-

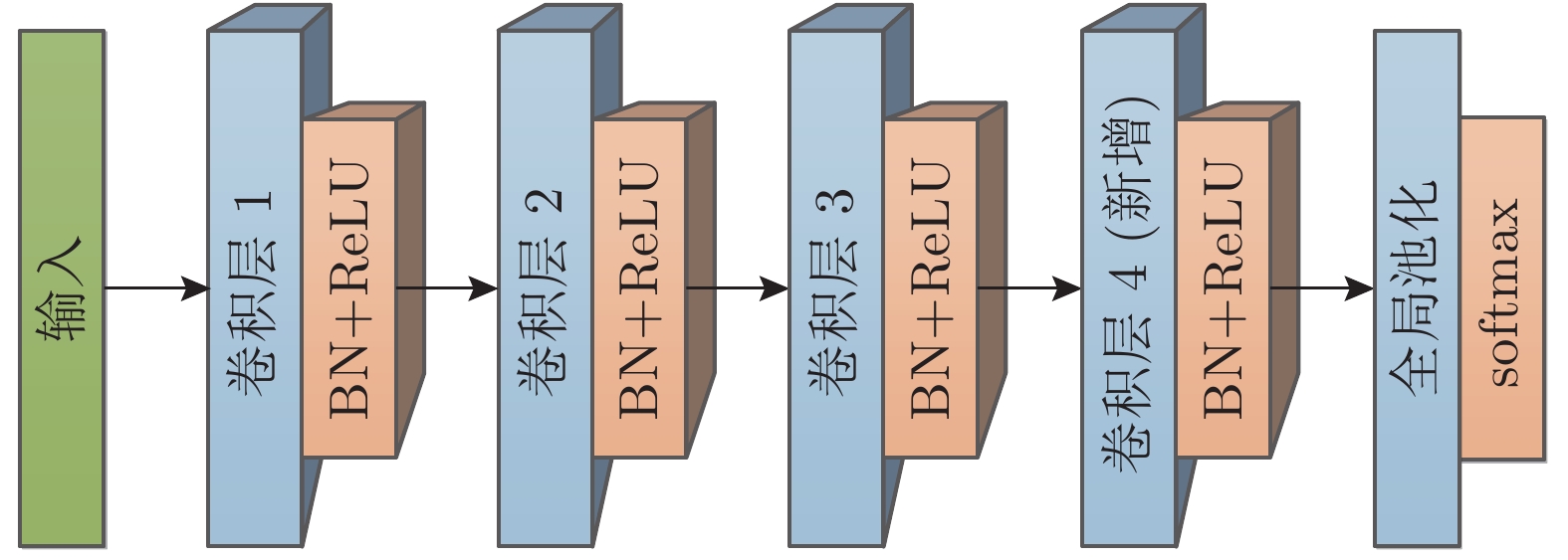

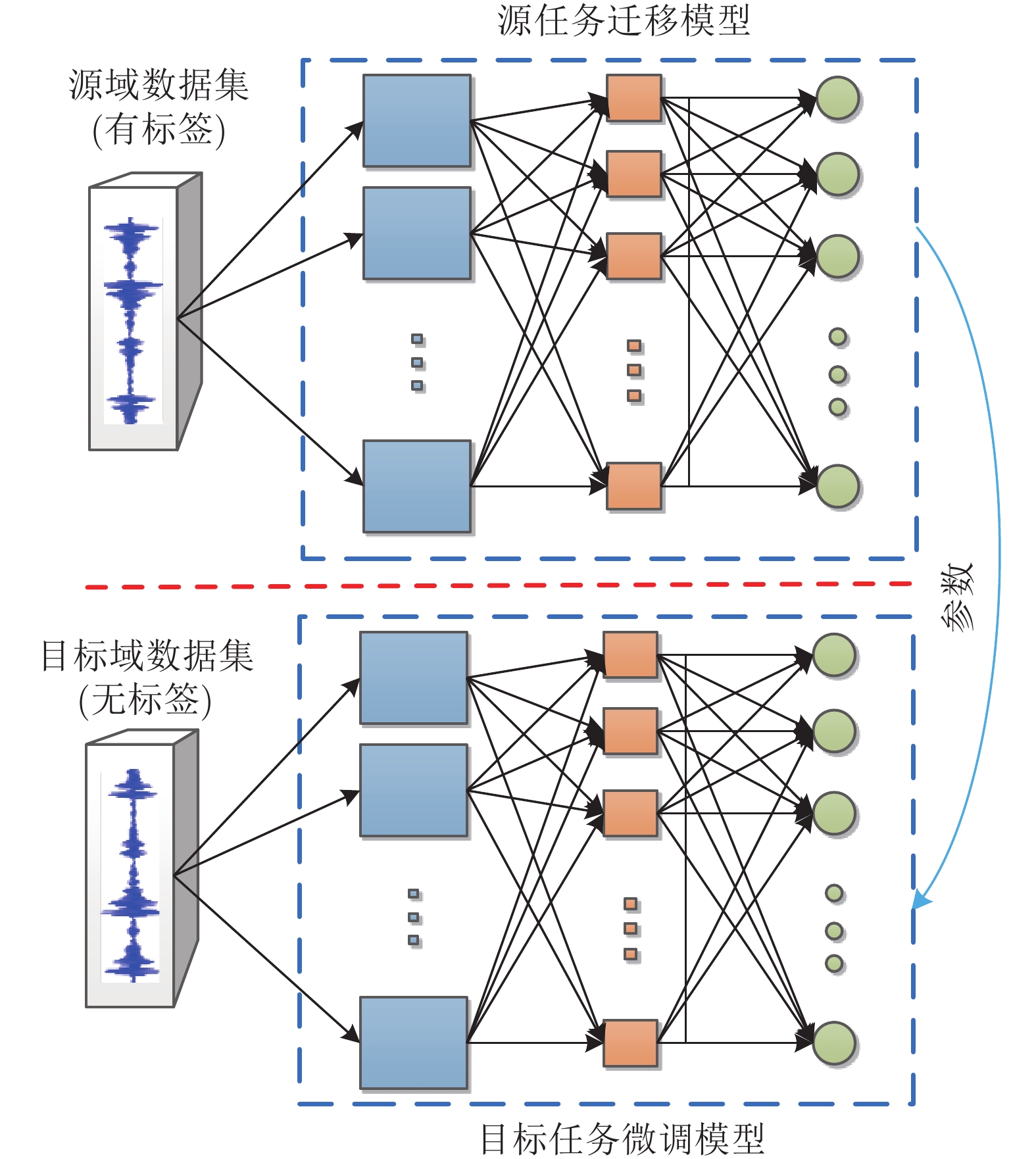

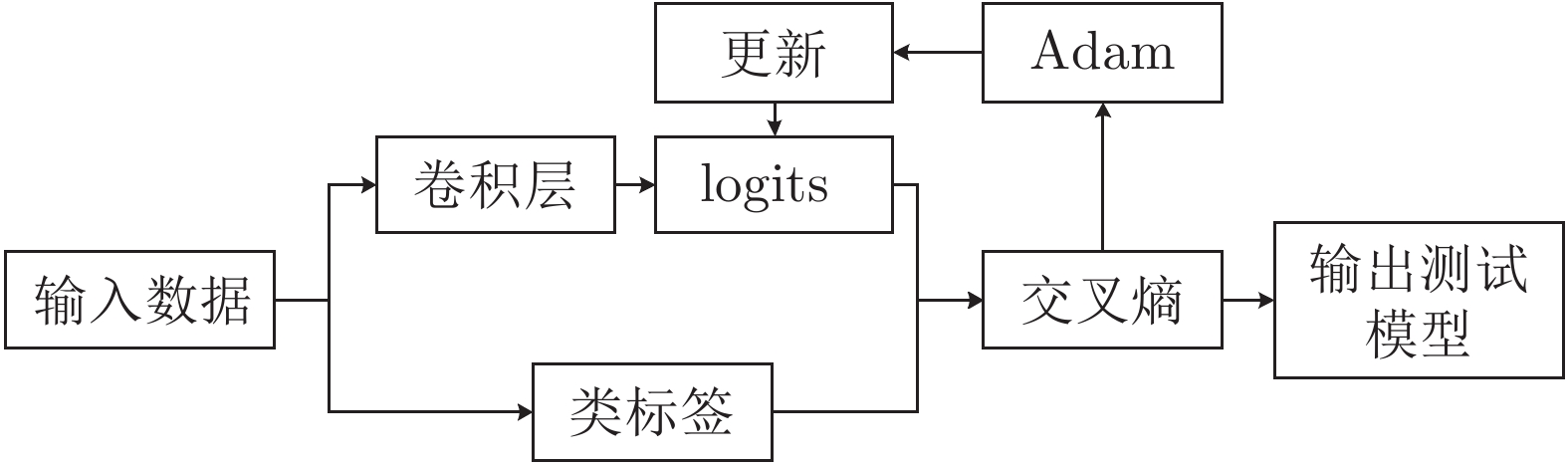

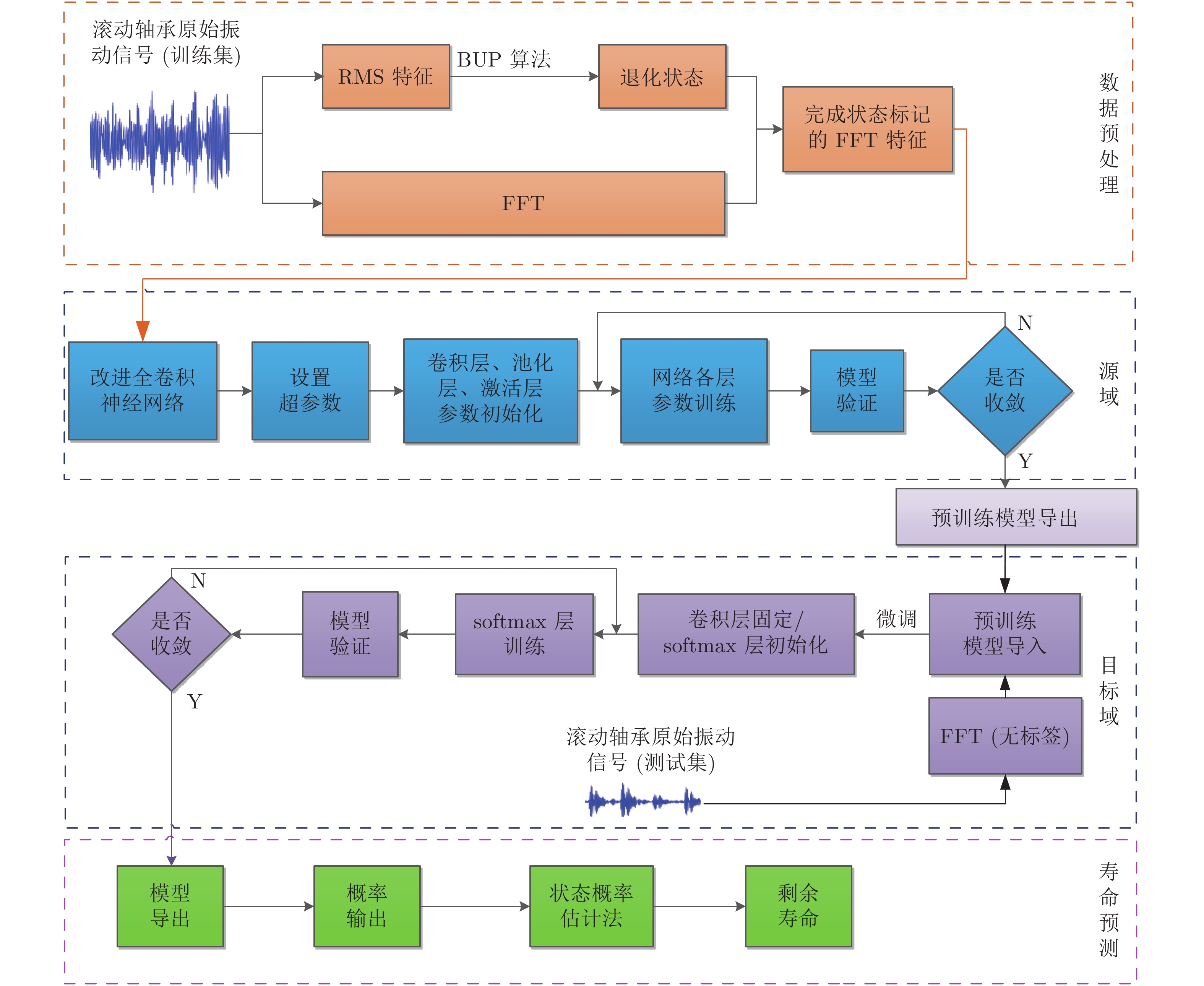

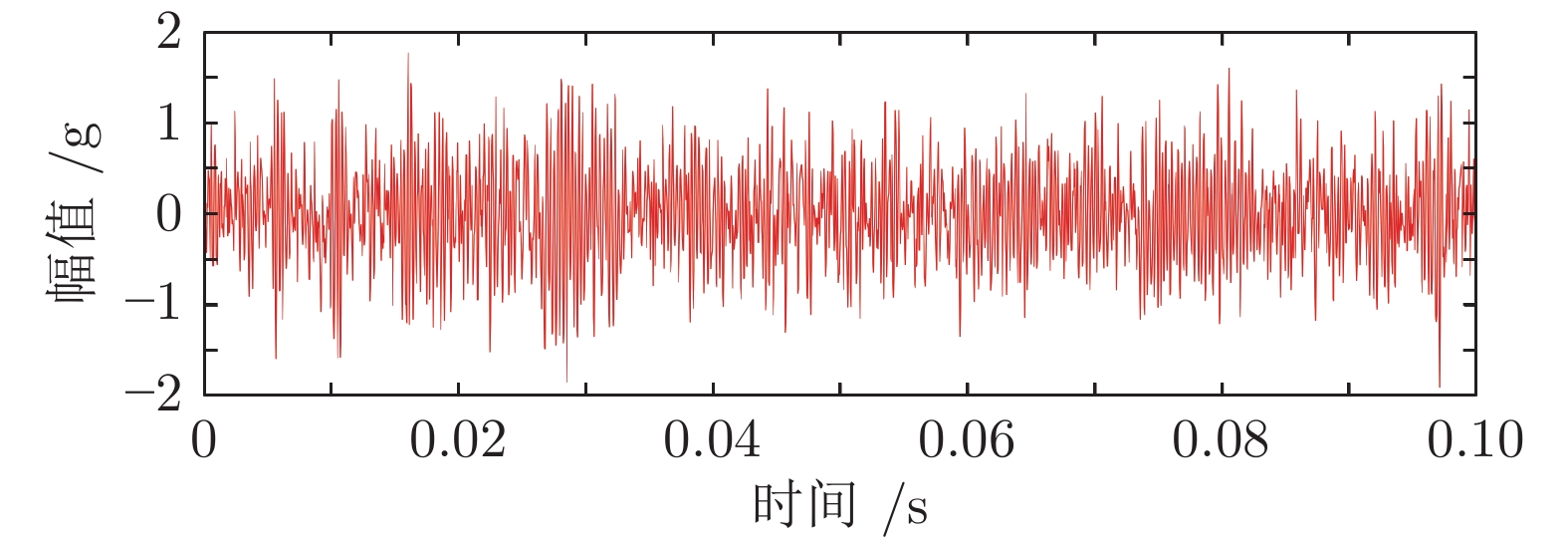

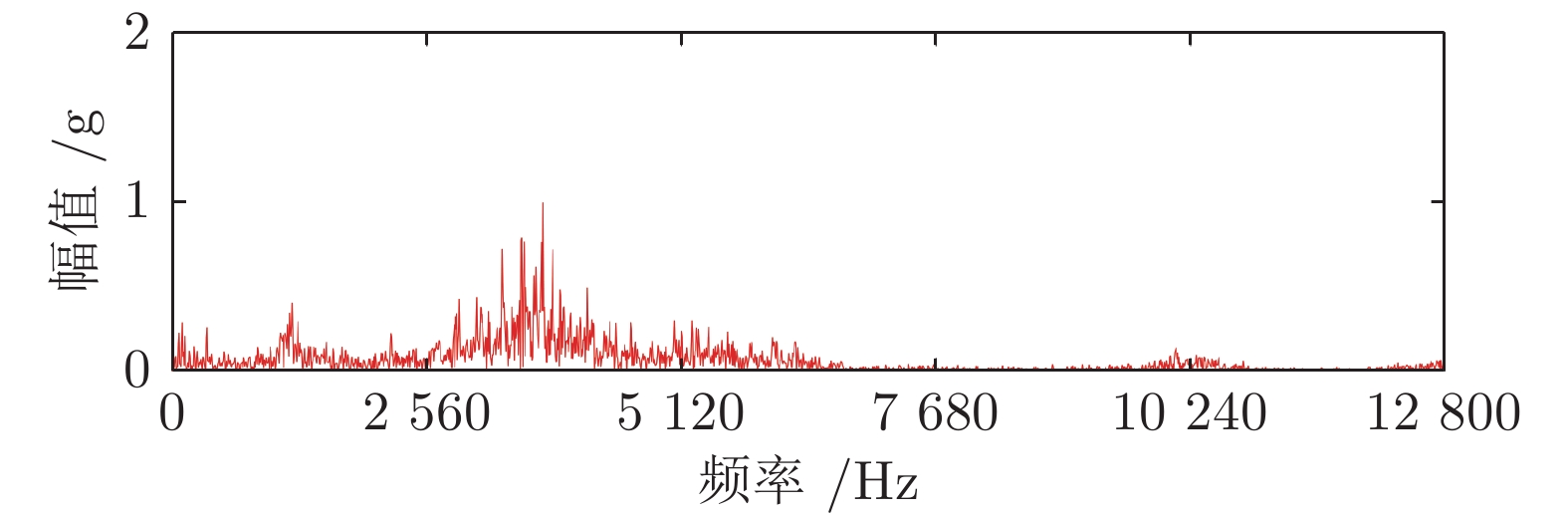

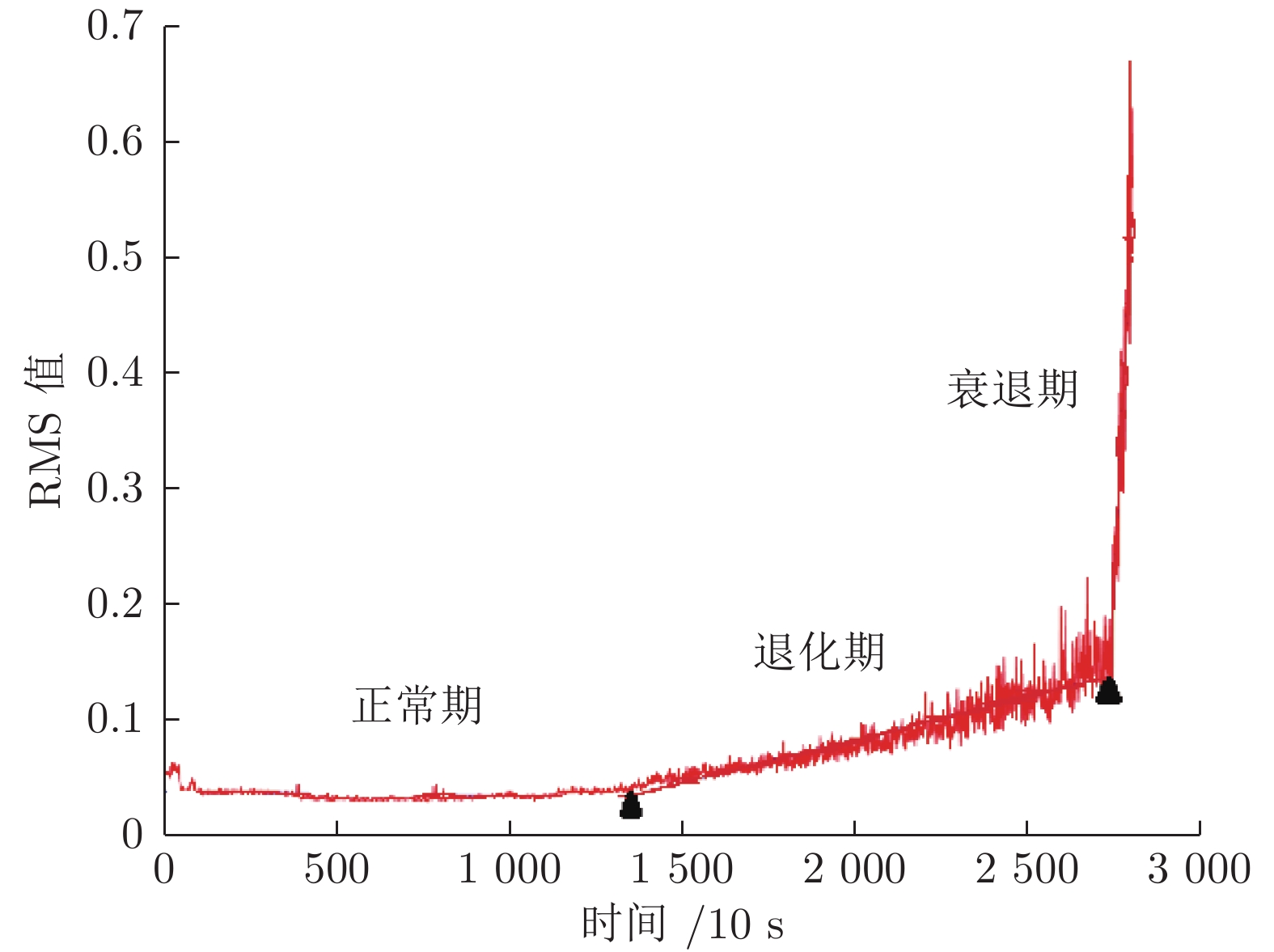

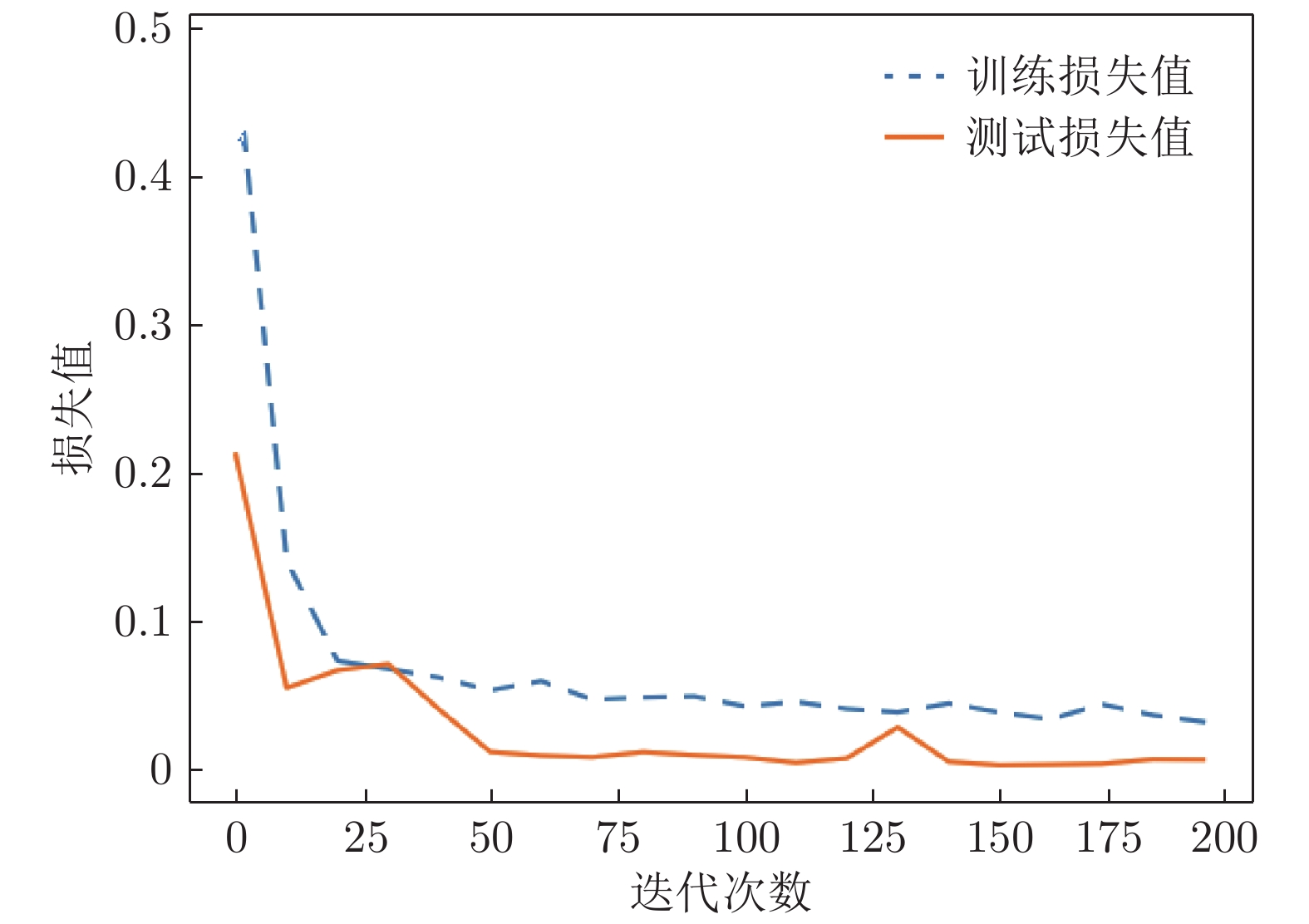

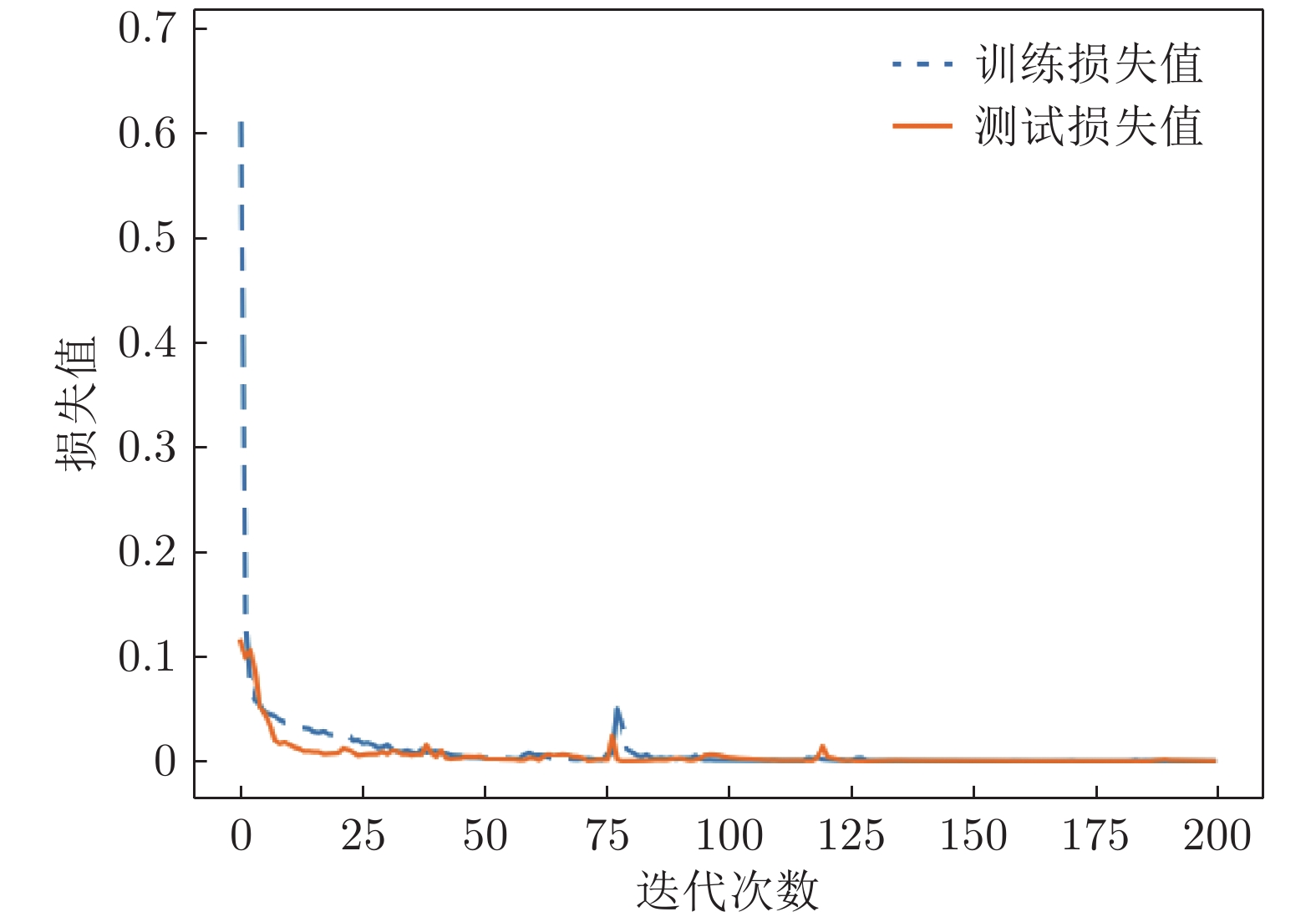

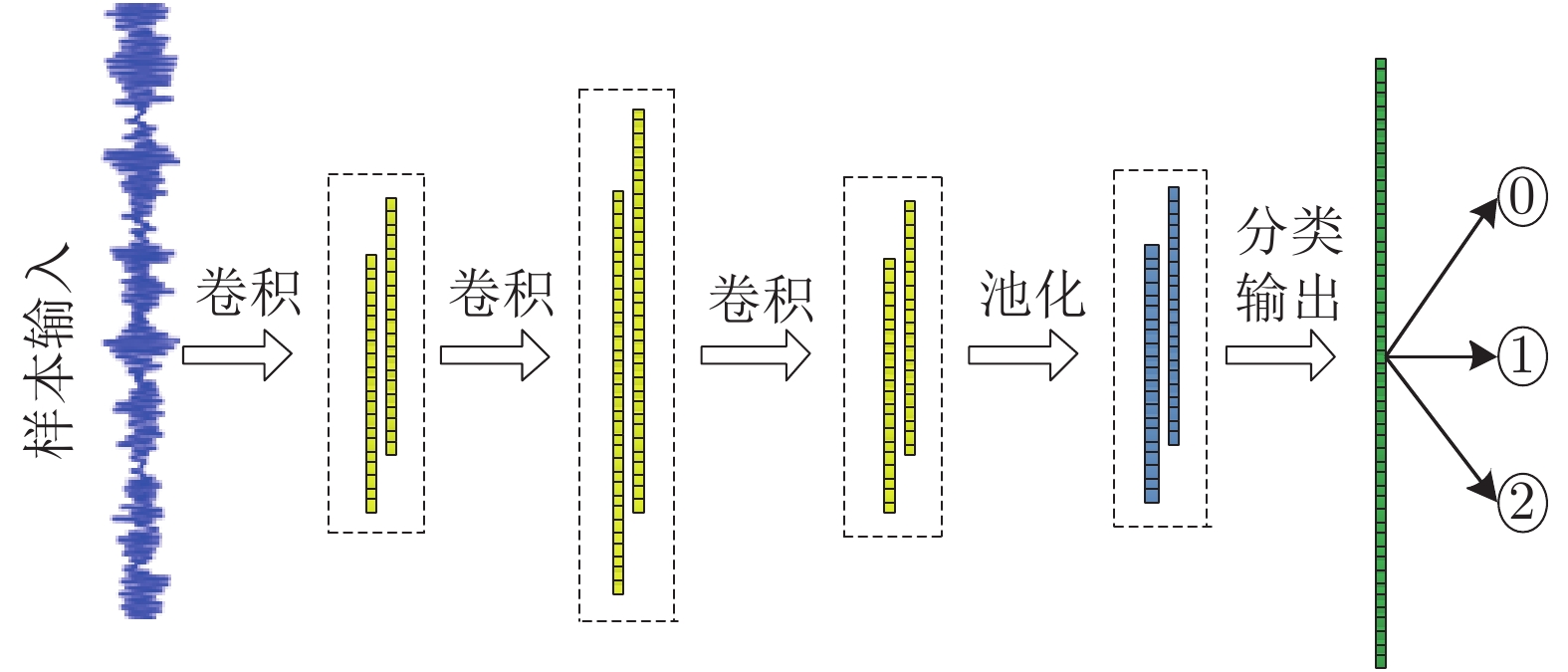

摘要: 针对实际中某种工况滚动轴承带标签振动数据获取困难, 健康指标难以构建及寿命预测误差大的问题, 提出一种基于无监督深度模型迁移的滚动轴承剩余使用寿命(Remaining useful life, RUL)预测方法. 该方法首先对滚动轴承全寿命周期振动数据提取均方根(Root mean square, RMS)特征, 并引入新的自下而上(Bottom-up, BUP)时间序列分割算法将特征序列分割为正常期、退化期和衰退期3种状态; 对振动信号经快速傅里叶(Fast Fourier transform, FFT)变换后的幅值序列进行状态信息标记, 并将其输入到新增卷积层的全卷积神经网络(Full convolutional neural network, FCN)中, 提取深层特征, 得到预训练模型; 提出将预训练模型的梯度作为一种“特征”与传统预训练模型特征一起参与目标域网络训练过程, 从而得到状态识别模型; 利用状态概率估计法结合状态识别模型建立滚动轴承寿命预测模型. 实验验证所提方法无需构建健康指标, 可实现无监督条件下不同工况滚动轴承剩余寿命预测, 并获得较好的效果.Abstract: In order to solve the problems such as difficulty in acquiring labeled vibration data of rolling bearings under certain working condition in practice, difficulty in constructing health indicators and large error in life prediction of rolling bearings, a method of remaining useful life (RUL) prediction of rolling bearings is proposed based on unsupervised deep model transfer. Firstly, the root mean square (RMS) features of the vibration data of the full life cycle of the rolling bearings are extracted, and a new bottom-up (BUP) time series segmentation algorithm is introduced to divide the feature sequence into three states: Normal period, degradation period and recession period. Mark the state information of the amplitude sequence of the vibration signal after the fast Fourier transform (FFT), and input it into the fully convolutional neural network (FCN) of the newly added convolutional layer to extract deep features, and the pre-trained model can be obtained. The gradient of the pre-trained model is proposed and used as a “feature” to participate in the target domain network training process together with the traditional pre-trained model features, and the state identification model is obtained. Using state probability estimation method combined with state identification model, life prediction model of rolling bearing can be established. Experiments verify that, without establishing health indicators, the proposed method can realize remaining useful life prediction of rolling bearings for different working conditions under unsupervised conditions, and achieve better results.

-

表 1 PHM 2012数据描述

Table 1 PHM 2012 data description

数据 工况 1 工况 2 工况 3 训练数据 轴承1_1 轴承2_1 轴承3_1 轴承1_2 轴承2_2 轴承3_2 测试数据 轴承1_3 轴承2_3 轴承3_3 轴承1_4 轴承2_4 轴承1_5 轴承2_5 轴承1_6 轴承2_6 轴承1_7 轴承2_7 表 2 三种工况描述

Table 2 Description of the three working conditions

工况 转速 (r/min) 载荷 (N) 工况 1 1800 4000 工况 2 1650 4200 工况 3 1500 5000 表 3 卷积层数修改前后实验结果

Table 3 Experimental results before and after modification of the number of convolutional layers

层数 准确率 (%) 原始卷积层数目 3 94.23 修改后卷积层数目 4 99.46 表 4 传递梯度特征前后实验对比结果

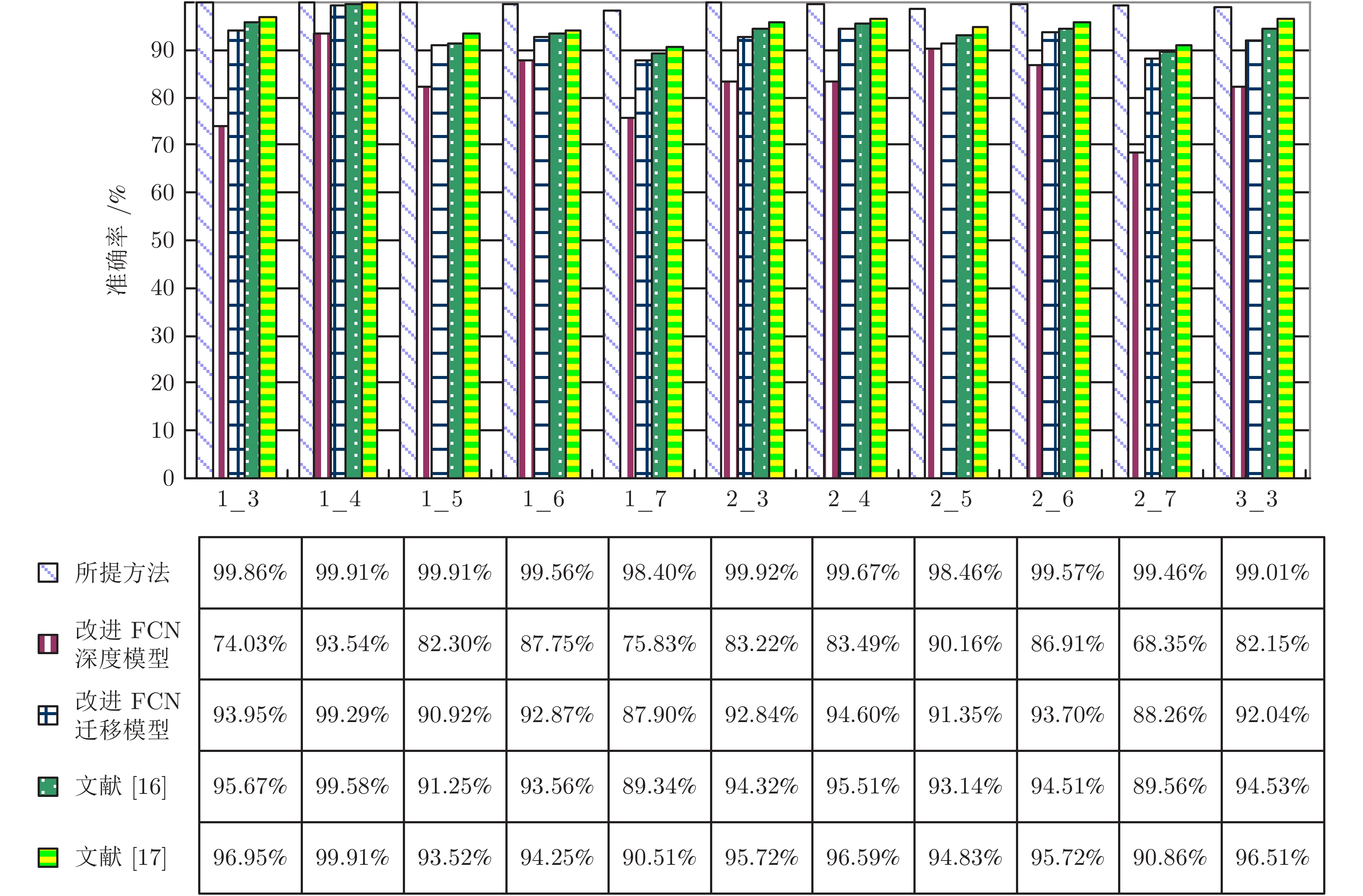

Table 4 Experimental comparison results before and after transferring gradient features

测试集 平均准确率 (%) 不传递梯度特征 传递梯度特征 1_3 93.95 99.86 1_4 99.29 99.91 1_5 90.92 99.91 1_6 92.87 99.56 1_7 87.90 98.40 2_3 92.84 99.92 2_4 94.60 99.67 2_5 91.35 98.46 2_6 93.70 99.57 2_7 88.26 99.46 3_3 92.04 99.01 表 5 不同轴承RUL预测误差结果对比

Table 5 Comparison of RUL prediction error results of different bearings

不同轴承 当前时间点 实际预测点 本文预测点 本文误差$E_J $ (%) 1_3 18010 5730 4270 25.35 1_4 11380 2900 2210 23.53 1_5 23010 1610 3630 −126.87 1_6 23010 1460 1540 −5.47 1_7 15010 7570 2930 61.24 2_3 12010 7530 2950 60.77 2_4 6110 1390 1180 14.49 2_5 20010 3090 350 88.63 2_6 5710 1290 1110 13.28 2_7 1710 580 330 42.11 3_3 3510 820 680 16.05 平均误差 — — — 19.37 平均得分 — — — 0.33 表 6 与其他方法预测误差结果对比

Table 6 Comparison of prediction error results with other methods

不同轴承 预测误差$E_J $ (%) 本文方法 方案1 方案2 文献 [25] 文献 [26] 1_3 25.35 35.98 32.54 43.28 −31.76 1_4 23.53 40.25 36.92 67.55 62.76 1_5 −126.87 −138.54 −129.35 −22.98 −136.03 1_6 −5.47 −20.18 −15.18 21.23 −32.88 1_7 61.24 79.65 75.64 17.83 −11.09 2_3 60.77 80.25 72.49 37.84 44.22 2_4 14.49 30.24 25.83 −19.42 −55.40 2_5 88.63 100.25 95.95 54.37 68.61 2_6 13.28 35.68 30.39 −13.95 −51.94 2_7 42.11 60.21 55.16 −55.17 −68.97 3_3 16.05 40.81 35.97 3.66 −21.96 平均误差 19.37 31.33 28.76 32.48 53.24 -

[1] 毛文涛, 田思雨, 窦智, 张迪, 丁玲. 一种基于深度迁移学习的滚动轴承早期故障在线检测方法. 自动化学报, 2022, 48(1): 302-314Mao Wen-Tao, Tian Si-Yu, Dou Zhi, Zhang Di, Ding Ling. A new deep transfer learning-based online detection method of rolling bearing early fault. Acta Automatica Sinica, 2022, 48(1): 302-314 [2] 张建勋, 杜党波, 司小胜, 胡昌华, 郑建飞. 基于最后逃逸时间的随机退化设备寿命预测方法. 自动化学报, 2022, 48(1): 249-260Zhang Jian-Xun, Du Dang-Bo, Si Xiao-Sheng, Hu Chang-Hua, Zheng Jian-Fei. Lifetime prediction for stochastic deteriorating systems based on the last exit time. Acta Automatica Sinica, 2022, 48(1): 249-260 [3] 康守强, 周月, 王玉静, 谢金宝, Mikulovich V I. 基于改进SAE和双向LSTM的滚动轴承RUL预测方法. 自动化学报, 2022, 48(9): 2327-2336Kang Shou-Qiang, Zhou Yue, Wang Yu-Jing, Xie Jin-Bao, Mikulovich V I. RUL prediction method of a rolling bearing based on improved SAE and Bi-LSTM. Acta Automatica Sinica, 2022, 48(9): 2327-2336 [4] 文娟, 高宏力. 一种基于UPF的轴承剩余寿命预测方法. 振动与冲击, 2018, 37(24): 208−213, 243Wen Juan, Gao Hong-Li. Remaining useful life prediction of bearings with the unscented particle filter approach. Journal of Vibration and Shock, 2018, 37(24): 208−213, 243 [5] 裴洪, 胡昌华, 司小胜, 张建勋, 庞哲楠, 张鹏. 基于机器学习的设备剩余寿命预测方法综述. 机械工程学报, 2019, 55(8): 1−13 doi: 10.3901/JME.2019.08.001Pei Hong, Hu Chang-Hua, Si Xiao-Sheng, Zhang Jian-Xun, Pang Zhe-Nan, Zhang Peng. Review of machine learning based remaining useful life prediction methods for equipment. Journal of Mechanical Engineering, 2019, 55(8): 1−13 doi: 10.3901/JME.2019.08.001 [6] 雷亚国, 李乃鹏, 林京. 基于粒子滤波的滚动轴承寿命预测方法. 见: 2014年全国机械行业可靠性技术学术交流会暨可靠性工程分会第五届委员会成立大会论文集. 成都, 中国: 中国机械工程学会可靠性工程分会, 2014. 198−203Lei Ya-Guo, Li Nai-Peng, Lin Jing. A particle filtering-based approach for remaining useful life predication of rolling element bearings. In: Proceedings of the National Reliability Technology Academic Exchange Conference and Reliability Engineering Branch of National Machinery Industry Proceedings of the Founding Conference of the 5th Committee. Chengdu, China: Reliability Engineering Branch of Chinese Mechanical Engineering Society, 2014. 198−203 [7] 杨宇, 张娜, 程军圣. 全参数动态学习深度信念网络在滚动轴承寿命预测中的应用. 振动与冲击, 2019, 38(10): 199−205, 249Yang Yu, Zhang Na, Cheng Jun-Sheng. Global parameters dynamic learning deep belief networks and its application in rolling bearing life prediction. Journal of Vibration and Shock, 2019, 38(10): 199−205, 249 [8] 瞿家明, 周易文, 王恒, 黄希, 姜杰. 基于改进HMM和Pearson相似度分析的滚动轴承自适应寿命预测方法. 振动与冲击, 2020, 39(8): 172−177, 201Qu Jia-Ming, Zhou Yi-Wen, Wang Heng, Huang Xi, Jiang Jie. An adaptive life prediction method for rolling bearings based on improved HMM and similarity calculation. Journal of Vibration and Shock, 2020, 39(8): 172−177, 201 [9] 王玉静, 王诗达, 康守强, 王庆岩, Mikulovich V I. 基于改进深度森林的滚动轴承剩余寿命预测方法. 中国电机工程学报, 2020, 40(15): 5032−5042Wang Yu-Jing, Wang Shi-Da, Kang Shou-Qiang, Wang Qing-Yan, Mikulovich V I. Prediction method of remaining useful life of rolling bearings based on improved GcForest. Proceedings of the CSEE, 2020, 40(15): 5032−5042 [10] Guo T, Deng Z M. An improved EMD method based on the multi-objective optimization and its application to fault feature extraction of rolling bearing. Applied Acoustics, 2017, 127: 46−62 doi: 10.1016/j.apacoust.2017.05.018 [11] Xu Y G, Cao J X, Zhao J Y, Zhang K, Tian W K. Application of fast singular spectrum decomposition method based on order statistic filter in rolling bearing fault diagnosis. Measurement Science and Technology, 2019, 30(12): Article No. 125001 doi: 10.1088/1361-6501/ab39eb [12] 赵春华, 胡恒星, 陈保家, 张毅娜, 肖嘉伟. 基于深度学习特征提取和WOA-SVM状态识别的轴承故障诊断. 振动与冲击, 2019, 38(10): 31−37, 48Zhao Chun-Hua, Hu Heng-Xing, Chen Bao-Jia, Zhang Yi-Na, Xiao Jia-Wei. Bearing fault diagnosis based on the deep learning feature extraction and WOA SVM state recognition. Journal of Vibration and Shock, 2019, 38(10): 31−37, 48 [13] Xu F, Tse P W. Automatic roller bearings fault diagnosis using DSAE in deep learning and CFS algorithm. Soft Computing, 2019, 23(13): 5117−5128 doi: 10.1007/s00500-018-3178-x [14] 王玉静, 那晓栋, 康守强, 谢金宝, Mikulovich V I. 基于EEMD-Hilbert包络谱和DBN的变负载下滚动轴承状态识别方法. 中国电机工程学报, 2017, 37(23): 6943−6950Wang Yu-Jing, Na Xiao-Dong, Kang Shou-Qiang, Xie Jin-Bao, Mikulovich V I. State recognition method of a rolling bearing based on EEMD-hilbert envelope spectrum and DBN under variable load. Proceedings of the CSEE, 2017, 37(23): 6943−6950 [15] 昝涛, 王辉, 刘智豪, 王民, 高相胜. 基于多输入层卷积神经网络的滚动轴承故障诊断模型. 振动与冲击, 2020, 39(12): 142−149, 163Zan Tao, Wang Hui, Liu Zhi-Hao, Wang Min, Gao Xiang-Sheng. A fault diagnosis model for rolling bearings based on a multi-input layer convolutional neural network. Journal of Vibration and Shock, 2020, 39(12): 142−149, 163 [16] Guo L, Lei Y G, Xing S B, Yan T, Li N P. Deep convolutional transfer learning network: A new method for intelligent fault diagnosis of machines with unlabeled data. IEEE Transactions on Industrial Electronics, 2019, 66(9): 7316−7325 doi: 10.1109/TIE.2018.2877090 [17] Li J L, Li X Y, He D, Qu Y Z. A domain adaptation model for early gear pitting fault diagnosis based on deep transfer learning network. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, 2020, 234(1): 168-182 doi: 10.1177/1748006X19867776 [18] Zhang R, Tao H Y, Wu L F, Guan Y. Transfer learning with neural networks for bearing fault diagnosis in changing working conditions. IEEE Access, 2017, 5: 14347−14357 doi: 10.1109/ACCESS.2017.2720965 [19] Eker O F, Camci F. State-based prognostics with state duration information. Quality and Reliability Engineering International, 2013, 29(4): 465−476 doi: 10.1002/qre.1393 [20] Lin J, Keogh E, Truppel W. Clustering of streaming time series is meaningless. In: Proceedings of the 8th ACM SIGMOD Workshop on Research Issues in Data Mining and Knowledge Discovery. San Diego, USA: ACM, 2003. 56−65 [21] Atamuradov V, Medjaher K, Camci F, Zerhouni N, Dersin P, Lamoureux B. Feature selection and fault-severity classification-based machine health assessment methodology for point machine sliding-chair degradation. Quality and Reliability Engineering International, 2019, 35(4): 1081−1099 doi: 10.1002/qre.2446 [22] Bui D T, Hoang N D, Martínez-Álvarez F, Ngo P T T, Hoa P V, Pham T D, et al. A novel deep learning neural network approach for predicting flash flood susceptibility: A case study at a high frequency tropical storm area. Science of the Total Environment, 2020, 701: Article No. 134413 doi: 10.1016/j.scitotenv.2019.134413 [23] 齐申武. 基于振动信号分析的滚动轴承故障诊断及寿命预测研究 [硕士学位论文], 燕山大学, 中国, 2018.Qi Shen-Wu. Rolling Bearing Fault Diagnosis and Remain Useful Life Prediction Research Based on Vibration Signal Analysis [Master thesis], Yanshan University, China, 2018. [24] Nectoux P, Gouriveau R, Medjaher K, Ramasso E, Chebel-Morello B, Zerhouni N, et al. PRONOSTIA: An experimental platform for bearings accelerated degradation test. In: Proceedings of the IEEE International Conference on Prognostics and Health Management. Denver, USA: IEEE, 2012. 1−8 [25] Guo L, Li N P, Jia F, Lei Y G, Lin J. A recurrent neural network based health indicator for remaining useful life prediction of bearings. Neurocomputing, 2017, 240: 98−109 doi: 10.1016/j.neucom.2017.02.045 [26] Hong S, Zhou Z, Zio E, Hong K. Condition assessment for the performance degradation of bearing based on a combinatorial feature extraction method. Digital Signal Processing, 2014, 27: 159−166 doi: 10.1016/j.dsp.2013.12.010 -

下载:

下载: