-

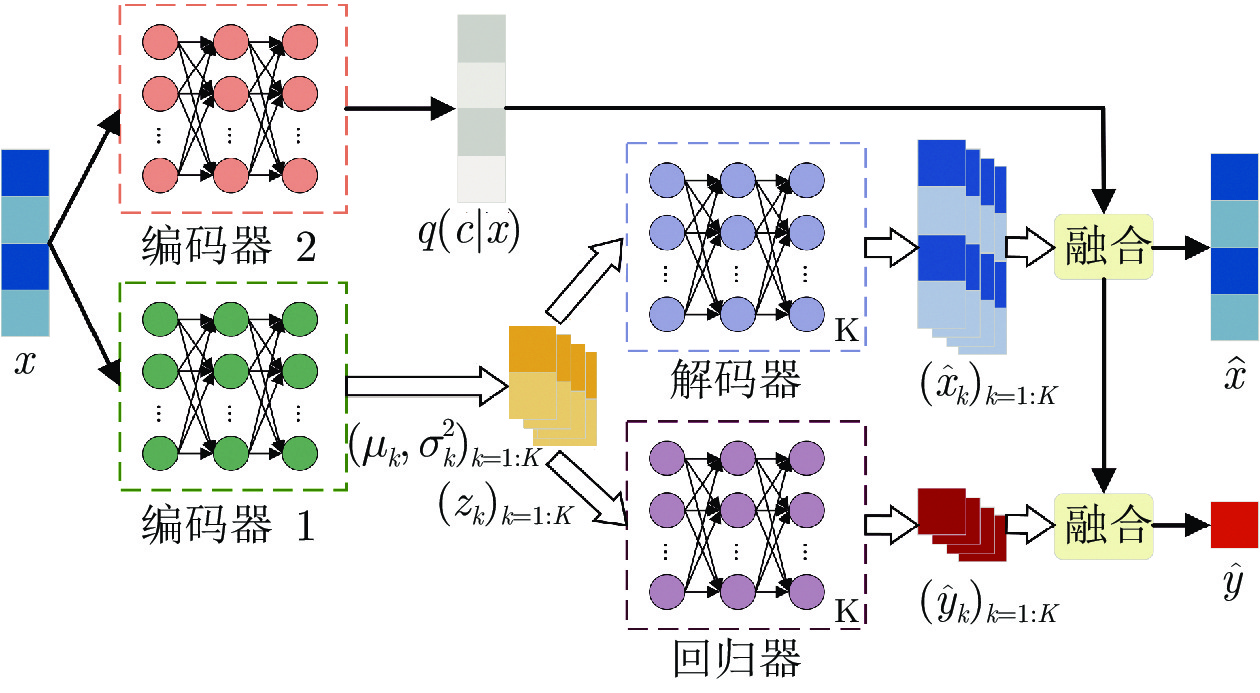

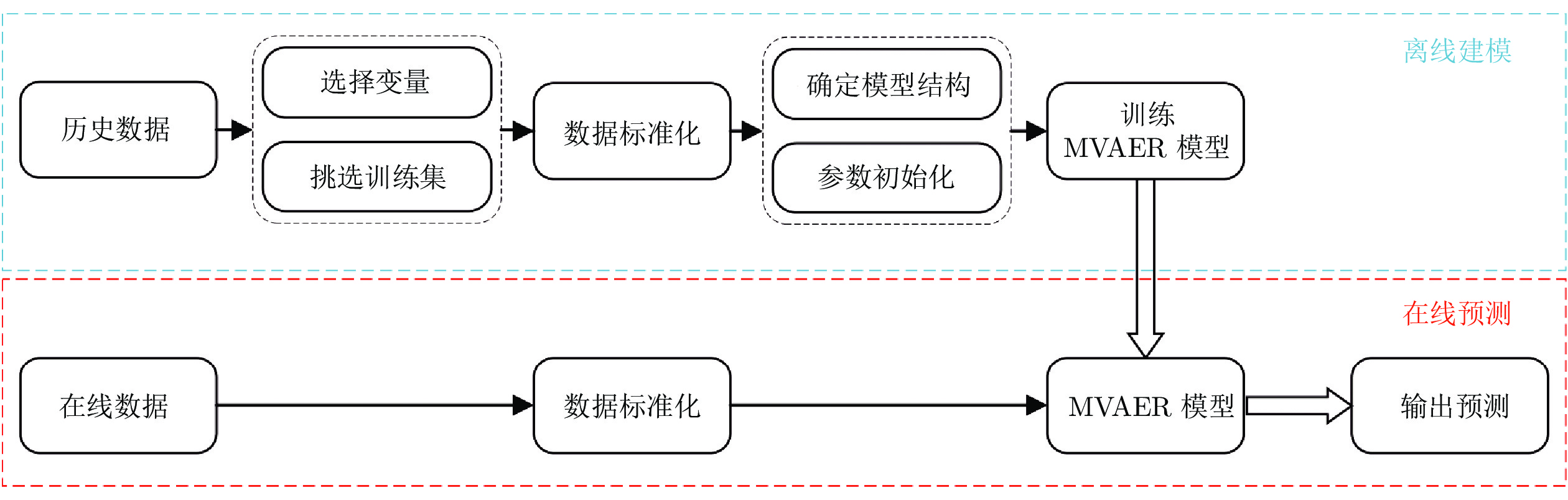

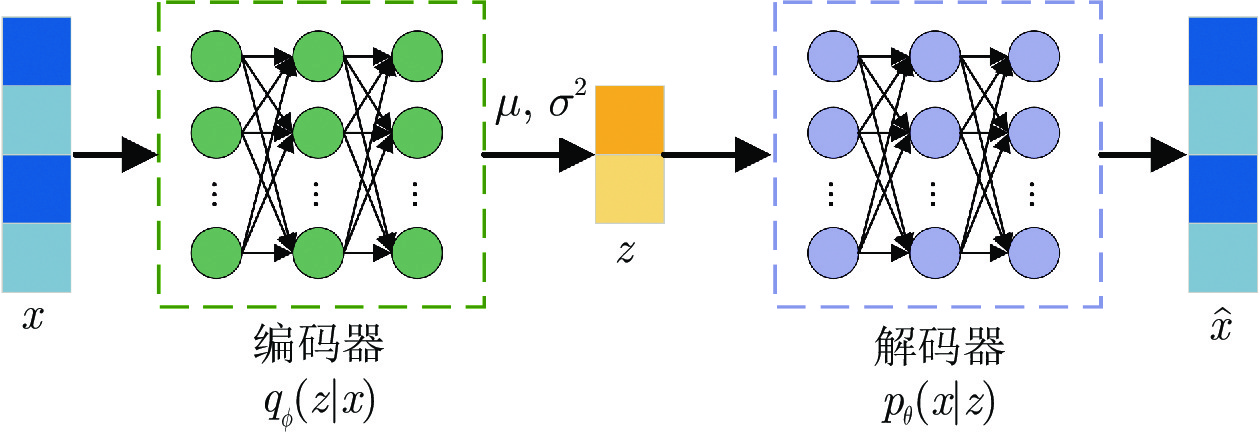

摘要: 近年来, 变分自编码器(Variational auto-encoder, VAE)模型由于在概率数据描述和特征提取能力等方面的优越性, 受到了学术界和工业界的广泛关注, 并被引入到工业过程监测、诊断和软测量建模等应用中. 然而, 传统基于VAE的软测量方法使用高斯分布作为潜在变量的分布, 限制了其对复杂工业过程数据, 尤其是多模态数据的建模能力. 为了解决这一问题, 本论文提出了一种混合变分自编码器回归模型(Mixture variational autoencoder regression, MVAER), 并将其应用于复杂多模态工业过程的软测量建模. 具体来说, 该方法采用高斯混合模型来描述VAE的潜在变量分布, 通过非线性映射将复杂多模态数据映射到潜在空间, 学习各模态下的潜在变量, 获取原始数据的有效特征表示. 同时, 建立潜在特征表示与关键质量变量之间的回归模型, 实现软测量应用. 通过一个数值例子和一个实际工业案例, 对所提模型的性能进行了评估, 验证了该模型的有效性和优越性.

-

关键词:

- 软测量 /

- 变分自编码器 /

- 高斯混合模型 /

- 混合变分自编码器回归模型 /

- 多模态工业过程

Abstract: Recently, variational autoencoder (VAE) has caught much attention from academia and industry owing to its superiority in probabilistic data description and feature extraction, and has been introduced into industrial applications such as process monitoring, diagnosis and soft sensor modeling. However, traditional soft sensing methods based on VAE use the Gaussian distribution as the distribution of latent variables, which limits their ability to model complex industrial process data, especially multimode data. To tackle this issue, a mixture variational autoencoder regression (MVAER) model is proposed and applied to soft sensor modeling for complex multimode industrial processes in this paper. Specifically, the proposed model maps multimode data to the latent space by nonlinear mapping and uses the Gaussian mixture model to describe the distribution of latent variables. Thus, the latent variables under each mode are learned to obtain the effective feature representation of the original data. Meanwhile, a regression model between latent features and key quality variables is established for soft sensor application. Case studies including a numerical example and a real-world industrial process are carried out to assess the performance of the MVAER model, which demonstrate the effectiveness and superiority of the proposed approach. -

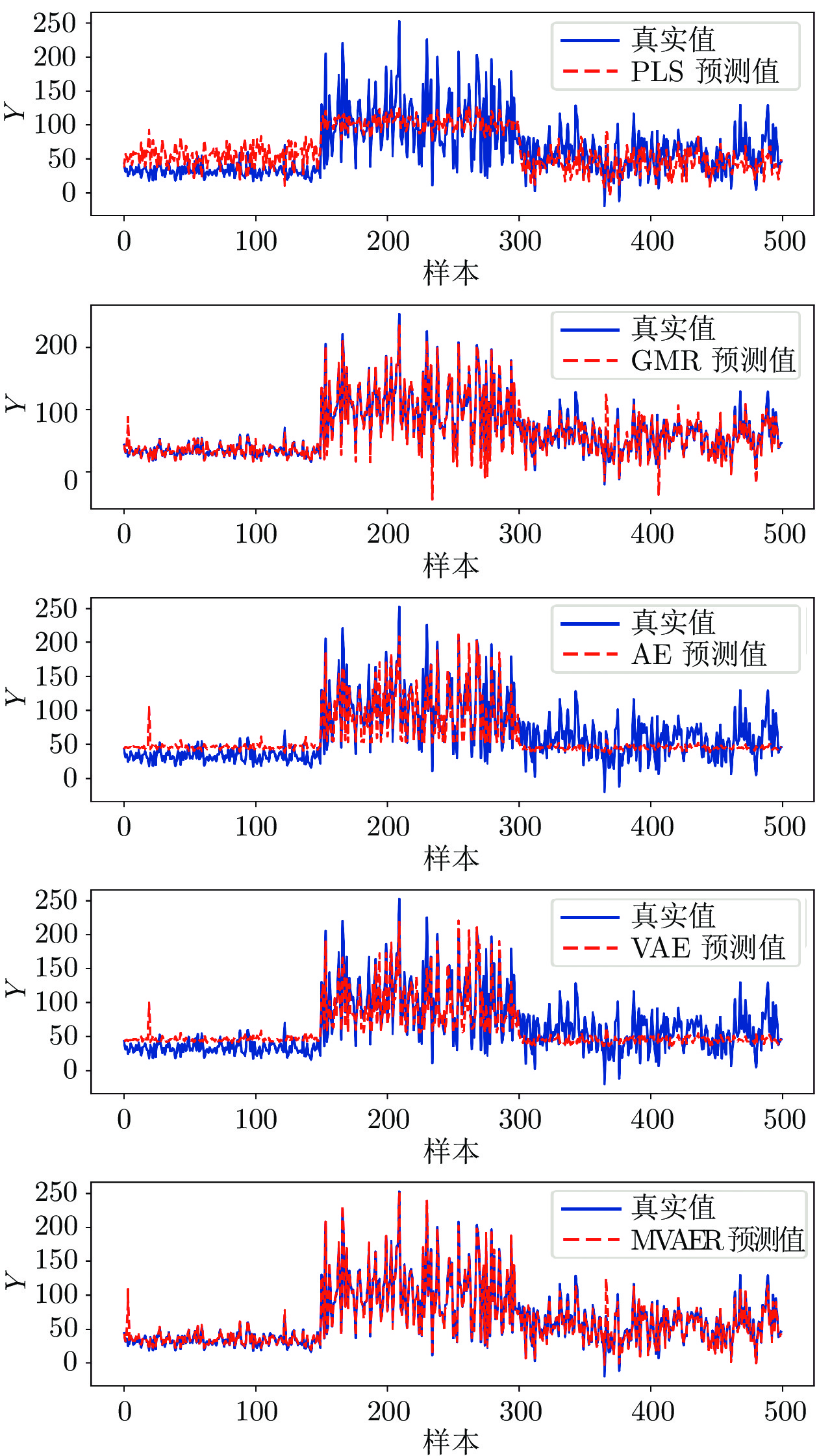

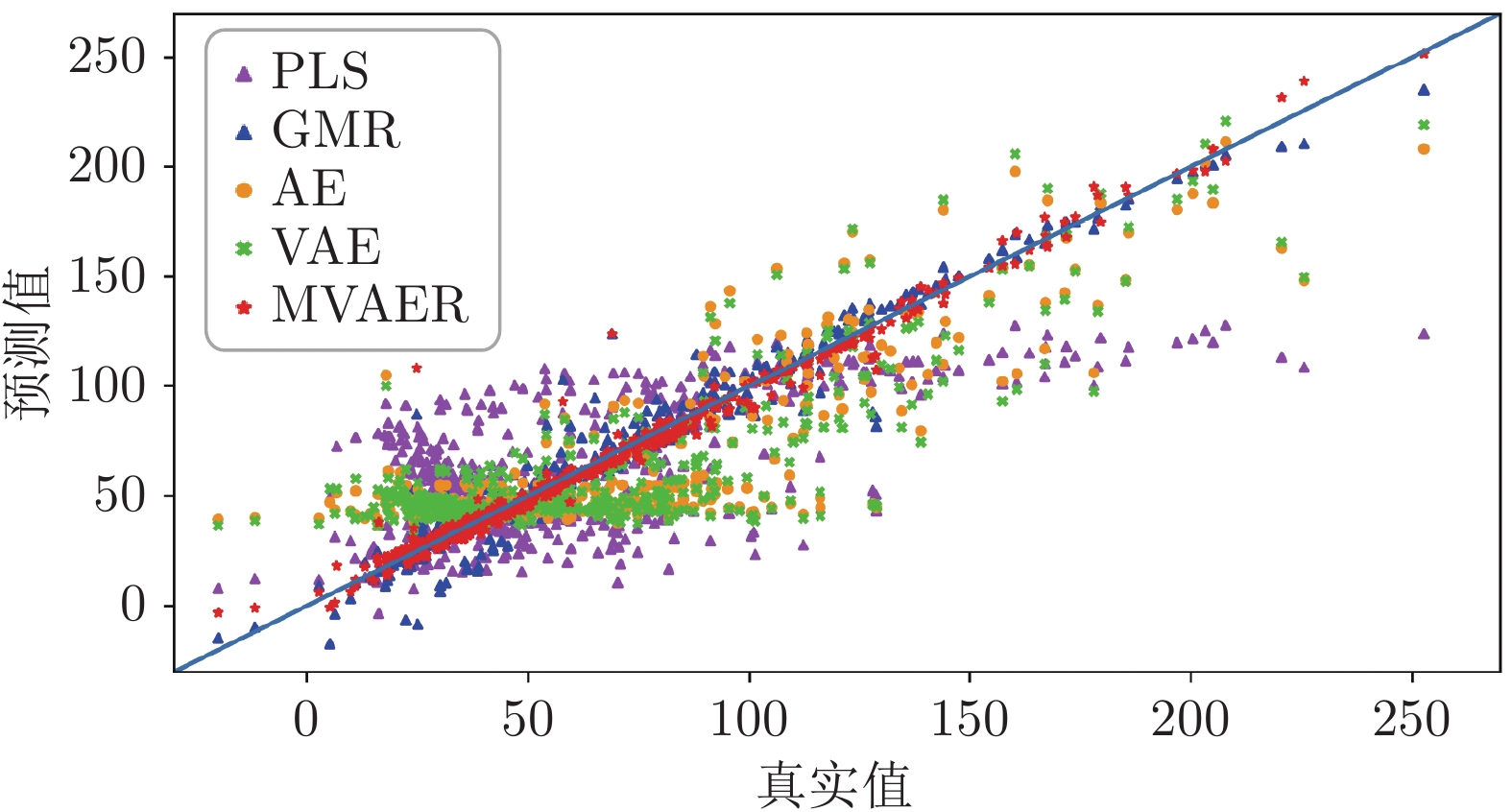

表 1 数值算例的配置

Table 1 Configuration of the numerical example

变量参数 $X({x_1},{x_2})$ $Y({y_1})$关系 $\pi$ $\mu$ $\Sigma $ $k = 1$ 0.3 [18 12] $\left[ \begin{aligned} \;\;{7.5}\;\; - 2.5\\{ - 2.5}\;\;\;{4.5}\;\;\end{aligned} \right]$ ${y_1} = 5{x_1}\sin {x_2}$ $k = 2$ 0.4 [1 10] $\left[ \begin{aligned} {4.5}\;\;{1.6}\\{1.6}\;\;{6.6}\end{aligned} \right]$ ${y_1} = {x_1} + x_2^2$ $k = 3$ 0.4 [12 5] $\left[ \begin{aligned}{8.2}\;\;{ - 2.5}\\{ - 2.5}\;\;\;{6.0}\;\;\end{aligned} \right]$ ${y_1} = {x_1}{x_2}$ 表 2 PLS、GMR、AE、VAE和MVAER模型的性能评价指标

Table 2 Performance evaluation indices of PLS, GMR, AE, VAE and MVAER models

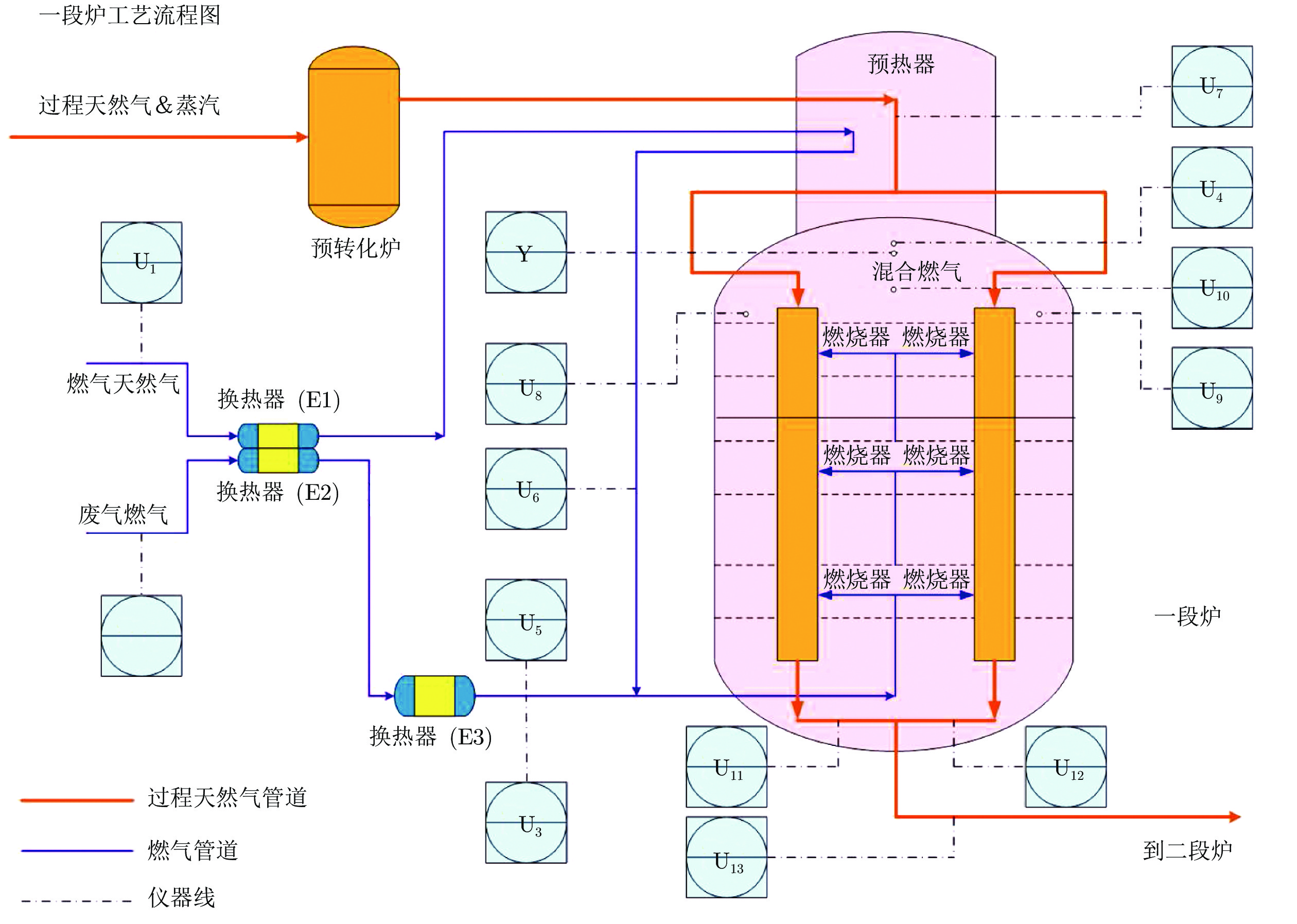

模型 PLS GMR AE VAE MVAER RMSE 33.2076 9.2463 25.0299 25.3014 6.1914 R2 0.3964 0.9532 0.6571 0.6496 0.9797 表 3 一段炉过程变量描述

Table 3 The description of the process instruments in the primary reformer

标签 名称 U1 燃料天然气流量 U2 燃料尾气流量 U3 E3 出口燃料天然气压力 U4 PR 出口炉膛烟气压力 U5 E3 出口燃料尾气温度 U6 PH 出口燃料天然气温度 U7 PR 入口工艺气温度 U8 PR 顶部左侧炉膛烟气温度 U9 PR 顶部右侧炉膛烟气温度 U10 PR 顶部混合炉膛烟气温度 U11 PR 出口转换气温度 U12 PR 右侧出口转换气温度 U13 PR 出口转换气温度 Y 炉内顶部氧气含量 表 4 PLS、GMR、VAE和MVAER模型的性能评价指标

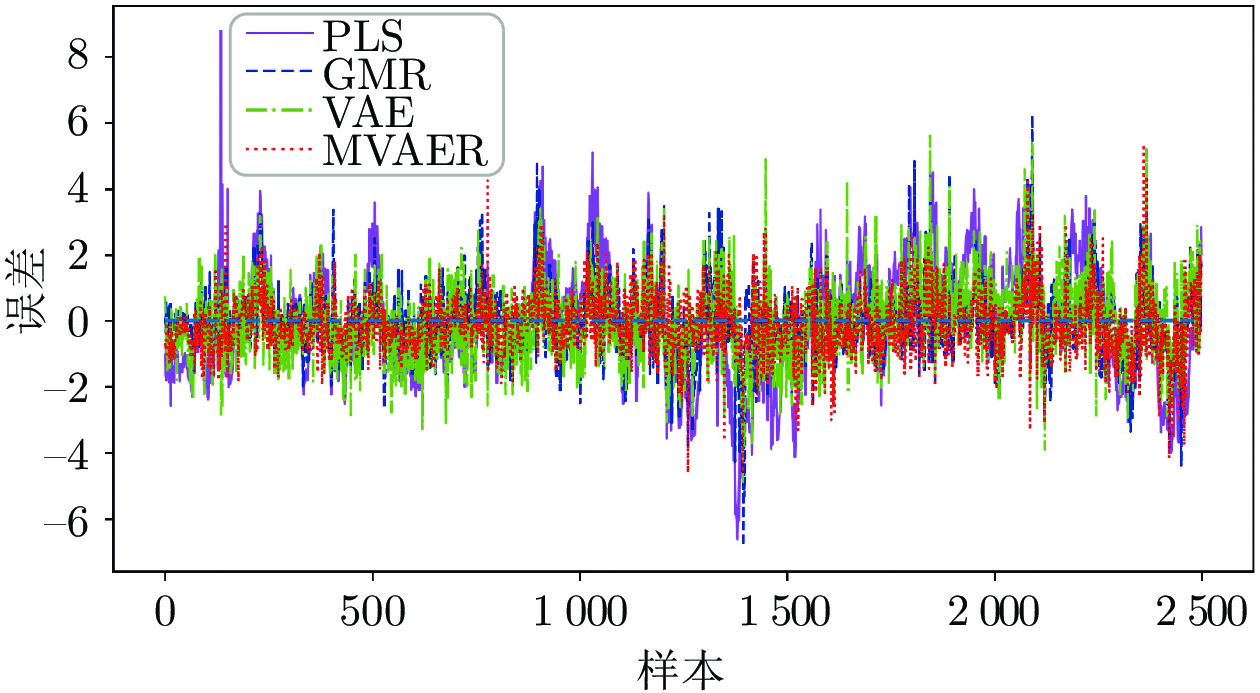

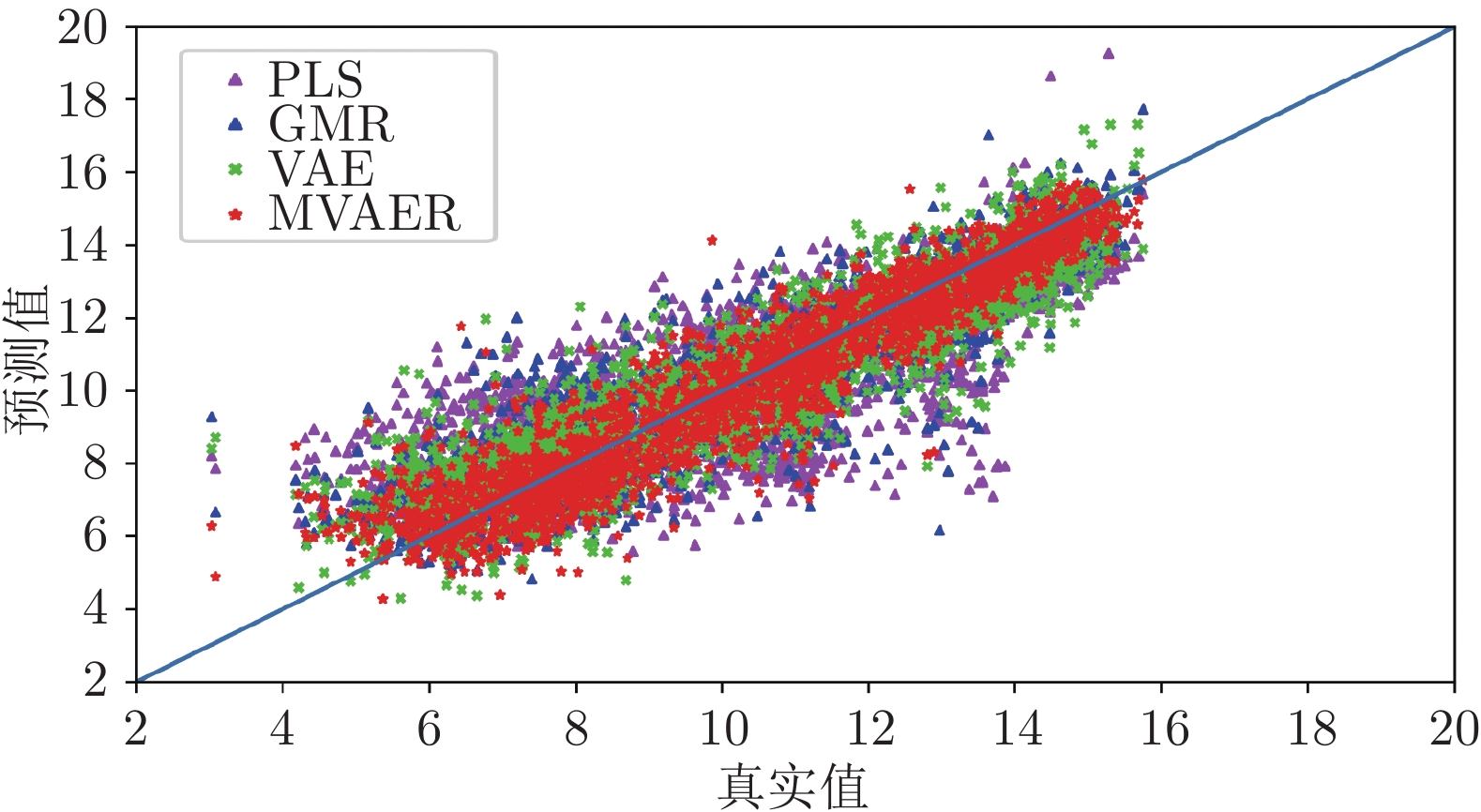

Table 4 Performance evaluation indices of PLS, GMR, VAE and MVAER models

模型 PLS GMR VAE MVAER RMSE 1.7329 1.0844 1.1379 0.8940 R2 0.6129 0.8484 0.8331 0.8970 -

[1] Sun, Q, Ge Z. A survey on deep learning for data-driven soft sensors. IEEE Transactions on Industrial Informatics, 2021, 17(9): 5853-5866 doi: 10.1109/TⅡ.2021.3053128 [2] Yin S, Li X, Gao H, et al. Data-based techniques focused on modern industry: An overview. IEEE Transactions on Industrial Electronics, 2014, 62(1): 657-667. [3] Liu Y, Yang C, Liu K, et al. Domain adaptation transfer learning soft sensor for product quality prediction. Chemometrics and Intelligent Laboratory Systems, 2019, 192: 103813. doi: 10.1016/j.chemolab.2019.103813 [4] Liu Y, Yang C, Gao Z, et al. Ensemble deep kernel learning with application to quality prediction in industrial polymerization processes. Chemometrics and Intelligent Laboratory Systems, 2018, 174: 15-21. doi: 10.1016/j.chemolab.2018.01.008 [5] 柴天佑. 复杂工业过程运行优化与反馈控制. 自动化学报, 2013, 39(11): 1744-1757 doi: 10.3724/SP.J.1004.2013.01744Chai Tian-You. Operational optimization and feedback control for complex industrial processes. Acta Automatica Sinica, 2013, 39(11): 1744-1757 doi: 10.3724/SP.J.1004.2013.01744 [6] Sun, Q, Ge Z. Deep Learning for Industrial KPI Prediction: When Ensemble Learning Meets Semi-Supervised Data.IEEE Transactions on Industrial Informatics, 2021, 17: 260-269. doi: 10.1109/TII.2020.2969709 [7] Shao W, Tian X, Wang P, et al. Online soft sensor design using local partial least squares models with adaptive process state partition. Chemometrics and Intelligent Laboratory Systems, 2015, 144: 108-121. doi: 10.1016/j.chemolab.2015.04.003 [8] Yuan X, Ou C, Wang Y, et al. A novel semi-supervised pre-training strategy for deep networks and its application for quality variable prediction in industrial processes. Chemical Engineering Science, 2020, 217: 115509. doi: 10.1016/j.ces.2020.115509 [9] Zheng W, Liu Y, Gao Z, et al. Just-in-time semi-supervised soft sensor for quality prediction in industrial rubber mixers. Chemometrics and Intelligent Laboratory Systems, 2018, 180: 36-41. doi: 10.1016/j.chemolab.2018.07.002 [10] Xie R, Hao K, Huang B, et al. Data-Driven Modeling Based on Two-Stream λ Gated Recurrent Unit Network With Soft Sensor Application. IEEE Transactions on Industrial Electronics, 2019, 67(8): 7034-7043. [11] Yan W, Tang D, Lin Y. A data-driven soft sensor modeling method based on deep learning and its application. IEEE Transactions on Industrial Electronics, 2016, 64(5): 4237-4245. [12] Kadlec P, Gabrys B, Strandt S. Data-driven soft sensors in the process industry. Computers & chemical engineering, 2009, 33(4): 795-814. [13] Yuan X, Huang B, Wang Y, et al. Deep learning-based feature representation and its application for soft sensor modeling with variable-wise weighted SAE. IEEE Transactions on Industrial Informatics, 2018, 14(7): 3235-3243. doi: 10.1109/TII.2018.2809730 [14] Ge Z. Process data analytics via probabilistic latent variable models: A tutorial review. Industrial & Engineering Chemistry Research, 2018, 57(38): 12646-12661. [15] Chen N, Dai J, Yuan X, et al. Temperature prediction model for roller kiln by ALD-based double locally weighted kernel principal component regression. IEEE Transactions on Instrumentation and Measurement, 2018, 67(8): 2001-2010. doi: 10.1109/TIM.2018.2810678 [16] Peng K, Zhang K, You B, et al. Quality-related prediction and monitoring of multi-mode processes using multiple PLS with application to an industrial hot strip mill. Neurocomputing, 2015, 168: 1094-1103. doi: 10.1016/j.neucom.2015.05.014 [17] Kaneko H, Funatsu K. Database monitoring index for adaptive soft sensors and the application to industrial process. AIChE Journal, 2014, 60(1): 160-169. doi: 10.1002/aic.14260 [18] Gonzaga J C B, Meleiro L A C, Kiang C, et al. ANN-based soft-sensor for real-time process monitoring and control of an industrial polymerization process. Computers & chemical engineering, 2009, 33(1): 43-49. [19] Shang C, Yang F, Huang D, et al. Data-driven soft sensor development based on deep learning technique. Journal of Process Control, 2014, 24(3): 223-233. doi: 10.1016/j.jprocont.2014.01.012 [20] Yao L, Ge Z. Deep learning of semisupervised process data with hierarchical extreme learning machine and soft sensor application. IEEE Transactions on Industrial Electronics, 2018, 65(2): 1490-1498. doi: 10.1109/TIE.2017.2733448 [21] Yuan X, Zhou J, Huang B, et al. Hierarchical quality-relevant feature representation for soft sensor modeling: a novel deep learning strategy. IEEE Transactions on Industrial Informatics, 2019, 16(6): 3721-3730. [22] Zhang X, Ge Z. Automatic Deep Extraction of Robust Dynamic Features for Industrial Big Data Modeling and Soft Sensor Application. IEEE Transactions on Industrial Informatics, 2020, 16(7): 4456-4467. doi: 10.1109/TII.2019.2945411 [23] Zheng S, Liu K, Xu Y, et al. Robust soft sensor with deep kernel learning for quality prediction in rubber mixing processes. Sensors, 2020, 20(3): 695. doi: 10.3390/s20030695 [24] Zhou L, Chen J, Song Z, et al. Probabilistic latent variable regression model for process-quality monitoring. Chemical Engineering Science, 2014, 116: 296-305. doi: 10.1016/j.ces.2014.04.045 [25] Yuan X, Ge Z, Huang B, et al. A probabilistic just-in-time learning framework for soft sensor development with missing data. IEEE Transactions on Control Systems Technology, 2016, 25(3): 1124-1132. [26] Kingma D P, Welling M. Auto-encoding variational bayes. arXiv preprint arXiv: 1312.6114, 2013. [27] Wang K, Forbes M G, Gopaluni B, et al. Systematic development of a new variational autoencoder model based on uncertain data for monitoring nonlinear processes. IEEE Access, 2019, 7: 22554-22565. doi: 10.1109/ACCESS.2019.2894764 [28] Lee S, Kwak M, Tsui K L, et al. Process monitoring using variational autoencoder for high-dimensional nonlinear processes. Engineering Applications of Artificial Intelligence, 2019, 83: 13-27. doi: 10.1016/j.engappai.2019.04.013 [29] Shen B, Yao L, Ge Z. Nonlinear probabilistic latent variable regression models for soft sensor application: From shallow to deep structure. Control Engineering Practice, 2020, 94: 104198. doi: 10.1016/j.conengprac.2019.104198 [30] Guo F, Xie R, Huang B. A deep learning just-in-time modeling approach for soft sensor based on variational autoencoder. Chemometrics and Intelligent Laboratory Systems, 2020, 197: 103922. doi: 10.1016/j.chemolab.2019.103922 [31] Shen B, Ge Z. Supervised nonlinear dynamic system for soft sensor application aided by variational auto-encoder[J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(9): 6132-6142. [32] Grbić R, Slišković D, Kadlec P. Adaptive soft sensor for online prediction and process monitoring based on a mixture of Gaussian process models. Computers & chemical engineering, 2013, 58: 84-97. [33] Souza F A A, Araújo R. Mixture of partial least squares experts and application in prediction settings with multiple operating modes. Chemometrics and Intelligent Laboratory Systems, 2014, 130: 192-202. doi: 10.1016/j.chemolab.2013.11.006 [34] 郭小萍, 刘诗洋, 李元. 基于稀疏残差距离的多工况过程故障检测方法研究. 自动化学报, 2019, 45(3): 617-625Guo Xiao-Ping, Liu Shi-Yang, Li Yuan. Fault Detection of Multi-mode Processes Employing Sparse Residual Distance. Acta Automatica Sinica, 2019, 45(3): 617-625 [35] Dilokthanakul N, Mediano P A M, Garnelo M, et al. Deep unsupervised clustering with gaussian mixture variational autoencoders. arXiv preprint arXiv: 1611.02648, 2016. [36] Jiang Z, Zheng Y, Tan H, et al. Variational deep embedding: An unsupervised and generative approach to clustering. arXiv preprint arXiv: 1611.05148, 2016. [37] Yang L, Cheung N M, Li J, et al. Deep clustering by Gaussian mixture variational autoencoders with graph embedding. In: Proceedings of International Conference on Computer Vision. Seoul, Korea: IEEE, 2019. 6439−6448 [38] Doersch C. Tutorial on variational autoencoders. arXiv preprint arXiv: 1606.05908, 2016. [39] 胡铭菲, 左信, 刘建伟. 深度生成模型综述. 自动化学报, 2022, 48(2): 40-74Hu Ming-Fei, Zuo Xin, Liu Jian-Wei. Survey on deep generative model. Acta Automatica Sinica, 2020, 41(x): 1-34 -

下载:

下载: