Optimal Tracking Control for Slag Grinding Process Based on Adaptive Dynamic Programming

-

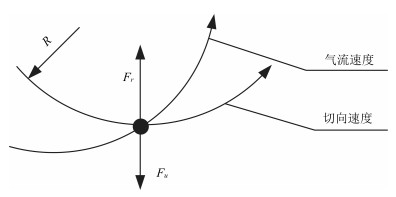

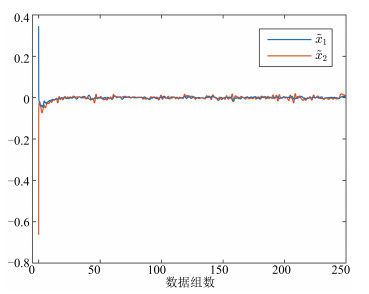

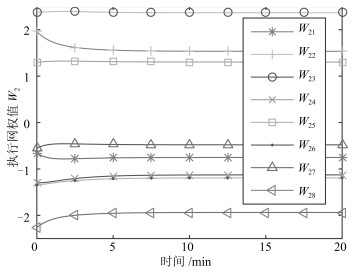

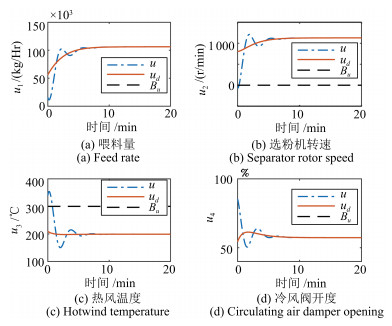

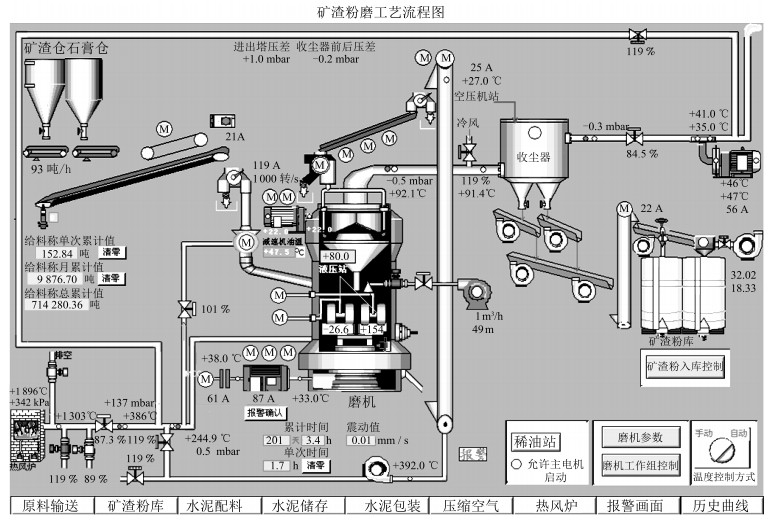

摘要: 矿渣微粉是一种新型绿色环保型建材,可以大大提高水泥混凝土的力学性能.本文以矿渣微粉生产过程为研究对象,针对该过程难以通过机理建模进行辨识和控制的特点,利用数据驱动的思想,建立矿渣微粉生产过程的递归神经网络模型.在此基础上,利用自适应动态规划,设计具有控制约束的跟踪控制器,并将其应用到矿渣微粉生产过程中.仿真分析表明,建立的数据驱动模型能够有效地辨识矿渣微粉生产过程,同时,本文提出的控制方法能够实现输入受限的微粉比表面积及磨内压差的最优跟踪控制.Abstract: Super fine slag powder is a new kind of green environmental-friendly construction material, which can greatly improve the mechanical properties of cement concrete. However, the slag powder grinding process is hard to identify by a mechanism model. In this paper, a data-driven based recurrent neural network model is constructed utilizing the information measured from slag grinding system. Based on this model, an adaptive dynamic programming algorithm is proposed to realize the optimal tracking control with constrained control input. Further, this algorithm is applied to the slag grinding process. Simulation examples show that the data-based model can effectively identify the grinding process, and the control method can realize the optimal tracking control of specific surface area and mill differential pressure with control constraints.

-

表 1 济钢鲁新建材3号矿渣微粉生产线生产运行数据

Table 1 Production data of Luxin mill line 3

编号 水渣进料

(103 kg/Hr)电机转速

(r/min)进口风温

(℃)入磨循环风阀开度

(%)比表面积

(cm2/g)磨内压差

(mbar)1 85.60 1 250 230 65.13 438.5 27.60 2 84.81 1 160 229 69.50 426.3 28.13 3 84.77 1 240 235 66.17 430.7 26.97 ⋮ ⋮ ⋮ ⋮ ⋮ ⋮ ⋮ 323 99.63 1 049 242 60.59 438.5 24.65 324 100.42 1 050 243 60.53 426.3 24.94 325 101.20 1 051 248 60.62 433.9 25.00 表 2 各控制变量容许变化范围

Table 2 Tolerance range of different variables

水渣进料

(103 kg/Hr)电机转速

(r/min)进口风温

(℃)入磨循环风阀开度

(%)最大值 160 1 300 300 80 最小值 0 0 150 0 -

[1] Işikdağ, Topču Ī B. The effect of ground granulated blast-furnace slag on properties of Horasan mortar. Construction and Building Materials, 2013, 40:448-454 doi: 10.1016/j.conbuildmat.2012.11.016 [2] Zhang Y J, Zhang X. Grey correlation analysis between strength of slag cement and particle fractions of slag powder. Cement and Concrete Composites, 2007, 29(6):498-504 doi: 10.1016/j.cemconcomp.2007.02.004 [3] 陈远.大型立磨选粉机研究[硕士学位论文], 重庆大学, 中国, 2008. http://cdmd.cnki.com.cn/article/cdmd-10611-2009050041.htmChen Yuan. Study on Separator of Large-scale Vertical Mill[Master dissertation], Chongqing University, China, 2008. http://cdmd.cnki.com.cn/article/cdmd-10611-2009050041.htm [4] Xu J X, Hou Z S. Notes on data-driven system approaches. Acta Automatica Sinica, 2009, 35(6):668-675 https://www.researchgate.net/profile/Zhong_Sheng_Hou/publication/245568563_Notes_on_Data-driven_System_Approaches/links/56cc290908aee3cee5433e86.pdf?inViewer=0&pdfJsDownload=0&origin=publication_detail [5] 侯忠生, 许建新.数据驱动控制理论及方法的回顾和展望.自动化学报, 2009, 35(6):650-667 doi: 10.3724/SP.J.1004.2009.00650Hou Zhong-Sheng, Xu Jian-Xin. On data-driven control theory:the state of the art and perspective. Acta Automatica Sinica, 2009, 35(6):650-667 doi: 10.3724/SP.J.1004.2009.00650 [6] 代伟, 柴天佑.数据驱动的复杂磨矿过程运行优化控制方法.自动化学报, 2014, 40(9):2005-2014 http://www.aas.net.cn/CN/article/downloadArticleFile.do?attachType=PDF&id=18472Dai Wei, Chai Tian-You. Data-driven optimal operational control of complex grinding processes. Acta Automatica Sinica, 2014, 40(9):2005-2014 http://www.aas.net.cn/CN/article/downloadArticleFile.do?attachType=PDF&id=18472 [7] 颜文俊, 秦伟.水泥立磨流程的建模和控制优化.控制工程, 2012, 19(6):929-943 http://www.cnki.com.cn/Article/CJFDTOTAL-JZDF201206001.htmYan Wen-Jun, Qin Wei. Modeling and control optimization in cement vertical roller mill process. Control Engineering of China, 2012, 19(6):929-943 http://www.cnki.com.cn/Article/CJFDTOTAL-JZDF201206001.htm [8] Cai X Y, Meng Q J, Luan W L. Soft sensor of vertical mill material layer based on LS-SVM. In:Proceedings of the 2013 International Conference on Measurement, Information, and Control (ICMIC). Harbin, China:IEEE, 2013. 22-25 [9] Lin X F, Qian Z. Modeling of vertical mill raw meal grinding process and optimal setting of operating parameters based on wavelet neural network. In:Proceedings of the 2014 International Joint Conference on Neural Networks (IJCNN). Beijing, China:IEEE, 2014. 3015-3020 [10] Umucu Y, Çağlar M F, Gündüz L, Bozkurt V, Deniz V. Modeling of grinding process by artificial neural network for calcite mineral. In:Proceedings of the 2011 International Symposium on Innovations in Intelligent Systems and Applications (INISTA). Istanbul, Turkey:IEEE, 2011. 344-348 [11] 张化光, 张欣, 罗艳红, 杨王君}.自适应动态规划综述.自动化学报, 2013, 39(4):303-311 doi: 10.1016/S1874-1029(13)60031-2Zhang Hua-Guang, Zhang Xin, Luo Yan-Hong, Yang Jun. An overview of research on adaptive dynamic programming. Acta Automatica Sinica, 2013, 39(4):303-311 doi: 10.1016/S1874-1029(13)60031-2 [12] Xu X, Zuo L, Huang Z H. Reinforcement learning algorithms with function approximation:recent advances and applications. Information Sciences, 2014, 261:1-31 doi: 10.1016/j.ins.2013.08.037 [13] Murray J J, Cox C J, Lendaris G G, Saeks R. Adaptive dynamic programming. IEEE Transactions on Systems, Man, and Cybernetics, Part C:Applications and Reviews, 2002, 32(2):140-153 doi: 10.1109/TSMCC.2002.801727 [14] Wei Q L, Liu D R, Yang X. Infinite horizon self-learning optimal control of nonaffine discrete-time nonlinear systems. IEEE Transactions on Neural Networks and Learning Systems, 2015, 26(4):866-879 doi: 10.1109/TNNLS.2015.2401334 [15] Liu D R, Wei Q L. Policy iteration adaptive dynamic programming algorithm for discrete-time nonlinear systems. IEEE Transactions on Neural Networks and Learning Systems, 2014, 25(3):621-634 doi: 10.1109/TNNLS.2013.2281663 [16] Zhang H, Cui L, Zhang X, Luo Y H. Data-driven robust approximate optimal tracking control for unknown general nonlinear systems using adaptive dynamic programming method. IEEE Transactions on Neural Networks, 2011, 22(12):2226-2236 doi: 10.1109/TNN.2011.2168538 [17] Modares H, Lewis F L, Naghibi-Sistani M B. Integral reinforcement learning and experience replay for adaptive optimal control of partially-unknown constrained-input continuous-time systems. Automatica, 2014, 50(1):193-202 doi: 10.1016/j.automatica.2013.09.043 [18] Wei Q, Liu D. A novel iterative θ-adaptive dynamic programming for discrete-time nonlinear systems. IEEE Transactions on Automation Science and Engineering, 2014, 11(4):1176-1190 doi: 10.1109/TASE.2013.2280974 [19] Qin C B, Zhang H G, Luo Y H. Adaptive optimal control for nonlinear discrete-time systems. In:Proceedings of the 2013 IEEE Symposium on Adaptive Dynamic Programming and Reinforcement Learning. Singapore:IEEE, 2013. 13-18 -

下载:

下载: