A Modeling Method of Blast Furnace Burden Surface Accumulation Shape Based on the Motion Trajectory and Radial Distance

-

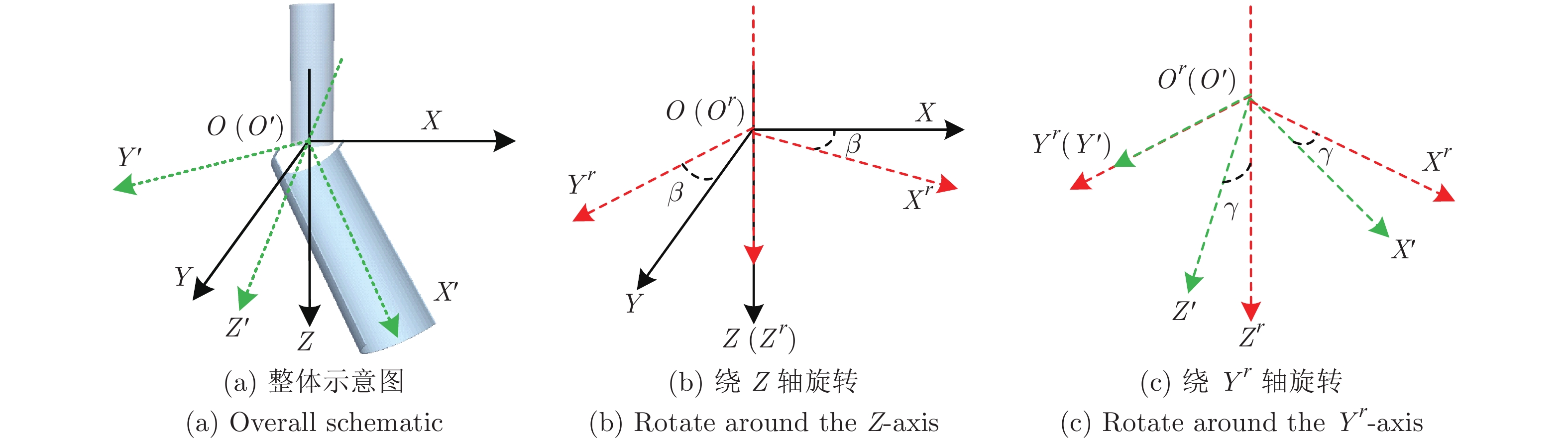

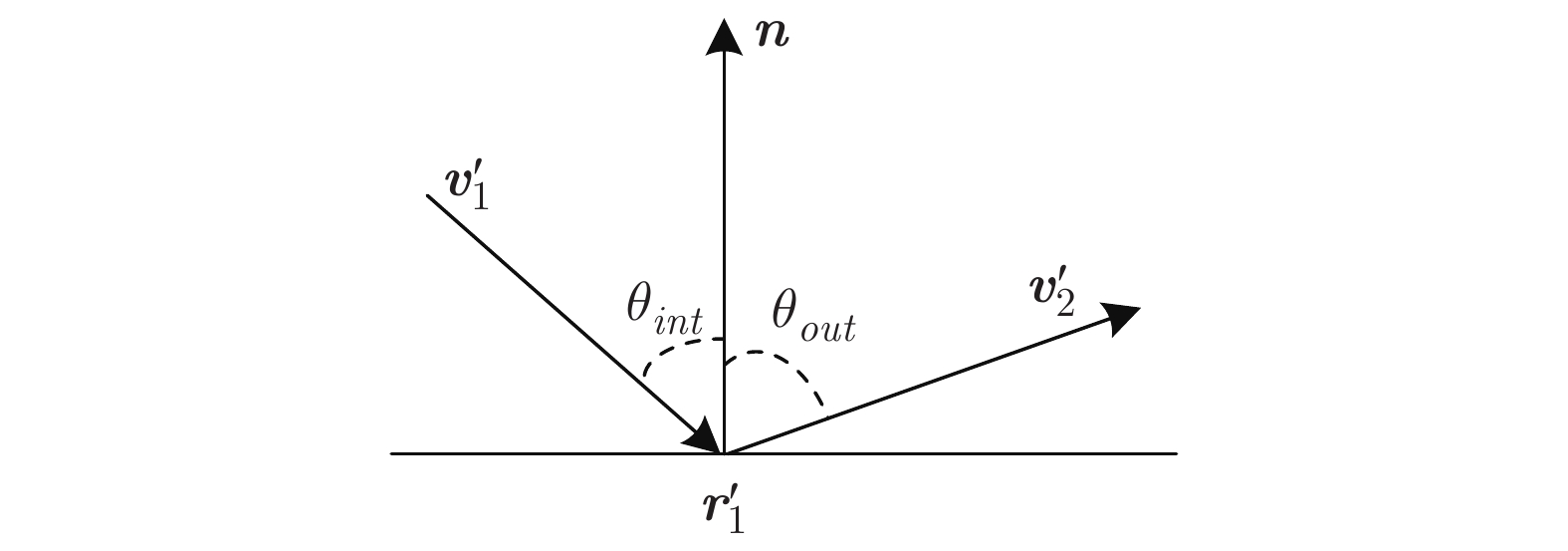

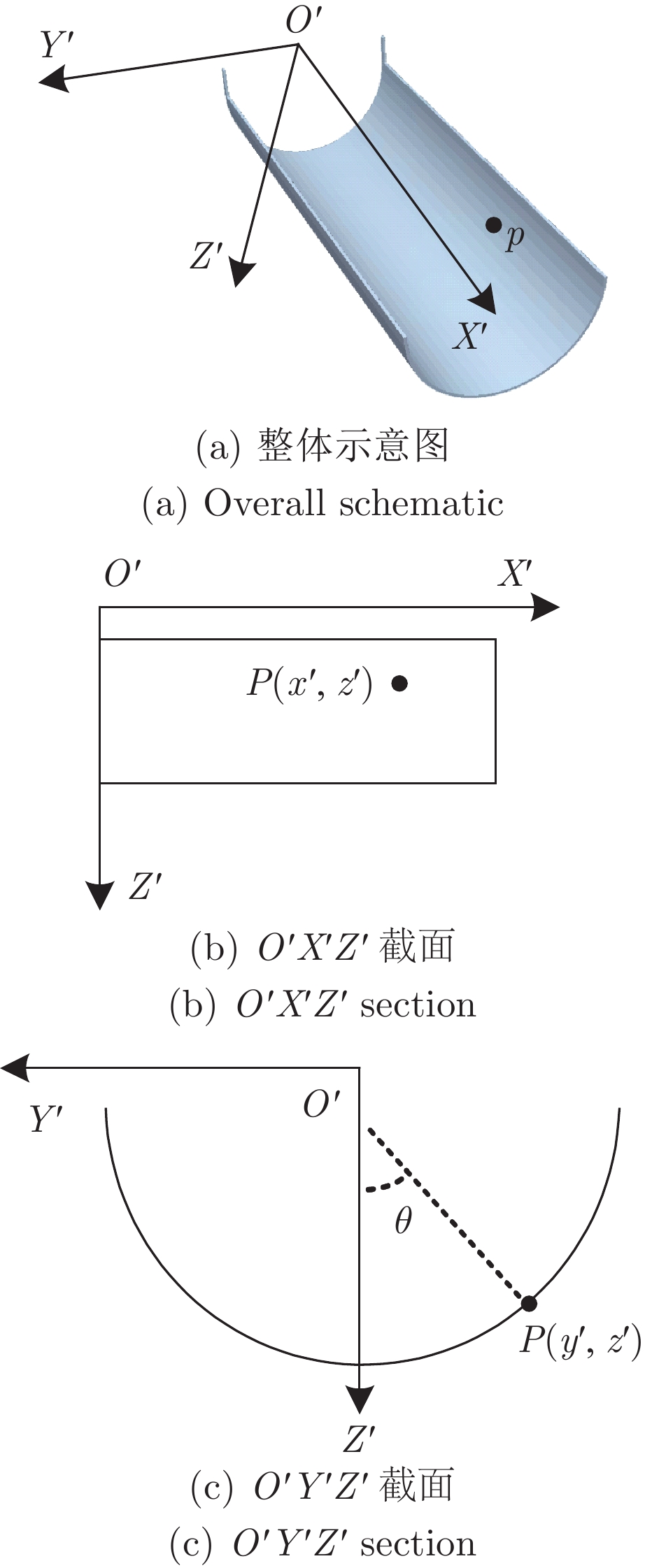

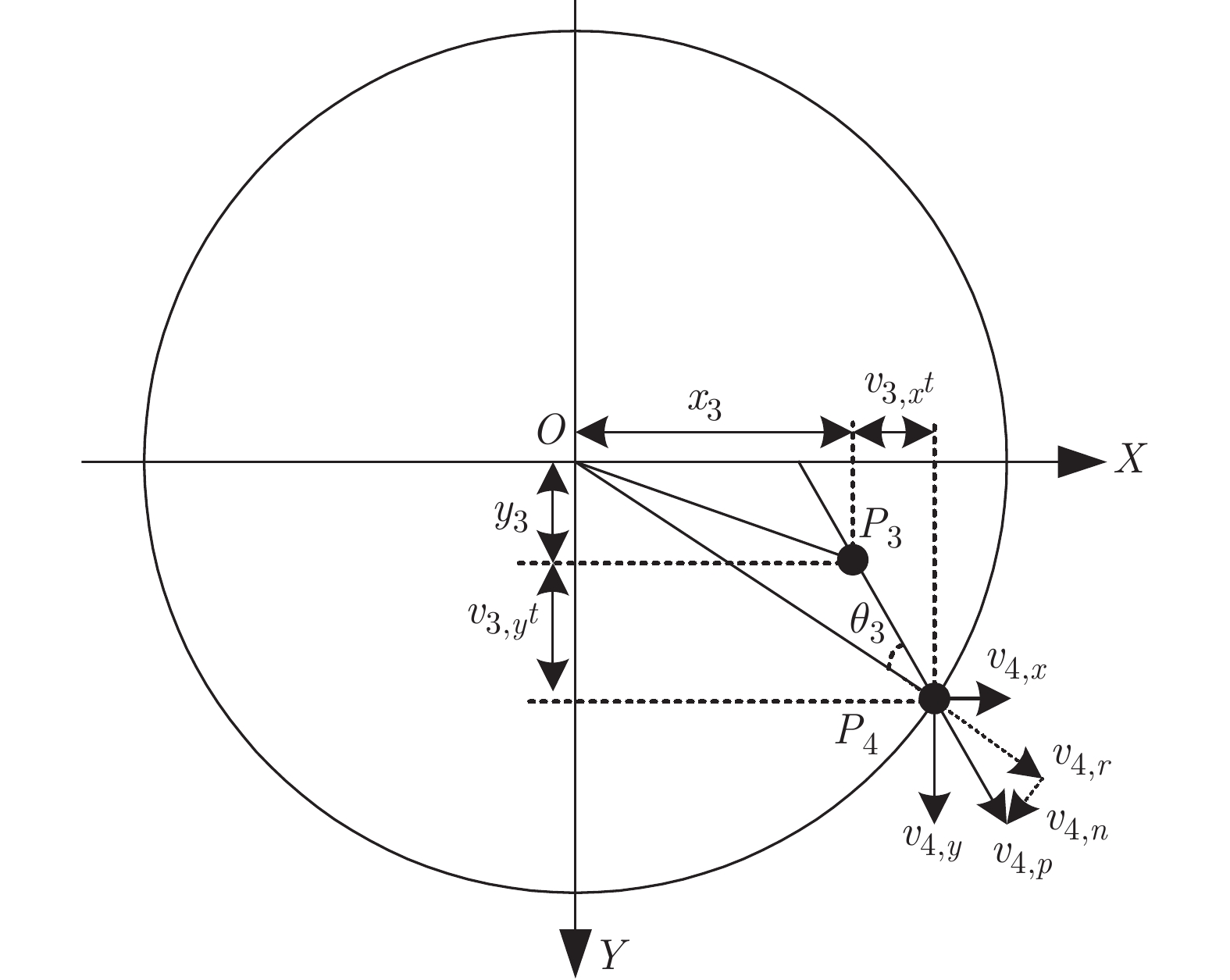

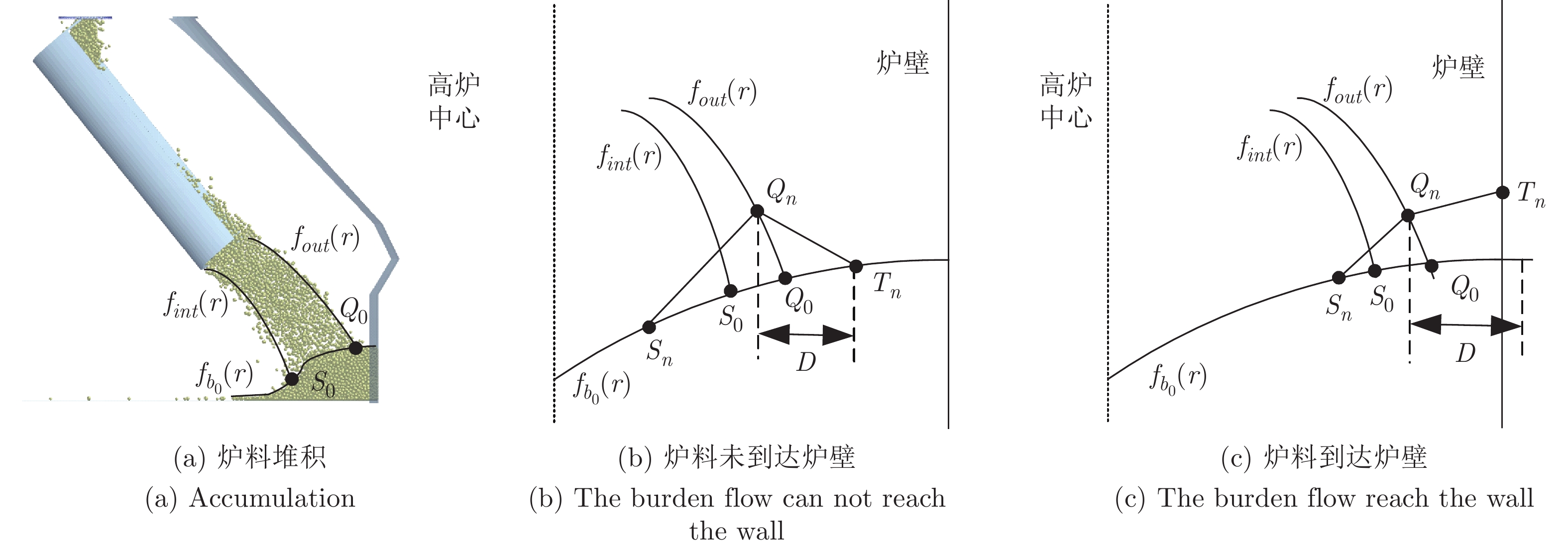

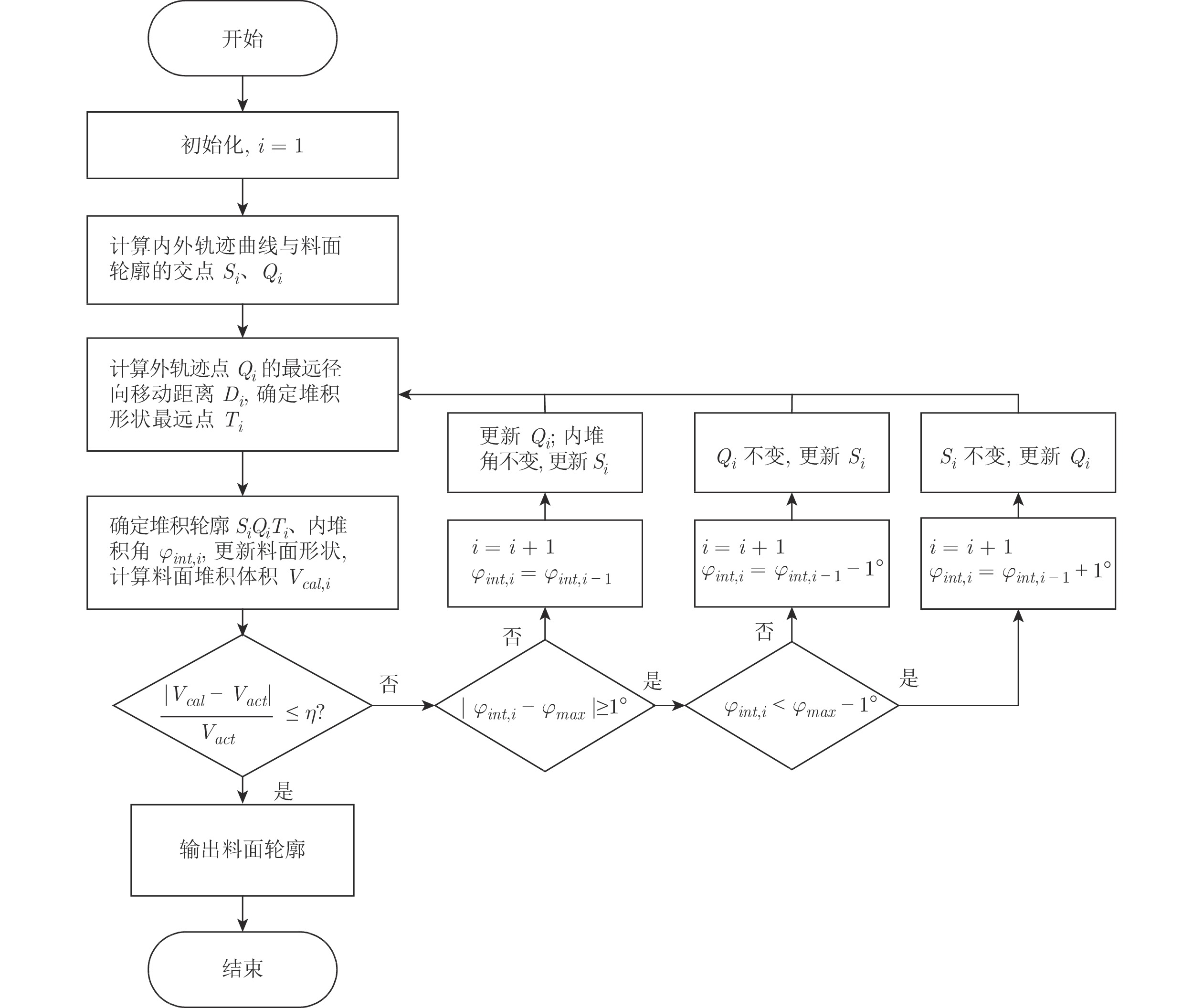

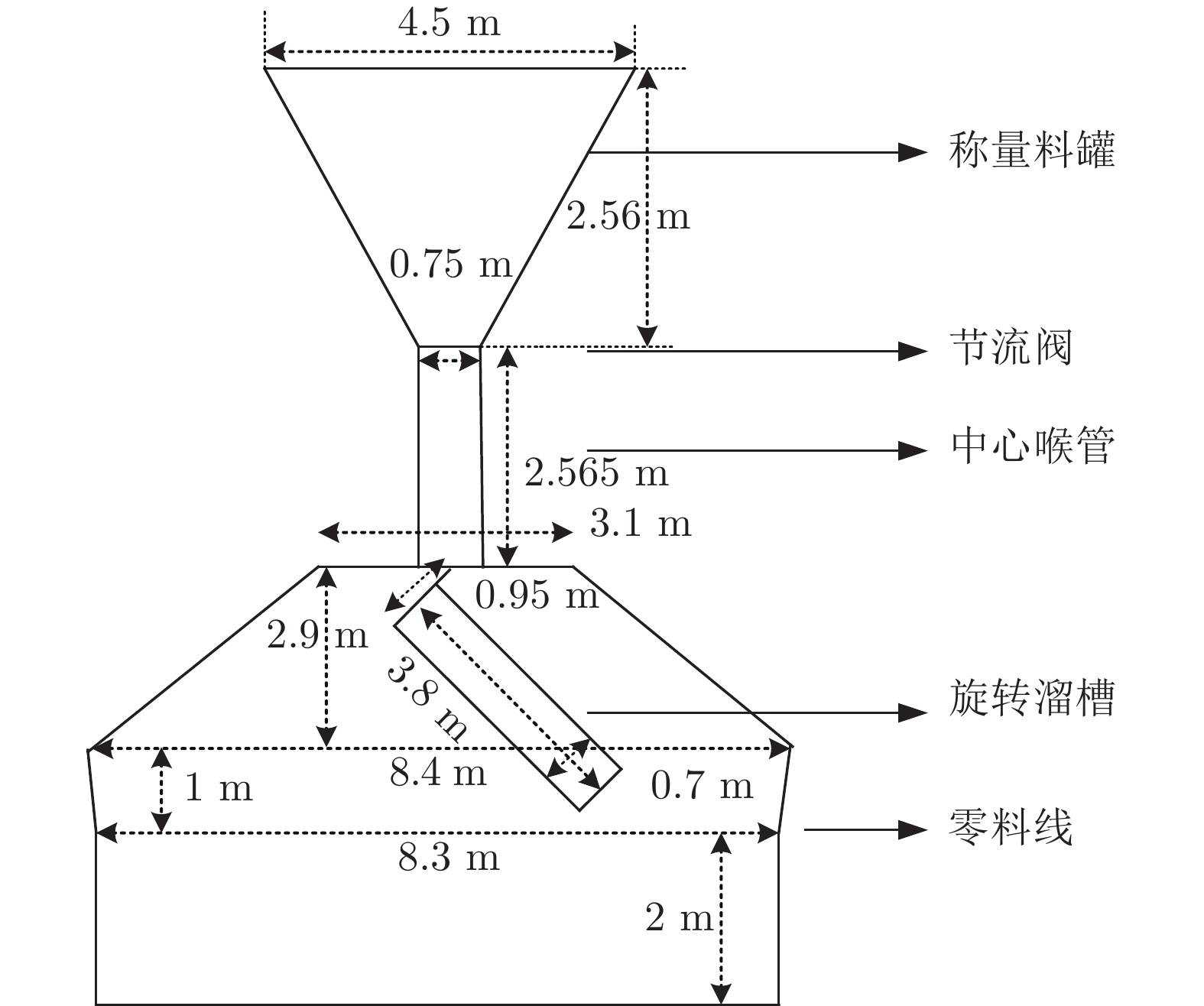

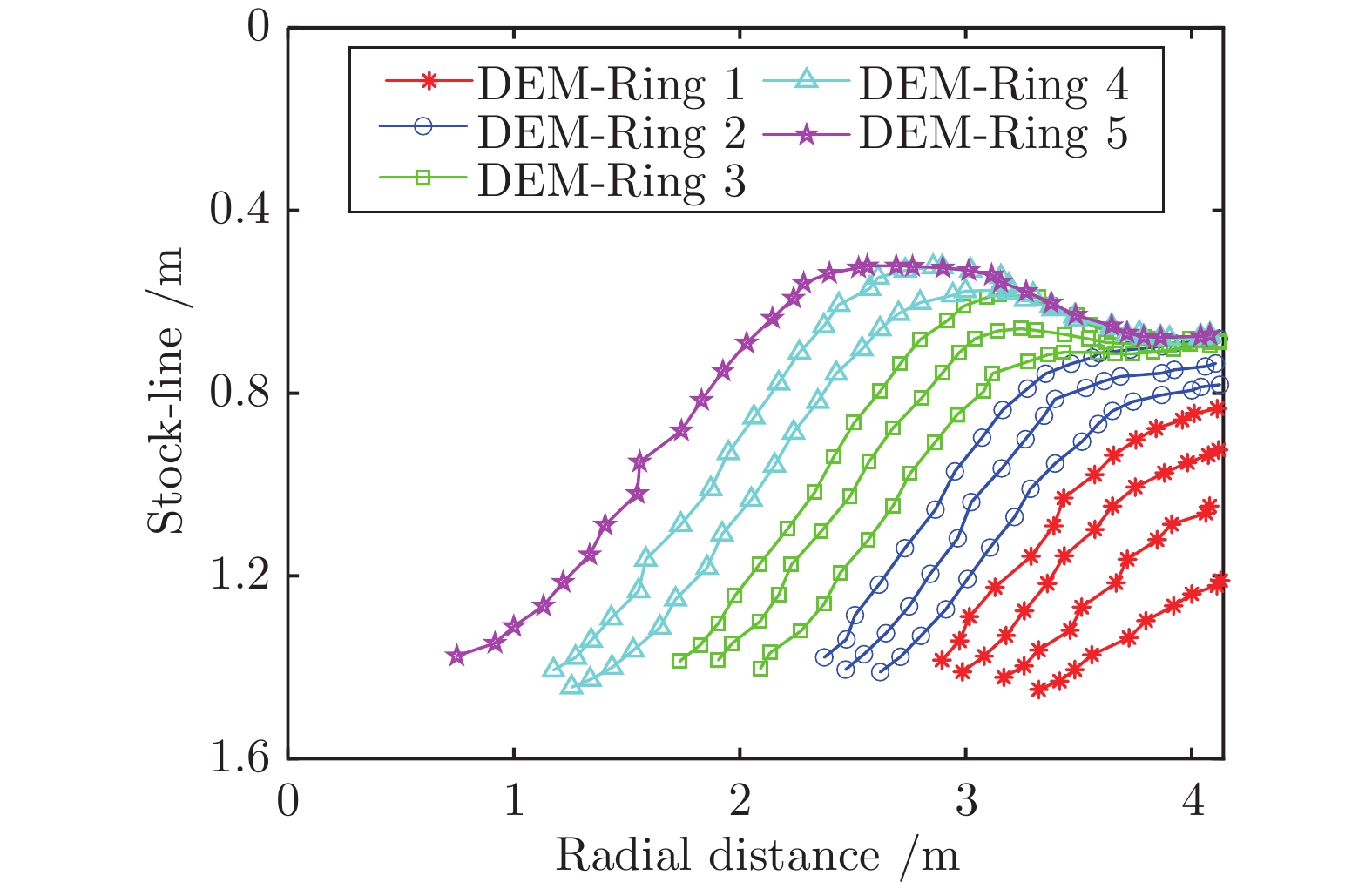

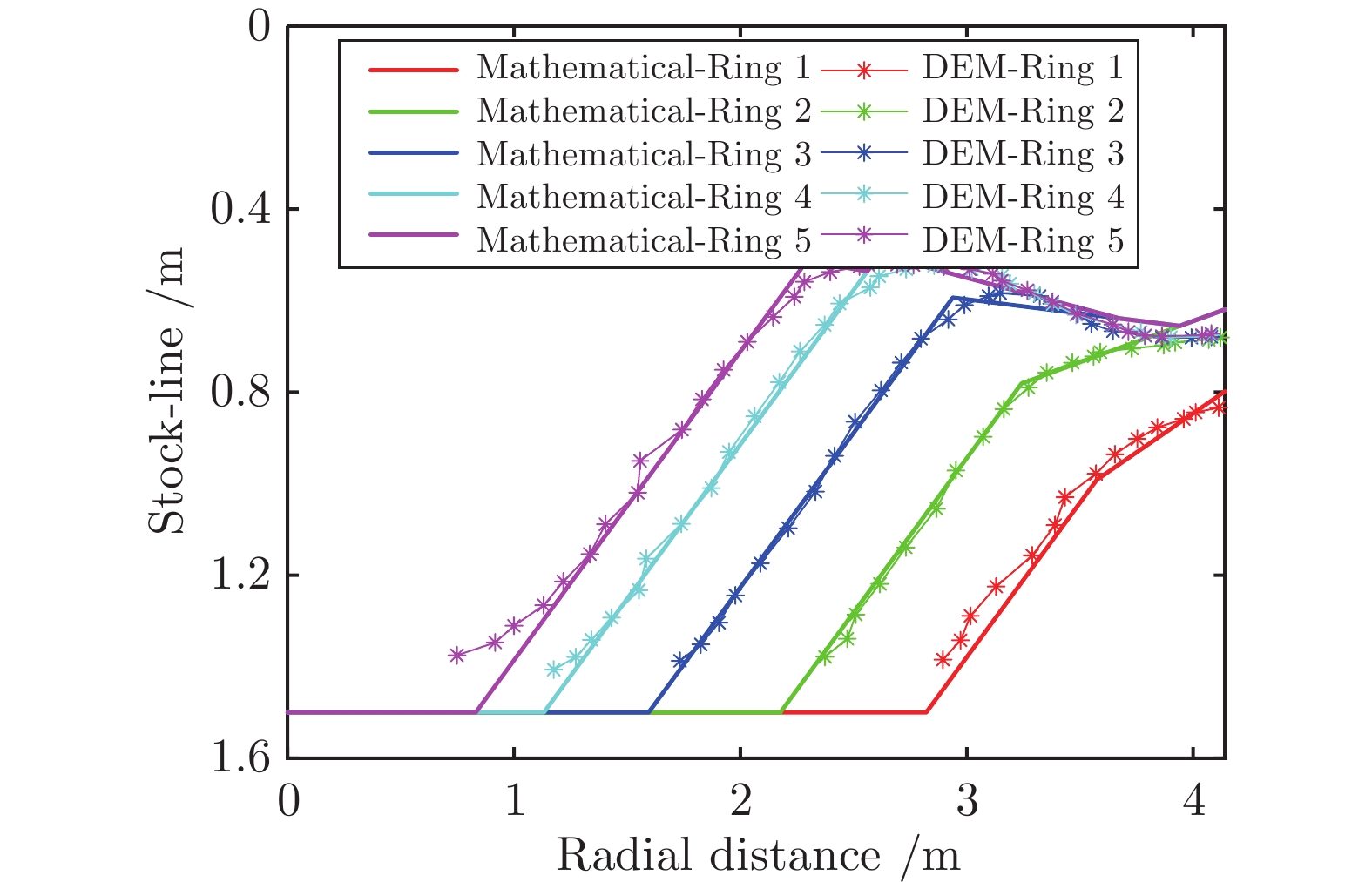

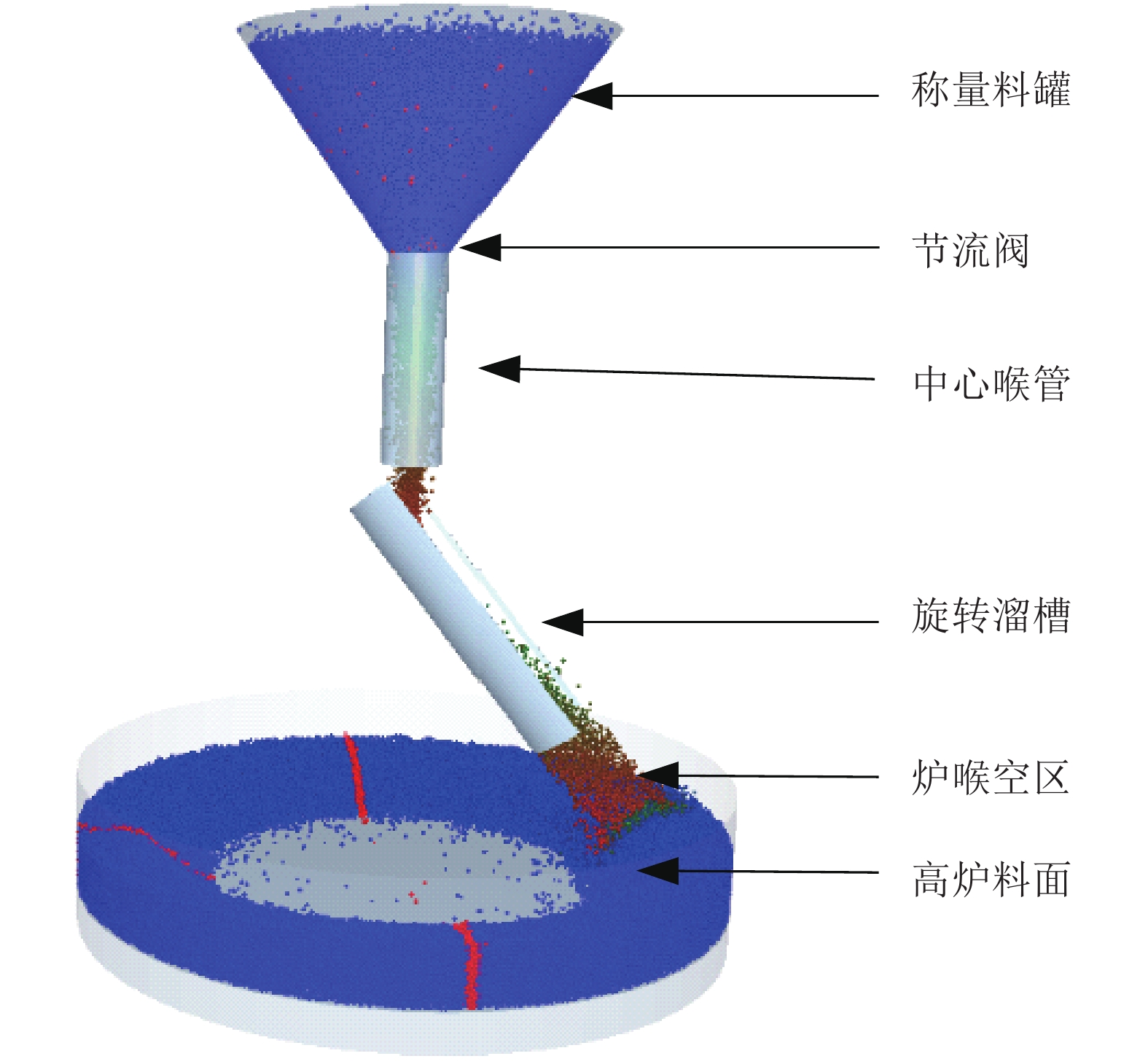

摘要: 高炉料面形貌是反映煤气流分布和煤气利用率的关键指标, 研究高炉料面炉料堆积形状数学建模方法对实现高炉精准布料控制和“双碳”战略在钢铁行业落地具有重要意义. 针对高炉多环布料情况下料面堆积形状预测难的问题, 本文提出了一种基于炉料运动轨迹和径向移动距离的高炉料面炉料堆积形状建模方法. 首先, 提出了一种与炉料初始状态和溜槽状态相关的炉料运动轨迹建模方法, 获取炉料从节流阀至料面的炉料运动轨迹, 并确定炉料在炉喉空区的内轨迹曲线和外轨迹曲线. 然后, 基于炉料运动轨迹和初始料面形状, 以体积守恒原则为约束, 提出了一种基于炉料径向移动距离的高炉料面炉料堆积形状数学建模方法, 获取炉料在料面的堆积形状. 最后, 基于某钢铁厂2# 高炉的尺寸建立离散单元法 (Discrete element method, DEM) 仿真模型, 模型仿真结果验证了所提方法的准确性和有效性.Abstract: The blast furnace burden surface is the key index to reflect the distribution of gas flow and the utilization rate of gas. Studying the mathematical modeling method of burden flow accumulation shape on the blast furnace burden surface is of great significance to realize the precise charging control and the implementation of “dual carbon” strategy in the steel industry. Aiming at the difficulty of predicting the burden flow accumulation shape in the blast furnace multi-ring charging, a modeling method for the accumulation shape of the burden flow on the blast furnace burden surface based on the burden flow motion trajectory and radial movement distance is proposed. Firstly, a modeling method of burden flow motion trajectory relate to the burden flow state and chute state is proposed to obtain the motion trajectory of burden flow from throttle valve to the burden surface, and further determine the internal and external trajectory of burden flow in the blast throat. Secondly, a mathematical modeling method of burden flow accumulation on the blast furnace burden surface based on the radial moving distance is proposed to obtain the accumulation shape of burden flow on the burden surface according to the motion trajectory, initial shape of burden surface, and the principle of volume conservation. Finally, a discrete element method (DEM) simulation model is established based on the 2# blast furnace of a steel plant, and the simulation results verify the accuracy and effectiveness of the proposed method.

-

表 1 DEM仿真中的粒子属性

Table 1 The particle properties used in DEM simulation

参数 数值 焦炭属性 半径(m) 0.04 ~ 0.06 泊松比(P−P) 0.22 剪切模量(Pa) 2.2×107 密度(kg/m3) 1050 恢复系数 碰撞恢复系数(P−P; P−C) 0.18; 0.2 静摩擦系数(P−P; P−C) 0.56; 0.41 滚动摩擦系数(P−P; P−C) 0.15; 0.09 (P−P和P−C分别表示粒子与粒子、粒子与溜槽接触) 表 2 仿真中高炉布料操作参数

Table 2 The charging operation parameters in the simulation

布料环 环1 环2 环3 环4 环5 溜槽转速(°/s) 60 60 60 60 60 溜槽倾角(°) 41 39 36 33 30 旋转圈数 4 3 3 2 1 表 3 基于数学模型的料面高度预测性能

Table 3 The charging operation parameters in the burden furnace simulation

布料环 环1 环2 环3 环4 环5 合计轮廓点数 料面轮廓点 14 19 25 31 34 123 RMSE 0.0429 0.0240 0.0214 0.0259 0.0376 0.0308 $\Delta h \le 0.08$m $H(n)$ 14 19 25 31 32 121 ${\rm{HR}}$ 100% 100% 100% 100% 94.12% 98.37% $\Delta h \le 0.06$m $H(n)$ 11 19 25 31 32 116 ${\rm{HR}}$ 78.57% 100% 100% 96.77% 91.18% 94.31% -

[1] 蒋珂, 蒋朝辉, 谢永芳, 潘冬, 桂卫华. 基于动态注意力深度迁移网络的高炉铁水硅含量在线预测方法. 自动化学报, 2023, 49(5): 949−963Jiang Ke, Jiang Zhao-Hui, Xie Yong-Fang, Pan Dong, Gui Wei-Hua. Online prediction method for silicon content of molten iron in blast furnace based on dynamic attention deep transfer network. Acta Automatica Sinica, 2023, 49(5): 949−963 [2] 周平, 张丽, 李温鹏, 戴鹏, 柴天佑. 集成自编码与PCA的高炉多元铁水质量随机权神经网络建模. 自动化学报, 2018, 44(10): 1799-1811Zhou Ping, Zhang Li, Li Wen-Peng, Dai Peng, Chai Tian-You. Modeling of blast furnace multi-element molten iron quality with random weight neural network based on self-encoding and PCA. Acta Automatica Sinica, 2018, 44(10): 1799-1811 [3] Jimenez J, Mochon J, Formoso A, de Ayala J S. Burden distribution analysis by digital image processing in a scale model of a blast furnace shaft. ISIJ International, 2000, 40(2): 114-120 doi: 10.2355/isijinternational.40.114 [4] Mitra T, Saxén H. Simulation of burden distribution and charging in an ironmaking blast furnace. IFAC-PapersOnLine, 2015, 48(17): 183-188 doi: 10.1016/j.ifacol.2015.10.100 [5] Kajiwara Y, Jimbo T, Joko T, Aminaga Y, Inada T. Investigation of bell-less charging based on full scale model experiments. Transactions of the Iron and Steel Institute of Japan, 1984, 24(10): 799-807 doi: 10.2355/isijinternational1966.24.799 [6] Mio H, Komatsuki S, Akashi M, Shimosaka A, Shirakawa Y, Hidaka J, Kadowaki M, Matsuzaki S, Kunitomo K. Effect of Chute Angle on Charging Behavior of Sintered Ore Particles at Bell-less Type Charging System of Blast Furnace by Discrete Element Method. ISIJ International, 2009, 49(4): 479-486 doi: 10.2355/isijinternational.49.479 [7] Kou M Y, Wu S L, Zhou H, Yu Y M, Xu J. Numerical Investigation of Coke Collapse and Size Segregation in the Bell-less Top Blast Furnace. Isij International, 2018, 58(11): 2018-2024 doi: 10.2355/isijinternational.ISIJINT-2018-415 [8] Zhou K, Jiang Z H, Pan D, Gui W H, Huang J C. Influence of charging parameters on the burden flow velocity and distribution on the blast furnace chute based on discrete element method. Steel Research International, 2022, 93(1): Article No. 2100332 [9] Hong Z B, Zhou H, Wu J L, Zhan L L, Fan Y B, Zhang Z W, et al. Effects of operational parameters on particle movement and distribution at the top of a bellless blast furnace based on discrete element method. Steel Research International, 2021, 92(1): Article No. 2000262 [10] 马洪佑, 王振阳, 戴建华, 袁军, 李秀亮, 王永龙. 不同溜槽形状下的料流偏析现象. 钢铁, 2020, 55(09): 23-28Ma Hong-You, Wang Zhen-Yang, Dai Jian-Hua, Yuan Jun, Li Xiu-Liang, Wang Yong-Long.Segregation of material flow under different chute shapes.Iron and Steel, 2022, 55(09): 23-28 [11] 孙俊杰, 狄瞻霞, 李家新, 卢开成. 溜槽形状及倾角对料流运动的影响. 钢铁, 2019, 54(04): 19-23Sun Jun-Jie, Di Zhan-Xia, Li Jia-Xin, Lu Kai-Cheng. Influence of inclination and shape of chute on movement of burden flow.Iron and Steel, 2019, 54(04): 19-23 [12] Kou M Y, Xu J, Wu S L, Zhou H, Gu K, Yao S, Wen B J. Effect of cross-section shape of rotating chute on particle movement and distribution at the throat of a bell-less top blast furnace. Particuology, 2019, 44: 194-206 doi: 10.1016/j.partic.2018.07.010 [13] Govender N, Wilke D N, Wu C Y, Tuzun U, Kureck H. A numerical investigation into the effect of angular particle shape on blast furnace burden topography and percolation using a GPU solved discrete element model. Chemical Engineering Science, 2019, 204: 9-26 doi: 10.1016/j.ces.2019.03.077 [14] 寇明银, 吴胜利, 周恒, 于亚光, 顾凯. 高炉DEM模拟用炉料系数的测定及其应用. 钢铁, 2018, 53(12): 30-36+61 doi: 10.13228/j.boyuan.issn0449-749x.20180163Kou Ming-Yin, Wu Sheng-Li, Zhou Heng, Yu Ya-Guang, Gu Kai.Measurements and application of burden coefficients for DEM simulation in blast furnace. Iron and Steel, 2018, 53(12): 30-36+61 doi: 10.13228/j.boyuan.issn0449-749x.20180163 [15] 夏修浩, 周连勇, 马华庆, 赵永志. 颗粒形状模型对高炉布料过程DEM模拟的影响. 钢铁研究学报, 2021, 33(12): 1228-1236Xia Xiu-Hao, Zhou Lian-Yong, Ma Hua-Qing, Zhao Yong-Zhi. Effect of particle shape model on DEM simulation of charging process in blast furnace.Journal of Iron and Steel Research, 2021, 33(12): 1228-1236 [16] Mio H, Narita Y, Matsuzaki S, Nishioka K, Nomura S. Measurement of particle charging trajectory via rotating chute of 1/3-scale blast furnace and its comparing with numerical analysis using Discrete Element Method. Powder Technology, 2019, 344: 797-803 doi: 10.1016/j.powtec.2018.12.047 [17] Wei S Y, Wei H, Saxen H, Yu Y W. Numerical analysis of the relationship between friction coefficient and repose angle of blast furnace raw materials by discrete element method. Materials, 2022, 15(3): Article No. 903 [18] Holzinger G, Schatzl M. Effect of chute start angle and hopper change on burden distribution during the charging process of a bell-less top blast furnace with two parallel hoppers. Powder Technology, 2022, 395: 669-680 doi: 10.1016/j.powtec.2021.10.005 [19] Yu Y W, Saxen H. Particle Flow and Behavior at Bell-Less Charging of the Blast Furnace. Steel Research International, 2013, 84(10): 1018-1033 [20] Mitra T, Saxén H. Discrete element simulation of charging and mixed layer formation in the ironmaking blast furnace. Computational Particle Mechanics, 2016, 3(4): 541-555 doi: 10.1007/s40571-015-0084-1 [21] Mitra T, Saxen H. Investigation of Coke Collapse in the Blast Furnace Using Mathematical Modeling and Small Scale Experiments. ISIJ International, 2016, 56(9): 1570-1579 doi: 10.2355/isijinternational.ISIJINT-2016-114 [22] Radhakrishnan V R, Ram K M. Mathematical model for predictive control of the bell-less top charging system of a blast furnace. Journal of Process Control, 2001, 11(5): 565-586 doi: 10.1016/S0959-1524(00)00026-3 [23] 朱清天, 程树森, 魏志江, 郭喜斌. 高炉炉料落点的确定. 中国冶金, 2006, (09): 24-26Zhu Qing-Tian, Cheng Shu-Sen, Wei Zhi-Jiang, Guo Xi-Bin. Establishment of Landing Point of Burden in Blast Furnace. China Metallurgy, 2006, (09): 24-26 [24] 杜鹏宇, 程树森, 胡祖瑞, 吴桐. 高炉无钟炉顶布料料流宽度数学模型及试验研究. 钢铁, 2010, 45(01): 14-18Du Peng-Yu, Cheng Shu-Sen, Hu Zu-Rui, Wu Tong. Mathematical Model of Burden Width in a Bell-Less Top Blast Furnace and Modeling Experimental Research. Iron and Steel, 2010, 45(01): 14-18 [25] Fu D, Chen Y, Zhou C Q. Mathematical modeling of blast furnace burden distribution with non-uniform descending speed. Applied Mathematical Modelling, 2015, 39(23-24): 7554-7567 doi: 10.1016/j.apm.2015.02.054 [26] 张森, 李酉, 陈先中, 尹怡欣. 高炉料面形状双驱动模型研究. 控制理论与应用, 2020, 37(05): 978-986Zhang Sen, Li You, Chen Xian-Zhong, Yin Yi-Xin. Research on double-driven model of blast furnace burden profile. Control Theory & Applications, 2020, 37(05): 978-986 [27] Fojtik D, Tuma J, Faruzel P. Computer modelling of burden distribution in the blast furnace equipped by a bell-less top charging system. Ironmaking & Steelmaking, 2021, 48(10): 1226-1238 [28] Nag S, Gupta A, Paul S, Gavel D J, Aich B. Prediction of Heap Shape in Blast Furnace Burden Distribution. ISIJ International, 2014, 54(7): 1517-1520 doi: 10.2355/isijinternational.54.1517 [29] Li M, Wei H, Ge Y, Xiao G C, Yu Y W. A Mathematical model combined with radar data for bell-less charging of a blast furnace. Processes, 2020, 8(2): Article No. 239 [30] 周科, 蒋朝辉, 桂卫华, 黄建才, 朱既承. 基于坐标变换的高炉U型溜槽上炉料运动轨迹数学建模研究. 2021 中国自动化大会. 昆明, 中国: 2021. 289−294Zhou Ke, Jiang Zhao-Hui, Gui Wei-Hua, Huang Jian-Cai, Zhu Ji-Cheng. Research on mathematical modeling of three-dimensional movement of particle on U-shaped chute of blast furnace based on coordinate transformation. In: Proceedings of the 2021 China Automation Conference Proceedings. Kunming, China: 2021. 289−294 [31] 冯建强, 孙诗一. 四阶龙格—库塔法的原理及其应用. 数学学习与研究, 2017, (17) : 3-5Feng Jian-Qiang, Sun Shi-Yi. Principle and application of fourth-order Runge-Kutta method. Mathematics Learning and Research, 2017, (17): 3-5 [32] 李晓理, 刘德馨, 周翔, 陈先中. 高炉布料设定值优化控制. 控制理论与应用, 2015, 32(12) : 1660-1668 doi: 10.7641/CTA.2015.40856Li Xiao-Li, Liu De-Xin, Zhou Xiang, Chen Xian-Zhong. Setting value optimal control for blast furnace burden distribution. Control Theory & Applications, 2015, 32(12): 1660-1668 doi: 10.7641/CTA.2015.40856 [33] 马财生, 任廷志. 无钟高炉炉料分布预测模型. 工程科学学报, 2017, 39(02): 276-282Ma Cai-Sheng, Ren Yan-Ting. Burden distribution prediction model in a blast furnace with bell-less top. Chinese Journal of Engineering, 2017, 39(02): 276-282 [34] Cundall P A, Strack O D L. A discrete numerical model for granular assemblies. Geotechnique, 1979, 29(1): 47-65 doi: 10.1680/geot.1979.29.1.47 [35] Yu Y W, Saxen H. Segregation behavior of particles in a top hopper of a blast furnace. Powder Technology, 2014, 262: 233-241 doi: 10.1016/j.powtec.2014.04.010 [36] Zhou K, Jiang Z, Pan D, Gui W H, Huang J C, Xu C. Research on the velocity distribution law of the coke in the chute of blast furnace based on discrete element method. Computational Particle Mechanics, 2022: 1-9 [37] Ester M, Kriegel H P, Sander J, et al. A density-based algorithm for discovering clusters in large spatial databases with noise. KDD, 1996: 226-231 -

下载:

下载: