Converter Steelmaking Oxygen Consumption Prediction Based on Granularity Clustering

-

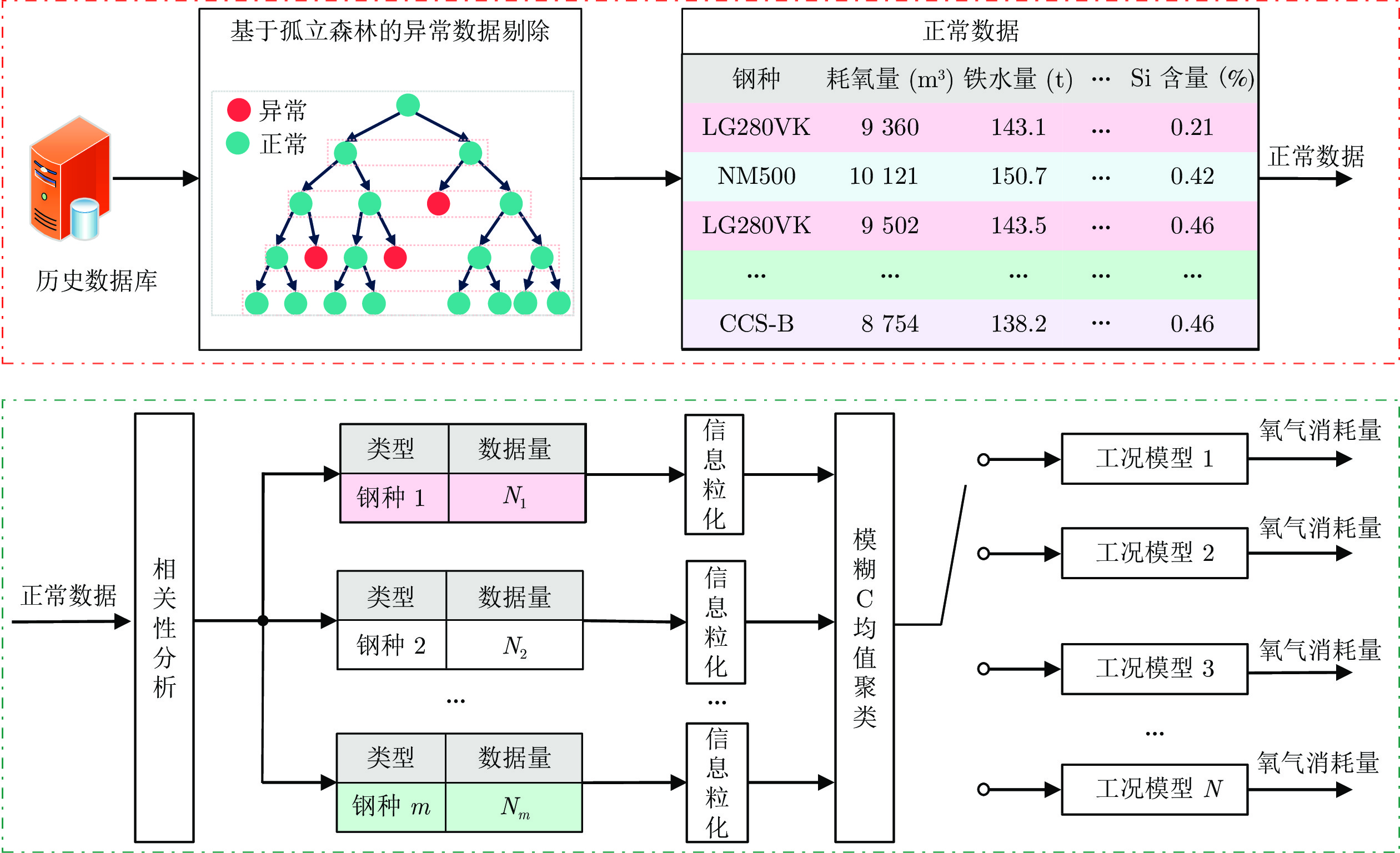

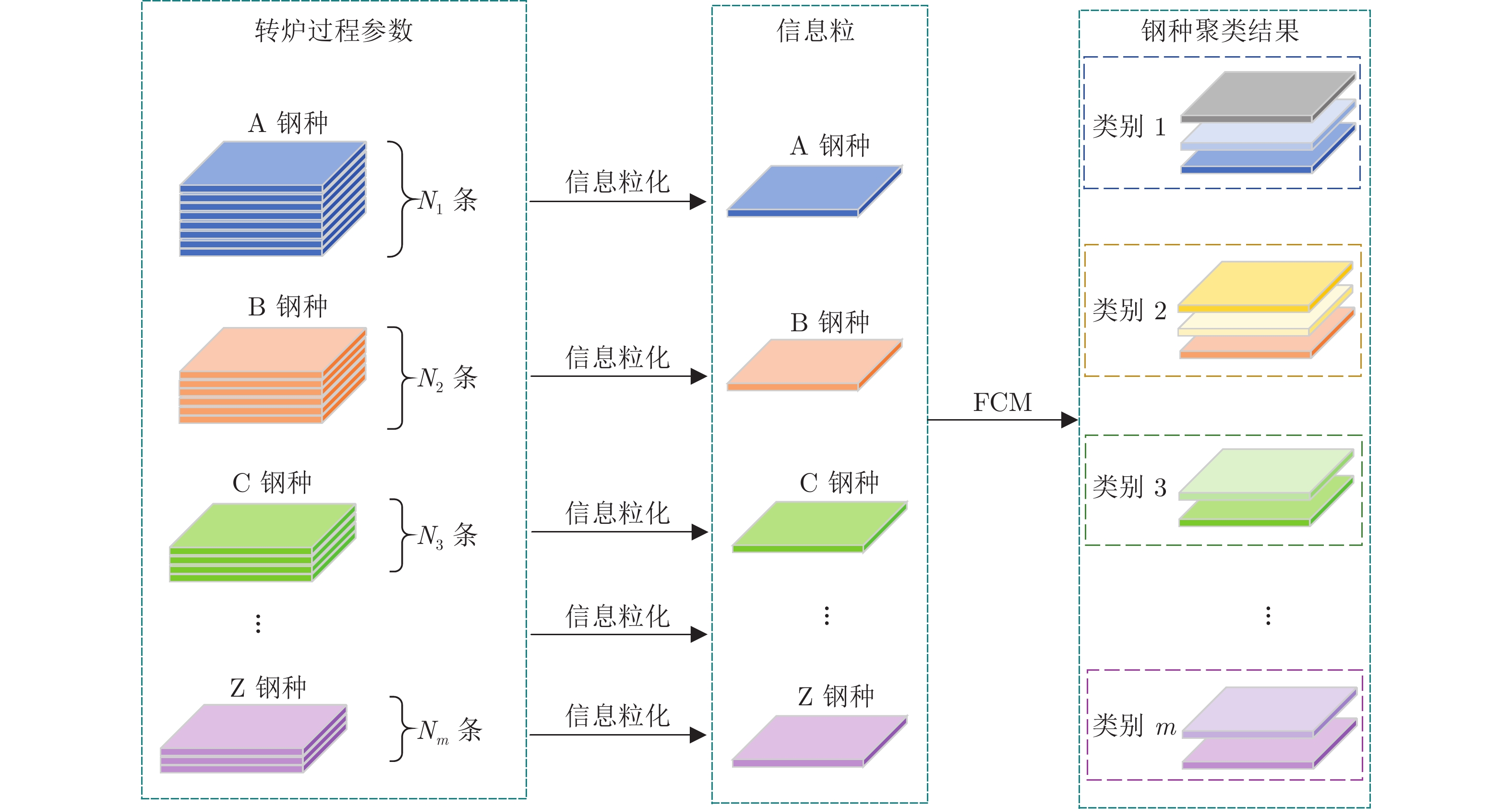

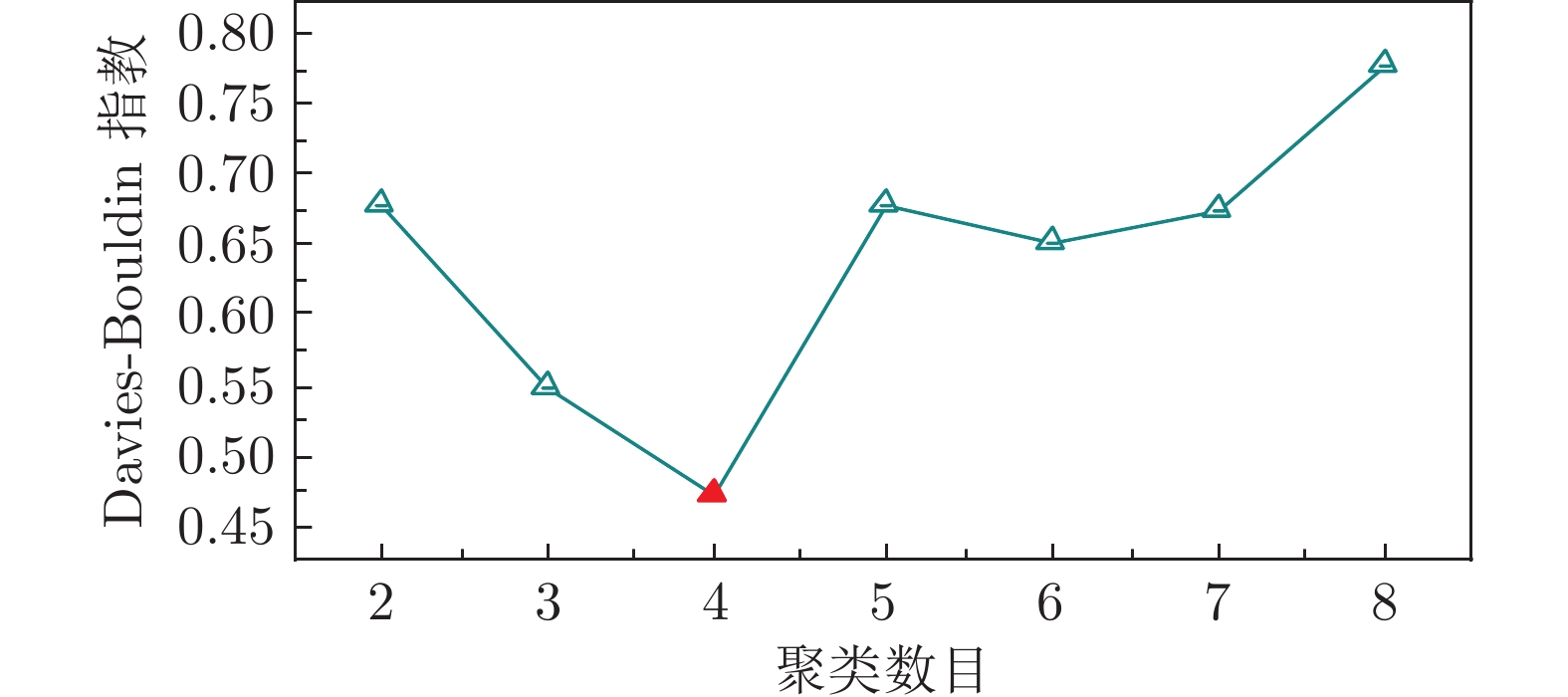

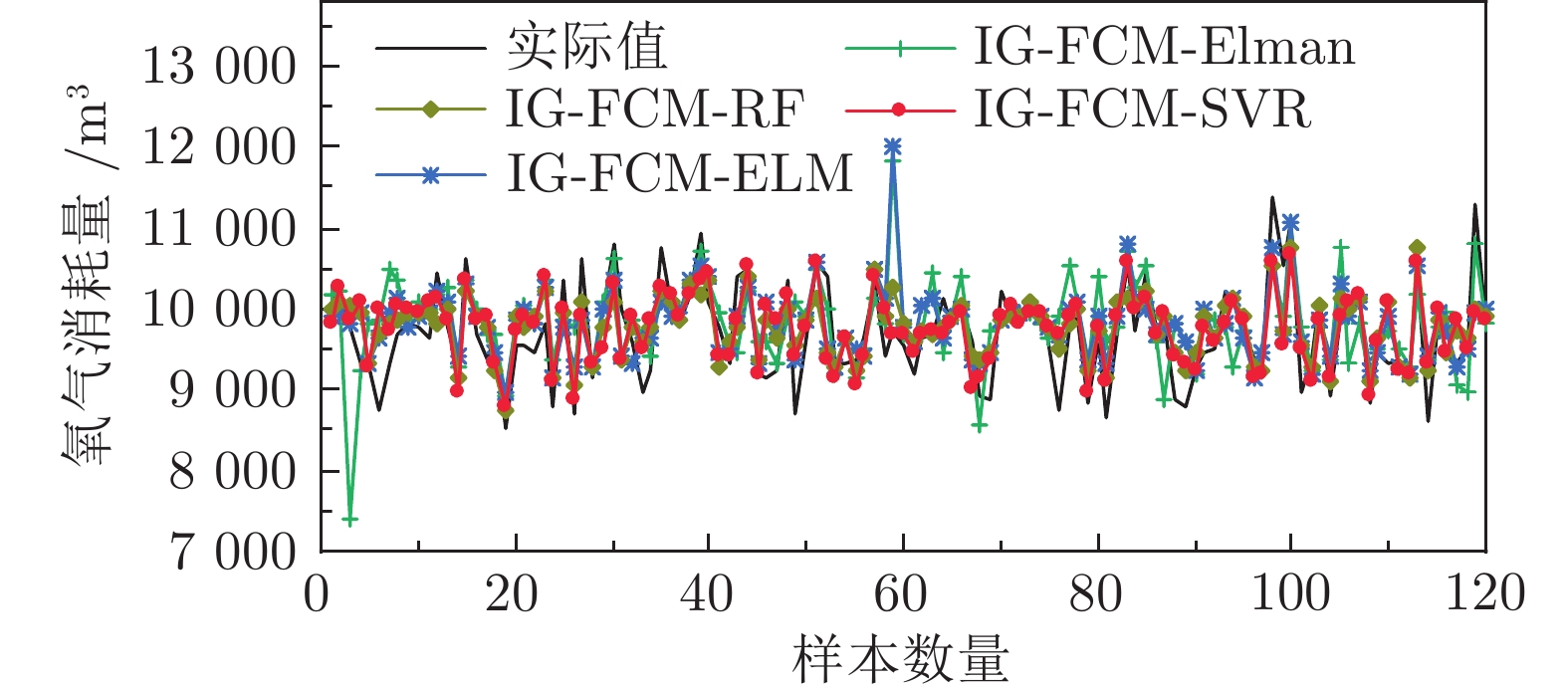

摘要: 转炉炼钢是钢铁企业的主要耗氧工序, 预测转炉炼钢的氧气消耗量对氧气系统合理调度、保证生产安全具有重要意义. 考虑到转炉冶炼工况多、钢种数据粒度不统一, 提出一种基于粒度聚类的转炉炼钢氧气消耗量预测方法. 首先, 利用孤立森林异常检测法剔除历史数据库中的异常数据; 接着, 采用皮尔逊相关性分析和互信息相关系数选取相关影响因子, 对不同钢种数据进行信息粒化, 实现数据特征提取和维度统一, 使用模糊C均值(Fuzzy C-means, FCM) 划分工况并建立不同工况下的氧气消耗量预测子模型; 最后, 利用企业的实际生产数据进行实验, 验证所提方法的准确性和有效性.Abstract: Oxygen consumption prediction in converter steelmaking is of great significance for the rational scheduling of the oxygen system and ensuring production safety in steel enterprise. Considering the diverse operating conditions of converter smelting and the inconsistent granularity of steel grade data, this paper proposes a prediction method for oxygen consumption in converter steelmaking based on granularity clustering. Firstly, the isolation forest anomaly detection method is used to remove abnormal data from the historical database. Then, Pearson correlation analysis and mutual information correlation coefficient are employed to select relevant influencing factors and achieve information granulation for different steel grade data, thereby extracting data features and unifying dimensions. Fuzzy C-means (FCM) clustering is utilized to divide the operating conditions and establish oxygen consumption prediction sub-models for different conditions. Finally, the accuracy and effectiveness of the proposed method are validated through experiments using actual production data from the steel enterprise.

-

表 1 符号说明

Table 1 Symbol description

符号 含义 符号 含义 ${C_1}$ 铁水重量 ${C_2}$ 废钢重量 ${C_3}$ 石灰重量 ${C_{\rm{Si}}}$ 铁水中化学元素Si的含量 ${C_{\rm{Mn}}}$ 铁水中化学元素Mn的含量 ${C_{\rm{P}}}$ 铁水中化学元素P的含量 ${C_{\rm{S}}}$ 铁水中化学元素S的含量 ${C_{\rm{Cu}}}$ 铁水中化学元素Cu的含量 ${C_{\rm{As}}}$ 铁水中化学元素As的含量 ${C_{\rm{Sn}}}$ 铁水中化学元素Sn的含量 ${C_{\rm{Ti}}}$ 铁水中化学元素Ti的含量 ${C_{\rm{V}}}$ 铁水中化学元素V的含量 ${C_{\rm{Pb}}}$ 铁水中化学元素Pb的含量 ${C_{\rm{Zn}}}$ 铁水中化学元素Zn的含量 ${C_{\rm{Cr}}}$ 铁水中化学元素Cr的含量 ${C_{\rm{Ni}}}$ 铁水中化学元素Ni的含量 ${C_{\rm{Nb}}}$ 铁水中化学元素Nb的含量 ${C_{\rm{Mo}}}$ 铁水中化学元素Mo的含量 ${C_{\rm{Sb}}}$ 铁水中化学元素Sb的含量 ${C_{\rm{W}}}$ 铁水中化学元素W的含量 ${Y}$ 氧气消耗量 $S({X})$ 样本${X}$的异常得分 ${\rho _{\rm{pcc}}}$ 皮尔逊相关系数值 ${\rho _{\rm{NMI}}}$ 归一化互信息相关系数值 ${X_A}$ A钢种 ${\tilde X_A}$ A钢种信息粒 ${r_1}$ 均方根误差 (Root mean square error, RMSE) ${r_2}$ 平均绝对误差 (Mean absolute error, MAE) ${r_3}$ 平均绝对百分比误差 (Mean absolute percentage error, MAPE) ${r_4}$ 最大绝对百分比误差 (Maximum absolute percentage error, MaxAPE) ${D_b}$ Davies-Bouldin指数 表 2 相关参数与吹氧量的${\rho _{\rm{pcc}}}$和${\rho _{\rm{NMI}}}$ 值

Table 2 ${\rho _{\rm{pcc}}}$ and ${\rho _{\rm{NMI}}}$ values between relevant parameters and oxygen blowing amount

过程参数 $C_1$ $C_2$ $C_3$ $C_{\rm{Si}}$ $C_{\rm{Mn}}$ ${\rho _{\rm{pcc}}}$ 0.281 0.510 0.340 0.054 0.180 ${\rho_{\rm{NMI}}}$ 0.776 0.820 0.831 0.864 0.856 过程参数 $C_{\rm{P}}$ $C_{\rm{S}}$ $C_{\rm{Cu}}$ $C_{\rm{As}}$ $C_{\rm{Sn}}$ ${\rho _{\rm{pcc}}}$ 0.016 0.117 0.120 0.102 0.012 ${\rho_{\rm{NMI}}}$ 0.758 0.812 0.766 0.757 0.710 过程参数 $C_{\rm{Ti}}$ $C_{\rm{V}}$ $C_{\rm{Pb}}$ $C_{\rm{Zn}}$ $C_{\rm{Cr}}$ ${\rho _{\rm{pcc}}}$ 0.025 0.102 0.053 0.015 0.022 ${\rho_{\rm{NMI}}}$ 0.851 0.841 0.542 0.554 0.770 过程参数 $C_{\rm{Ni}}$ $C_{\rm{Nb}}$ $C_{\rm{Mo}}$ $C_{\rm{Sb}}$ $C_{\rm{W}}$ ${\rho _{\rm{pcc}}}$ 0.019 0.019 0.046 0.036 0.030 ${\rho_{\rm{NMI}}}$ 0.718 0.535 0.472 0.314 0.609 表 3 不同模型预测误差

Table 3 Prediction errors of different models

预测模型 ${r_1}$ ${r_2}$ ${r_3}$ ${r_4}$ Elman 575.60 465.41 4.85 0.19 IG-FCM-Elman 565.11 415.35 4.35 0.24 ELM 480.12 359.38 3.74 0.17 IG-FCM-ELM 471.48 352.71 3.68 0.24 RF 417.17 324.69 3.36 0.13 IG-FCM-RF 400.04 313.11 3.24 0.12 SVR 415.40 321.54 3.33 0.16 IG-FCM-SVR 407.64 304.74 3.16 0.14 -

[1] 李桦, 雷豪. 转炉炼钢冶炼氧气消耗相关影响因素分析及预测模型. 南方金属, 2022, 246(3): 37-42 doi: 10.3969/j.issn.1009-9700.2022.03.008Li Hua, Lei Hao. Analysis and prediction model of related affecting factors of oxygen consumption in converter steel-making. Southern Metals, 2022, 246(3): 37-42 doi: 10.3969/j.issn.1009-9700.2022.03.008 [2] 章家岩, 马中海, 钱晓斌, 李绍铭, 郎佳红. 转炉煤气回收系统优化控制策略应用. 自动化学报, 2012, 38(6): 1017-1024 doi: 10.3724/SP.J.1004.2012.01017Zhang Jia-Yan, Ma Zhong-Hai, Qian Xiao-Bin, Li Shao-Ming, Lang Jia-Hong. Application of optimal control strategy to converter gas recovery system. Acta Automatica Sinica, 2012, 38(6): 1017-1024 doi: 10.3724/SP.J.1004.2012.01017 [3] Wang Z, Liu Q, Xie F M, Wang B, Lu X C, Fu G Q. Model for prediction of oxygen required in BOF steelmaking. Ironmaking & Steelmaking, 2012, 39(3): 228-233 [4] Sen P, Roy M, Pal P. Application of ARIMA for forecasting energy consumption and GHG emission: A case study of an Indian pig iron manufacturing organization. Energy, 2016, 116(Part 1): 1031-1038 [5] 陈中林, 杨翠丽, 乔俊飞. 基于TG-LSTM神经网络的非完整时间序列预测. 控制理论与应用, 2022, 39(5): 867-878Chen Zhong-Lin, Yang Cui-Li, Qiao Jun-Fei. The prediction of incomplete time series via TG-LSTM neural network. Control Theory and Applications, 2022, 39(5): 867-878 [6] Wu M, Zhang K X, An J Q, She J H, Liu K Z. An energy efficient decision-making strategy of burden distribution for blast furnace. Control Engineering Practice, 2018, 78: 186-195 doi: 10.1016/j.conengprac.2018.06.019 [7] Li J P, Hua C C, Yang Y N, Guan X P. Bayesian block structure sparse based T-S fuzzy modeling for dynamic prediction of hot metal silicon content in the blast furnace. IEEE Transactions on Industrial Electronics, 2018, 65(6): 4933-4942 doi: 10.1109/TIE.2017.2772141 [8] Zhao J, Wang W, Liu Y, Pedrycz W. A two-stage online prediction method for a blast furnace gas system and its application. IEEE Transactions on Control Systems Technology, 2011, 19(3): 507-520 doi: 10.1109/TCST.2010.2051545 [9] Hu J, Wu M, Chen X, Du S, Zhang P, Cao W H, et al. A multilevel prediction model of carbon efficiency based on the differential evolution algorithm for the iron ore sintering process. IEEE Transactions on Industrial Electronics, 2018, 65(11): 8778-8787 doi: 10.1109/TIE.2018.2811371 [10] Du S, Wu M, Chen L F, Cao W H, Pedrycz W. Operating mode recognition of iron ore sintering process based on the clustering of time series data. Control Engineering Practice, 2020, 96: Article No. 104297 [11] 陈聪, 吴敏, 陈略峰, 章文, 杜胜. 基于工况识别的辊式淬火过程板形预报方法. 控制理论与应用, 2021, 38(9): 1407-1413Chen Cong, Wu Min, Chen Lue-Feng, Zhang Wen, Du Sheng. Flatness prediction method based on operating mode recognition for roller quenching process. Control Theory and Applications, 2021, 38(9): 1407-1413 [12] Liu F T, Ting K M, Zhou Z H. Isolation-based anomaly detection. ACM Transactions on Knowledge Discovery From Data, 2012, 6(1): 1-39 [13] Li L, Li W, Du Q, Tao R. Low-rank and sparse decomposition with mixture of Gaussian for hyperspectral anomaly detection. IEEE Transactions on Cybernetics, 2021, 51(9): 4363-4372 doi: 10.1109/TCYB.2020.2968750 [14] 邹同华, 高云鹏, 伊慧娟, 徐长宝, 夏睿, 吴聪. 基于Thompson tau-四分位和多点插值的风电功率异常数据处理. 电力系统自动化, 2020, 44(15): 156-162Zou Tong-Hua, Gao Yun-Peng, Yi Hui-Juan, Xu Chang-Bao, Xia Rui, Wu Cong. Processing of wind power a bnormal data based on Thompson tau-quartile and multi-point interpolation. Automation of Electric Power Systems, 2020, 44(15): 156-162 [15] 王跃飞, 于炯, 苏国平, 钱育蓉, 廖彬, 刘粟. ODIC-DBSCAN: 一种新的簇内孤立点分析算法. 自动化学报, 2019, 45(11): 2107-2127Wang Yue-Fei, Yu Jiong, Su Guo-Ping, Qian Yu-Rong, Liao Bin, Liu Su. ODIC-DBSCAN: A new analytical algorithm for inliers. Acta Automatica Sinica, 2019, 45(11): 2107-2127 [16] Reshef D N, Reshef Y A, Finucane H K, Grossman S R, Mcvean G, Turnbaugh P J, et al. Detecting novel associations in large data sets. Science, 2011, 334(6062): 1518-1524 doi: 10.1126/science.1205438 [17] Pedrycz W. Granular computing for data analytics: A manifesto of human-centric computing. IEEE/CAA Journal of Automatica Sinica, 2018, 5(6): 1025-1034 doi: 10.1109/JAS.2018.7511213 [18] 杜胜, 吴敏, 陈略峰, Pedrycz Witold. 基于粒度聚类的铁矿石烧结过程运行性能评价. 自动化学报, 2023, 49(6): 1272-1282Du Sheng, Wu Min, Chen Lue-Feng, Pedrycz Witold. Operating performance assessment based on granular clustering for iron ore sintering process. Acta Automatica Sinica, 2023, 49(6): 1272-1282 [19] Hu J, Wu M, Chen L F, Zhou K L, Pedrycz W. Weighted kernel fuzzy C-means-based broad learning model for time-series prediction of carbon efficiency in iron ore sintering process. IEEE Transactions on Cybernetics, 2022, 52(6): 4751-4763 doi: 10.1109/TCYB.2020.3035800 [20] Davies D L, Bouldin D W. A Cluster Separation Measure. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1979, PAMI-1(2): 224-227 doi: 10.1109/TPAMI.1979.4766909 [21] Zhou P, Guo D W, Wang H, Chai T Y. Data-driven robust M-LS-SVR-based NARX modeling for estimation and control of molten iron quality indices in blast furnace ironmaking. IEEE Transactions on Neural Networks and Learning Systems, 2018, 29(9): 4007-4021 doi: 10.1109/TNNLS.2017.2749412 [22] Wang T T, Wang X P, Ma R Z, Li X Y, Hu X P, Chan F T S, et al. Random forest-Bayesian optimization for product quality prediction with large-scale dimensions in process industrial cyber-physical systems. IEEE Internet of Things Journal, 2020, 7(9): 8641-8653 doi: 10.1109/JIOT.2020.2992811 -

下载:

下载: