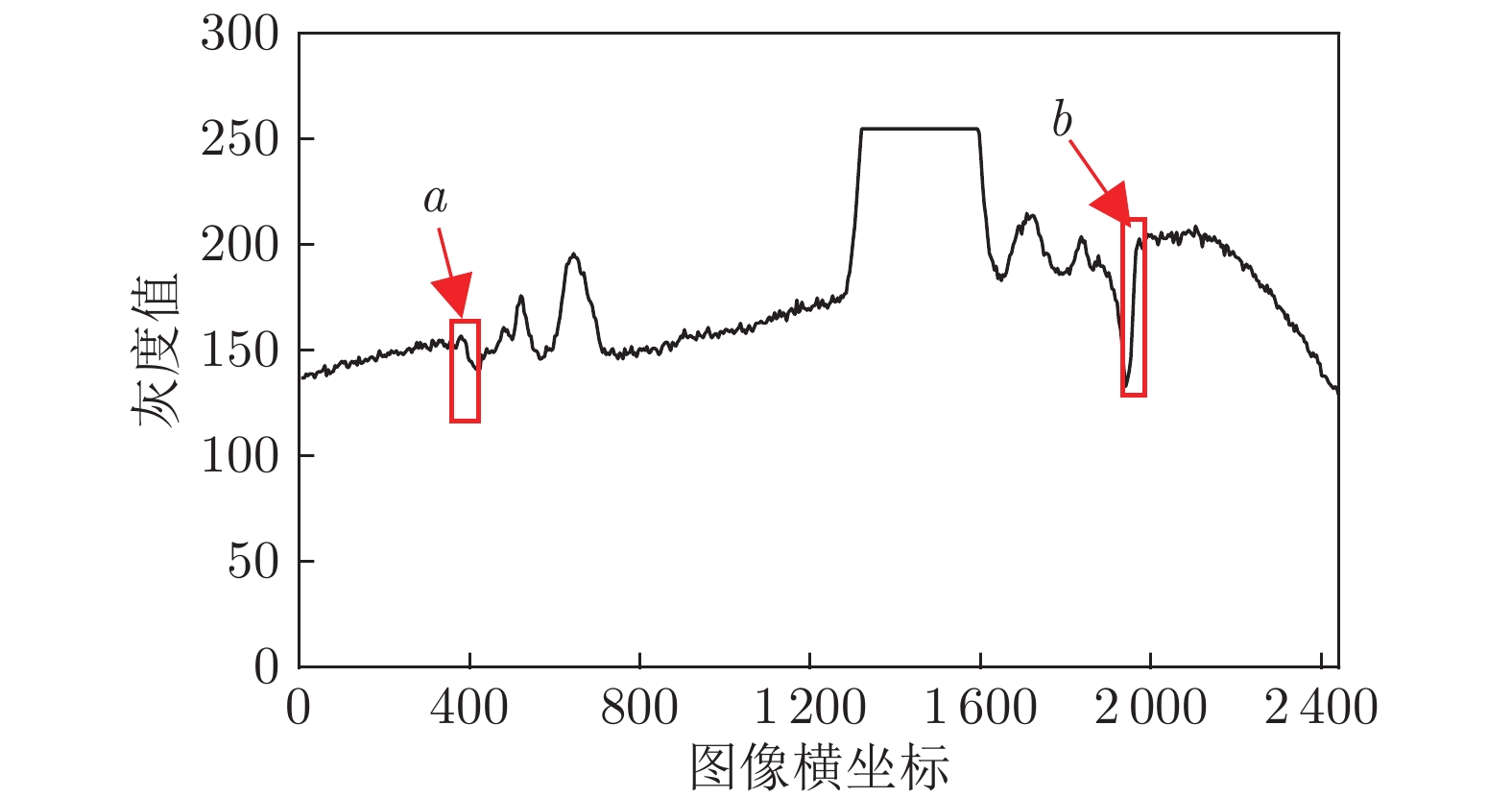

摘要: 在一些微装配任务中, 对微器件姿态的测量是至关重要的一步. 带有微孔的球形微器件, 特征较少, 姿态测量困难. 为此, 本文提出一种基于双目显微视觉的微球孔姿态高精度测量方法. 设计了微球/微孔边缘提取方法, 实现了微球球心和微孔孔心的精确定位. 通过对两路显微相机聚焦轴方向的标定, 弥补了由相机聚焦轴运动引入的测量误差, 提高了微球孔姿态的测量精度. 通过两路倾斜正交的显微相机的主动运动, 计算出微球孔姿态向量在相机运动坐标系中的分解角. 根据相机运动坐标系与微球调整平台坐标系间的角度转换矩阵, 将相机运动坐标系中的分解角转换为微球调整平台坐标系中的旋转角, 从而计算出精确的微球孔姿态向量. 实验结果表明, 微球孔姿态测量的最大误差为0.08°, 验证了本文方法的有效性.Abstract: In some microassembly tasks, the pose detection of micro-components is a crucial step. It is very difficult to measure the poses of spherical micro-components with micro-holes due to the lack of efficient features. A high-precision pose measurement method for the micro-hole on a micro-sphere is proposed based on binocular micro-vision. The edge extraction methods for the micro-sphere and micro-hole are designed. The image coordinates of the micro-sphere center and micro-hole center are obtained in high accuracy. The focusing movement directions of the two microscopic cameras are calibrated, which can compensate the measurement error caused by the focusing motions to improve the measurement accuracy of micro-hole' s pose. Through the active motions of two inclined orthogonal microscopic cameras, the decomposed angles of the micro-hole' s vector in the two frames of motion mechanisms for microscopic cameras are calculated. The decomposed angles are transformed to the rotation angles of the micro-sphere adjusting platform according to the angle transformation matrix from the two frames of motion mechanisms for microscopic cameras to the frame of micro-sphere adjusting platform. The micro-hole' s vector is computed with the rotation angles in high accuracy. The experimental results show that the maximum measurement error of the rotation angles indicating the micro-hole' s pose is 0.08 degrees. It verifies the effectiveness of the proposed method.

-

表 1 绕

$ X _{W} $ 轴旋转的实验结果(°)Table 1 Experimental results of rotation along with the

$ X _{W} $ axis (°)次数 本文方法 文献 [20] 真实值 ${\alpha}_{m1},$ ${\beta}_{m1}$ ${\alpha}_{m2},$ ${\beta}_{m2}$ ${\alpha}_{r},$ ${\beta}_{r}$ 1 2.03, 0.00 2.08, 0.04 2.00, 0.00 2 4.05, 0.04 3.90, 0.08 4.00, 0.00 3 6.05, 0.03 6.11, 0.10 6.00, 0.00 4 8.02, −0.04 8.18, 0.15 8.00, 0.00 5 −2.03, 0.04 −2.05, 0.03 −2.00, 0.00 6 −3.95, 0.05 −3.91, 0.04 −4.00, 0.00 7 −5.95, −0.04 −6.12, −0.08 −6.00, 0.00 8 −7.96, −0.03 −8.13, −0.13 −8.00, 0.00 表 2 绕

$ Y _{W} $ 轴旋转的实验结果(°)Table 2 Experimental results of rotation along with the

$ Y _{W} $ axis (°)次数 本文方法 文献 [20] 真实值 ${\alpha}_{m1}$, ${\beta}_{m1}$ ${\alpha}_{m2}$, ${\beta}_{m2}$ ${\alpha}_{r}$, ${\beta}_{r}$ 1 −0.06, 1.05 0.06, 1.07 0.00, 1.00 2 0.02, 1.92 0.04, 2.12 0.00, 2.00 3 0.08, 2.99 0.04, 3.11 0.00, 3.00 4 0.03, 4.03 0.05, 4.13 0.00, 4.00 5 −0.05, 5.04 −0.07, 5.16 0.00, 5.00 6 0.01, −1.01 −0.04, −1.09 0.00, −1.00 7 0.06, −2.04 −0.06, −2.11 0.00, −2.00 8 −0.04, −3.06 −0.05, −3.13 0.00, −3.00 9 0.07, −4.06 −0.07, −4.16 0.00, −4.00 10 0.01, −5.07 −0.10, −5.17 0.00, −5.00 表 3 绕

$ X _{W} $ 轴及$ Y _{W} $ 轴旋转的实验结果(°)Table 3 Experimental results of rotation along with the

$ X _{W} $ and$ Y _{W} $ axis, simultaneously (°)次数 本文方法 文献 [20] 真实值 ${\alpha}_{m1}$, ${\beta}_{m1}$ ${\alpha}_{m2}$, ${\beta}_{m2}$ ${\alpha}_{r}$, ${\beta}_{r}$ 1 1.03, 1.05 0.93, 1.03 1.00, 1.00 2 2.02, 0.98 1.86, 1.10 2.00, 1.00 3 3.01, 2.04 3.10, 2.08 3.00, 2.00 4 3.97, 3.04 3.89, 3.18 4.00, 3.00 5 4.96, 5.07 5.20, 4.88 5.00, 5.00 6 −1.01, −2.00 −1.04, −2.05 −1.00, −2.00 7 −2.02, −3.04 −1.92, −2.89 −2.00, −3.00 8 −3.03, −0.97 −3.07, −0.95 −3.00, −1.00 9 −3.96, −1.97 −3.85, −2.14 −4.00, −2.00 10 −4.99, 4.04 −4.83, 4.10 −5.00, 4.00 -

[1] 李福东. 基于显微视觉的微管-微球装配与胶接研究 [博士学位论文]. 中国科学院自动化研究所, 中国, 2014Li Fu-Dong. Research on Micro Tube and Micro Sphere Assembly Involving Adhesive Bonding Based on Microscopic Vision [Ph.D. dissertation]. Institute of Automation, Chinese Academy of Sciences, China, 2014. [2] Jia Z Y, Ma X, Liu W, Lu W B, Li X, Chen L, et al. Pose measurement method and experiments for high-speed rolling targets in a wind tunnel. Sensors, 2014, 14(12): 23933−23953 doi: 10.3390/s141223933 [3] Lins R G, Givigi S N, Kurka P R G. Vision-based measurement for localization of objects in 3-D for robotic applications. IEEE Transactions on Instrumentation and Measurement, 2015, 64(11): 2950−2958 doi: 10.1109/TIM.2015.2440556 [4] Hou D X, Mei X S, Huang W W, Li J, Wang C J, Wang X. An online and vision-based method for fixtured pose measurement of non-datum complex component. IEEE Transactions on Instrumentation and Measurement, 2020, 69(6): 3370−3376 [5] Yang J C, Man J B, Xi M, Gao X B, Lu W, Meng Q G. Precise measurement of position and attitude based on convolutional neural network and visual correspondence relationship. IEEE Transactions on Neural Networks and Learning Systems, 2020, 31(6): 2030−2041 [6] 李二闯, 张建杰, 袁亮, 吴金强. 基于四元数互补滤波的小型四旋翼姿态解算. 组合机床与自动化加工技术, 2019, (3): 37−39, 43Li Er-Chuang, Zhang Jian-Jie, Yuan Liang, Wu Jin-Qiang. Small quadruple rotor attitude solving based on quaternion complementary filtering. Modular Machine Tool and Automatic Manufacturing Technique, 2019, (3): 37−39, 43 [7] Jin P J, Matikainen P, Srinivasa S S. Sensor fusion for fiducial tags: Highly robust pose estimation from single frame RGBD. In: Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems. Vancouver, BC, Canada: IEEE, 2017. [8] Li J M, Wang J G, Zhou W T, Jia S W. Robot pose estimation and accuracy analysis based on stereo vision. In: Proceedings of the 9th IEEE International Conference on Mobile Ad-hoc and Sensor Networks. Dalian, China: IEEE, 2013. [9] Peng J Q, Xu W F, Liang B, Wu A G. Pose measurement and motion estimation of space non-cooperative targets based on laser radar and stereo-vision fusion. IEEE Sensors Journal, 2019, 19(8): 3008−3019 doi: 10.1109/JSEN.2018.2889469 [10] Su J, Huang X H, Wang M. Pose detection of partly covered target in micro-vision system. In: Proceedings of the 10th World Congress on Intelligent Control and Automation. Beijing, China: IEEE, 2012. [11] Zhang P C, Xu D, Wu B L. Pose estimation for plane based on monocular microscope vision system. In: Proceedings of the 32nd Chinese Control Conference. Xi' an, China: IEEE, 2013. [12] 刘国华, 邓钊钊. 基于双目视觉的探针姿态检测. 天津工业大学学报, 2019, 38(2): 68−72, 88 doi: 10.3969/j.issn.1671-024x.2019.02.012Liu Guo-Hua, Deng Zhao-Zhao. Probe attitude detection based on binocular vision. Journal of Tianjin Polytechnic University, 2019, 38(2): 68−72, 88 doi: 10.3969/j.issn.1671-024x.2019.02.012 [13] 张娟, 张正涛, 徐德. 基于显微视觉的微零件在线检测与装配策略研究. 高技术通讯, 2013, 23(8): 848−855 doi: 10.3772/j.issn.1002-0470.2013.08.011Zhang Juan, Zhang Zheng-Tao, Xu De. On-line detecting and assembling of micro parts based on microscope vision. High Technology Letters, 2013, 23(8): 848−855 doi: 10.3772/j.issn.1002-0470.2013.08.011 [14] Ma Y Q, Liu X L and Xu D. Precision pose measurement of an object with flange based on shadow distribution. IEEE Transactions on Instrumentation and Measurement, 2020, 69(5): 2003−2015 [15] Li F D, Xu D, Zhang Z T, Shi Y L. Realization of an automated micro assembly task involving micro adhesive bonding. International Journal of Automation and Computing, 2013, 10(6): 545−551 doi: 10.1007/s11633-013-0752-7 [16] Huang X H, Zeng X J, Wang M. SVM-based identification and un-calibrated visual servoing for micro manipulation. International Journal of Automation and Computing, 2010, 7(1): 47−54 doi: 10.1007/s11633-010-0047-1 [17] Qin F B, Shen F, Zhang D P, Liu X L, Xu D. Contour primitives of interest extraction method for microscopic images and its application on pose measurement. IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2018, 48(8): 1348−1359 doi: 10.1109/TSMC.2017.2669219 [18] 史亚莉, 张正涛, 徐德. 跨尺度微管微球三维半自动装配点胶系统. 光学精密工程, 2015, 23(11): 3121−3128Shi Ya-Li, Zhang Zheng-Tao, Xu De. 3D semi-automatic assembly and dispensing system for trans-scale parts of micro-tube and micro-sphere. Optics and Precision Engineering, 2015, 23(11): 3121−3128 [19] Li F D, Xu D, Zhang Z T, Shi Y L, Shen F. Pose measuring and aligning of a micro glass tube and a hole on the micro sphere. International Journal of Precision Engineering and Manufacturing, 2014, 15(12): 2483−2491 doi: 10.1007/s12541-014-0618-0 [20] 李迎, 张大朋, 刘希龙, 徐德. 基于单目显微视觉的微球姿态测量方法. 自动化学报, 2019, 45(7): 1281−1289Li Ying, Zhang Da-Peng, Liu Xi-Long, Xu De. A pose measurement method for micro sphere based on monocular microscopic vision. Acta Automatica Sinica, 2019, 45(7): 1281−1289 -

下载:

下载: