-

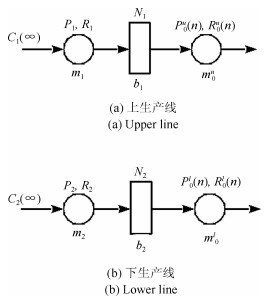

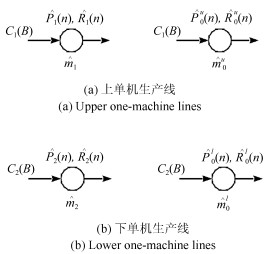

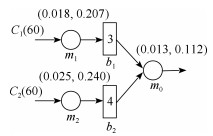

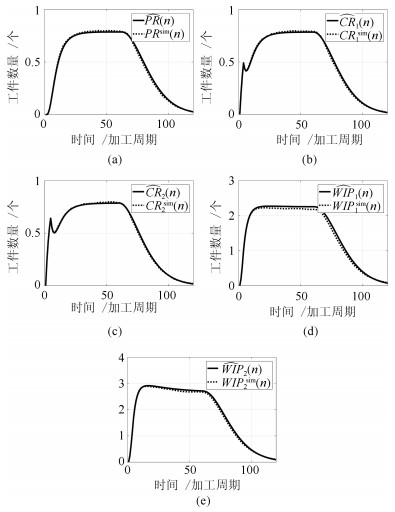

摘要: 装配系统是生产系统的基本结构之一, 广泛应用于汽车、电器、电子产品等实际生产环境中.与传统的串行生产线取得的研究成果相比, 装配系统的研究, 特别是对系统暂态过程的实时性能分析的研究仍然未得到深入探讨.本文针对具有三台几何可靠性机器模型和有限缓冲区容量框架下的装配系统, 首先建立了用于此类系统暂态性能分析的数学模型, 通过马尔科夫方法导出了系统性能分析的解析公式.然后, 提出了一种基于分解的性能评估算法来近似系统的实时性能.具体来说, 本文推导出了用于计算具有三台几何可靠性机器模型的装配系统的实时生产率、消耗率、在制品数量, 以及完成一个生产批次所需时间的解析表达式.最后, 通过数值实验对所提出算法的准确性进行验证.Abstract: Assembly system is one of the most fundamental production system structures. It can be widely seen in practical manufacturing environments (e.g., automomobile, appliance, consumer electronics). Compared to the extensive investigations of serial lines in the existing literature, investigations on assembly systems, especially transient-based realtime performance analysis, are still largely unexplored. In the framework of assembly systems with three geometric machines and finite buffers, a mathematical model for real time performance analysis of such systems is developed in this paper. The formulas for exact performance analysis are derived by using the Markovian approach first. Then, a decomposition-based computationally efficient algorithm for real-time performance evaluation is proposed. Specifically, closed-form formulas are derived for calculating real-time production rate, consumption rates, as well as work-in-process, completion time on completing a production run, of assembly systems with three geometric machines. Finally, the accuracy of the algorithm is justified by numerical experiments.

-

Key words:

- Assembly systems /

- performance evaluation /

- geometric reliability machine model /

- production system

1) 本文责任编委 段书凯 -

表 1 系统状态排序

Table 1 Arrangement of the system states

State $ h_1 $ $ h_2 $ $ f_0 $ $ s_0 $ $ s_1 $ $ s_2 $ $1$ 0 0 0 0 0 0 $2$ 0 0 0 0 0 1 $3$ 0 0 0 0 1 0 $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $9$ 0 0 1 0 0 0 $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ 8 $B+1$ 0 0 $B$ 0 0 0 8 $B+2$ 0 0 $B$ 0 0 1 $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $\vdots$ $Q-1$ $N_1$ $N_2$ $B$ 1 1 0 $Q$ $N_1$ $N_2$ $B$ 1 1 1 表 2 系统状态排序($k = 0, 1, \cdots, N_1$)

Table 2 Arrangement of the system states ($k = 0, 1, \cdots, N_1$)

State $ h_1$ $ s_1$ $ s_0^u$ $4k+1$ $k$ 0 0 $4k+2$ $k$ 0 1 $4k+3$ $k$ 1 0 $4k+4$ $k$ 1 1 -

[1] Bhat U N. Finite capacity assembly-like queues. Queueing Systems, 1986, 1(1): 85-101 doi: 10.1007/BF01149329 [2] Bonomi F. An approximate analysis for a class of assembly-like queues. Queueing Systems, 1987, 1(3): 289-309 doi: 10.1007/BF01149540 [3] Lipper E H, Sengupta E H. Assembly-like queues with finite capacity: bounds, asymptotics and approximations. Queueing Systems, 1986, 1(1): 67-83 doi: 10.1007/BF01149328 [4] Rao P C, Suri R. Approximate queueing network models for closed fabrication/assembly systems. Part I: single level systems. Production and Operations Management, 2010, 3(4): 244-275 [5] Rao P C, Suri R. Performance analysis of an assembly station with input from multiple fabrication lines. Production and Operations Management, 2000, 9(3): 283-302 [6] Manitz M. Queueing-model based analysis of assembly lines with finite buffers and general service times. Computers and Operations Research, 2008, 35(8): 2520-2536 doi: 10.1016/j.cor.2006.12.016 [7] Manitz M. Analysis of assembly/disassembly queueing networks with blocking after service and general service times. Annals of Operations Research, 2014, 226(1): 1-25 [8] Gershwin S B. Assembly/disassembly systems: an efficient decomposition algorithm for tree-structured networks. IIE Transactions, 1990, 23(4): 302-314 [9] Liu X G, Buzacott J A. Approximate models of assembly systems with finite inventory banks. European Journal of Operational Research, 1990, 45(2-3): 143-154 doi: 10.1016/0377-2217(90)90181-A [10] Helber S. Decomposition of unreliable assembly/disassembly networks with limited buffer capacity and random processing times. European Journal of Operational Research, 1998, 109(1): 24-42 doi: 10.1016/S0377-2217(97)00166-5 [11] Mascolo M D, David R, Dallery Y. Modeling and analysis of assembly systems with unreliable machines and finite buffers. IIE Transactions, 1991, 23(4): 315-330 doi: 10.1080/07408179108963866 [12] Gershwin S B, Burman M H. A decomposition method for analyzing inhomogeneous assembly/disassembly systems. Annals of Operations Research, 2000, 93(1-4): 91-115 [13] Kim Y D. Performance analysis of assembly/disassembly systems with unreliable machines and random processing times. IIE Transactions, 1998, 30(1): 41-53 doi: 10.1080/07408179808966436 [14] Chiang S Y, Kuo C T, Lim J T, Meerkov S M. Improvability of assembly systems I: problem formulation and performance evaluation. Mathematical Problems in Engineering, 2000, 6(4): 321-357 doi: 10.1155/S1024123X0000137X [15] Chiang S Y, Kuo C T, Lim J T, Meerkov S M. Improvability of assembly systems Ⅱ: improvability indicators and case study. Mathematical Problems in Engineering, 2000, 6(4): 359-393 doi: 10.1155/S1024123X00001381 [16] Li J, Blumenfeld D E, Huang N, Alden J M. Throughput analysis of production systems: recent advances and future topics. International Journal of Production Research, 2009, 47(14): 3823-3851 doi: 10.1080/00207540701829752 [17] Grassmann W K. Transient solutions in Markovian queueing systems. Computers and Operations Research, 1977, 4(1): 47-53 doi: 10.1016/0305-0548(77)90007-7 [18] Neuts M F. Structured Stochastic Matrices of M/G/1 Type and Their Applications. New York: Dekker, 1989. [19] Bertsimas D J, Nakazato D. Transient and busy period analysis of the GI/G/1 queue: the method of stages. Queueing Systems, 1992, 10(3): 153-184 doi: 10.1007/BF01159205 [20] Narahari Y, Viswanadham N. Transient analysis of manufacturing systems performance. IEEE Transactions on Robotics and Automation, 1994, 10(2): 230-244 doi: 10.1109/70.282547 [21] Klutke G A, Seiford L M. Transient behaviour of finite capacity tandem queues with blocking. International Journal of Systems Science, 1991, 22(11): 2205-2215 doi: 10.1080/00207729108910783 [22] Gopalan M N, Kumar U D. On the transient behaviour of a merge production system with an end buffer. International Journal of Production Economics. 1994, 34(2): 157-165 doi: 10.1016/0925-5273(94)90032-9 [23] Mocanu S. Numerical algorithms for transient analysis of fluid queues. In: Proceedings of the 5th International Conference on the Analysis of Manufacturing Systems. Zakymthos, Greece, 2005, 15-20 [24] Meerkov S M, Zhang L. Transient behavior of serial production lines with Bernoulli machines. IIE Transactions, 2008, 40(3): 297-312 doi: 10.1080/07408170701488037 [25] Meerkov S M, Zhang L. Unbalanced production systems with floats: analysis and lean design. International Journal of Manufacturing Technology and Management, 2011, 23(1-2): 4-15 [26] Zhang L, Wang C, Arinez J, Biller S. Transient analysis of Bernoulli serial lines: performance evaluation and system-theoretic properties. IIE Transactions, 2013, 45(5): 528-543 doi: 10.1080/0740817X.2012.721946 [27] Chen G, Zhang L, Arinez J, Biller S. Energy-efficient production systems through schedule-based operations. IEEE Transactions on Automation Science and Engineering, 2013, 10(1): 27-37 doi: 10.1109/TASE.2012.2202226 [28] Meerkov S M, Shimkin N, Zhang L. Transient behavior of two-machine geometric production lines. IEEE Transactions on Automatic Control, 2010, 55(2): 453-458 doi: 10.1109/TAC.2009.2036328 [29] Jia Z, Zhang L, Chen G, Arinez J, Xiao G. Performance evaluation in finite production run-based serial lines with geometric machines. In: Proceedings of the 2016 IEEE International Conference on Automation Science and Engineering (CASE). Fort Worth, USA: IEEE, 2016. 450-455 [30] Jia Z, Zhang L, Arinez J, Xiao G. Finite production run-based serial lines with Bernoulli machines: performance analysis, bottleneck, and case study. IEEE Transactions on Automation Science and Engineering, 2016, 13(1): 134-148 doi: 10.1109/TASE.2015.2433674 [31] Jia Z, Zhang L. Transient performance analysis of closed production lines with Bernoulli machines, finite buffers, and carriers. IEEE Robotics and Automation Letters, 2017, 2(4): 1893-1900 doi: 10.1109/LRA.2017.2713247 [32] Alexander D R, Premachandra I M, Kimura T. Transient and asymptotic behavior of synchronization processes in assembly-like queues. Annals of Operations Research, 2010, 181(1): 641-659 doi: 10.1007/s10479-010-0796-9 [33] Jia Z, Zhang L, Arinez J, Xiao G. Performance analysis of assembly systems with Bernoulli machines and finite buffers during transients. IEEE Transactions on Automation Science and Engineering, 2016, 13(2): 1018-1032 doi: 10.1109/TASE.2015.2442521 [34] Buzacott J A, Shanthikumar J G. Stochastic Models of Manufacturing Systems. Englewood Cliffs: Prentice Hall, 1993. [35] Papadopoulos H T, Heavy C, Browne J. Queueing Theory in Manufacturing Systems Analysis and Design. London: Chapman and Hill, 1993. [36] Gershwin S B. Manufacturing Systems Engineering. Englewood Cliff: Prentice Hall, 1994. [37] Altiok T. Performance Analysis of Manufacturing Systems. New York: Springer-Verlag, 1997. [38] Li J, Meerkov S M. Due-time performance in production systems with Markovian machines. Analysis and Modeling of Manufacturing Systems. Boston: Springer, 2003. [39] Liberopoulos G, Kozanidis G, Tsarouhas P. Performance evaluation of an automatic transfer line with WIP scrapping during long failures. Manufacturing and Service Operations Management, 2007, 9(1): 62-83 doi: 10.1287/msom.1060.0118 [40] Li F, Du C, Yang C, Gui W. Passivity-based asynchronous sliding mode control for delayed singular markovian jump systems. IEEE Transactions on Automatic Control, 2018, 63(8): 2715-2721 doi: 10.1109/TAC.2017.2776747 [41] Du C, Yang C, Li F, Gui W. A novel asynchronous control for artificial delayed markovian jump systems via output feedback sliding mode approach. IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2019, 49(2): 364-374 doi: 10.1109/TSMC.2018.2815032 [42] Chen G, Wang C, Zhang L, Arinez J, Xiao G. Transient performance analysis of serial production lines with geometric machines. IEEE Transactions on Automatic Control, 2016, 61(4): 877-891 doi: 10.1109/TAC.2015.2444071 -

下载:

下载: