-

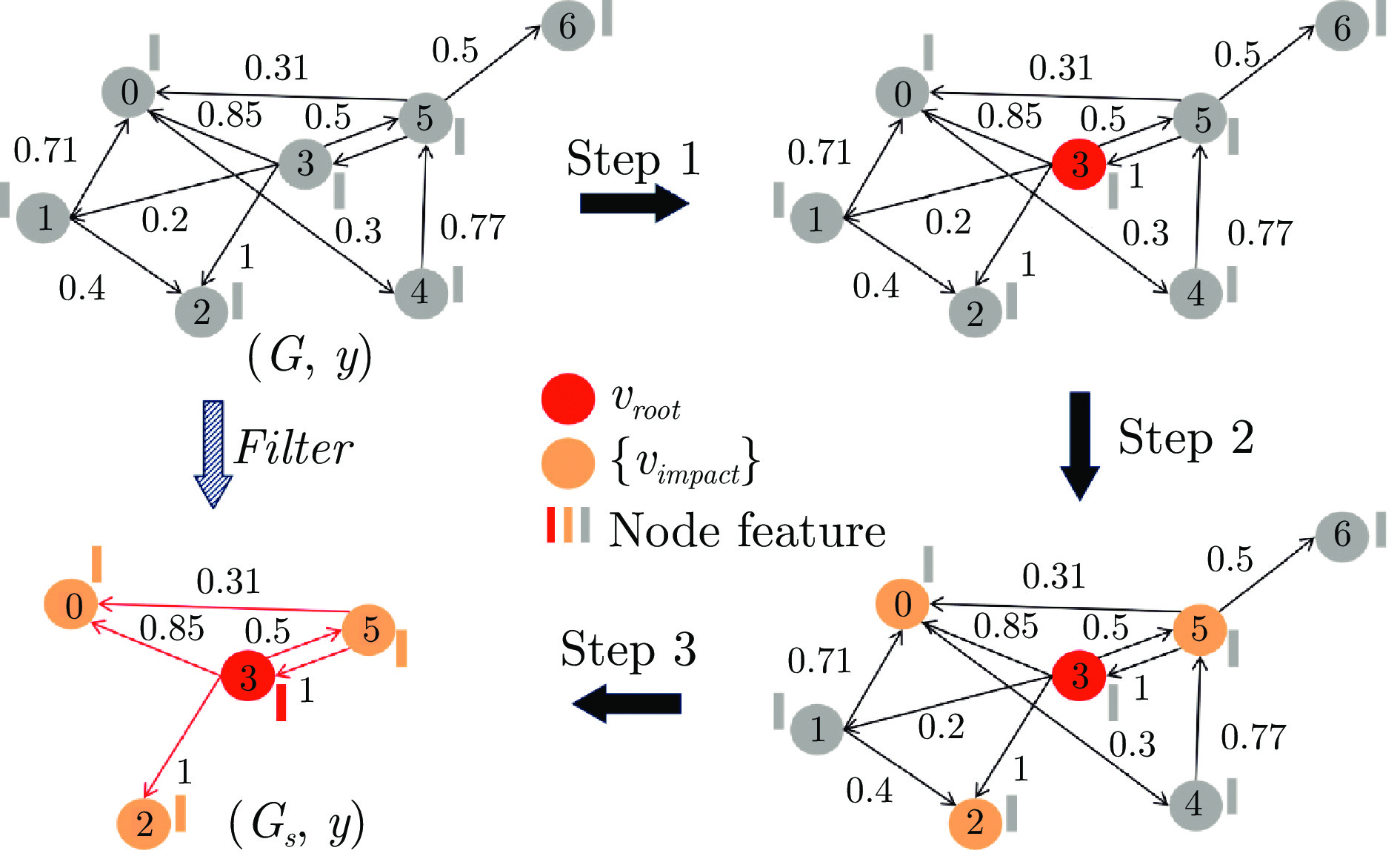

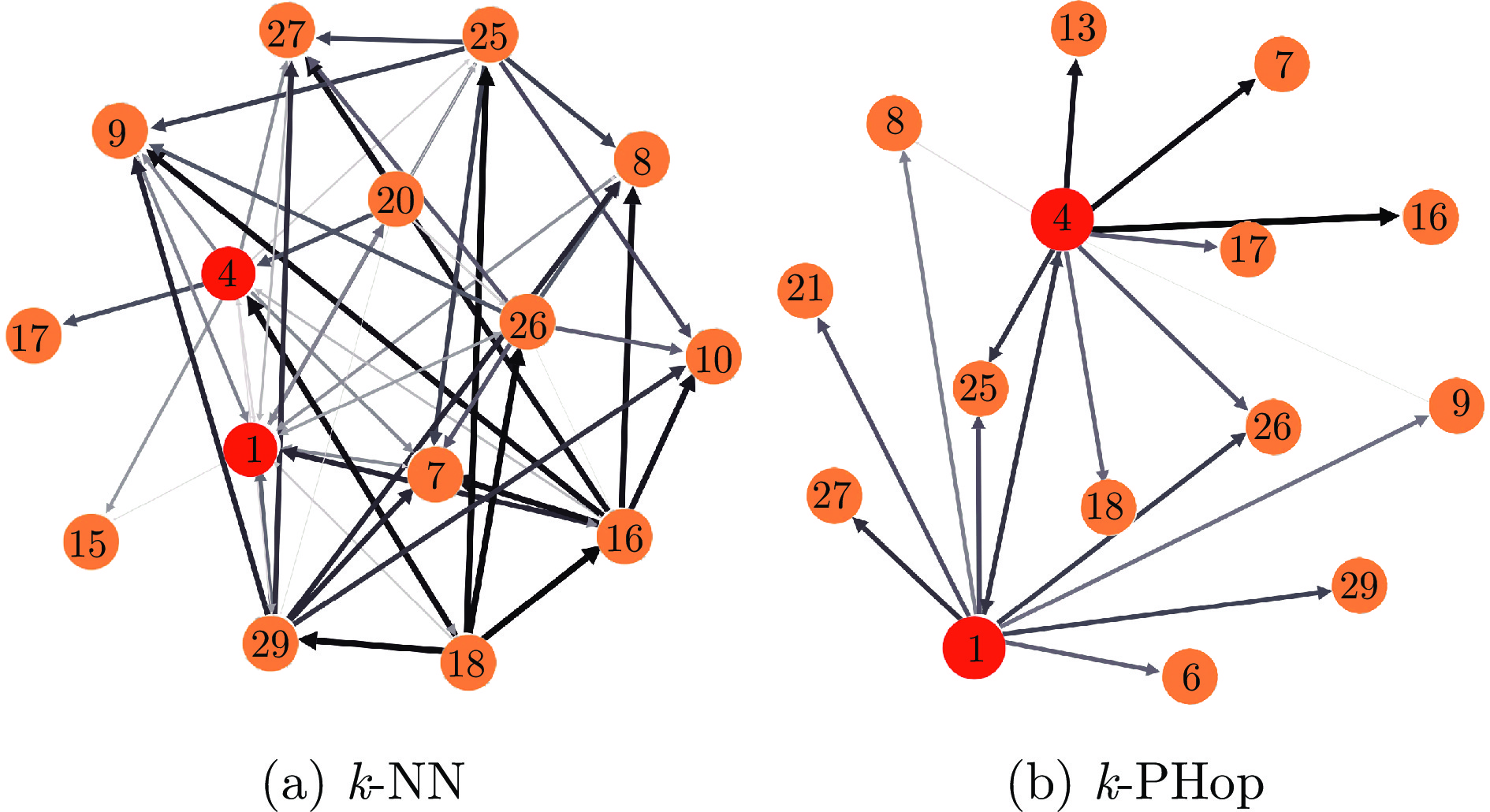

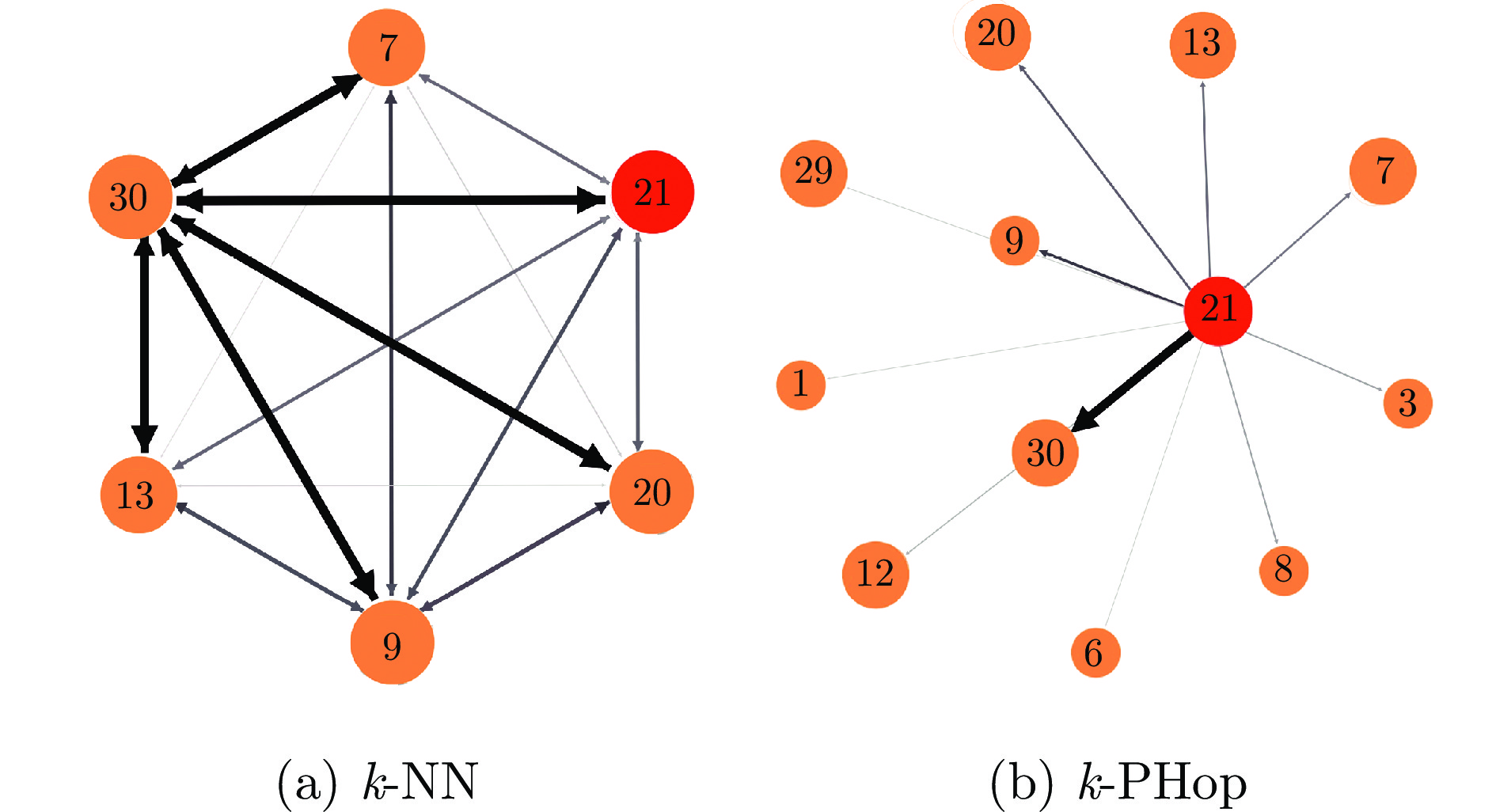

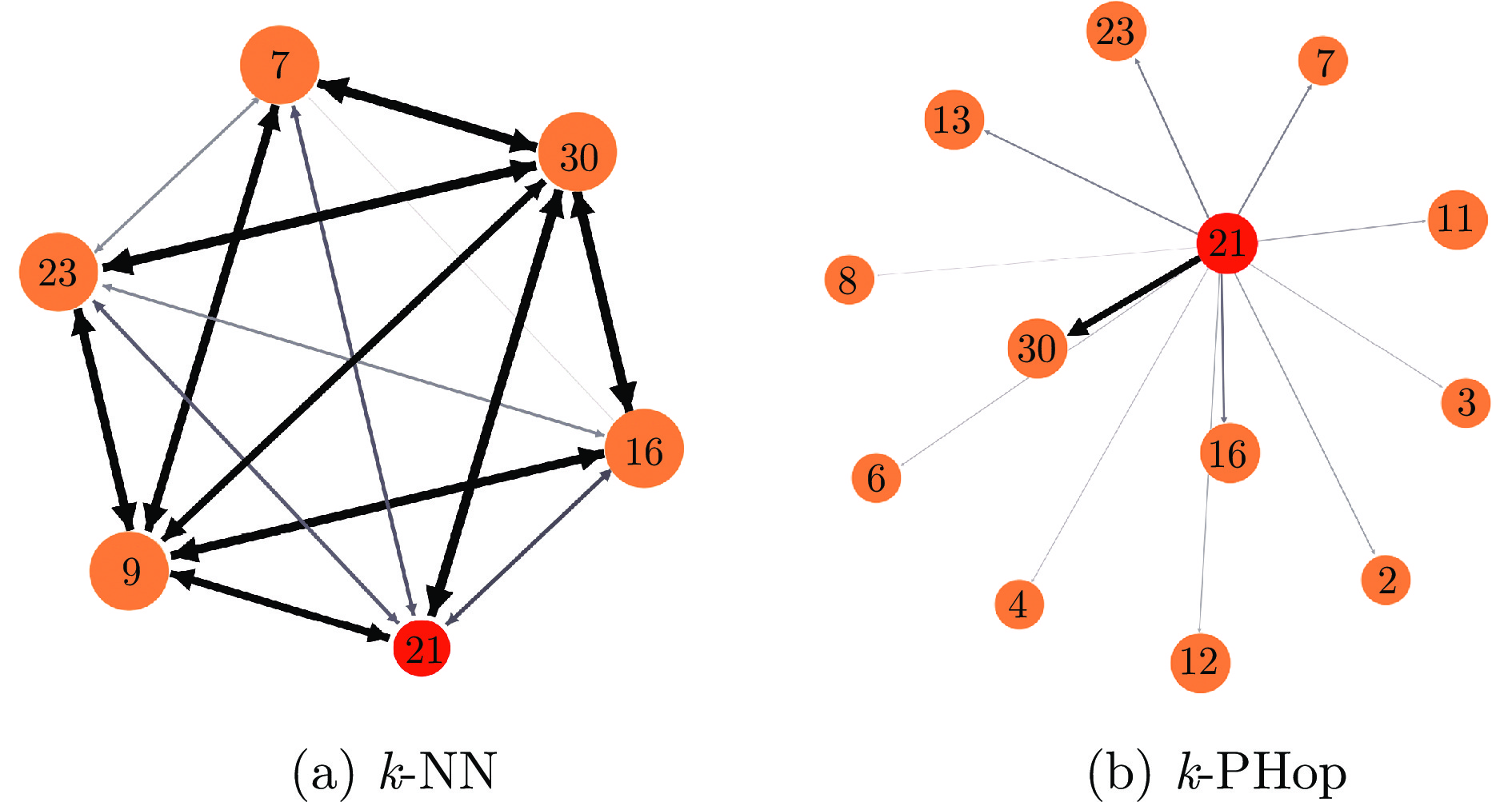

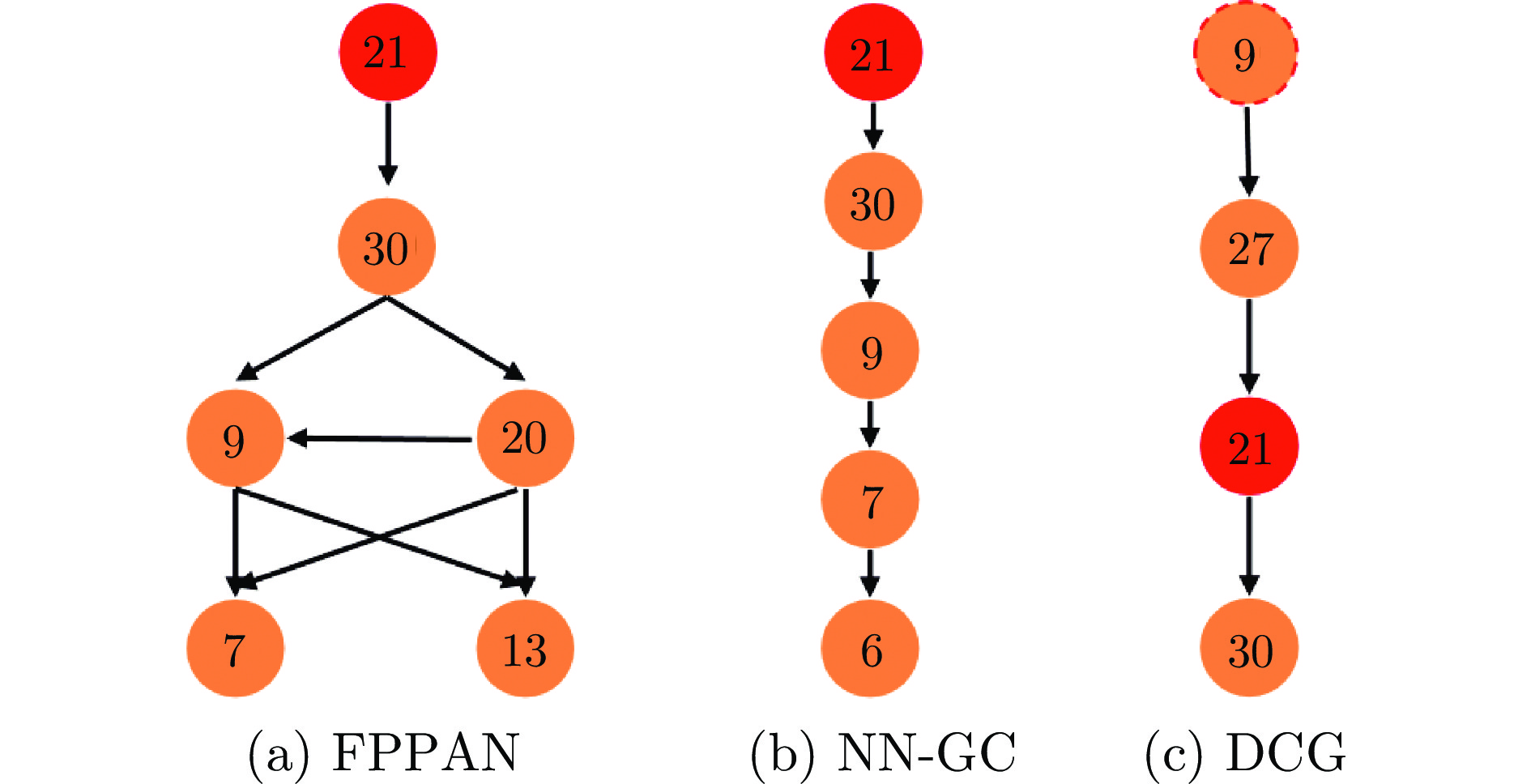

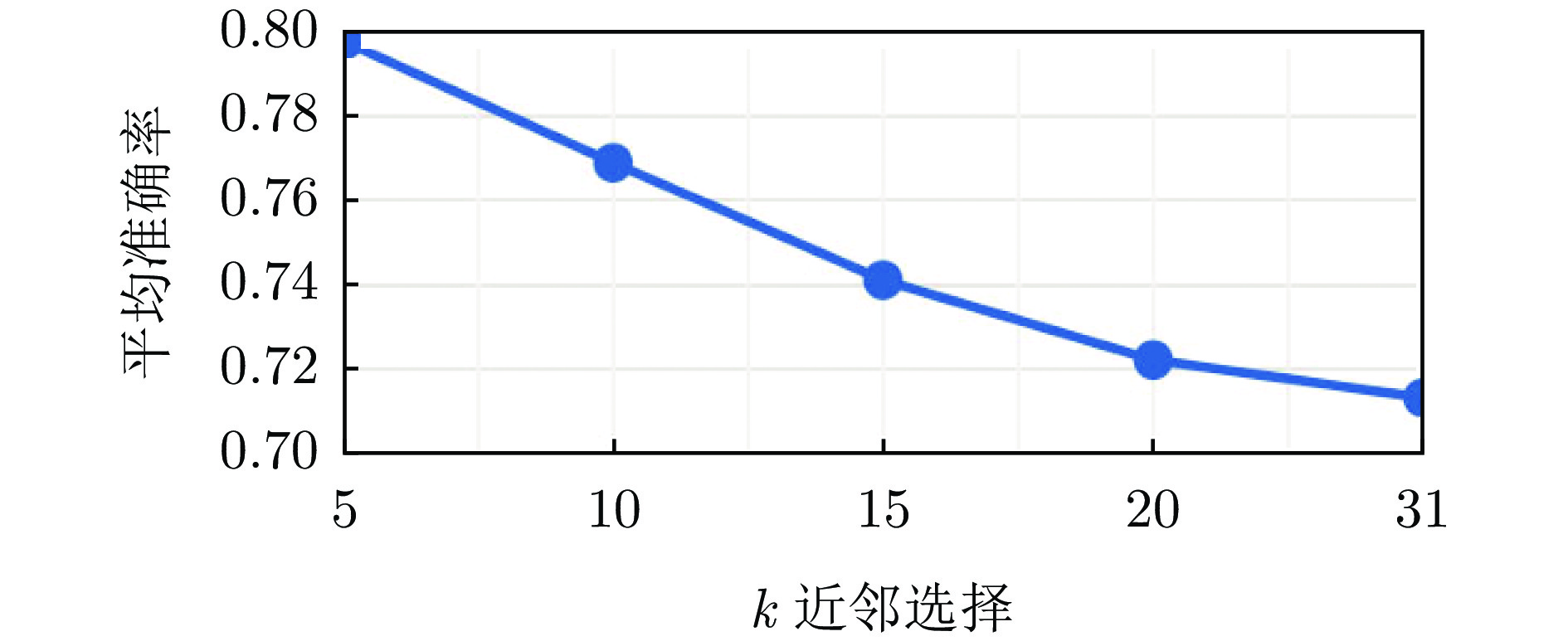

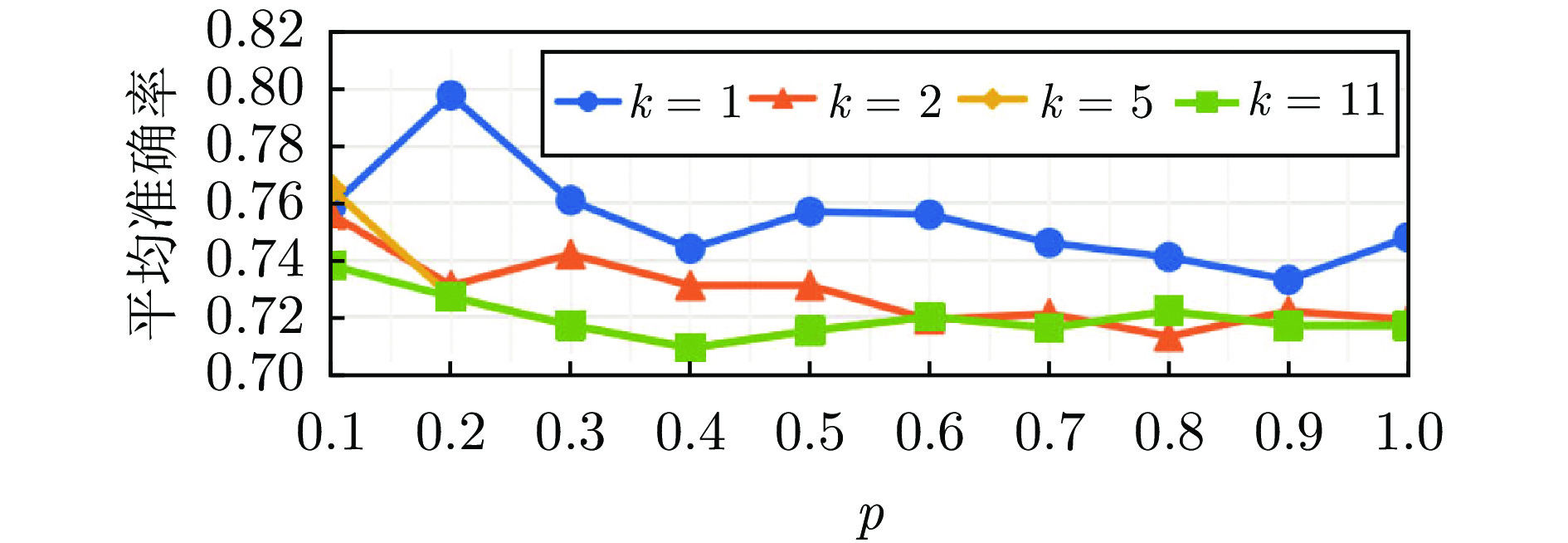

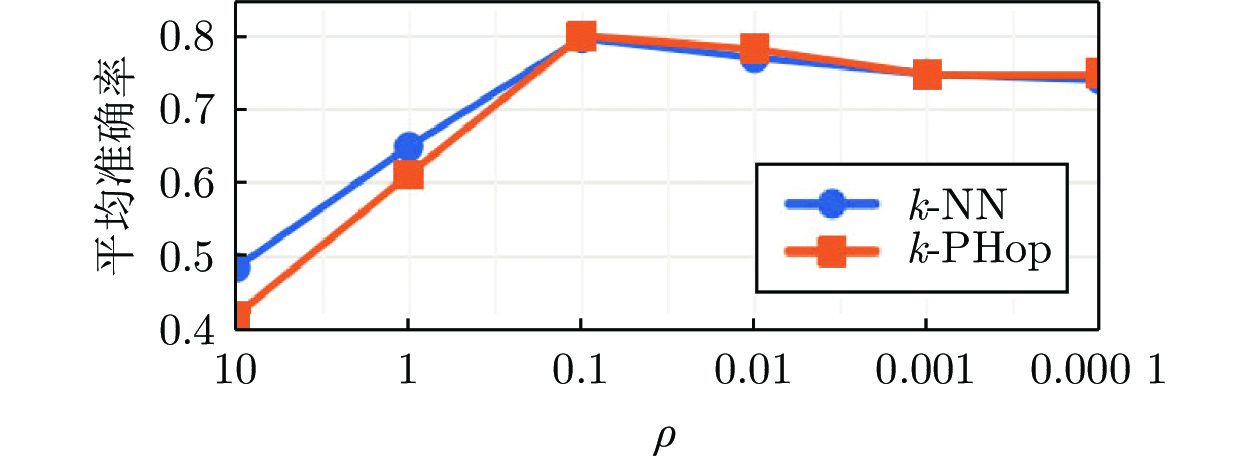

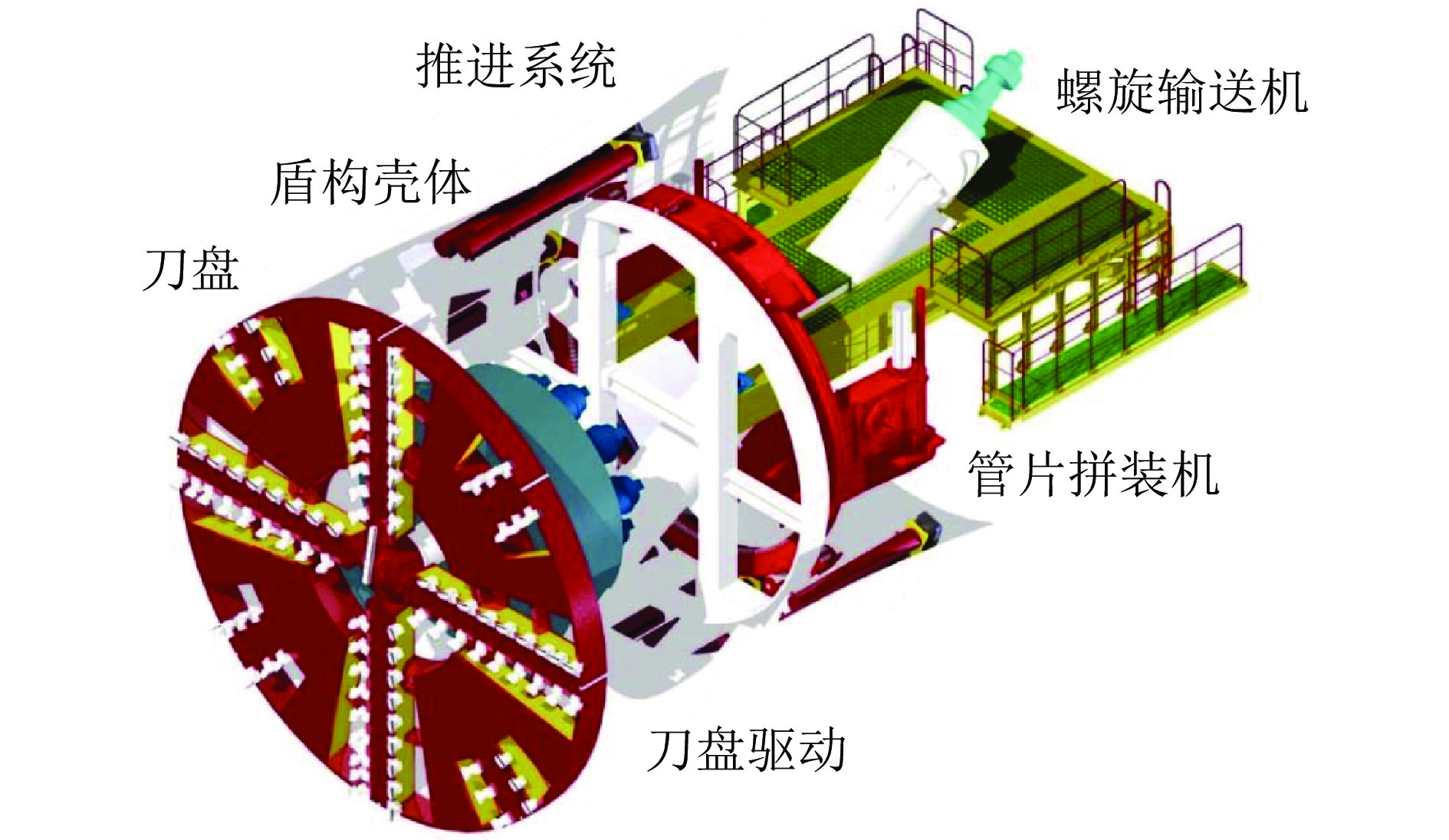

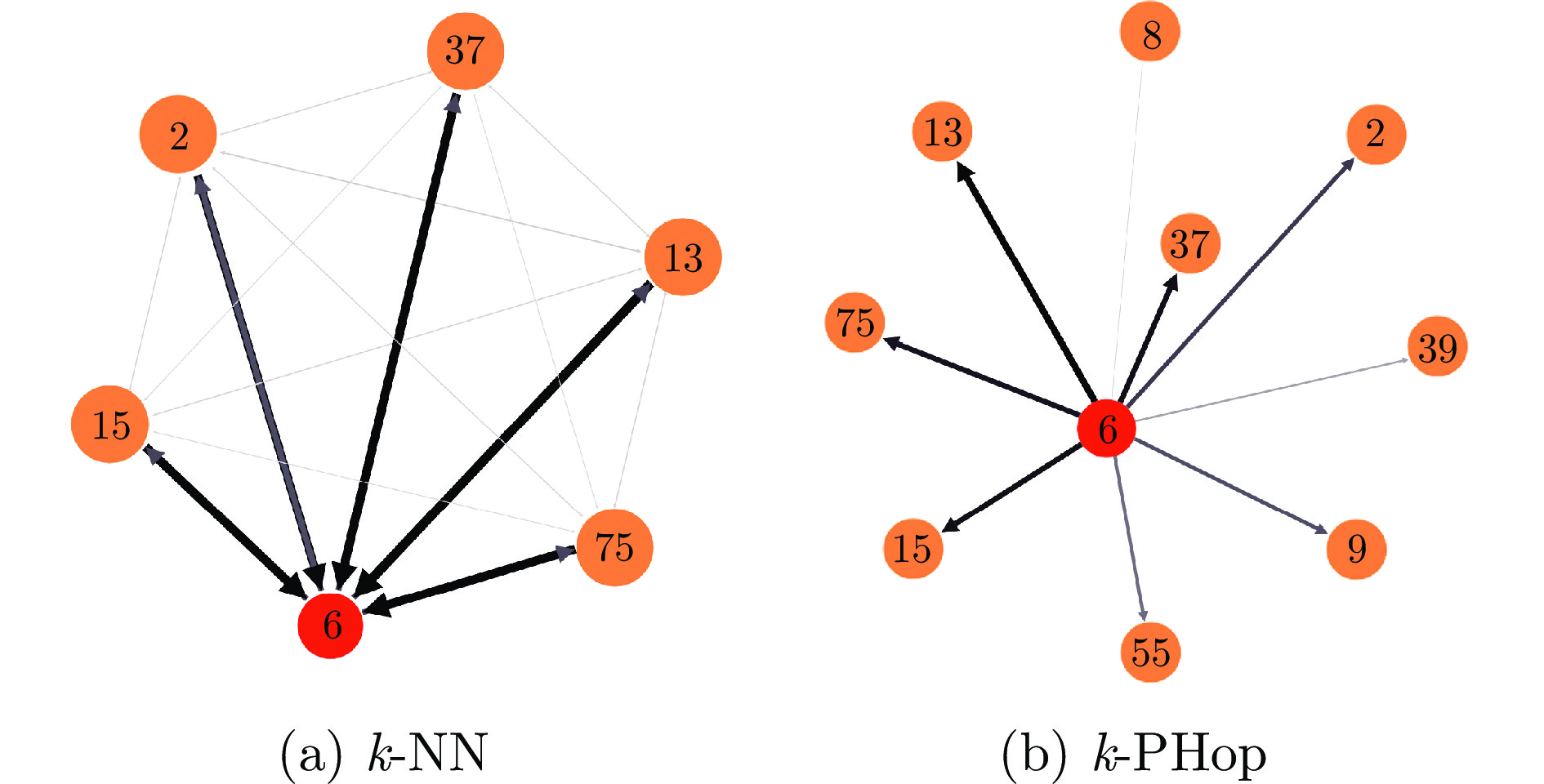

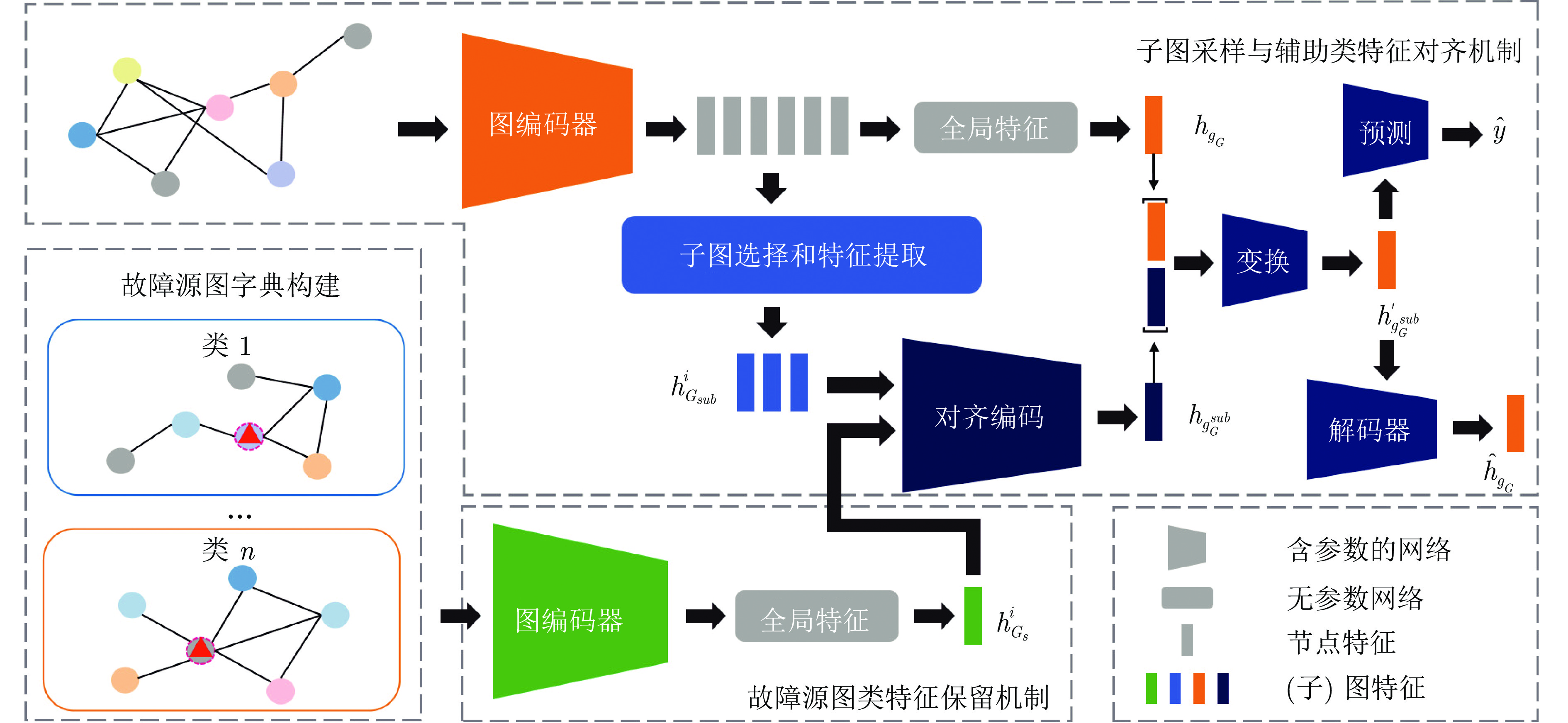

摘要: 针对工业过程中故障发生源与故障信息在传播过程中的差异性问题, 提出了一种基于不同故障传播路径差异化(Fault propagation path-aware network, FPPAN)的故障诊断方法. 该方法分别从故障源邻域信息关系和故障信息传播两个角度出发, 设计了基于k近邻筛选(k-nearest-neighbor, k-NN) 和基于剪枝的k跳可达路径选择 (Pruning-based k-hop reachable path selection, k-PHop) 的两种故障源图的构建方式, 构建“故障源图”. 从故障在变量间的差异化表现着手, 将基于特征的分类问题转换为基于结构关系的图匹配问题, 利用该结构化信息优化过程特征, 提升模型故障诊断性能. 最后, 通过田纳西−伊斯曼 (Tennessee-Eastman, TE)过程和某海底盾构掘进施工过程进行仿真验证, 实验结果证明了所提方法的有效性.Abstract: In order to address the issue of variability of fault sources and fault information in the propagation process in industrial processes, this paper proposes a fault diagnosis method based on fault propagation path-aware network (FPPAN). The method is based on two perspectives of fault source neighbourhood information relationship and fault information propagation, and designs two ways of constructing fault source graphs based on k-nearest-neighbour (k-NN) filtering and pruning-based k-hop reachable path selection (k-PHop) to construct a “fault source graph”. Based on the differentiation of faults among variables, the feature-based classification problem is viewed as a graph matching problem based on structural relationships, and the structural information is used to optimise the process features and improve the fault diagnosis performance of the model. Finally, the simulation is verified by the Tennessee-Eastman (TE) process and a submarine shield boring construction process, and the experimental results prove the effectiveness of the proposed method.

-

Key words:

- Fault diagnosis /

- graph neural network /

- fault source graph /

- fault root cause /

- fault propagation path

-

表 1 TE过程故障信息

Table 1 Fault information for the TE process

序号 故障描述 类型 1 $A/C $ 进料流量比值变化, B含量不变 阶跃 2 B含量变化, $A/C $进料流量比值不变 阶跃 3 物料D温度发生变化 阶跃 4 反应器冷却水入口温度变化 阶跃 5 冷凝器冷却水入口温度变化 阶跃 6 物料A损失 阶跃 7 物料C压力损失 阶跃 8 物料A、B、C 的组成成分变化 随机 9 D进料温度变化 随机 10 C进料温度变化 随机 11 反应器冷却水入口温度变化 随机 12 冷凝器冷却水入口温度变化 随机 13 反应器动力学常数变化 缓慢漂移 14 反应器冷却水阀门 粘滞 15 冷凝器冷却水阀门 粘滞 表 2 不同方法在TE过程上的故障诊断表现

Table 2 Fault diagnosis performance of different methods on TE process

序号 PCA + LDA SVM DCNN GCN GAT PTCN IAGNN-CON IAGNN-AT FPPAN-k-NN FPPAN-k-PHop 1 1.000 1.000 0.997 0.973 0.983 1.000 0.960 0.880 1.000 1.000 2 1.000 1.000 1.000 0.864 1.000 1.000 0.987 0.997 1.000 1.000 3 0.103 0.541 0.439 0.355 0.362 0.329 0.280 0.319 0.331 0.561 4 0.747 1.000 0.997 0.997 0.963 1.000 0.917 0.953 1.000 1.000 5 0.547 0.938 0.970 0.613 0.240 0.963 0.346 0.452 0.975 0.961 6 1.000 1.000 1.000 0.973 1.000 1.000 1.000 1.000 1.000 1.000 7 1.000 1.000 1.000 0.678 0.924 1.000 0.960 0.983 1.000 1.000 8 0.464 0.613 0.674 0.243 0.452 0.681 0.465 0.475 0.731 0.728 9 0.139 0.159 0.073 0.206 0.021 0.050 0.342 0.213 0.199 0.262 10 0.084 0.047 0.792 0.352 0.472 0.498 0.508 0.375 0.827 0.694 11 0.046 0.284 0.967 0.967 0.781 0.977 0.960 0.970 1.000 1.000 12 0.269 0.853 0.714 0.595 0.664 0.867 0.631 0.671 0.883 0.869 13 0.450 0.362 0.621 0.173 0.011 0.794 0.090 0.123 0.711 0.739 14 0.058 0.997 1.000 1.000 1.000 0.967 1.000 1.000 1.000 1.000 15 0.151 0.177 0.212 0.276 0.193 0.301 0.282 0.279 0.312 0.196 平均值 0.471 0.665 0.764 0.618 0.604 0.762 0.649 0.646 0.798 0.801 表 3 盾构施工故障信息

Table 3 Fault information for the shield tunneling construction

序号 故障描述 1 刀盘结泥饼 2 泥浆管路漏浆 3 刀盘驱动故障 4 推进系统故障 表 4 不同方法在盾构施工上的故障诊断表现

Table 4 Fault diagnosis performance of different methods for the shield tunneling construction

序号 PCA + LDA SVM DCNN GCN GAT PTCN IAGNN-CON IAGNN-AT FPPAN-k-NN FPPAN-k-PHop 1 0.853 1.000 1.000 0.751 0.976 1.000 0.835 0.923 1.000 1.000 2 0.741 0.802 1.000 0.664 0.936 1.000 0.785 0.889 1.000 1.000 3 0.579 0.631 0.931 0.875 0.756 0.944 0.823 0.845 1.000 1.000 4 0.601 0.629 0.900 0.520 0.892 0.961 0.717 0.803 0.994 0.996 平均值 0.694 0.770 0.958 0.703 0.890 0.976 0.790 0.865 0.999 0.999 -

[1] Ge Z Q. Review on data-driven modeling and monitoring for plant-wide industrial processes. Chemometrics and Intelligent Laboratory Systems, 2017, 171: 16−25 doi: 10.1016/j.chemolab.2017.09.021 [2] Yu J B, Zhang Y. Challenges and opportunities of deep learning-based process fault detection and diagnosis: A review. Neural Computing & Applications, 2023, 35(1): 211−252 [3] 马亮, 彭开香, 董洁. 工业过程故障根源诊断与传播路径识别技术综述. 自动化学报, 2022, 48(7): 1650−1663Ma Liang, Peng Kai-Xiang, Dong Jie. Review of root cause diagnosis and propagation path identification techniques for faults in industrial processes. Acta Automatica Sinica, 2022, 48(7): 1650−1663 [4] Huo M Y, Luo H, Cheng C, Li K, Yin S, Kaynak O, et al. Subspace-aided sensor fault diagnosis and compensation for industrial systems. IEEE Transactions on Industrial Electronics, 2023, 70(9): 9474−9482 doi: 10.1109/TIE.2022.3215823 [5] Tao Y, Shi H B, Song B, Tan S. A supervised multisegment probability density analysis method for incipient fault detection of quality indicator. Journal of Process Control, 2022, 116: 53−63 doi: 10.1016/j.jprocont.2022.04.006 [6] Yang G, Zhao Y L, Gu X H. A novel Bayesian framework with enhanced principal component analysis for chemical fault diagnosis. IEEE Transactions on Instrumentation and Measurement, 2021, 70: 1−9 [7] Yu J B. Local and global principal component analysis for process monitoring. Journal of Process Control, 2012, 22(7): 1358−1373 doi: 10.1016/j.jprocont.2012.06.008 [8] Drucker H, Burges C, Kaufman L, Smola A, Vapnik V. Support vector regression machines. In: Proceedings of the 9th International Conference on Neural Information Processing Systems. Cambridge, USA: 1997. 155−161 [9] Si Y B, Wang Y Q, Zhou D H. Key-performance-indicator-related process monitoring based on improved kernel partial least squares. IEEE Transactions on Industrial Electronics, 2021, 68(3): 2626−2636 doi: 10.1109/TIE.2020.2972472 [10] Yan T T, Wang D, Wang Y. Discrimination- and sparsity-driven weight-oriented optimization model for interpretable initial fault detection and fault diagnosis. IEEE Transactions on Instrumentation and Measurement, 2023, 73: 1−13 [11] Zhou K, Tong Y F, Li X T. Exploring global attention mechanism on fault detection and diagnosis for complex engineering processes. Process Safety and Environmental Protection, 2023, 170: 660−669 doi: 10.1016/j.psep.2022.12.055 [12] Li C J, Li S B, Wang H, Gu F H, Ball D A. Attention-based deep meta-transfer learning for few-shot fine-grained fault diagnosis. Knowledge-based Systems, 2023, 264: Article No. 110345 doi: 10.1016/j.knosys.2023.110345 [13] Wu H, Zhao J S. Deep convolutional neural network model based chemical process fault diagnosis. Computers & Chemical Engineering, 2018, 115: 185−197 [14] Chen S M, Yu J, Wang S. One-dimensional convolutional auto-encoder-based feature learning for fault diagnosis of multivariate processes. Journal of Process Control, 2020, 87: 54−67 doi: 10.1016/j.jprocont.2020.01.004 [15] 褚菲, 傅逸灵, 赵旭, 王佩, 尚超, 王福利. 基于ISDAE模型的复杂工业过程运行状态评价方法及应用. 自动化学报, 2021, 47(4): 849−863 doi: 10.16383/j.aas.c200475Chu Fei, Fu Yi-Ling, Zhao Xu, Wang Pei, Shang Chao, Wang Fu-Li. Operating performance assessment method and application for complex industrial process based on ISDAE model. Acta Automatica Sinica, 2021, 47(4): 849−863 doi: 10.16383/j.aas.c200475 [16] Li Y X, Chai Y, Yin H P. Autoencoder embedded dictionary learning for nonlinear industrial process fault diagnosis. Journal of Process Control, 2021, 101: 24−34 doi: 10.1016/j.jprocont.2021.02.002 [17] Gao Y P, Gao L, Li X Y, Cao S Y. A hierarchical training-convolutional neural network for imbalanced fault diagnosis in complex equipment. IEEE Transactions on Industrial Informatics, 2022, 18(11): 8138−8145 doi: 10.1109/TII.2022.3177662 [18] Wu D Y, Zhao J S. Process topology convolutional network model for chemical process fault diagnosis. Process Safety and Environmental Protection, 2021, 150: 93−109 doi: 10.1016/j.psep.2021.03.052 [19] Wu P, Wang Y X, Gao J F, Zhang X J, Luo S W, Yang C J. Multichannel dynamic graph convolutional network-based fault diagnosis and its application in blast furnace ironmaking process. IEEE Sensors Journal, 2023, 23(23): 29293−29302 doi: 10.1109/JSEN.2023.3325353 [20] Wan W Q, Chen J L, Xie J S. MIM-Graph: A multi-sensor network approach for fault diagnosis of HSR Bogie bearings at the IoT edge via mutual information maximization. ISA Transactions, 2023, 139: 574−585 doi: 10.1016/j.isatra.2023.04.033 [21] Chen D Y, Liu R N, Hu Q H, Ding S X. Interaction-aware graph neural networks for fault diagnosis of complex industrial processes. IEEE Transactions on Neural Networks and Learning Systems, 2021, 34(9): 6015−6028 [22] 尹进田, 谢永芳, 陈志文, 彭涛, 杨超. 基于故障传播与因果关系的故障溯源方法及其在牵引传动控制系统中的应用. 自动化学报, 2020, 46(1): 47−57Yin Jin-Tian, Xie Yong-Fang, Chen Zhi-Wen, Peng Tao, Yang Chao. Fault tracing method based on fault propagation and causality with its application to the traction drive control system. Acta Automatica Sinica, 2020, 46(1): 47−57 [23] Zhu Q X, Luo Y, He Y L. Novel multiblock transfer entropy based Bayesian network and its application to root cause analysis. Industrial & Engineering Chemistry Research, 2019, 58(12): 4936−4945 [24] 唐鹏, 彭开香, 董洁. 一种新颖的深度因果图建模及其故障诊断方法. 自动化学报, 2022, 48(6): 1616−1624Tang Peng, Peng Kai-Xiang, Dong Jie. A novel method for deep causality graph modeling and fault diagnosis. Acta Automatica Sinica, 2022, 48(6): 1616−1624 [25] Wang S, Zhao Q, Han Y H, Wang J K. Root cause diagnosis for process faults based on multisensor time-series causality discovery. Journal of Process Control, 2023, 122(9): 27−40 [26] Dong J, Cao K R, Peng K X. Hierarchical causal graph-based fault root cause diagnosis and propagation path identification for complex industrial process monitoring. IEEE Transactions on Instrumentation and Measurement, 2023, 72: Article No. 3513911 [27] Zhang H J, Peng K X, Ma L. A systematic nonstationary causality analysis framework for root cause diagnosis of faults in manufacturing processes. Control Engineering Practice, 2023, 131: Article No. 105404 doi: 10.1016/j.conengprac.2022.105404 [28] Ma L, Dong J, Peng K X. A novel key performance indicator oriented hierarchical monitoring and propagation path identification framework for complex industrial processes. ISA Transactions, 2020, 96: 1−13 doi: 10.1016/j.isatra.2019.06.004 [29] Xu K, Hu W H, Leskovec J, Jegelka S. How powerful are graph neural networks. In: Proceedings of the 7th International Conference on Learning Representations. New Orleans, USA: 2019. [30] Kipf T N, Welling M. Semi-supervised classification with graph convolutional networks. In: Proceedings of the 5th International Conference on Learning Representations. Toulon, France: 2017. [31] Veličković P, Cucurull G, Casanova A, Romero A, Liò P, Bengio Y. Graph attention networks. In: Proceedings of the 6th International Conference on Learning Representations. Vancouver, Canada: 2018. [32] Hamilton W, Ying Z, Leskovec J. Inductive representation learning on large graphs. In: Proceedings of the 31st Conference on Neural Information Processing Systems. Long Beach, USA: 2017. 1025−1035 [33] Downs J J, Vogel E F. A plant-wide industrial process control problem. Computers & Chemical Engineering, 1993, 17(3): 245−255 -

下载:

下载: