Modular Hardware-in-loop Platform of Intelligent Algorithm Testing and Verification for Municipal Solid Waste Incineration

-

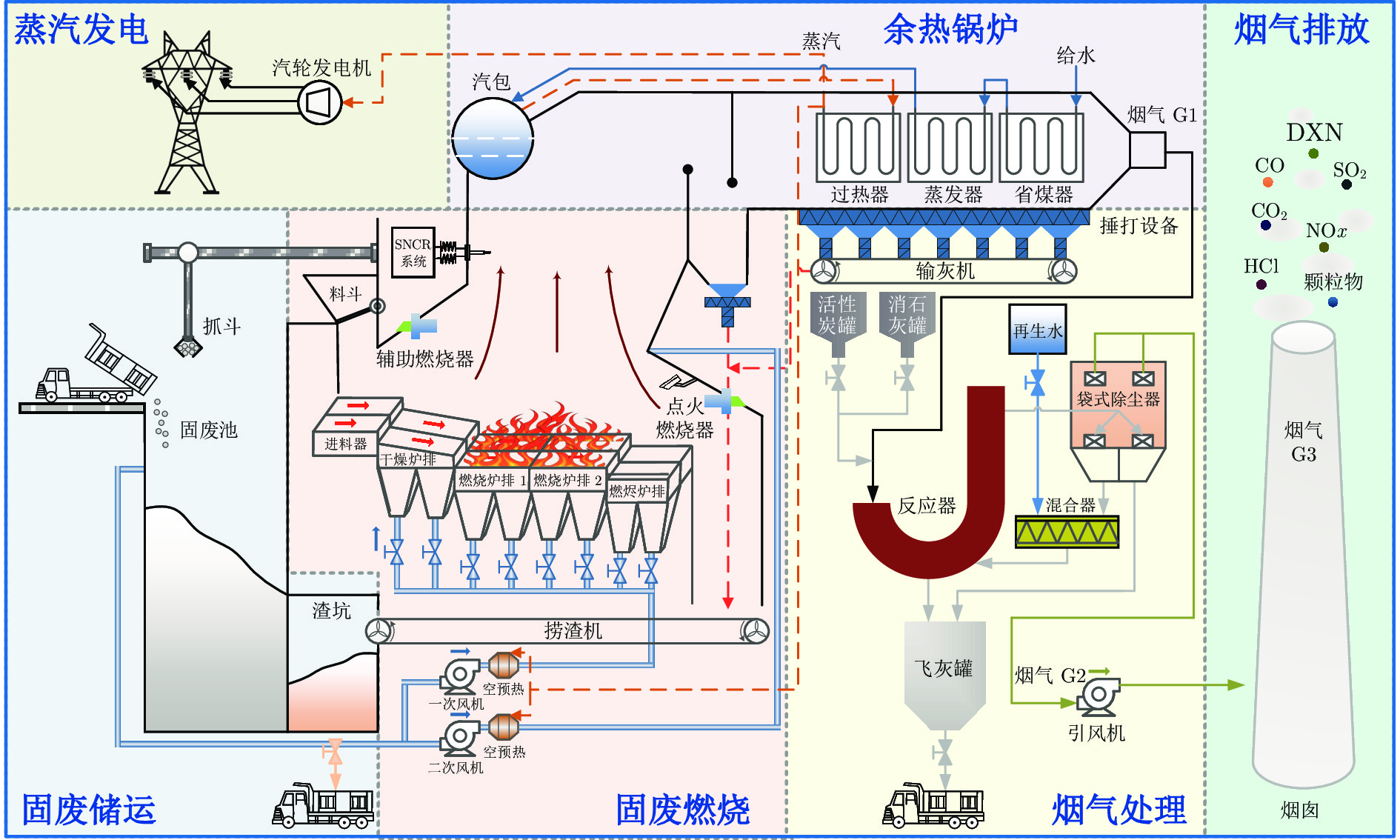

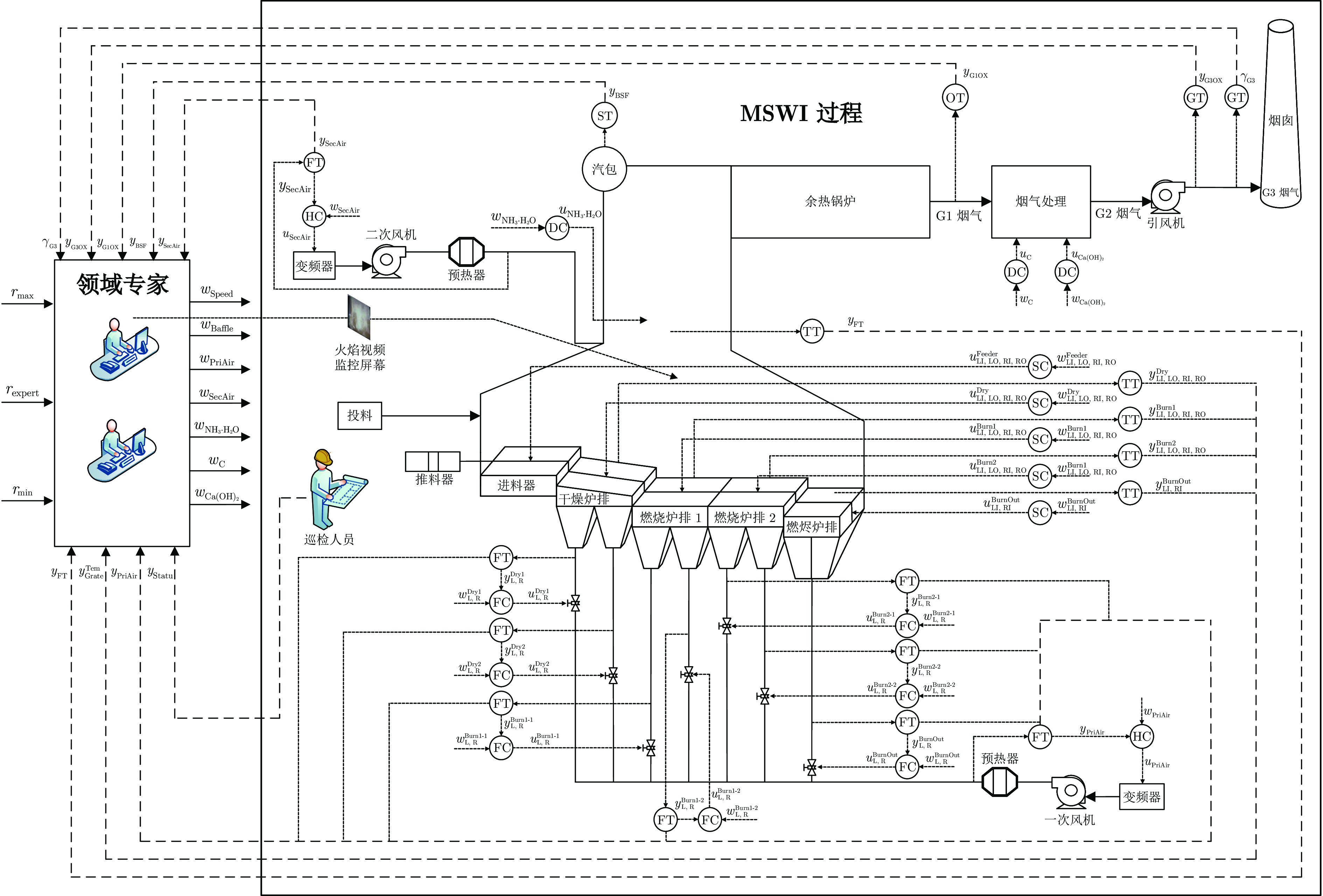

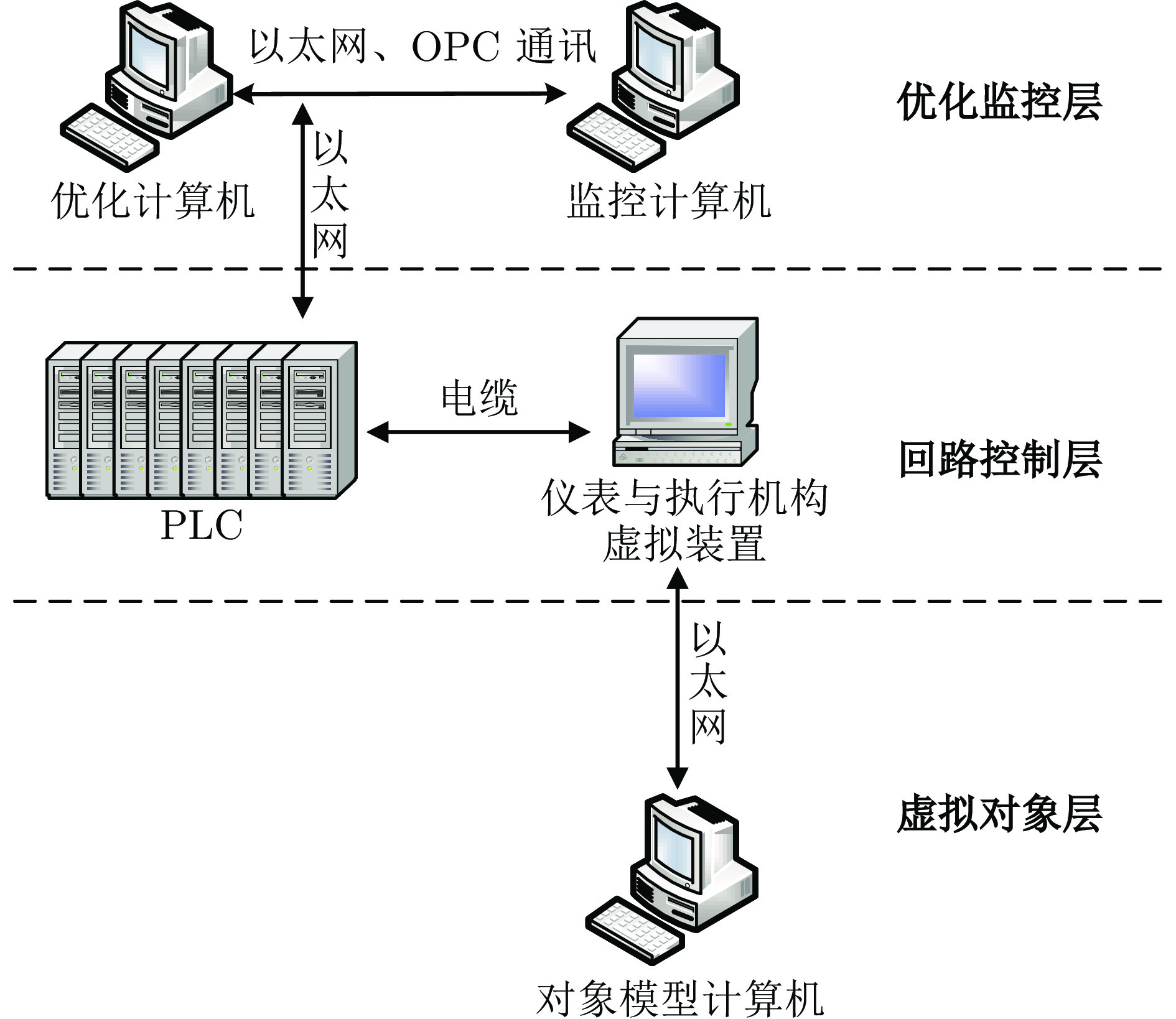

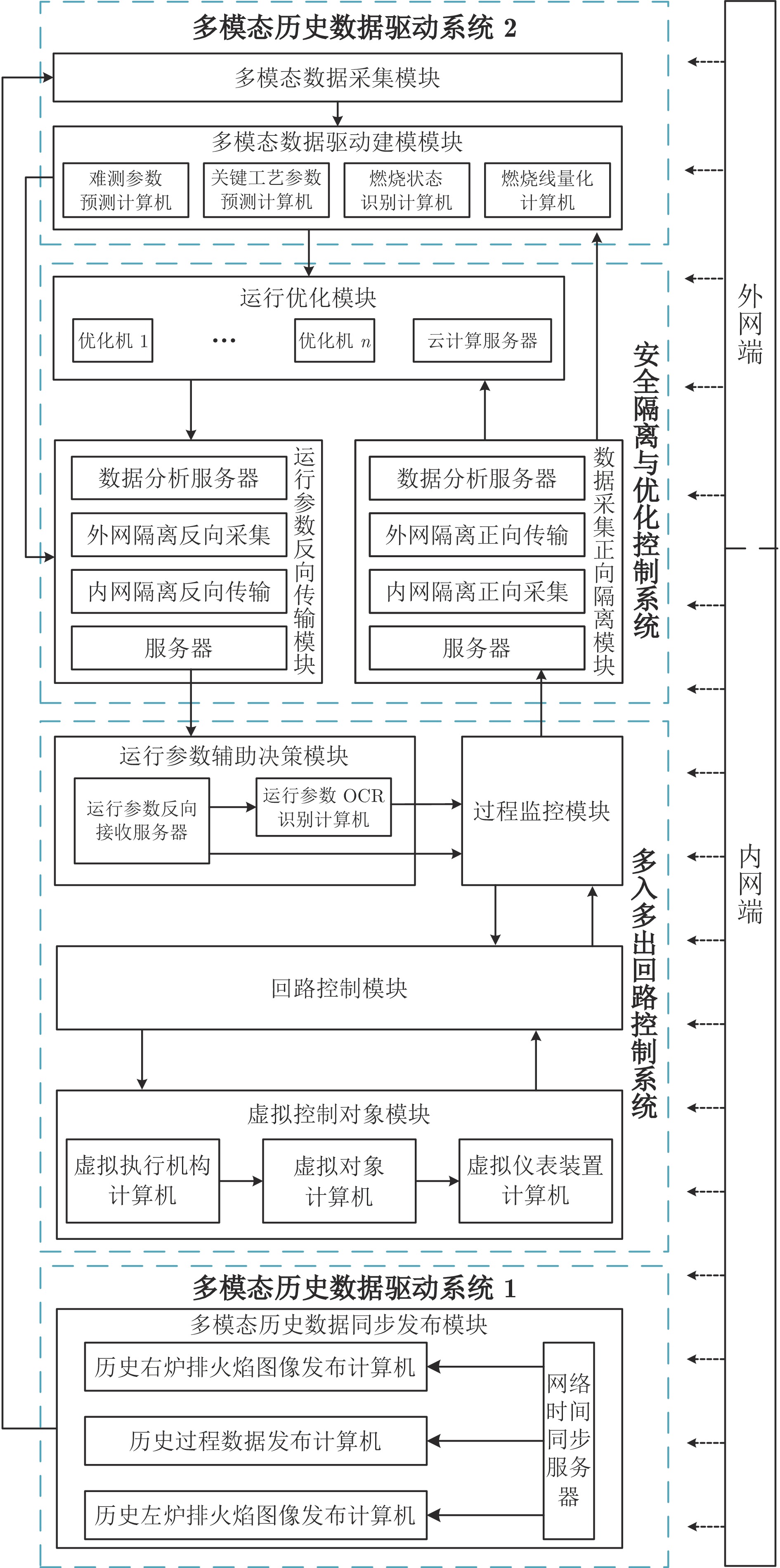

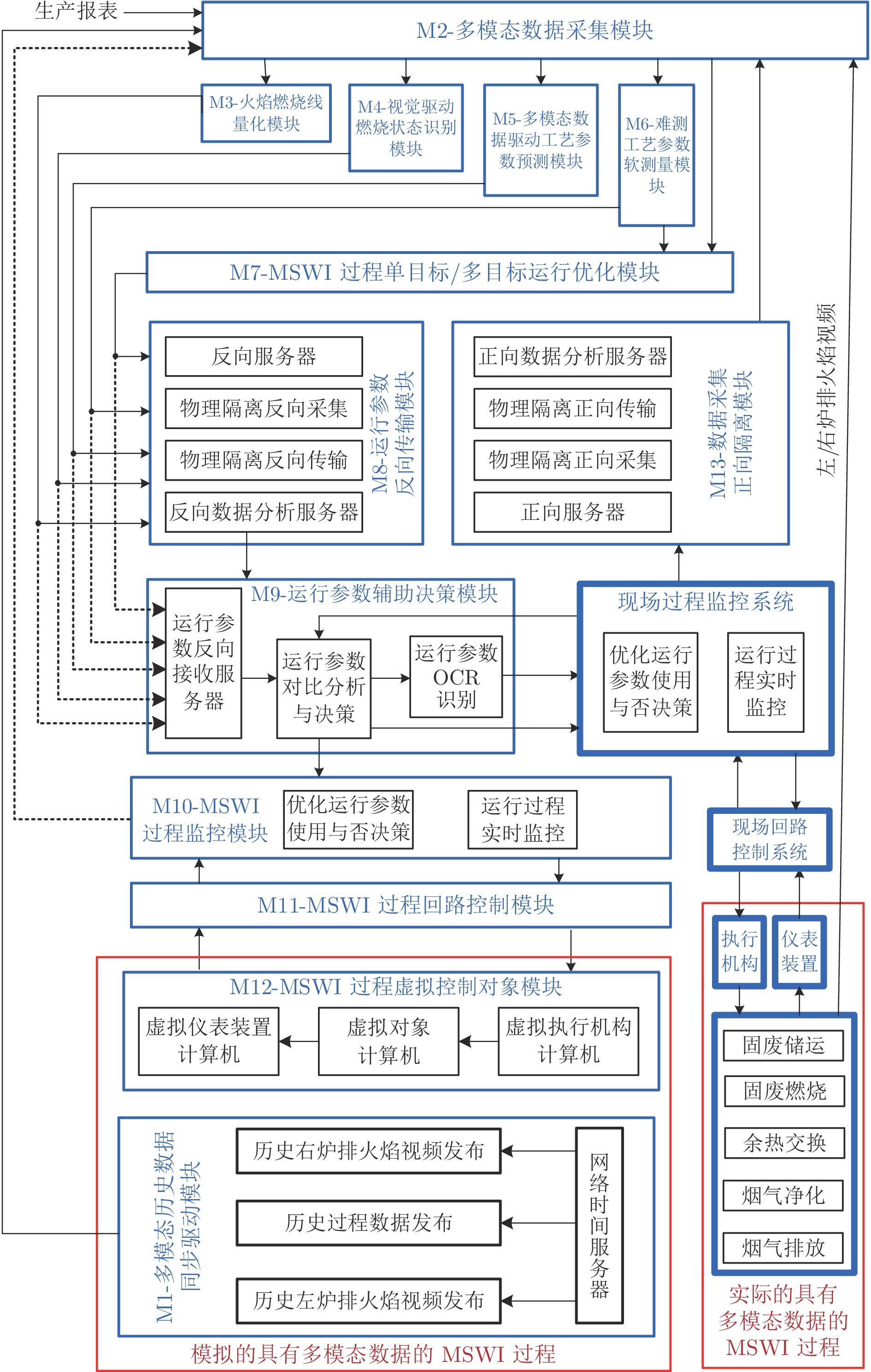

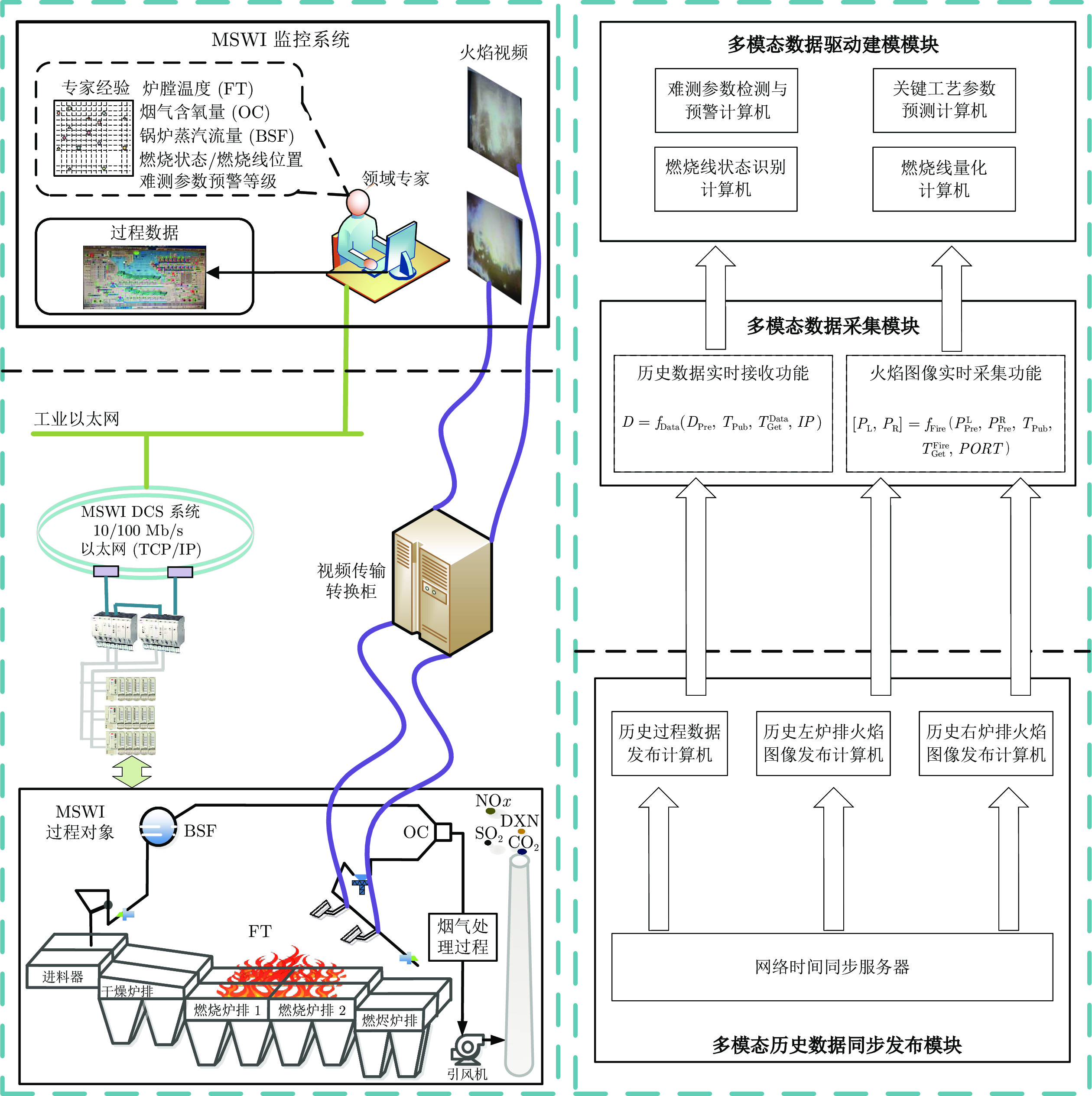

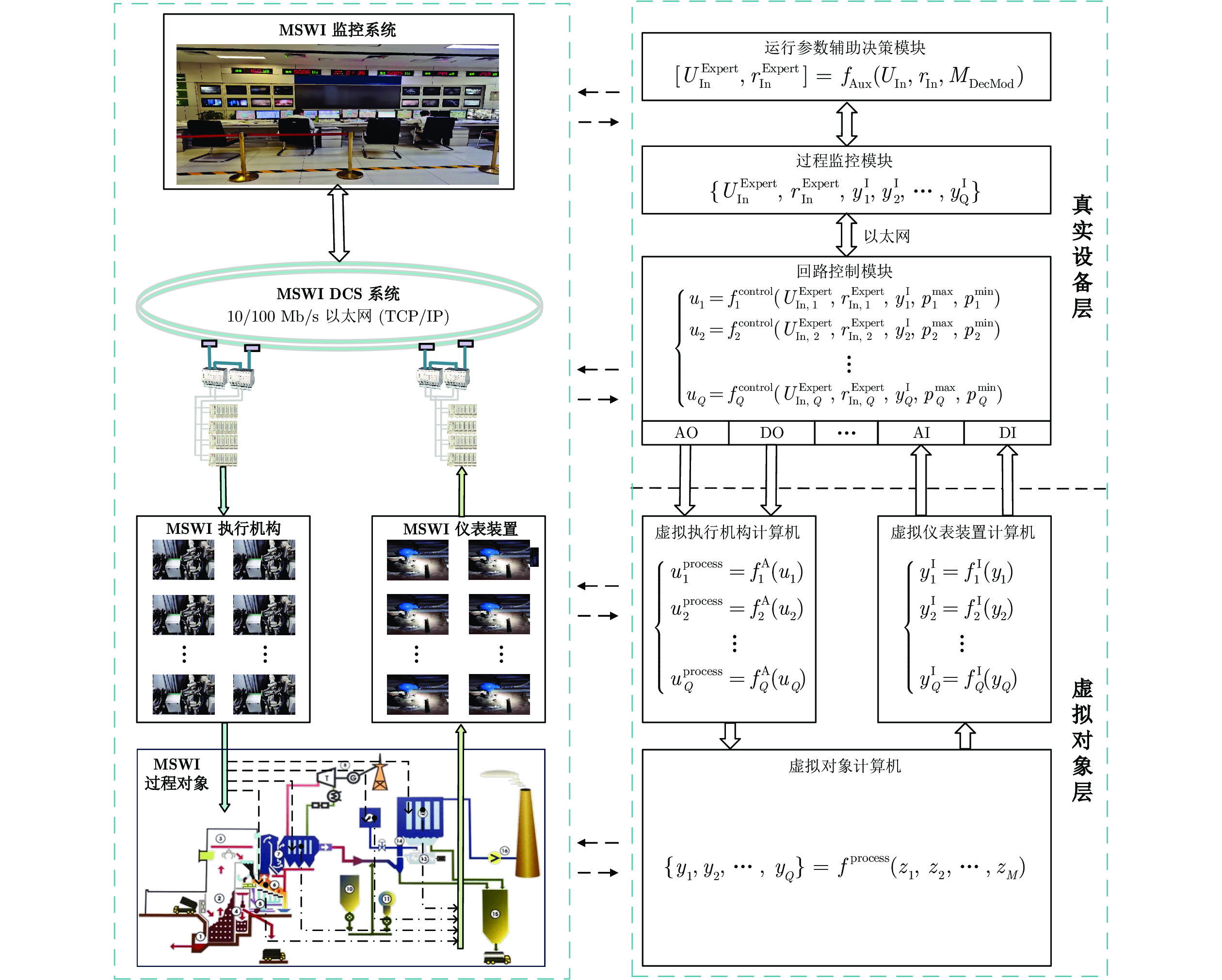

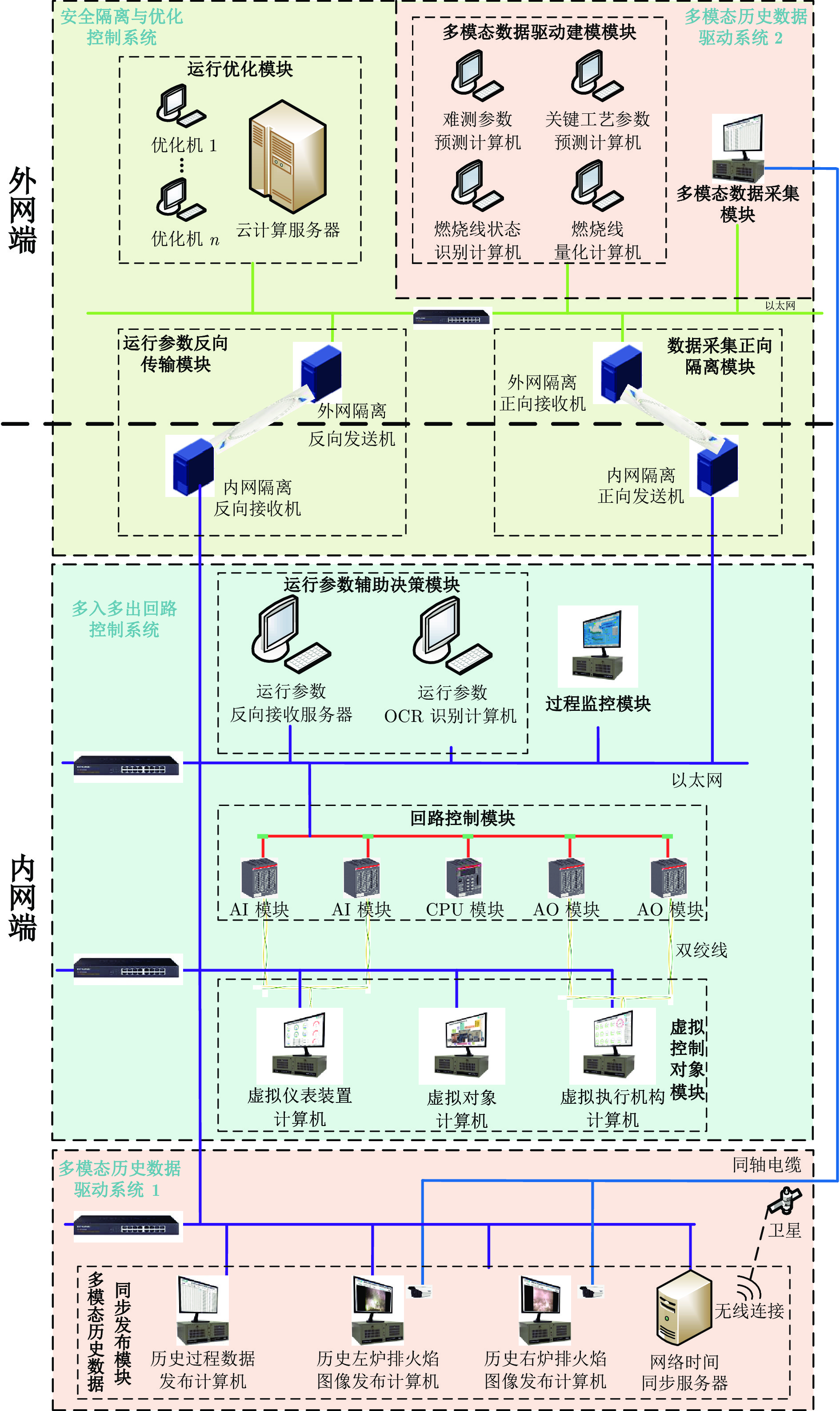

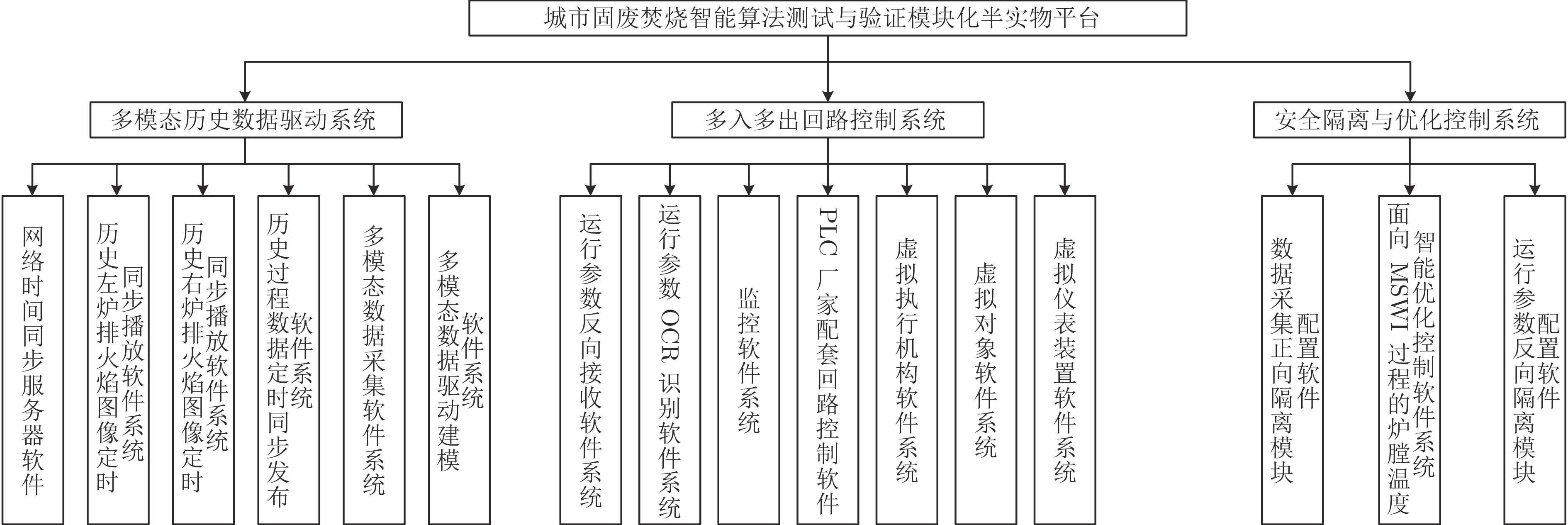

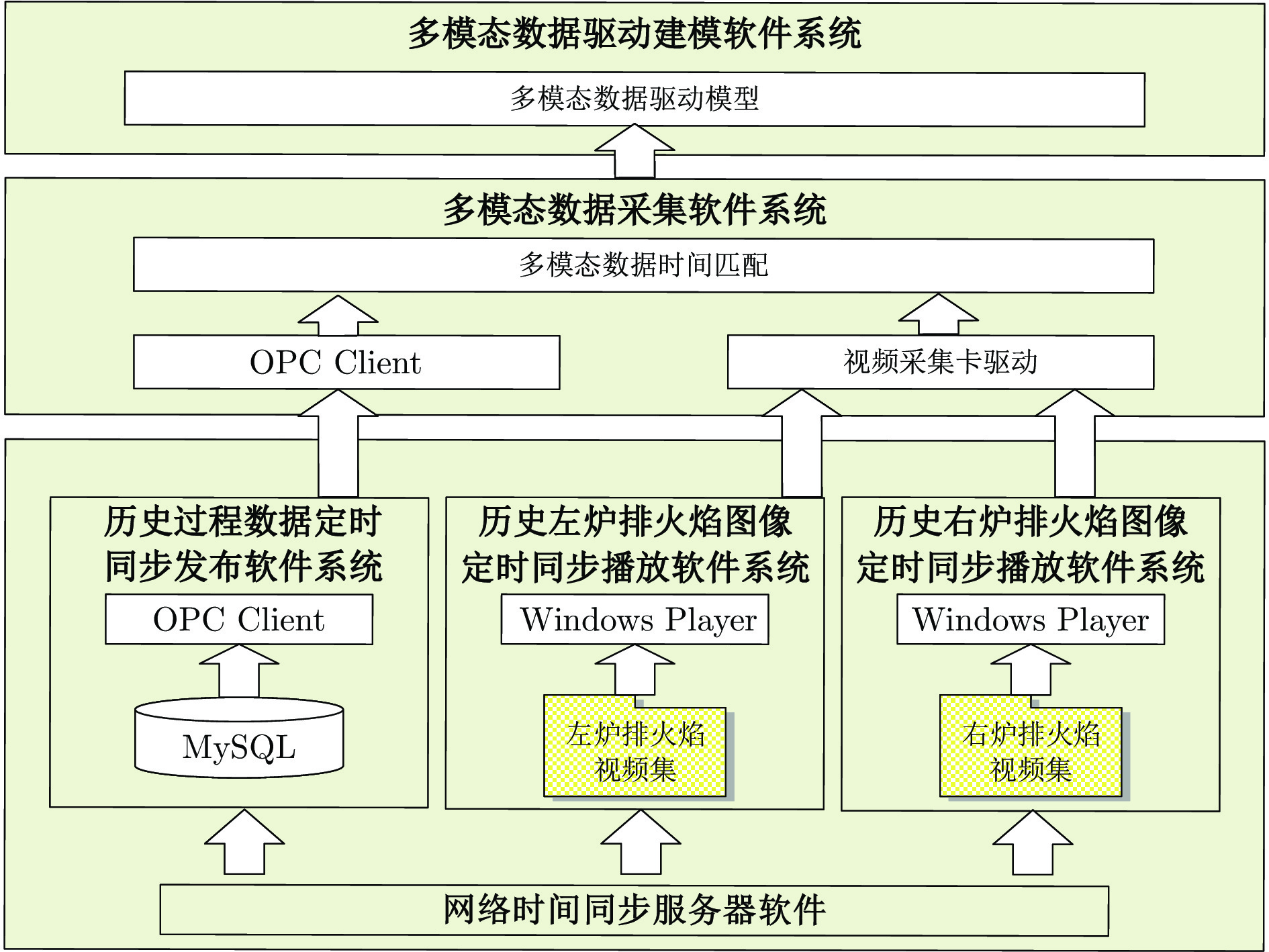

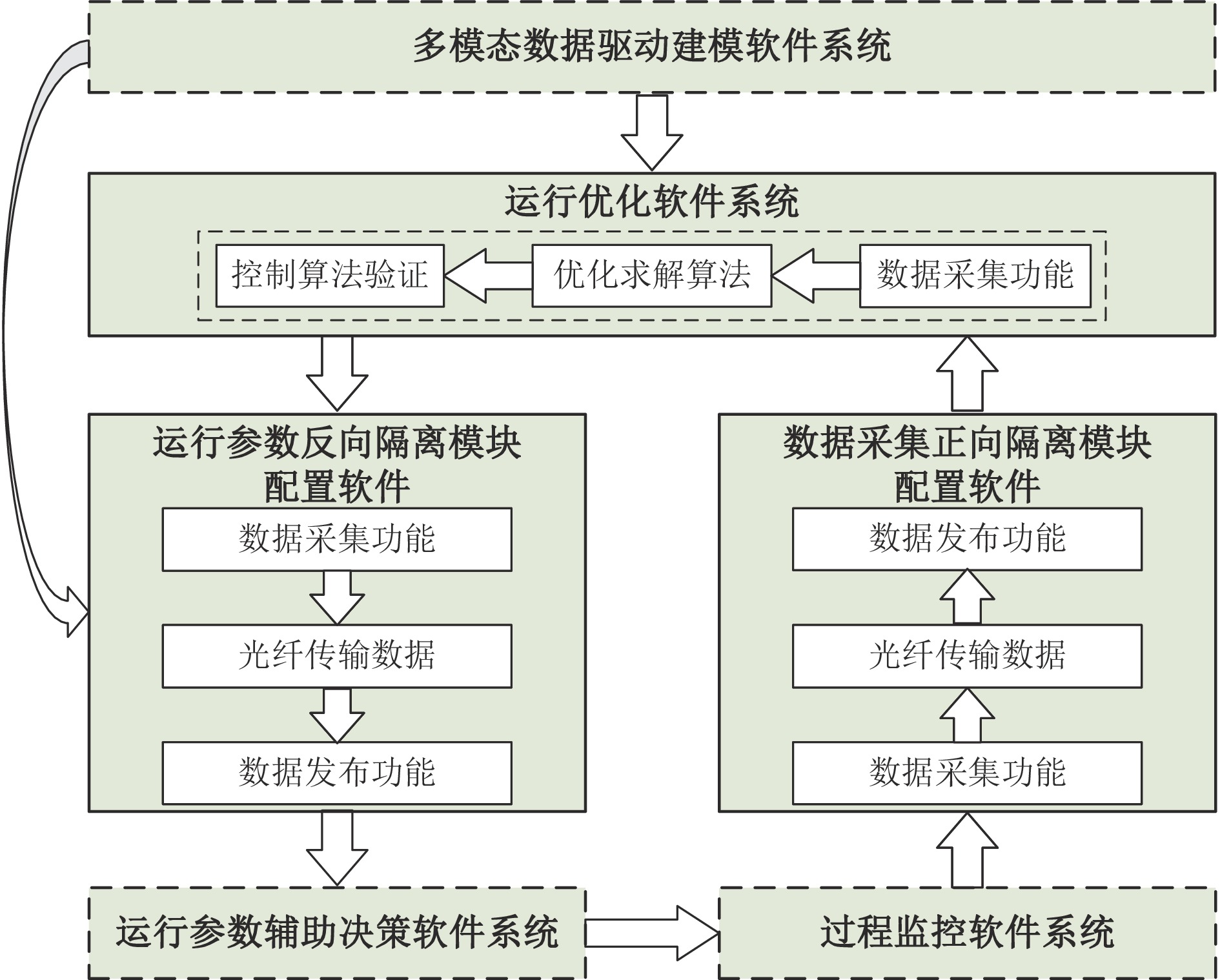

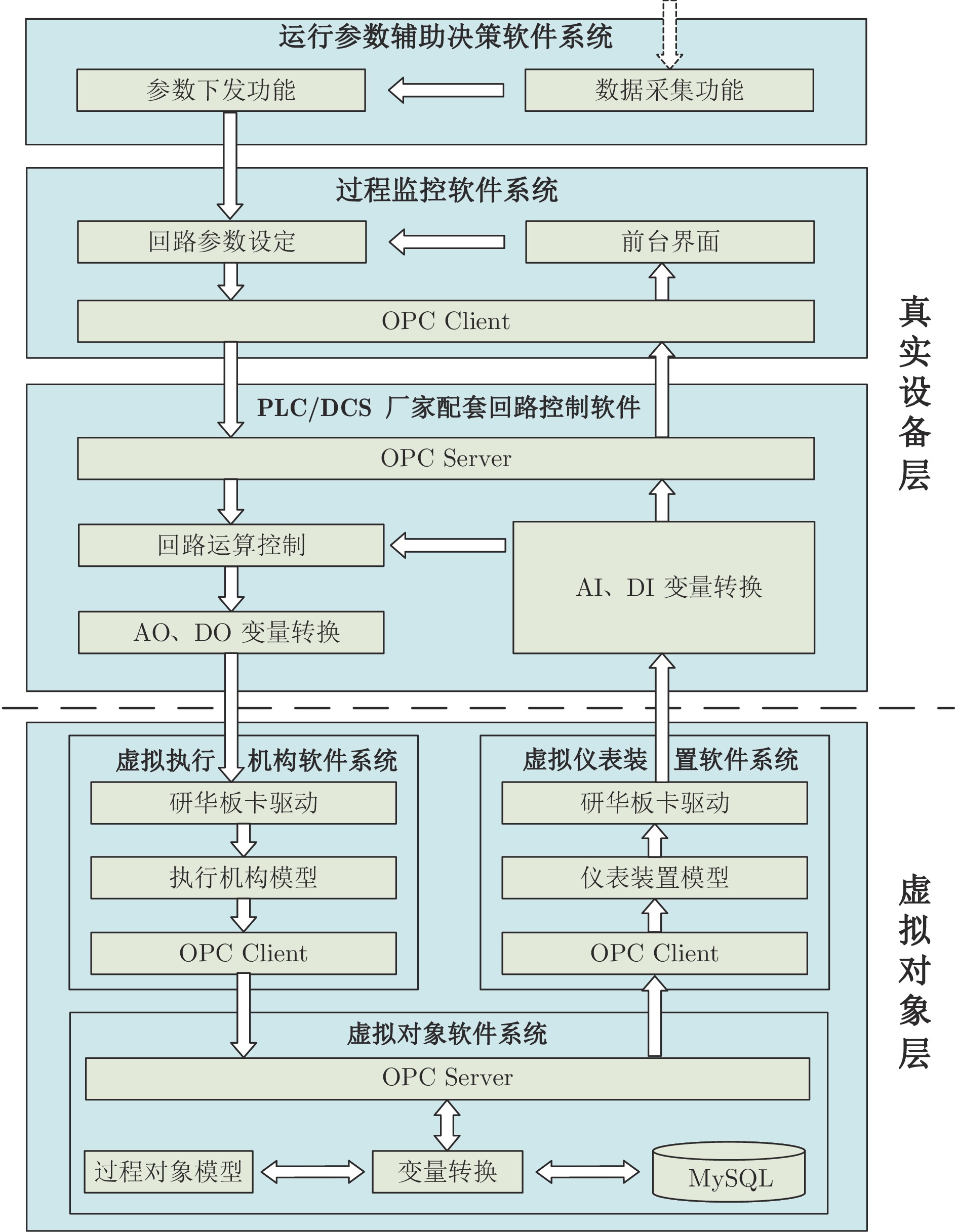

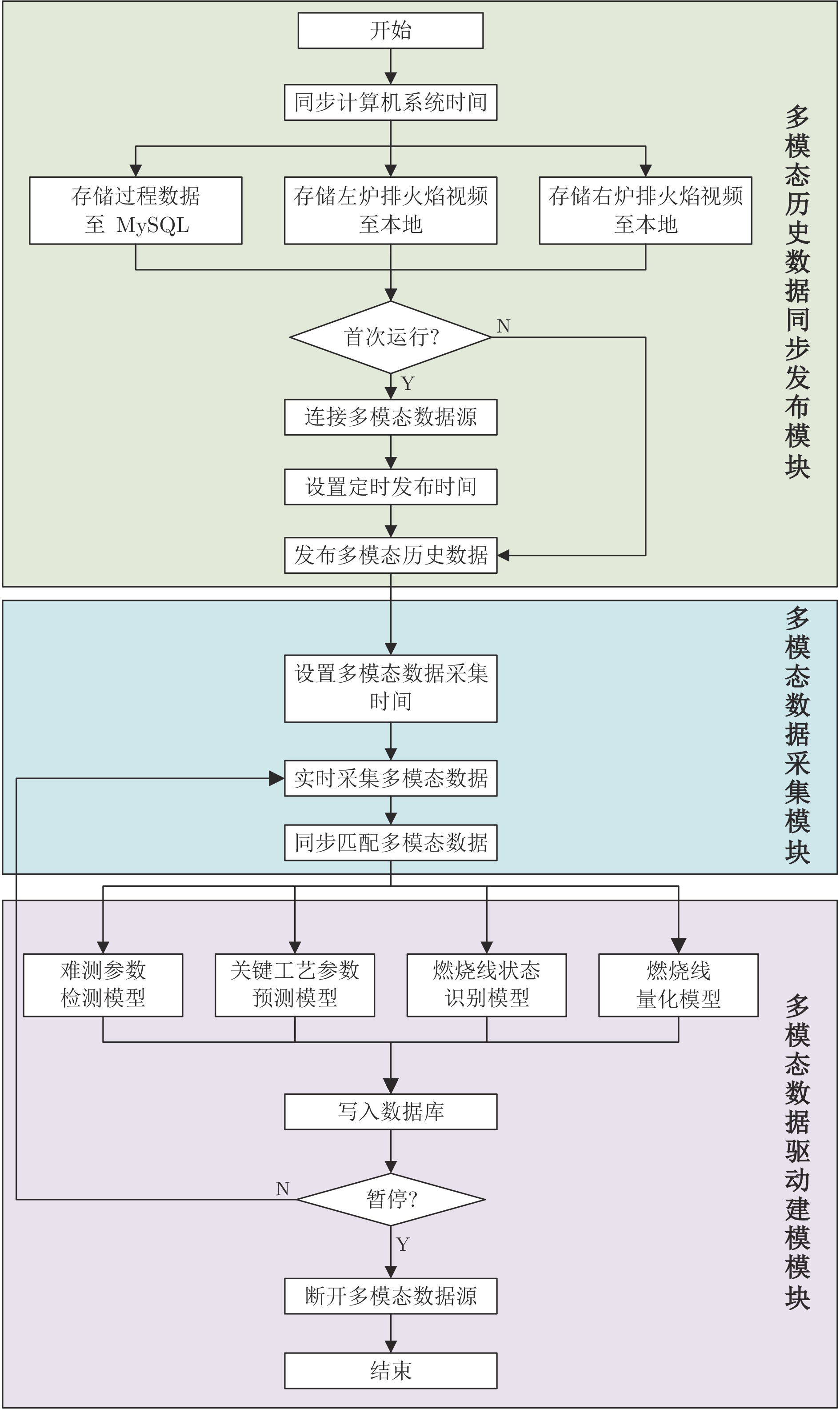

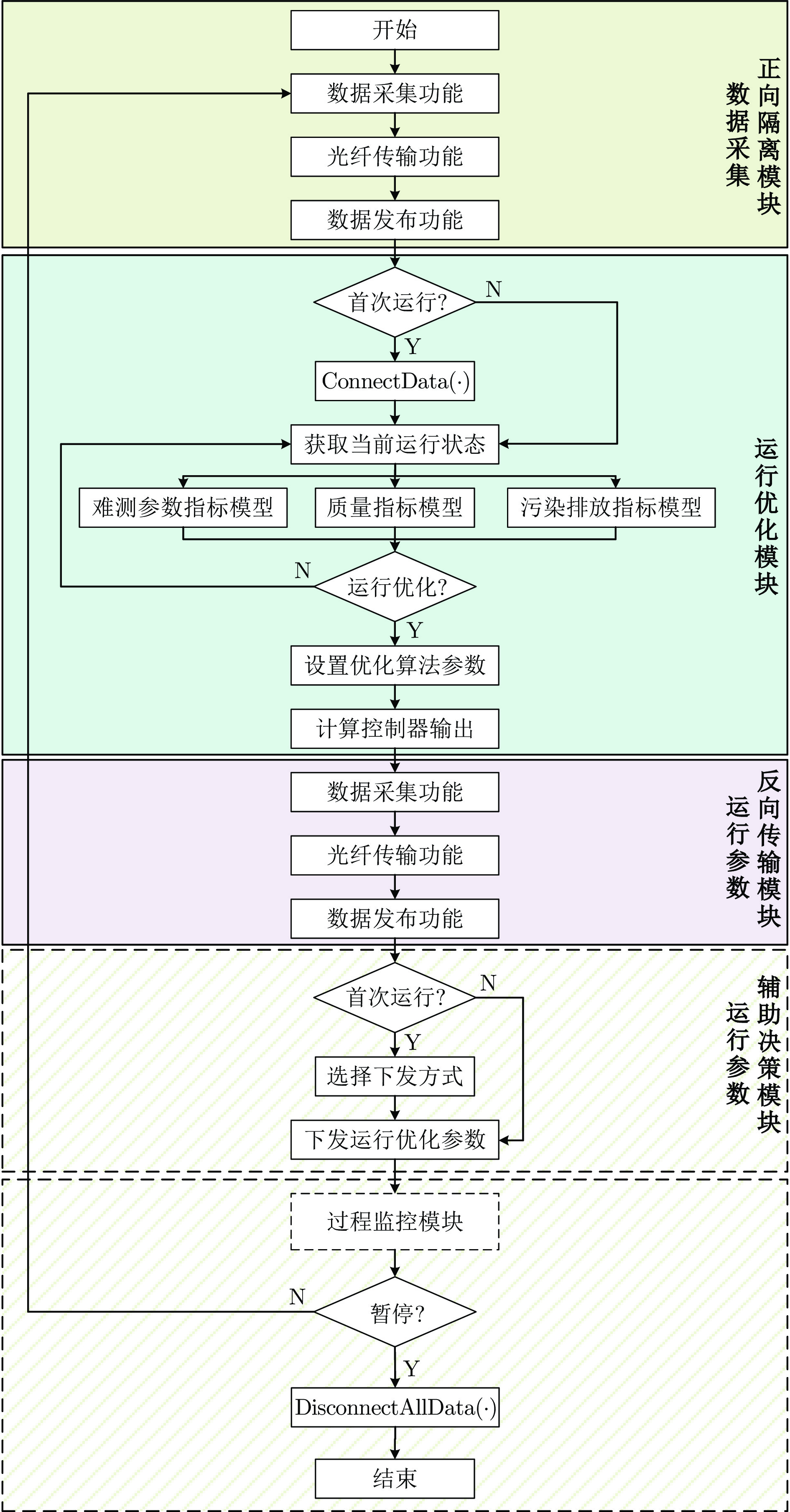

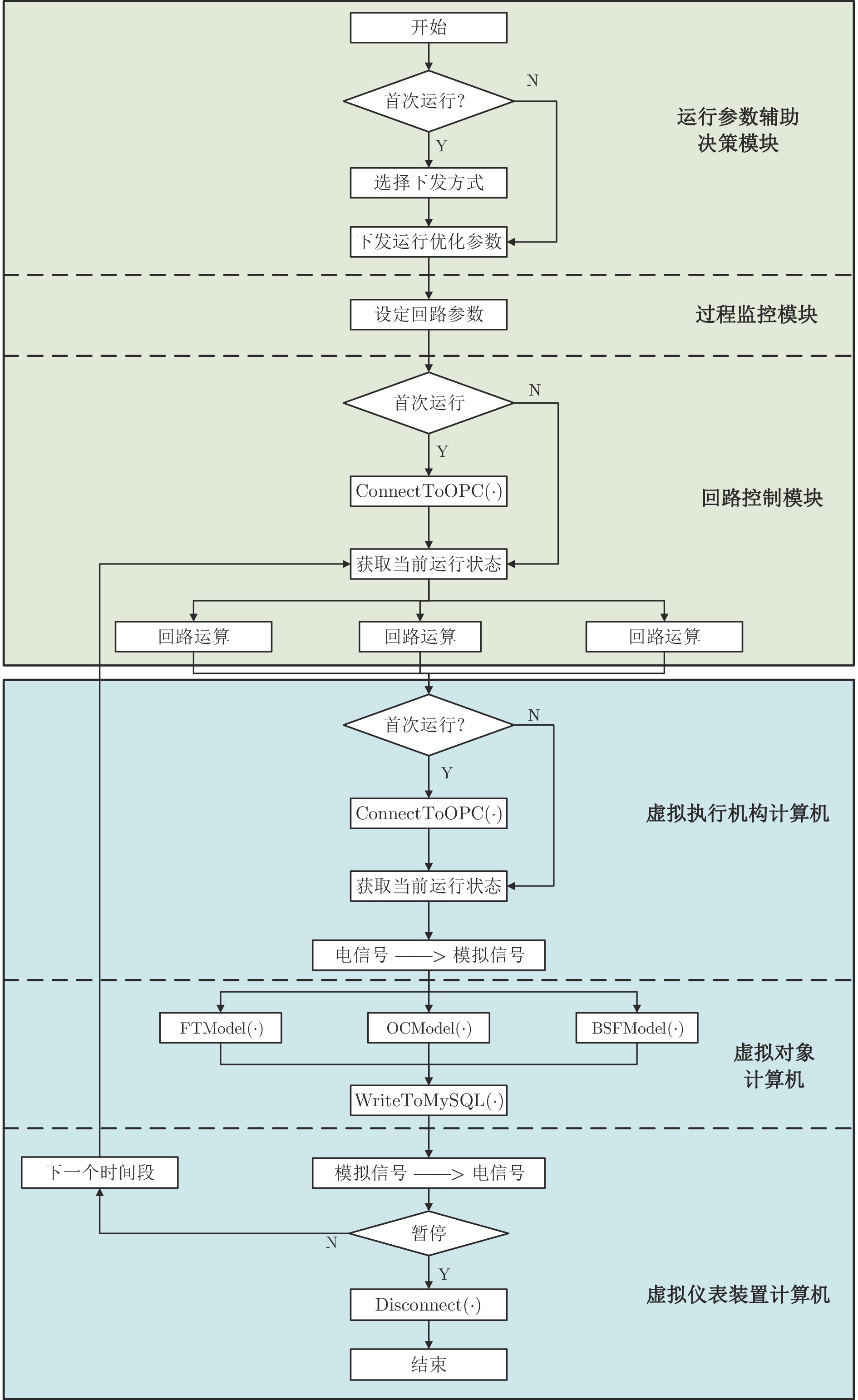

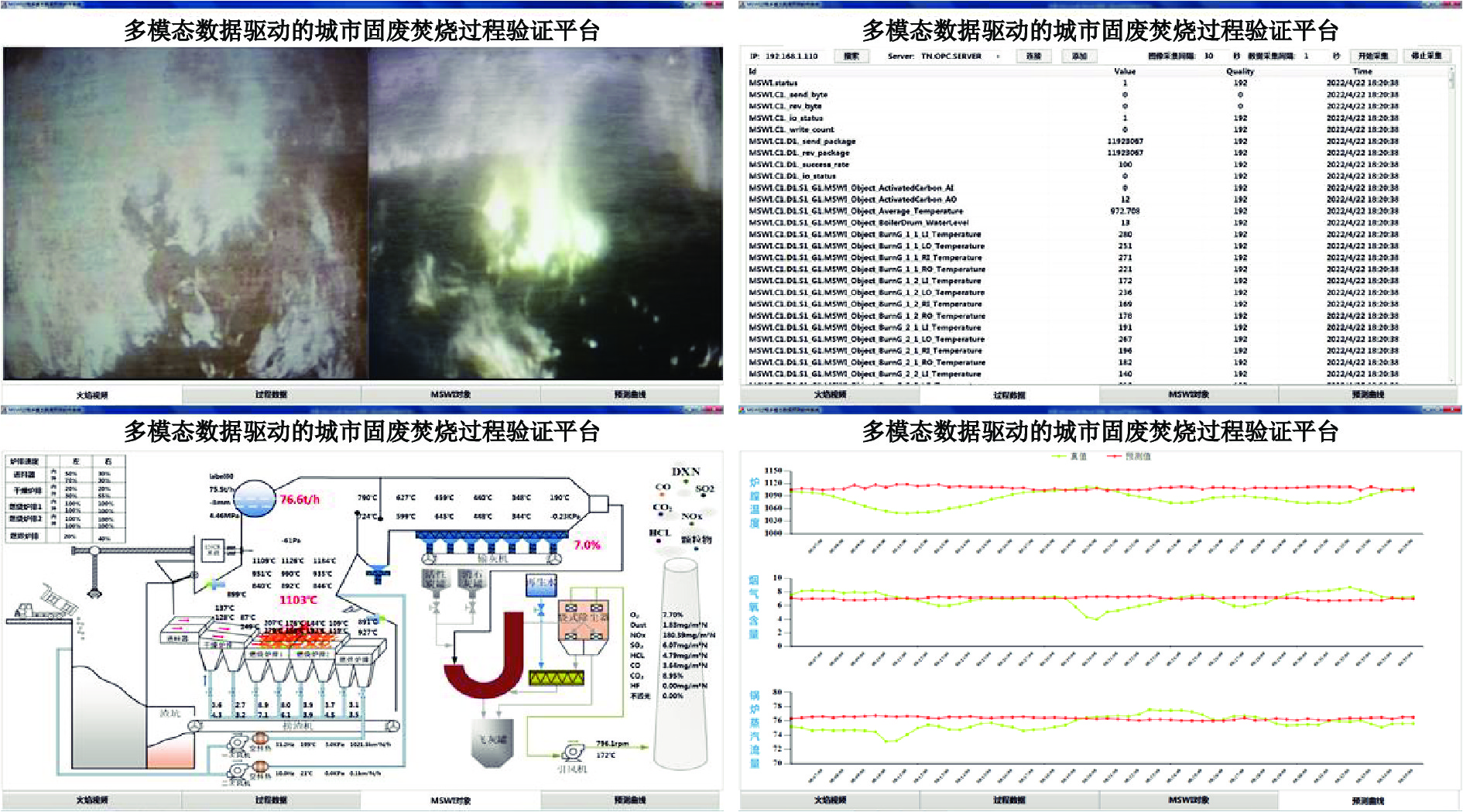

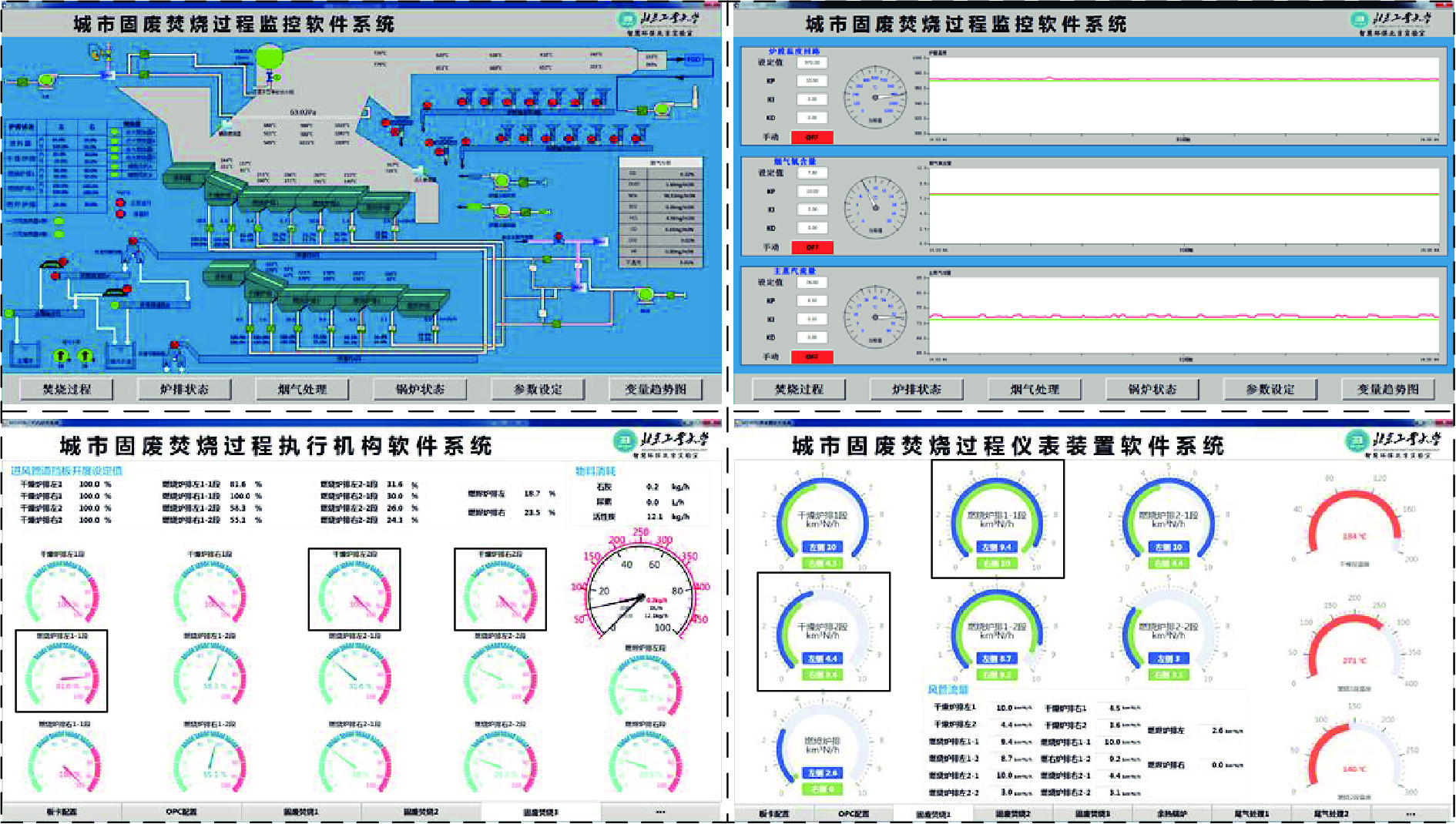

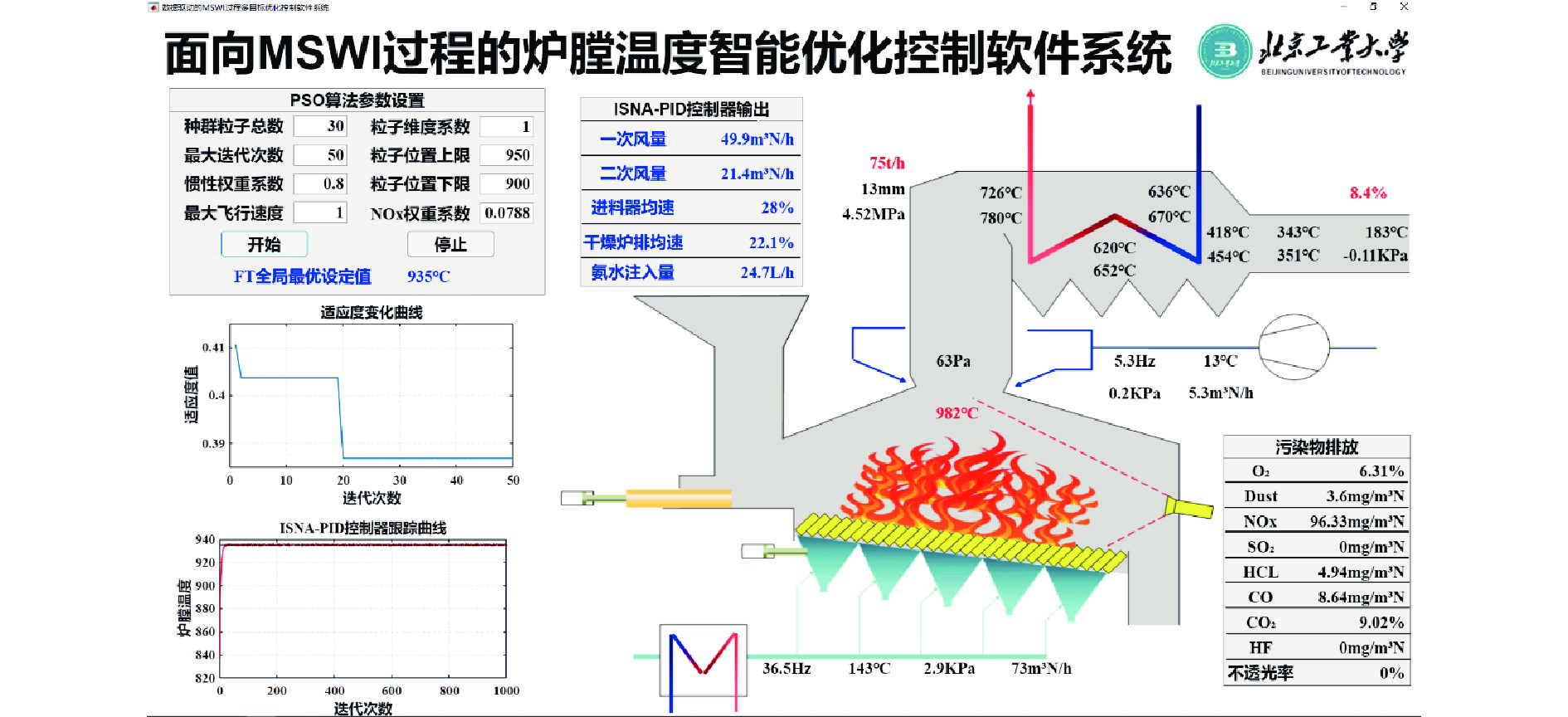

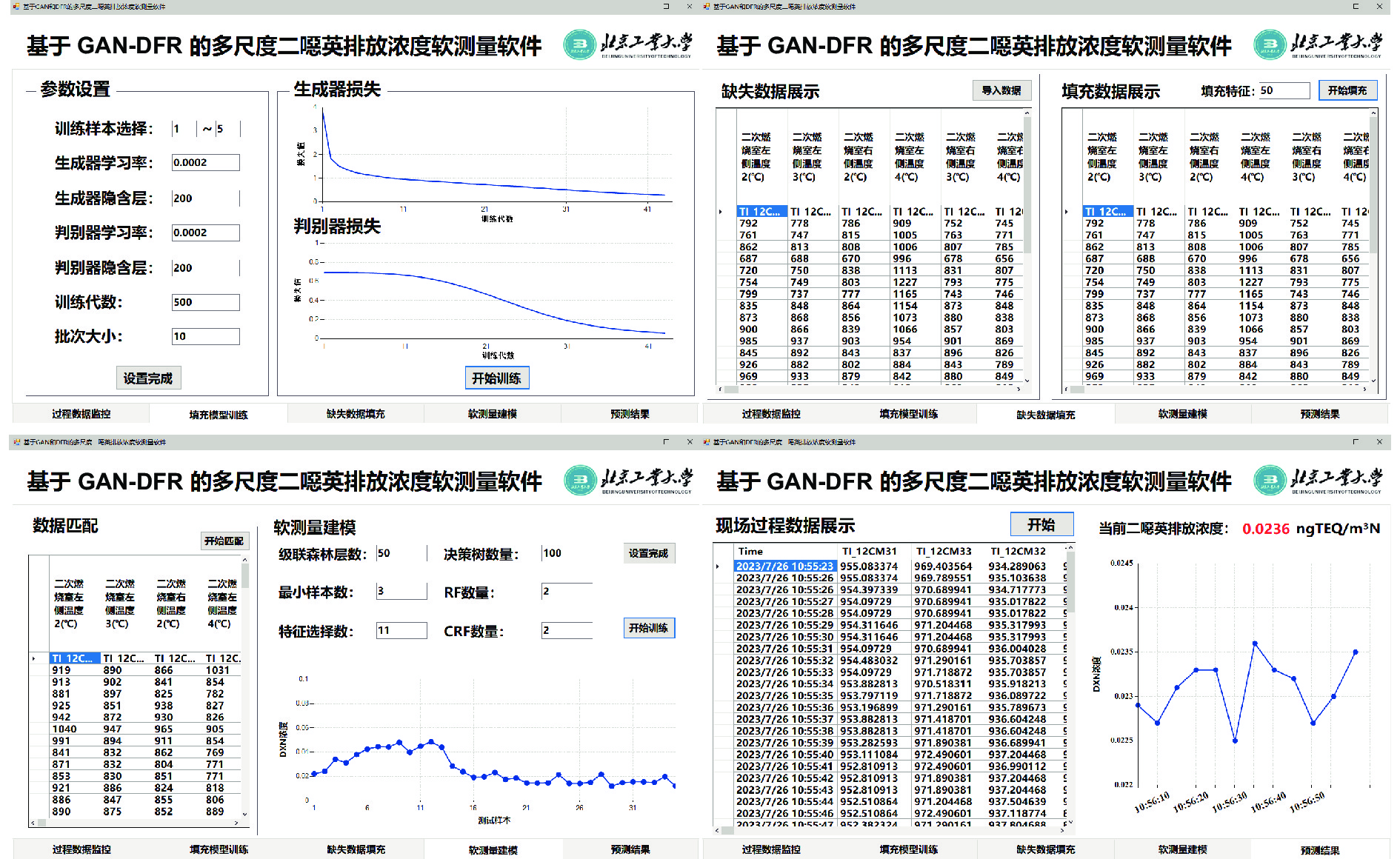

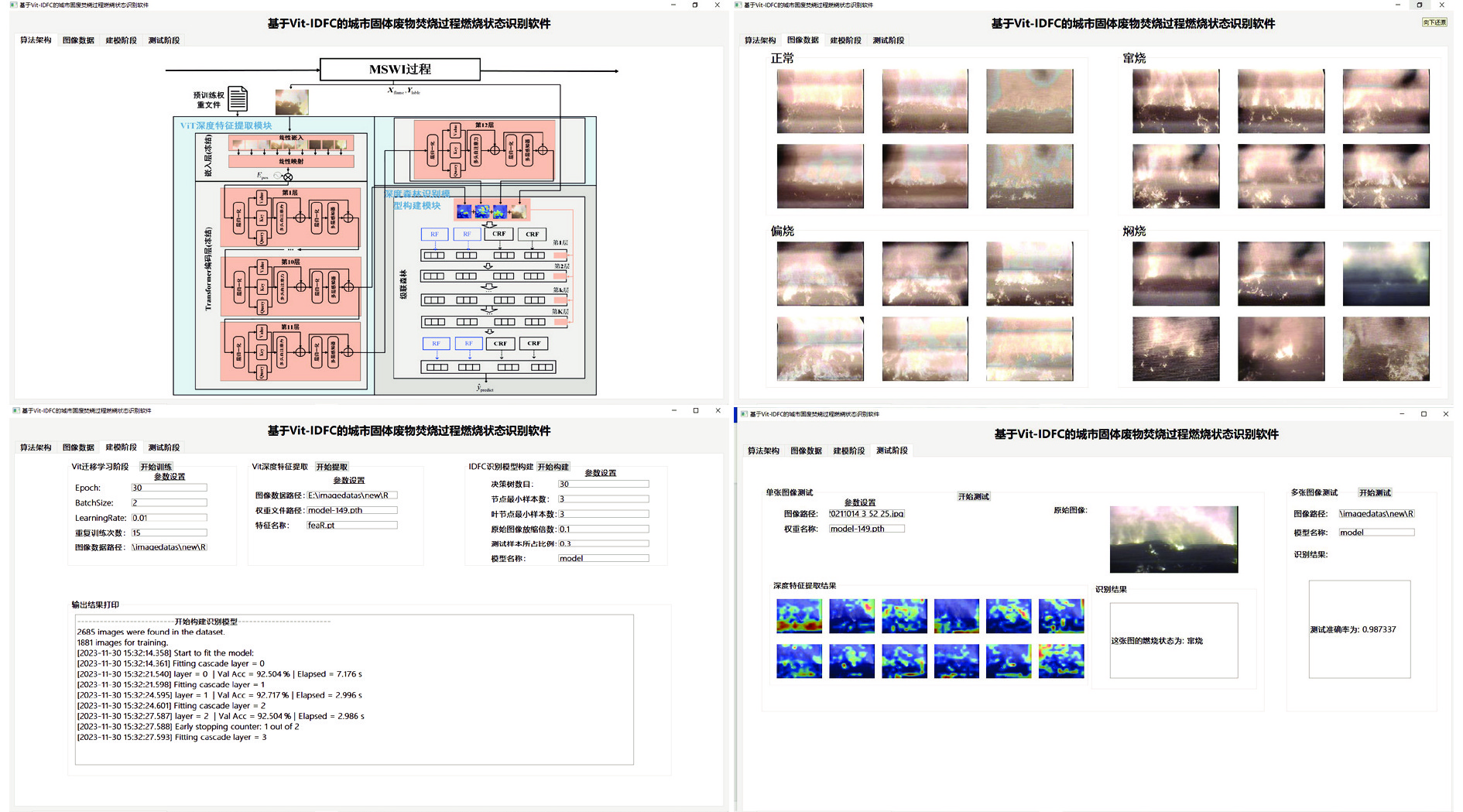

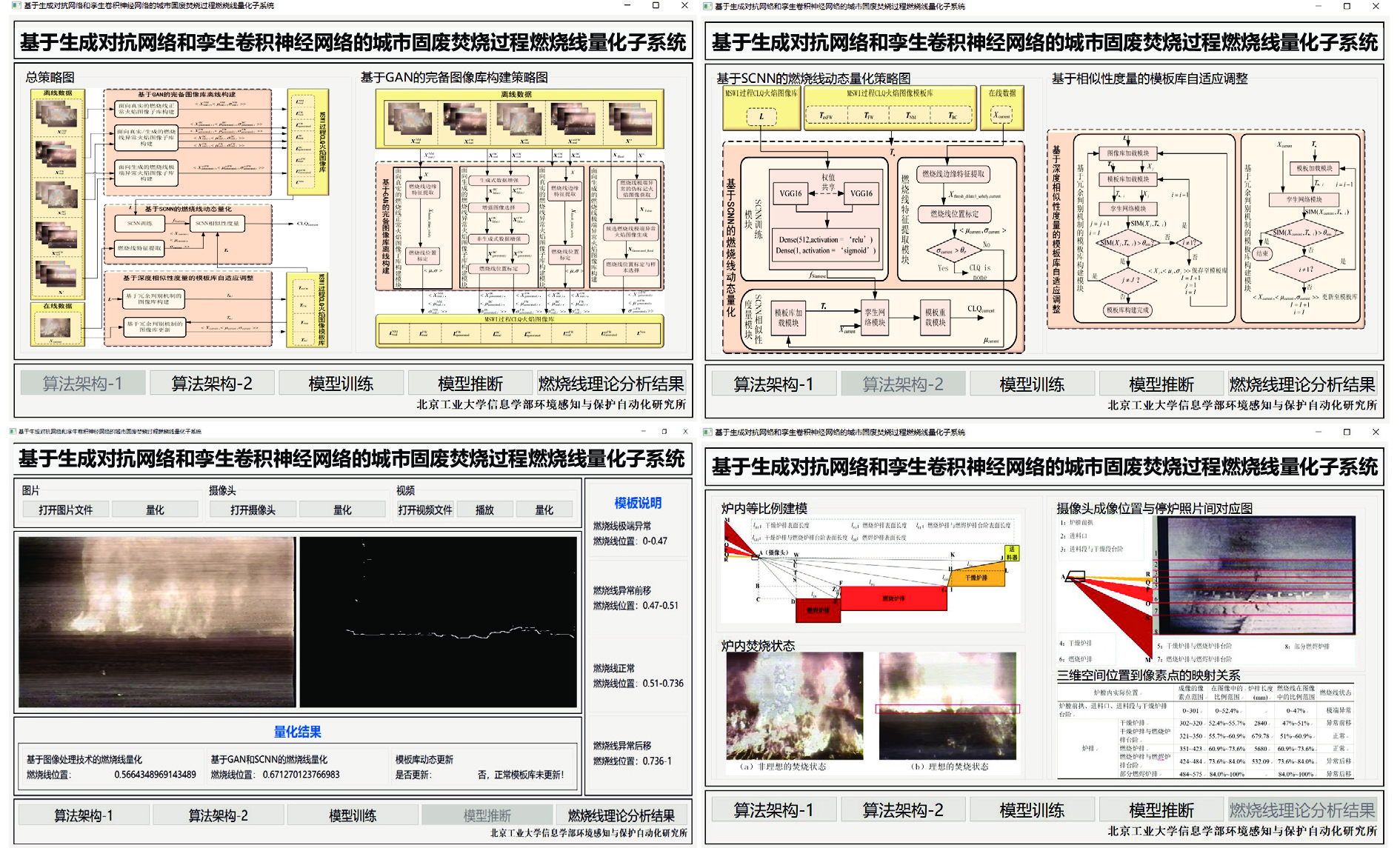

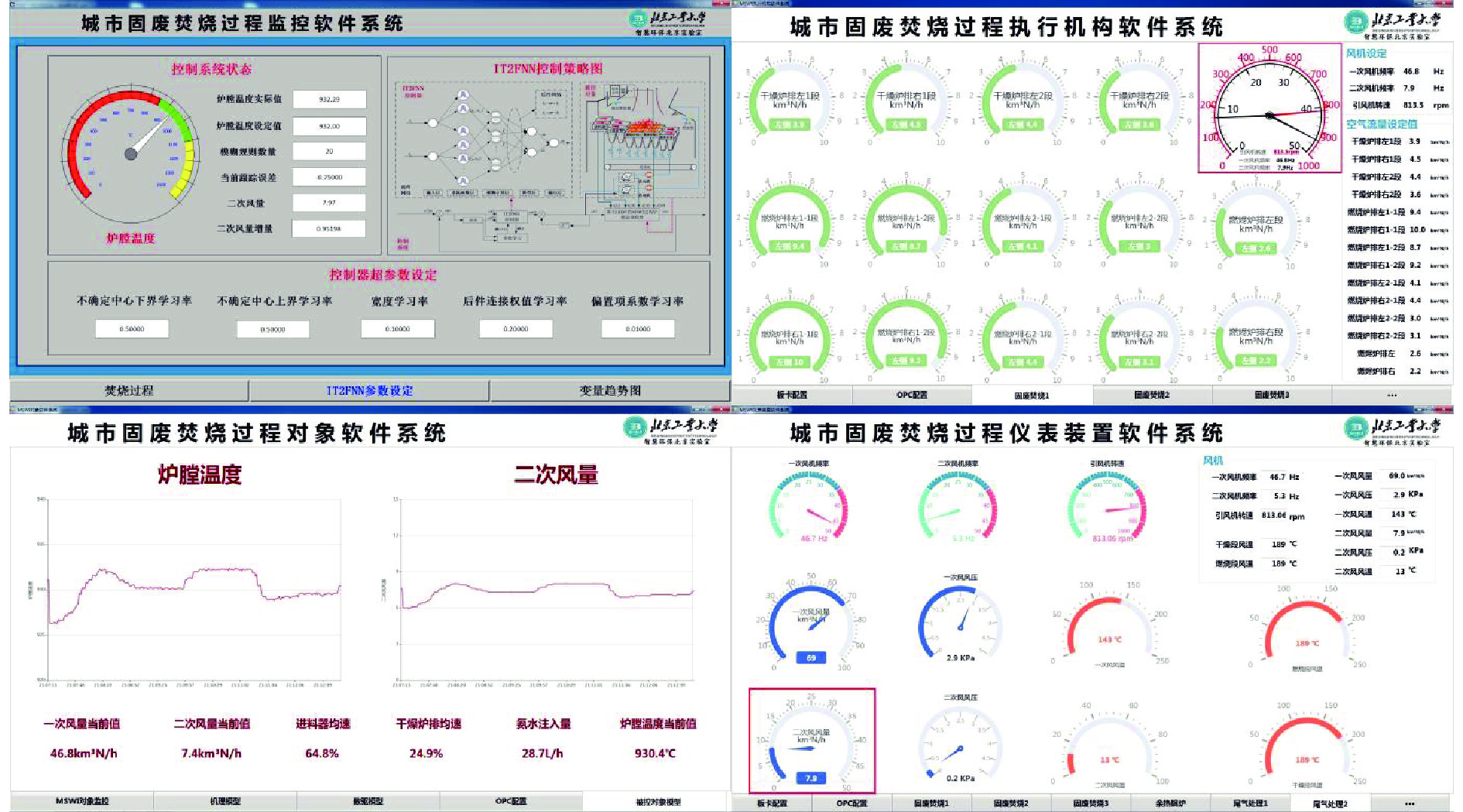

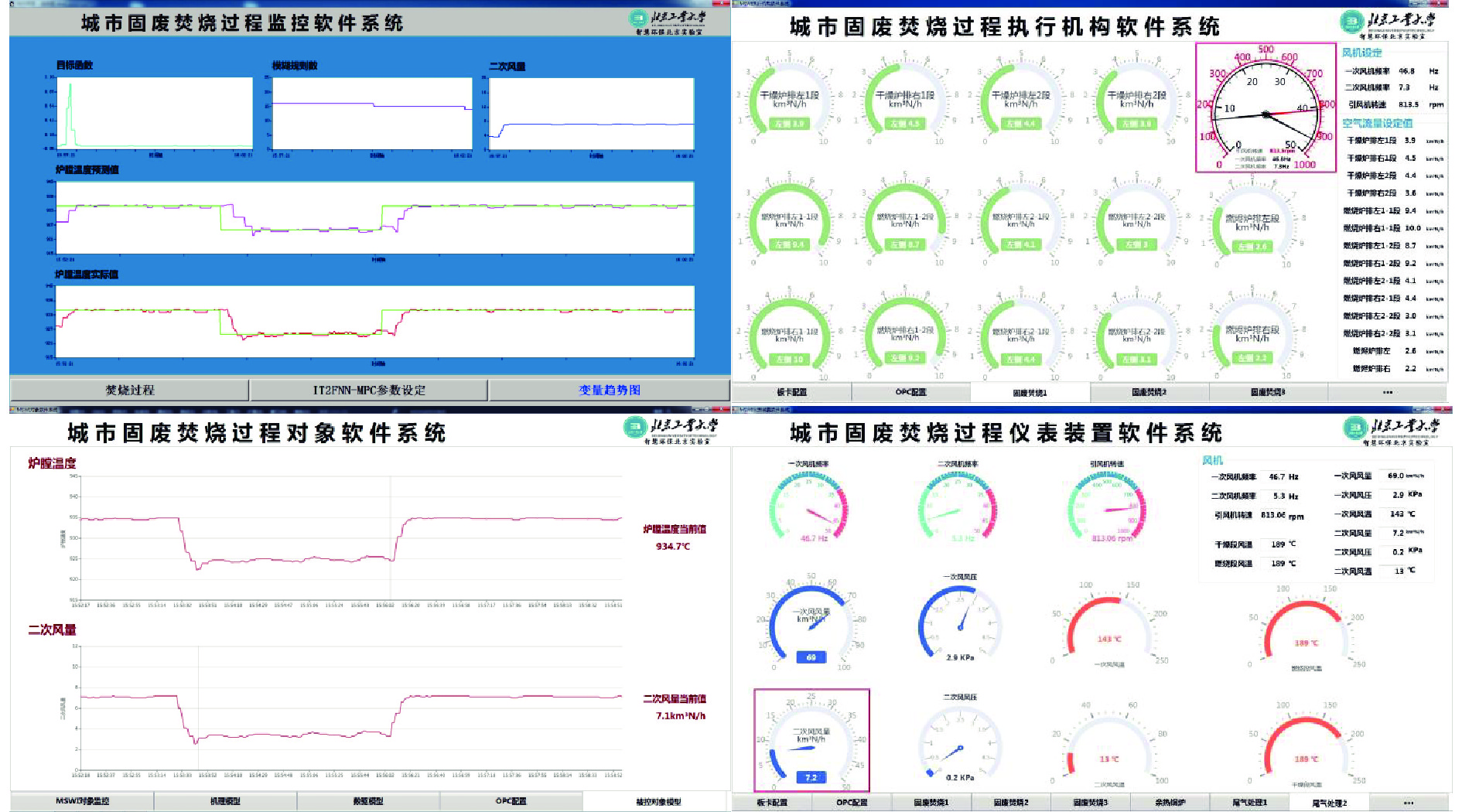

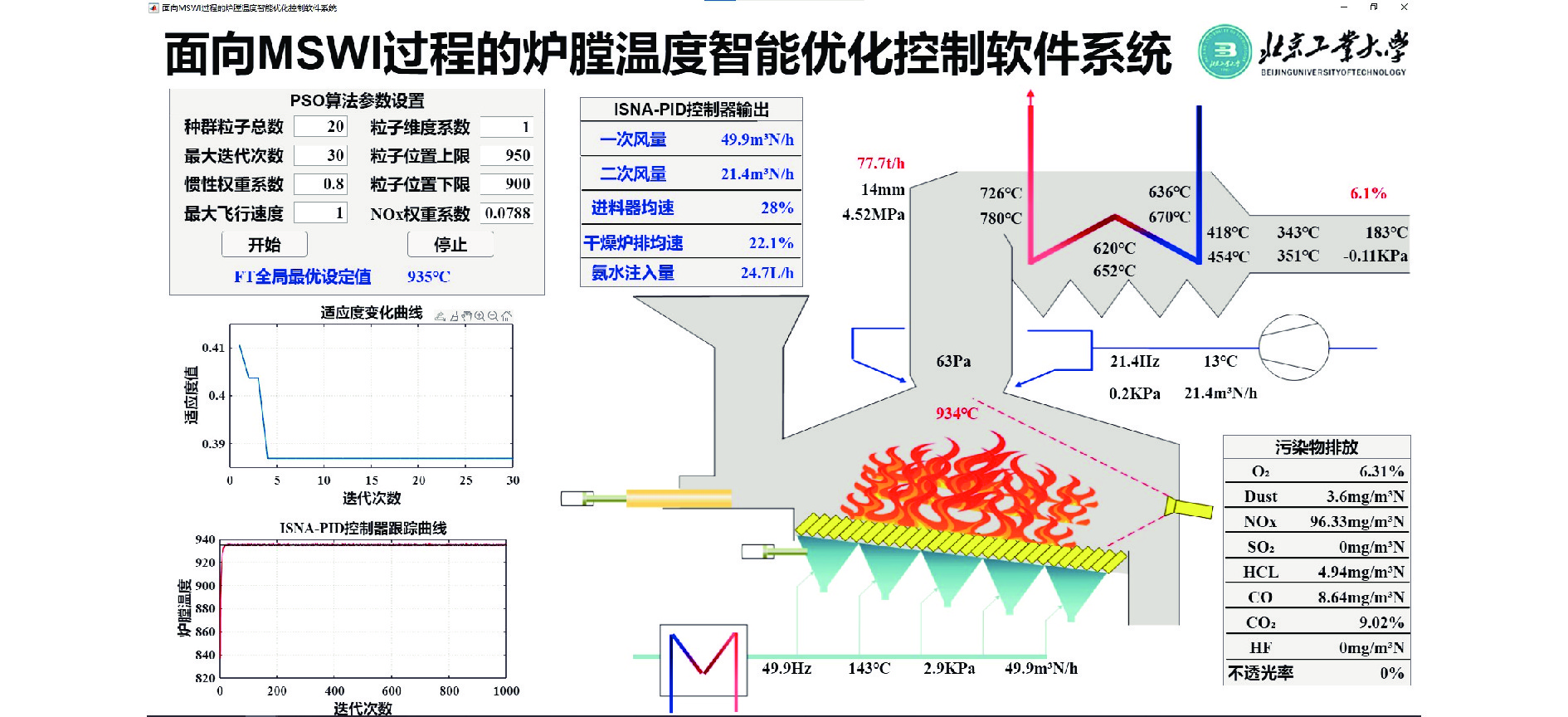

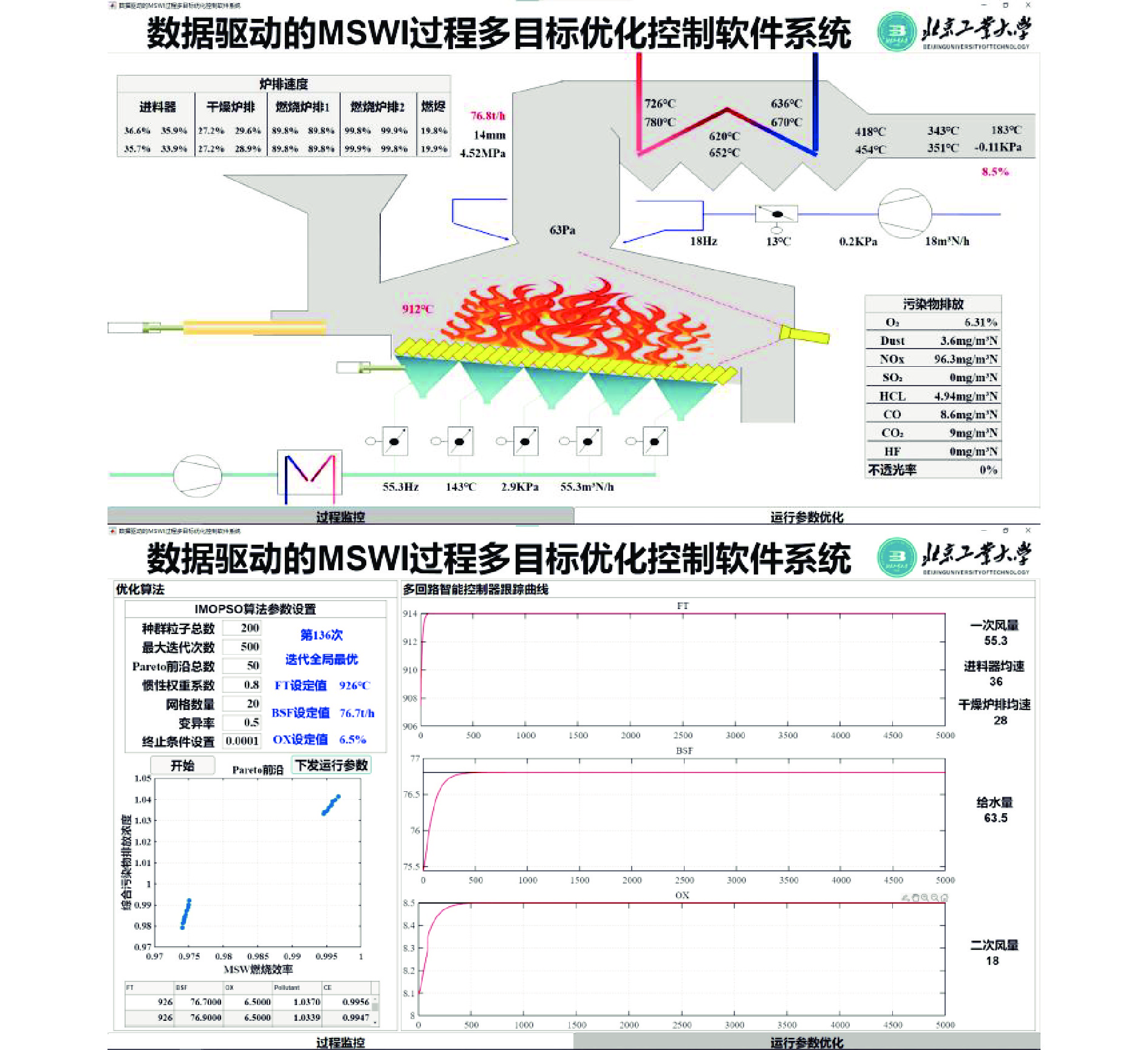

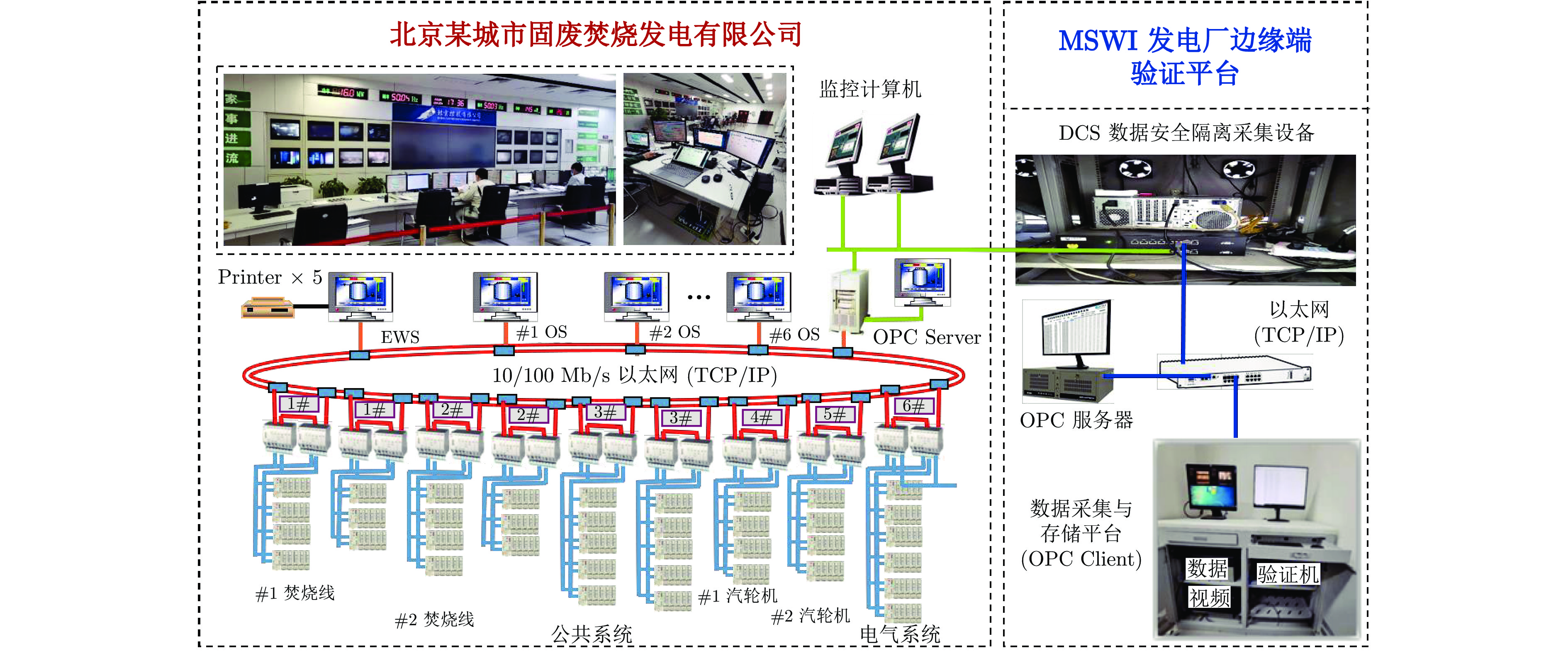

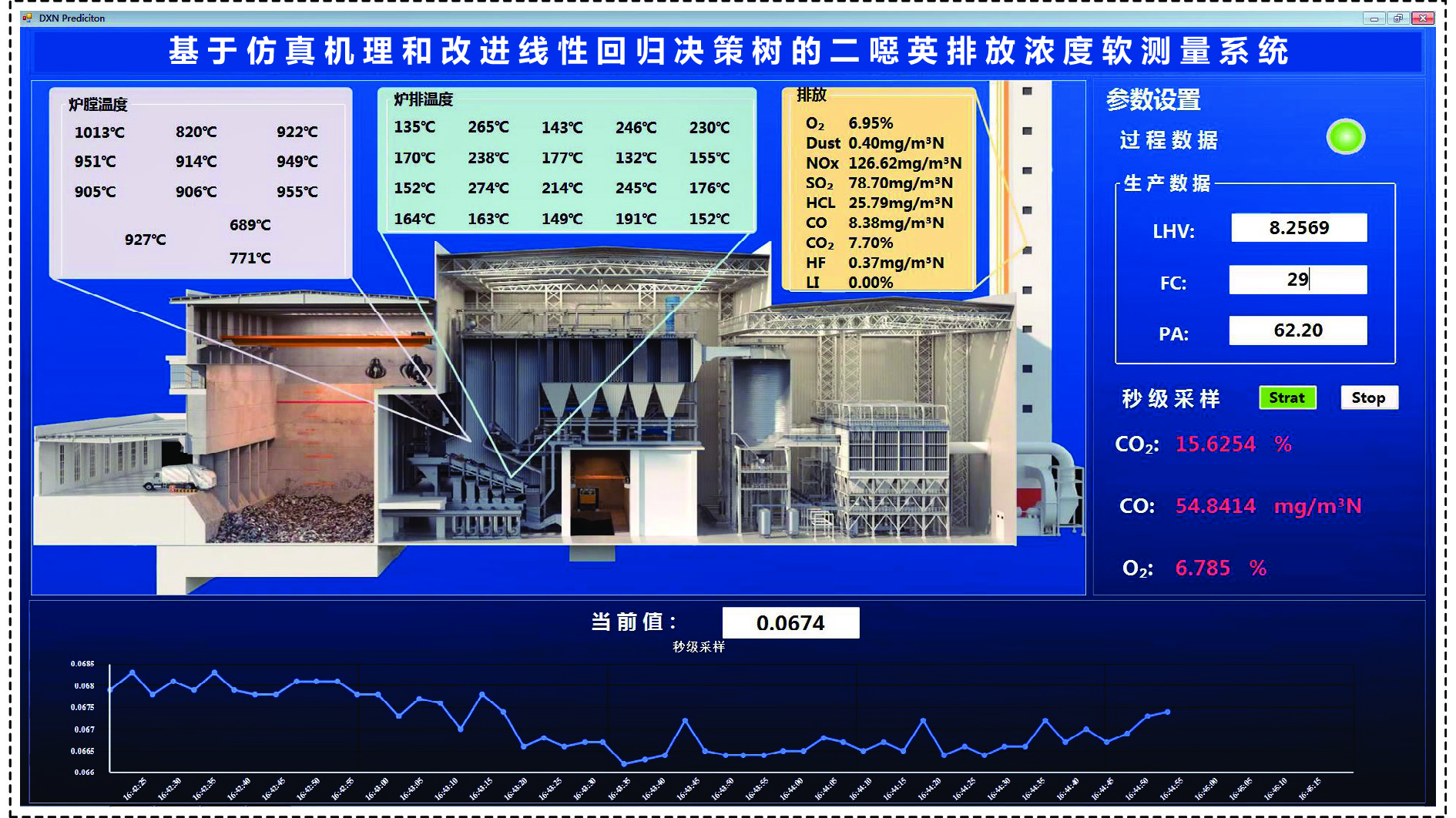

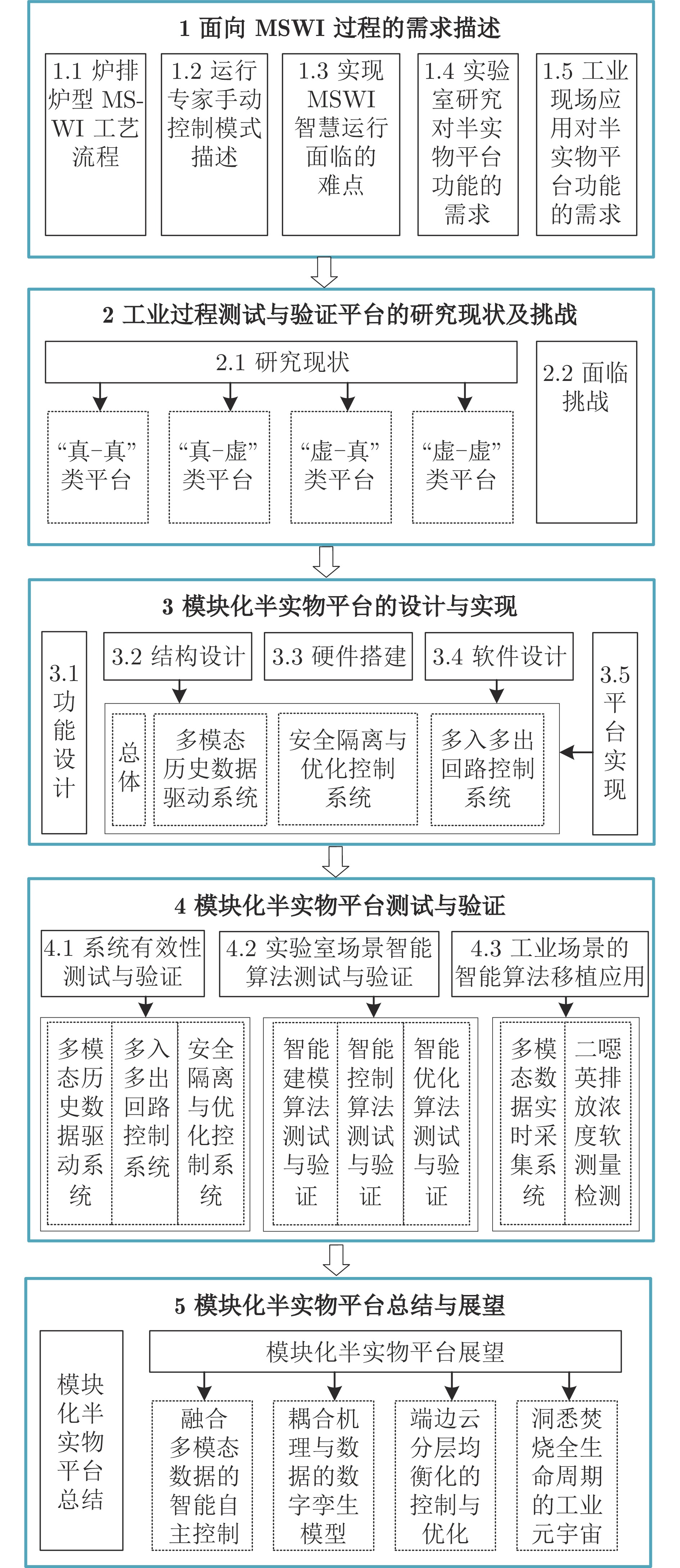

摘要: 城市固废焚烧(Municipal solid waste incineration, MSWI)过程因工业现场的安全要求和控制系统的封闭特性导致离线研究的各类智能算法难以在线验证. 此外, 已有的实验室仿真平台难以模拟领域专家基于多模态数据进行智能感知、认知、决策和控制的工业实际. 针对上述问题, 首先, 在综述现有面向工业过程的仿真平台研究现状和所面临挑战的基础上, 描述面向MSWI过程智能算法测试与验证平台的需求, 提出并构建由多模态历史数据驱动系统、安全隔离与优化控制系统和多入多出回路控制系统组成的模块化半实物平台. 然后, 在实验室环境中完成平台硬件搭建、工业软件开发、仿真功能实现和典型场景验证, 并移植部分模块至工业现场进行应用. 最后, 总结与展望模块化半实物平台的研究方向.Abstract: Due to the safety requirements of industrial sites and the closed characteristics of control systems, intelligent algorithms with off-line research mode are difficult to verify online in municipal solid waste incineration (MSWI) process. In addition, the existing laboratory simulation platform is difficult to simulate the industrial reality of domain experts' intelligent perception, cognition, decision-making and control based on multi-modal data. In view of the above problems, first, on the basis of summarizing the research status and challenge of the existing simulation platform for industrial process, the requirements of testing and verification platform for MSWI process are described. Furthermore, the modular hardware-in-loop platform for intelligent algorithm testing and verification is proposed and constructed, which is composed of multi-modal historical data-driven system, security isolation and optimal control system, and multi-input and multi-output loop control system. Then, the platform hardware construction, industrial software development, simulation function realization and typical scene verification are completed in the laboratory environment, and some modules are transplanted to the industrial site for application. Finally, the research direction of the modular hardware-in-loop platform is summaried and prospected.

-

表 1 各类平台研究现状

Table 1 Research status of different type platforms

平台类型 序号 工业过程类别 单位 年份 文献 特点描述 “真−真” 1 化学水处理工艺流程 华北电力大学 2010年 [40] 作为被控对象的化学水处理系统, 由阳离子、阴离子和混合离子交换器以及除碳器、中间水泵、中间水箱、凝结水换热器、其他辅助设备组成, 并设计电路板控制阀门状态 “真−虚” 2 炼焦生产过程 中南大学 2008年 [45] 以大型钢铁企业焦化厂优化控制系统的机、焦侧火道温度实际运行数据与本系统上模拟运行数据进行比较, 表明了温度稳定良好 3 磨矿生产过程 东北大学 2008年 [46] 以泵池液位和旋流给矿量的控制为例给出控制效果 4 磨矿流程 清华大学 2008年 [47] 基于磨矿分级过程动态模型, 能够正确反映磨机入口给矿、给水等过程控制量变化后的粒度指标动态趋势、重要工艺参数与状态变量(磨矿浓度、分级机溢流浓度、旋流器给矿浓度等)的动态趋势 5 强磁选过程 东北大学 2008年 [48] 基础回路控制系统包括6个独立回路, 能够优化控制精矿品位和尾矿品位在目标范围内 6 蒸发过程 东北大学 2009年 [49] 采用非线性自适应解耦PID控制算法对强制循环蒸发系统进行有效控制 7 电厂烟气脱硫系统 高斯图文印刷系统

(中国)有限公司2010年 [50] 国产自主品牌的DCS分散控制系统, 用于运行人员培训以及对整个脱硫系统设备运行进行分析 8 电熔镁炉 东北大学 2011年 [51] 基于规则推理与案例推理相结合进行智能优化控制实验 9 铝酸钠叶滤过程 东北大学 2011年 [52] 进行叶滤机和阀门的逻辑启停、联锁控制以及叶滤机入口流量、压力等回路控制 10 竖炉焙烧过程 东北大学 2012年 [53] 基于正常和异常工况进行运行优化控制实验, 所采用优化控制方法包括控制回路预设定、前馈、反馈补偿、故障诊断、自愈控制及磁选管回收率软测量等 11 电厂锅炉控制系统 云南大学 2012年 [54] 基于模糊神经网络控制算法进行锅炉出口蒸汽压力实验, 被控对象模型为三入三出传递函数矩阵 12 烧结生产过程 中南大学 2012年 [44] 基于物理/虚拟资源建立云仿真平台, 利用接口层提供系统验证与调试环境, 实现料层厚度解耦控制 13 甲醇生产过程/浮式储油卸油装置 天津理工大学 2014年 [55] 用于模型预测控制、控制系统性能评价与故障诊断等, 为先进过程控制研究提供实施与验证环境 14 黄铜矿浮选过程 东北大学 2014年 [56] 基于回路控制层和优化控制层双网运行控制算法进行不确定丢包情况下的优化控制实验 15 自然循环锅炉系统 云南大学 2016年 [57] 用于顺序逻辑控制和控制策略等模块的调试与验证 16 氧化铝生料浆配料过程 沈阳镁铝设计研究院

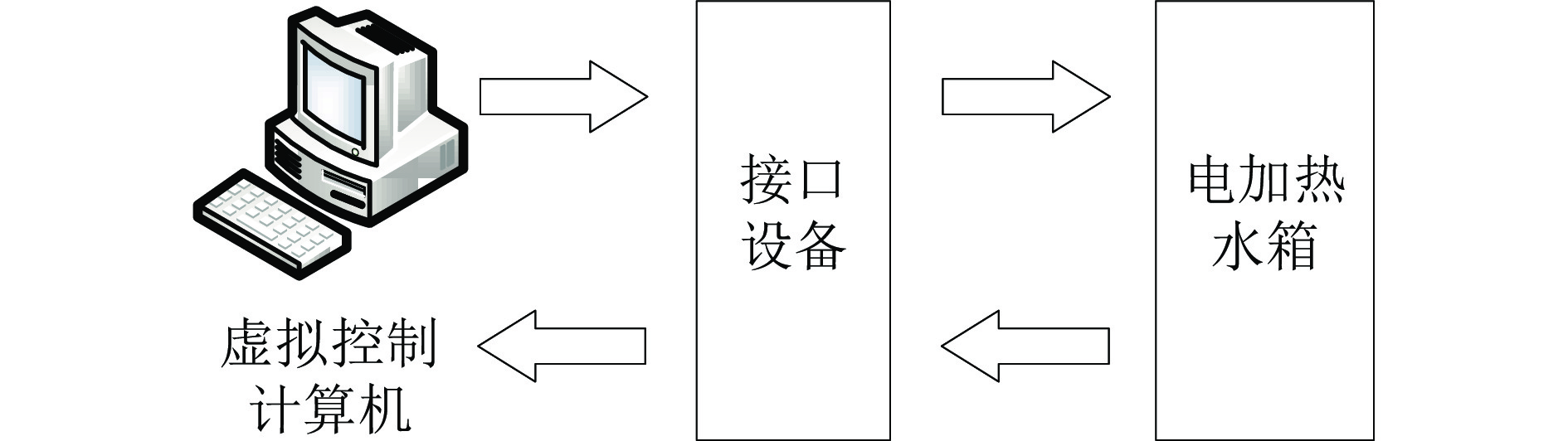

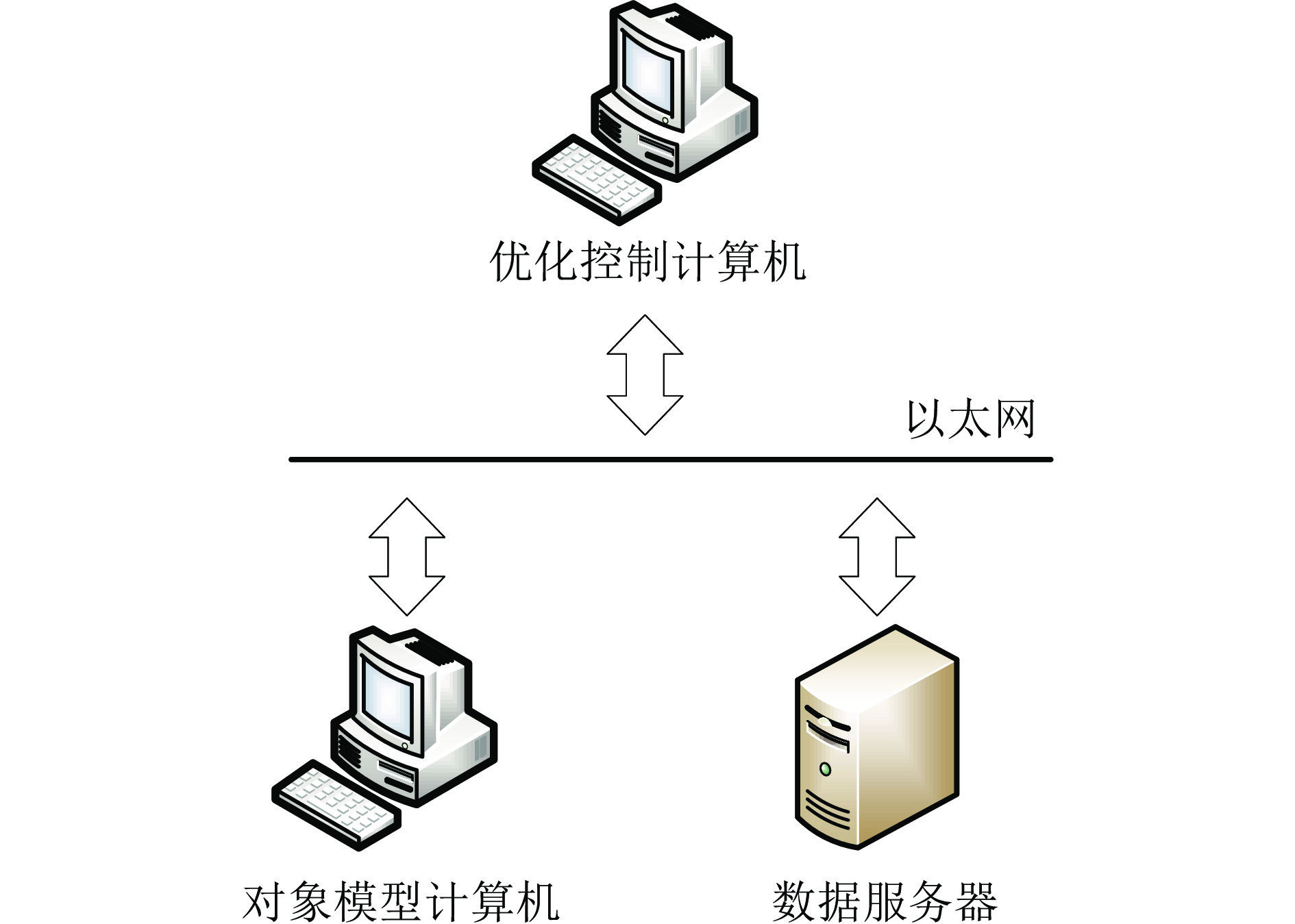

有限公司2017年 [58] 结合了PowerFlex系列变频器, 用于控制系统的调试与开发 17 电厂自动加药系统 长沙理工大学 2018年 [59] 用于现场参数的调试与整定, 炉水模型由Simulink搭建 “虚−真” 18 电加热水箱 华北电力大学 2017年 [42] 真实对象为电加热水箱及其管道回路, 控制器由MATLAB实现, 控制器参数可在线调试 19 风电机组 沈阳工业大学 2020年 [43] 用于教学实验, 能够基于此平台分析不同被控对象特性 “虚−虚” 20 间歇生产过程 上海大学 2011年 [37] 结合MATLAB和WinCC实现, 采用微分形式的机理模型 表 2 平台硬件描述

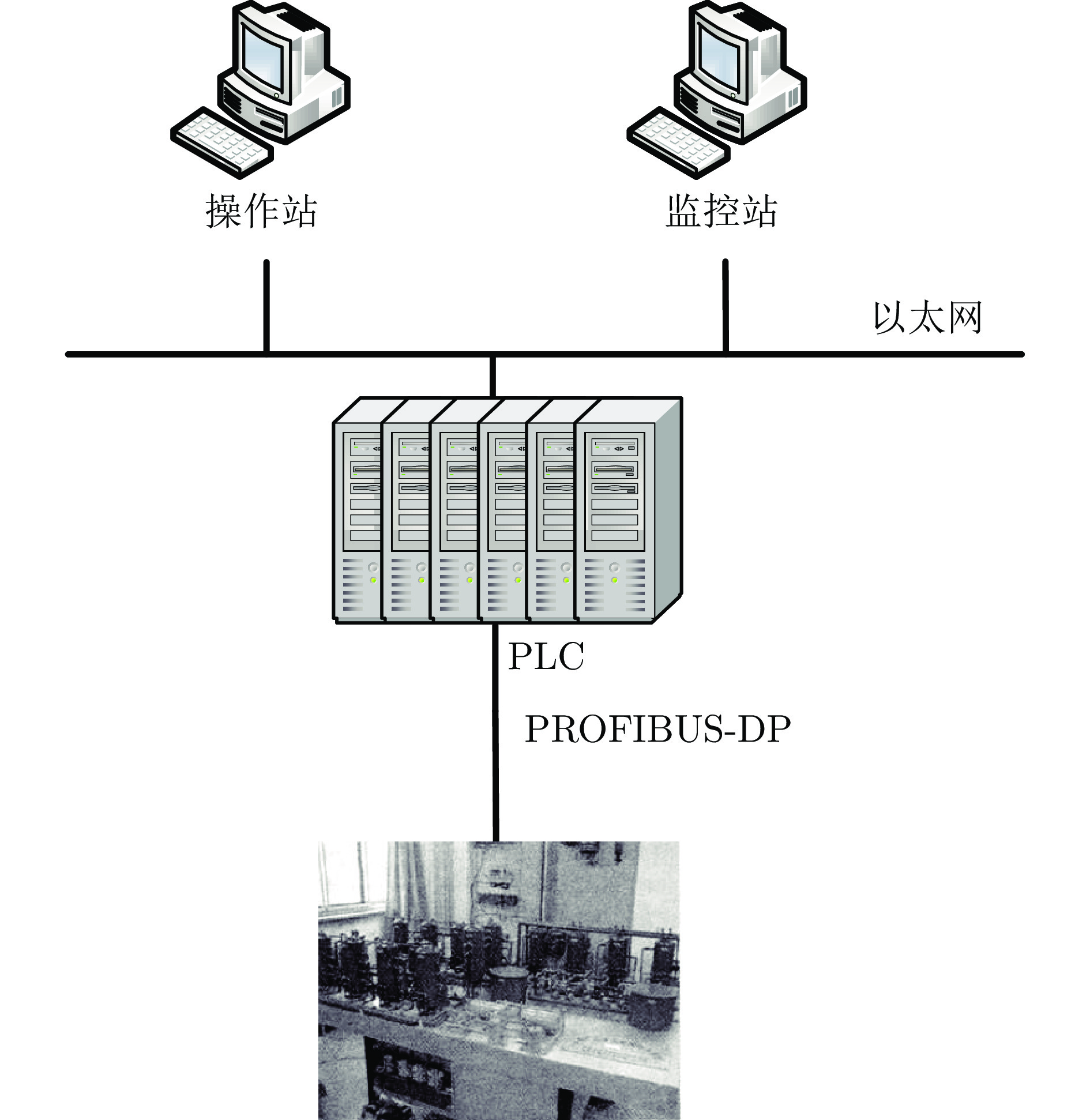

Table 2 Description of platform hardware

设备类型 硬件名称 型号 网络设备 交换机 TP-LINK 16口全千兆交换机TL-SG1016DT 隔离设备 数据采集正向隔离模块 安盟定制式采集装置, 内外网各6个千兆电口, 内外网各128 GB SSD, 内外网主机各1个串口、2个USB口和2U机箱, 主动采集模块、主动发布模块、协议转换模块等, 支持通用工业协议OPC UA/DA、Modbus等 运行参数反向传输模块 辅助设备 PCI板卡 32路隔离模拟量输入PCI-1713U板卡, 32路模拟量输出通道PCI-1724U板卡 摄像头 海康威视红外监控摄像头, DS-2CE16C3T 6 mm 视频采集卡 天创恒达TC-330N4 4路软压缩标清音视频卡 网络时间同步服务器 北斗时讯(天津)科技有限公司BDTS801 基础设备 工控机 研华IPC-610L工控机, 配置Windows7 64位专业版系统 回路控制模块 ABB可编程控制器, 8输入8输出AX522模块、16输出AO523模块、8输入8输出AX522 PLC模块和16输出AO523 PLC模块等 表 3 平台软件描述

Table 3 Description of platform softwares

软件名称 功能描述 Visual Studio Professional 2022 WinForm包含不同功能的控件及触发事件函数, 用于编写和绘制前台软件系统 MATLAB 2022a 通过编写代码实现复杂计算, 同时具备强大GUI设计功能, 利用该软件实现相关算法的开发与GUI界面的设计 Automation Builder 设备制造商和系统集成商构建设备和系统的工程软件套装, 实现回路控制模块的硬件组态程序的编写功能 OPC Server配置软件 模拟实际工业现场中数据点位和平台中新增点位, 实现数据的传输和发布功能 网络时间同步服务器软件 接收卫星时间为计算机授时和同步多模态历史数据驱动系统中各计算机的系统时间 隔离模块配置软件 配置数据采集和传输的OPC Server和相关点位以及调用模块硬件, 实现数据单向传输 -

[1] Gómez-Sanabria A, Kiesewetter G, Klimont Z, Schoepp W, Haberl H. Potential for future reductions of global GHG and air pollutants from circular waste management systems. Nature Communications, 2022, 13(1): Article No. 106 doi: 10.1038/s41467-021-27624-7 [2] 汤健, 夏恒, 余文, 乔俊飞. 城市固废焚烧过程智能优化控制研究现状与展望. 自动化学报, 2023, 49(10): 2019−2059Tang Jian, Xia Heng, Yu Wen, Qiao Jun-Fei. Research status and prospects of intelligent optimization control for municipal solid waste incineration process. Acta Automatica Sinica, 2023, 49(10): 2019−2059 [3] Walser T, Limbach L K, Brogioli R, Erismann E, Flamigni L, Hattendorf B, et al. Persistence of engineered nanoparticles in a municipal solid-waste incineration plant. Nature Nanotechnology, 2012, 7(8): 520−524 doi: 10.1038/nnano.2012.64 [4] Xia H, Tang J, Aljerf L. Dioxin emission prediction based on improved deep forest regression for municipal solid waste incineration process. Chemosphere, 2022, 294: Article No. 133716 doi: 10.1016/j.chemosphere.2022.133716 [5] 乔俊飞, 郭子豪, 汤健. 面向城市固废焚烧过程的二噁英排放浓度检测方法综述. 自动化学报, 2020, 46(6): 1063−1089Qiao Jun-Fei, Guo Zi-Hao, Tang Jian. Dioxin emission concentration measurement approaches for municipal solid wastes incineration process: A survey. Acta Automatica Sinica, 2020, 46(6): 1063−1089 [6] 何汶峰, 郑宇, 刘蓓蓓, 张炳. 垃圾分类政策对垃圾焚烧大气污染排放的影响. 中国环境科学, 2022, 42(5): 2433−2441 doi: 10.3969/j.issn.1000-6923.2022.05.050He Wen-Feng, Zheng Yu, Liu Bei-Bei, Zhang Bing. Effects of garbage classification on air pollutant emissions from garbage incineration. China Environmental Science, 2022, 42(5): 2433−2441 doi: 10.3969/j.issn.1000-6923.2022.05.050 [7] Kumar A, Samadder S R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Management, 2017, 69: 407−422 doi: 10.1016/j.wasman.2017.08.046 [8] Liu Y L, Sun W X, Liu J G. Greenhouse gas emissions from different municipal solid waste management scenarios in China: Based on carbon and energy flow analysis. Waste Management, 2017, 68: 653−661 doi: 10.1016/j.wasman.2017.06.020 [9] Wang T Z, Tang J, Xia H, Aljerf L, Zhang R Y, Tian H, et al. Intelligent optimal control of furnace temperature for the municipal solid waste incineration process using multi-loop controller and particle swarm optimization. Expert Systems With Applications, 2024, 257 : Article No. 125015 [10] Zhuang J B, Tang J, Aljerf L. Comprehensive review on mechanism analysis and numerical simulation of municipal solid waste incineration process based on mechanical grate. Fuel, 2022, 320: Article No. 123826 doi: 10.1016/j.fuel.2022.123826 [11] Kammen D M, Sunter D A. City-integrated renewable energy for urban sustainability. Science, 2016, 352(6288): 922−928 doi: 10.1126/science.aad9302 [12] 国家统计局. 中国统计年鉴. 北京: 中国统计出版社, 2021.National Bureau of Statistics. China Statistical Yearbook. Beijing: China Statistics Press, 2021. [13] Ding H X, Qiao J F, Huang W M, Yu T. Cooperative event-triggered fuzzy-neural multivariable control with multitask learning for municipal solid waste incineration process. IEEE Transactions on Industrial Informatics, 2024, 20(1): 765−774 doi: 10.1109/TII.2023.3264108 [14] Qiao J F, Sun J, Meng X. Event-triggered adaptive model predictive control of oxygen content for municipal solid waste incineration process. IEEE Transactions on Automation Science and Engineering, 2024, 21(1): 463−474 doi: 10.1109/TASE.2022.3227918 [15] Hunsinger H, Jay K, Vehlow J. Formation and destruction of PCDD/F inside a grate furnace. Chemosphere, 2002, 46(9−10): 1263−1272 doi: 10.1016/S0045-6535(01)00256-9 [16] Hershkowitz A, Salerni E. Municipal solid waste incineration in Japan. Environmental Impact Assessment Review, 1989, 9(3): 257−278 doi: 10.1016/0195-9255(89)90008-5 [17] Onishi K. Fuzzy control of municipal refuse incineration plant. Automatic Measurement Control Society, 1991, 27(3): 326−332 [18] Schuler F, Rampp F, Martin J, Wolfrum J. TACCOS-A thermography-assisted combustion control system for waste incinerators. Combustion and Flame, 1994, 99(2): 431−439 doi: 10.1016/0010-2180(94)90150-3 [19] Zipser S, Gommlich A, Matthes J, Keller H B. Combustion plant monitoring and control using infrared and video cameras. IFAC Proceedings Volumes, 2006, 39(7): 249−254 doi: 10.3182/20060625-4-CA-2906.00048 [20] Kaza S, Yao L, Bhada-Tata P, Van Woerden F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Washington: World Bank, 2018. [21] 谷琳, 何坤, 刘海威. 中国生活垃圾焚烧发电项目垃圾热值特性及其影响研究. 见: 中国环境科学学会2022年科学技术年会——环境工程技术创新与应用分会场论文集(3). 南昌, 中国: 《环境工程》编辑部, 2022.Gu Lin, He Kun, Liu Hai-Wei. Study on waste heat value characteristics and its impact on waste incineration power generation project in China. In: Proceedings of the Chinese Society of Environmental Sciences, 2022 Science and Technology Annual Conference——Environmental Engineering Technology Innovation and Application (3). Nanchang, China: Environmental Engineering Branch of Chinese Society of Environmental Sciences: Editorial Department of Environ mental Engineering, 2022. [22] Yamada T, Asari M, Miura T, Niijima T, Yano J, Sakai S I. Municipal solid waste composition and food loss reduction in Kyoto City. Journal of Material Cycles and Waste Management, 2017, 19(4): 1351−1360 doi: 10.1007/s10163-017-0643-z [23] Sun J, Meng X, Qiao J F. Data-driven optimal control for municipal solid waste incineration process. IEEE Transactions on Industrial Informatics, 2023, 19(12): 11444−11454 doi: 10.1109/TII.2023.3246467 [24] 丁海旭, 汤健, 乔俊飞. 城市固废焚烧过程数据驱动建模与自组织控制. 自动化学报, 2023, 49(3): 550−566Ding Hai-Xu, Tang Jian, Qiao Jun-Fei. Data-driven modeling and self-organizing control of municipal solid waste incineration process. Acta Automatica Sinica, 2023, 49(3): 550−566 [25] Liu Y L, Xing P X, Liu J G. Environmental performance evaluation of different municipal solid waste management scenarios in China. Resources, Conservation and Recycling, 2017, 125: 98−106 doi: 10.1016/j.resconrec.2017.06.005 [26] Meng X, Tang J, Qiao J F. NOx emissions prediction with a brain-inspired modular neural network in municipal solid waste incineration processes. IEEE Transactions on Industrial Informatics, 2022, 18(7): 4622−4631 doi: 10.1109/TII.2021.3116528 [27] 郑南宁. 软件不再是单一的工具, 而是一个个强大的平台, 支撑着整个工业生态. 冶金自动化, 2023, 47 (6): 56Zheng Nan-Ning. Software is no longer a single tool, but a powerful platform that supports the entire industrial ecosystem. Mentallurgical Industrial Automation, 2023, 47 (6): 56 [28] 杨超, 彭涛, 阳春华, 陈志文, 桂卫华. 高速列车牵引传动系统故障测试与验证仿真平台研究. 自动化学报, 2019, 45(12): 2218−2232Yang Chao, Peng Tao, Yang Chun-Hua, Chen Zhi-Wen, Gui Wei-Hua. Fault testing and validation simulation platform for traction drive system of high-speed trains. Acta Automatica Sinica, 2019, 45(12): 2218−2232 [29] 柴天佑. 工业人工智能发展方向. 自动化学报, 2020, 46(10): 2005−2012Chai Tian-You. Development directions of industrial artificial intelligence. Acta Automatica Sinica, 2020, 46(10): 2005−2012 [30] Zhou P, Gao B H, Wang S, Chai T Y. Identification of abnormal conditions for fused magnesium melting process based on deep learning and multisource information fusion. IEEE Transactions on Industrial Electronics, 2022, 69(3): 3017−3026 doi: 10.1109/TIE.2021.3070512 [31] Xia H, Tang J, Aljerf L, Cui C L, Gao B Y, Ukaogo P O. Dioxin emission modeling using feature selection and simplified DFR with residual error fitting for the grate-based MSWI process. Waste Management, 2023, 168: 256−271 doi: 10.1016/j.wasman.2023.05.056 [32] Xia H, Tang J, Aljerf L, Wang T Z, Gao B Y, Xu Q D, et al. Assessment of PCDD/Fs formation and emission characteristics at a municipal solid waste incinerator for one year. Science of the Total Environment, 2023, 883: Article No. 163705 doi: 10.1016/j.scitotenv.2023.163705 [33] 柴天佑. 复杂工业过程运行优化与反馈控制. 自动化学报, 2013, 39(11): 1744−1757 doi: 10.3724/SP.J.1004.2013.01744Chai Tian-You. Operational optimization and feedback control for complex industrial processes. Acta Automatica Sinica, 2013, 39(11): 1744−1757 doi: 10.3724/SP.J.1004.2013.01744 [34] Sahin C, Bolat E D. Development of remote control and monitoring of web-based distributed OPC system. Computer Standards & Interfaces, 2009, 31(5): 984−993 [35] 翟廉飞, 柴天佑, 高忠江, 岳恒. 制粉系统智能解耦控制的分布式仿真实验平台. 系统仿真学报, 2006, 18(7): 1824−1828 doi: 10.3969/j.issn.1004-731X.2006.07.023Zhai Lian-Fei, Chai Tian-You, Gao Zhong-Jiang, Yue Heng. A distributed simulation platform for intelligent decoupling control of coal pulverizing systems. Journal of System Simulation, 2006, 18(7): 1824−1828 doi: 10.3969/j.issn.1004-731X.2006.07.023 [36] 肖金壮, 魏会然, 王洪瑞, 张伟. 基于Q8的电阻炉控制系统的半实物仿真. 系统仿真学报, 2008, 20(5): 1196−1198Xiao Jin-Zhuang, Wei Hui-Ran, Wang Hong-Rui, Zhang Wei. Hardware-in-the-loop simulation of furnace temperature control system based on Q8 card. Journal of System Simulation, 2008, 20(5): 1196−1198 [37] 贾立, 袁凯. 间歇生产过程优化控制的分布式仿真平台. 系统仿真学报, 2011, 23(10): 2254−2257Jia Li, Yuan Kai. Distributed simulation platform for optimization control of batch processes. Journal of System Simulation, 2011, 23(10): 2254−2257 [38] 阳春华, 孙备, 李勇刚, 黄科科, 桂卫华. 复杂生产流程协同优化与智能控制. 自动化学报, 2023, 49(3): 528−539Yang Chun-Hua, Sun Bei, Li Yong-Gang, Huang Ke-Ke, Gui Wei-Hua. Cooperative optimization and intelligent control of complex production processes. Acta Automatica Sinica, 2023, 49(3): 528−539 [39] 汤健, 柴天佑, 片锦香, 岳恒. 工业过程智能优化控制半实物仿真实验平台. 东北大学学报(自然科学版), 2009, 30(11): 1530−1533 doi: 10.3321/j.issn:1005-3026.2009.11.003Tang Jian, Chai Tian-You, Pian Jin-Xiang, Yue Heng. A hardware-in-the-loop simulation platform for optimized intelligent control of industrial process. Journal of Northeastern University (Natural Science), 2009, 30(11): 1530−1533 doi: 10.3321/j.issn:1005-3026.2009.11.003 [40] 赵珊珊, 白焰, 黄从智. 化学水处理系统的半物理仿真. 化工自动化及仪表, 2010, 37(1): 79−84 doi: 10.3969/j.issn.1000-3932.2010.01.023Zhao Shan-Shan, Bai Yan, Huang Cong-Zhi. Semi-physical simulation of chemical water treatment system. Control and Instruments in Chemical Industry, 2010, 37(1): 79−84 doi: 10.3969/j.issn.1000-3932.2010.01.023 [41] 片锦香, 柴天佑, 贾树晋, 岳恒. 层流冷却系统过程优化控制仿真实验平台. 系统仿真学报, 2007, 19(24): 5667−5671 doi: 10.3969/j.issn.1004-731X.2007.24.016Pian Jin-Xiang, Chai Tian-You, Jia Shu-Jin, Yue Heng. Simulation platform for optimal control of laminar cooling system. Journal of System Simulation, 2007, 19(24): 5667−5671 doi: 10.3969/j.issn.1004-731X.2007.24.016 [42] 马平, 王凯宸, 李紫君. 基于半实物仿真平台的温度控制系统设计. 实验科学与技术, 2017, 15(5): 10−14 doi: 10.3969/j.issn.1672-4550.2017.05.003Ma Ping, Wang Kai-Chen, Li Zi-Jun. Design of temperature control system using semi-physical simulation platform. Experiment Science and Technology, 2017, 15(5): 10−14 doi: 10.3969/j.issn.1672-4550.2017.05.003 [43] 颜宁, 张冠锋, 满林坤, 马少华, 赵海川. 基于RT-LAB半实物仿真平台的风电机组一次调频实验方法研究. 实验技术与管理, 2020, 37(11): 226−229Yan Ning, Zhang Guan-Feng, Man Lin-Kun, Ma Shao-Hua, Zhao Hai-Chuan. Research on primary frequency regulation experimental method of wind turbine based on RT-LAB semi-physical simulation platform. Experimental Technology and Management, 2020, 37(11): 226−229 [44] 熊永华, 许虎, 吴敏, 赖旭芝. 一种烧结生产过程控制云制造仿真实验平台. 计算机集成制造系统, 2012, 18(7): 1627−1636Xiong Yong-Hua, Xu Hu, Wu Min, Lai Xu-Zhi. Cloud manafacturing simulation platform for sintering production process control. Computer Integrated Manufacturing Systems, 2012, 18(7): 1627−1636 [45] 李可夫, 吴敏, 雷琪. 炼焦生产全流程优化控制实验平台设计与开发. 计算技术与自动化, 2008, 27(4): 48−53 doi: 10.3969/j.issn.1003-6199.2008.04.012Li Ke-Fu, Wu Min, Lei Qi. Design on simulation platform aimed to the intelligent integrated optimizing control for whole coking process. Computing Technology and Automation, 2008, 27(4): 48−53 doi: 10.3969/j.issn.1003-6199.2008.04.012 [46] 迟瑛, 岳恒, 丁进良, 汤健. 磨矿仿真实验平台的设计和实现. 控制工程, 2008, 15(5): 598−601 doi: 10.3969/j.issn.1671-7848.2008.05.032Chi Ying, Yue Heng, Ding Jin-Liang, Tang Jian. Design and implementation of the simulation experiment for grinding process. Control Engineering of China, 2008, 15(5): 598−601 doi: 10.3969/j.issn.1671-7848.2008.05.032 [47] 铁鸣, 范玉顺, 柴天佑. 磨矿流程优化控制的分布式仿真平台. 系统仿真学报, 2008, 20(15): 4000−4005Tie Ming, Fan Yu-Shun, Chai Tian-You. Distributed simulation platform for optimizing control of mineral grinding process. Journal of System Simulation, 2008, 20(15): 4000−4005 [48] 刘卓, 刘金礼, 刘建昌. 强磁选过程智能优化控制仿真实验平台. 控制工程, 2008, 15(S1): 155−158Liu Zhuo, Liu Jin-Li, Liu Jian-Chang. Intelligent optimizing control simulation experiment platform for the high intensity magnetic separation process. Control Engineering of China, 2008, 15(S1): 155−158 [49] 王永刚, 柴天佑. 蒸发过程的解耦控制仿真实验平台. 系统仿真学报, 2009, 21(18): 5812−5815Wang Yong-Gang, Chai Tian-You. Distributed simulation platform for decoupling control of evaporation process. Journal of System Simulation, 2009, 21(18): 5812−5815 [50] 黄昕昀. 电厂烟气脱硫控制系统半实物仿真平台. 电气自动化, 2010, 32(6): 28−29 doi: 10.3969/j.issn.1000-3886.2010.06.010Huang Xin-Yun. Semi-physical simulation platform on flue gas desulfurization control system. Electrical Automation, 2010, 32(6): 28−29 doi: 10.3969/j.issn.1000-3886.2010.06.010 [51] 吴永建, 吴志伟, 张莉, 岳恒, 柴天佑. 电熔镁炉智能优化仿真实验平台. 系统仿真学报, 2011, 23(4): 676−680Wu Yong-Jian, Wu Zhi-Wei, Zhang Li, Yue Heng, Chai Tian-You. Simulation platform for intelligent optimization control of electric-fused magnesia furnace. Journal of System Simulation, 2011, 23(4): 676−680 [52] 李健, 岳恒, 郭向红, 柴天佑. 铝酸钠叶滤过程控制仿真实验平台. 化工学报, 2011, 62(8): 2089−2094 doi: 10.3969/j.issn.0438-1157.2011.08.001Li Jian, Yue Heng, Guo Xiang-Hong, Chai Tian-You. Simulation experiment platform for sodium aluminates solution filtrating process. CIESC Journal, 2011, 62(8): 2089−2094 doi: 10.3969/j.issn.0438-1157.2011.08.001 [53] 周平, 代伟, 柴天佑. 竖炉焙烧过程运行优化控制系统的开发及实验研究. 控制理论与应用, 2012, 29(12): 1565−1572Zhou Ping, Dai Wei, Chai Tian-You. Exploration of operational optimization control system for shaft furnace roasting process and its experiment study. Control Theory & Applications, 2012, 29(12): 1565−1572 [54] 李鹏, 孙鹤, 张健, 洪建武, 曹敏. 电厂锅炉燃烧系统先进过程控制实验仿真平台. 计算机与应用化学, 2012, 29(10): 1216−1220 doi: 10.3969/j.issn.1001-4160.2012.10.014Li Peng, Sun He, Zhang Jian, Hong Jian-Wu, Cao Min. Advanced process control simulation platform for combustion system of boiler in power plant. Computers and Applied Chemistry, 2012, 29(10): 1216−1220 doi: 10.3969/j.issn.1001-4160.2012.10.014 [55] 高强, 李航, 高翔, 赵洪业, 吴楠. 一种用于先进过程控制研究的半实物仿真系统. 自动化与仪表, 2014, 29(2): 28−32 doi: 10.3969/j.issn.1001-9944.2014.02.008Gao Qiang, Li Hang, Gao Xiang, Zhao Hong-Ye, Wu Nan. Hardware-in-the-loop simulation system for advanced process control research. Automation & Instrumentation, 2014, 29(2): 28−32 doi: 10.3969/j.issn.1001-9944.2014.02.008 [56] Zhang Y W, Fan J L, Jiang Y, Wang L. Semi-physical simulation platform for double layer network-based operational control. In: Proceedings of the 11th World Congress on Intelligent Control and Automation. Shenyang, China: IEEE, 2014. 1118−1123 [57] 唐国泽, 李鹏, 任文平, 董吉开, 王江. 自然循环锅炉控制系统半实物仿真平台设计. 控制工程, 2016, 23(6): 933−936Tang Guo-Ze, Li Peng, Ren Wen-Ping, Dong Ji-Kai, Wang Jiang. Design of semi physical simulation platform for control of the natural circulation boiler. Control Engineering of China, 2016, 23(6): 933−936 [58] 李天庆. 生料浆配料过程控制系统及半实物仿真实验平台设计. 轻金属, 2017, (2): 58−62Li Tian-Qing. Design of the control system and hardware-in-loop simulation experiment platform for the raw slurry blending process. Light Metals, 2017, (2): 58−62 [59] 冯佳瑶, 乔越, 贺慧勇, 蔡启祥, 宋章明. 电厂加药系统半实物仿真平台设计. 天水师范学院学报, 2018, 38(2): 37−39 doi: 10.3969/j.issn.1671-1351.2018.02.011Feng Jia-Yao, Qiao Yue, He Hui-Yong, Cai Qi-Xiang, Song Zhang-Ming. Design of semi-physical simulation platform for dosing system in power plant. Journal of Tianshui Normal University, 2018, 38(2): 37−39 doi: 10.3969/j.issn.1671-1351.2018.02.011 [60] 王天峥, 汤健, 夏恒, 潘晓彤, 乔俊飞, 刘溪芷. 多模态数据驱动的城市固废焚烧过程验证平台设计与实现. 中国电机工程学报, 2023, 43(12): 4697−4707Wang Tian-Zheng, Tang Jian, Xia Heng, Pan Xiao-Tong, Qiao Jun-Fei, Liu Xi-Zhi. Design and implementation of multi-modal data-driven verification platform for municipal solid waste incineration process. Proceedings of the CSEE, 2023, 43(12): 4697−4707 [61] 王天峥, 汤健, 夏恒, 乔俊飞. 城市固废焚烧过程的回路控制半实物仿真平台. 系统仿真学报, 2023, 35(2): 241−253Wang Tian-Zheng, Tang Jian, Xia Heng, Qiao Jun-Fei. Hardware-in-the-loop simulation platform of loop control for municipal solid waste incineration process. Journal of System Simulation, 2023, 35(2): 241−253 [62] 郭帆, 白文涛, 黄彪. 输出相关的变分自编码器的实时软传感器建模缺失数据. 过程控制学报, 2020, 92: 90−97 doi: 10.1016/j.jprocont.2020.05.012Guo Fan, Bai Wen-Tao, Huang Biao. Output-relevant variational autoencoder for just-in-time soft sensor modeling with missing data. Journal of Process Control, 2020, 92: 90−97 doi: 10.1016/j.jprocont.2020.05.012 [63] Cui C L, Tang J, Xia H, Yu W, Qiao J F. Multiscale modeling using GAN and deep forest regression with application to dioxin emission soft sensor. IEEE Transactions on Instrumentation and Measurement, 2023, 72: Article No. 2526813 [64] 柴天佑, 程思宇, 李平, 贾瑶, 郑锐. 端边云协同的复杂工业过程运行控制智能系统. 控制与决策, 2023, 38(8): 2051−2062Chai Tian-You, Cheng Si-Yu, Li Ping, Jia Yao, Zheng Rui. Intelligent system for operational control of complex industrial process based on end-edge-cloud collaboration. Control and Decision, 2023, 38(8): 2051−2062 [65] 柴天佑. 工业人工智能与工业互联网协同实现生产过程智能化及其未来展望. 控制工程, 2023, 30(8): 1378−1388Chai Tian-You. Industrial AI and industrial internet collaboratively achieving production process intelligence and its future perspectives. Control Engineering of China, 2023, 30(8): 1378−1388 [66] Xiang W, Yu K, Han F L, Fang L, He D H, Han Q L. Advanced manufacturing in Industry 5.0: A survey of key enabling technologies and future trends. IEEE Transactions on Industrial Informatics, 2024, 20(2): 1055−1068 doi: 10.1109/TII.2023.3274224 [67] Mogaji E, Wirtz J, Belk R W, Dwivedi Y K. Immersive time (ImT): Conceptualizing time spent in the metaverse. International Journal of Information Management, 2023, 72: Article No. 102659 doi: 10.1016/j.ijinfomgt.2023.102659 [68] Dolgui A, Ivanov D. Metaverse supply chain and operations management. International Journal of Production Research, 2023, 61(23): 8179−8191 doi: 10.1080/00207543.2023.2240900 [69] Guendouzi B S, Ouchani S, El Assaad H, El Zaher M. A systematic review of federated learning: Challenges, aggregation methods, and development tools. Journal of Network and Computer Applications, 2023, 220: Article No. 103714 doi: 10.1016/j.jnca.2023.103714 [70] Yang W, Xiang W, Yang Y, Cheng P. Optimizing federated learning with deep reinforcement learning for digital twin empowered industrial IoT. IEEE Transactions on Industrial Informatics, 2023, 19(2): 1884−1893 doi: 10.1109/TII.2022.3183465 [71] Wang J G, Tian Y L, Wang Y T, Yang J, Wang X X, Wang S J, et al. A framework and operational procedures for metaverses-based industrial foundation models. IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2023, 53(4): 2037−2046 doi: 10.1109/TSMC.2022.3226755 -

下载:

下载: