-

摘要:

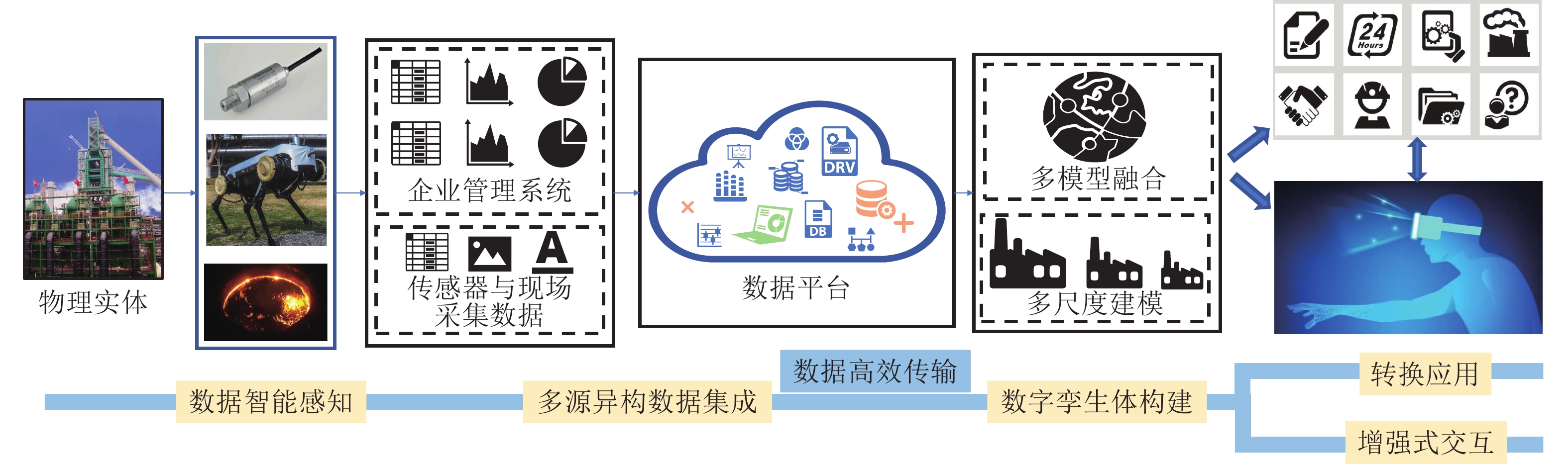

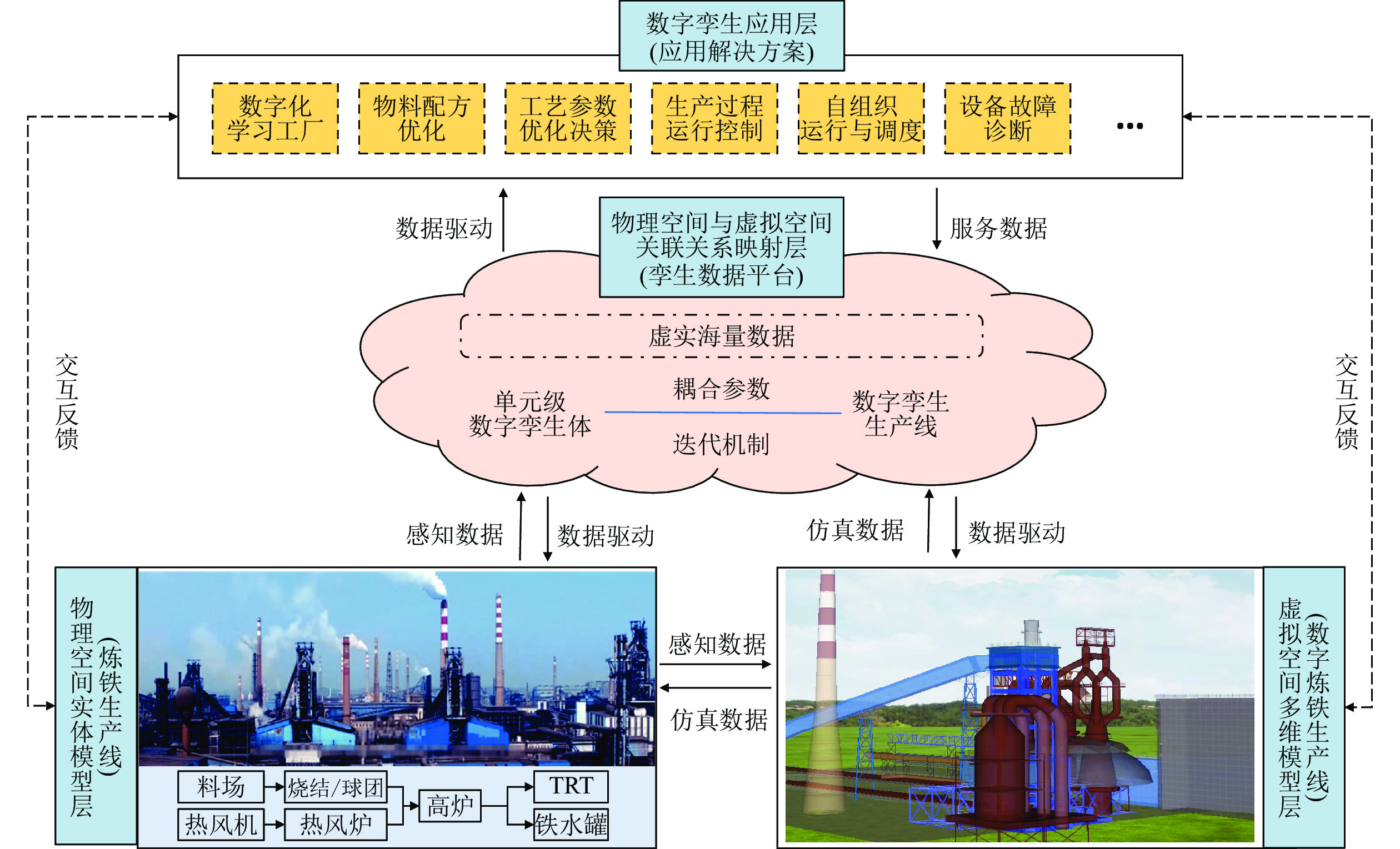

流程工业是制造业的重要组成部分, 是国民经济发展的重要基础, 主要包括化工、冶金、石化等行业, 其安全高效的生产对国家而言具有重要的战略意义. 然而, 流程工业物理化学变化反应复杂、流程间能质流严重耦合、多目标冲突、在线实验风险大, 给生产流程系统建模与高效协同优化带来极大困难, 严重制约了生产质量和资源利用率的进一步提升. 随着信息技术与人工智能的发展, 建立虚实结合、协同优化运行的流程工业数字孪生生产线所需技术逐渐成熟, 其在流程工业的应用价值与潜力日益凸显. 本文首先阐述数字孪生在流程工业应用的必要性与重要性, 并通过边界定义法将数字孪生与信息物理系统(Cyber-physical system, CPS)、工业互联网等概念进行对比分析,从而明确数字孪生的基本内涵与功能边界. 其次描述流程工业抽象模型和数字孪生理论模型间的映射关系, 并分析了如何用数字孪生技术解决流程工业系统建模与高效协同优化的瓶颈问题. 最后, 从数字孪生系统构建的角度探讨数字孪生发展的关键技术, 并以一条炼铁生产线为例, 展示数字孪生技术在实际工业中的应用解决方案.

Abstract:Process industry is a part of manufacturing industry and foundation of national economic development, mainly including chemical industry, metallurgy, petrochemical and other industries. Its safe and efficient production has strategic importance to the country. However, process industry is facing the problems of low efficiency of resource utilization, poor production quality and serious environmental pollution. With the development of information technology and artificial intelligence, the technology needed to create digital twin for process industry is gradually mature. The digital twin for process industry with the combination of virtual and real, intelligent and optimized operation, has a great application value and potential to change the whole industry. This paper focuses on the digital twin technology of process industry. First, we expound the necessity and importance of the application of digital twin and describe the mapping relationship between the abstract model of process industry and the digital twin theoretical model. Secondly, we summarize the concept of digital twin, and compare it with CPS (cyber-physical system), industrial internet and other concepts. Then, according to the sequence of data flow of digital twin system, this paper puts forward six key technologies of digital twin system, including data intelligent perception, multi-source heterogeneous data integration, data efficient transmission, digital twin construction, enhanced interaction and transformation application. Finally, taking a digital twin production line of ironmaking system as an example, the solution of digital twin system in practical industry is shown.

-

Key words:

- Digital twin /

- process industry /

- key technology /

- practical application

-

表 1 多采样率时序数据处理方法

Table 1 Multi rate time series data processing method

多采样率时序数据处理方法 优点 缺点 单维估计法 统计法 简单, 填补速度快 填补结果有偏 忽略多维度间影响 插值法 保留属性趋势 对采样频率有要求 时间序列法 保留数据时序特点 难以运用在非稳定序列 降采样 简单方便 丢失大量信息 多维估计法 考虑多维数据间的影响 计算量大, 容易过拟合 表 2 三种建模方法对比

Table 2 Comparison of three modeling methods

建模方法 优点 缺点 基于知识建模 模型简单、对极端情况建模效果好 模型精度低、无法实时更新、对不同场景无法迁移、

建立专家知识库人力成本大基于机理建模 模型覆盖变量空间大、模型可脱离物理实体、

模型具有可解释性计算复杂、难以对耦合复杂的流程工业建模 基于数据建模 模型精度高、可动态更新 需要数据支持、工业过程数据集分布不均匀、

异常情况数据少、模型没有可解释性表 3 3R技术对比

Table 3 Comparison of 3R technology

3R技术 真实场景信息 交互性 实时性 场景注册跟踪 相关场景 增强现实 包含 与真实环境交互 低 需要 工厂智能头盔 虚拟现实 不包含 与虚拟环境交互 较高 不需要 VR 数字化学习工厂 混合现实 包含 同时与真实环境和虚拟环境交互 高 不需要 设备维修 MR 辅助指导技术 -

[1] 丁进良, 杨翠娥, 陈远东, 柴天佑. 复杂工业过程智能优化决策系统的现状与展望. 自动化学报, 2018, 44(11): 1931−1943Ding Jin-Liang, Yang Cui-E, Chen Yuan-Dong, Chai Tian-You. Research progress and prospects of intelligent optimization decision making in complex industrial process. Acta Automatica Sinica, 2018, 44(11): 1931−1943 [2] 王维兴. 钢铁工业能耗现状和节能潜力分析. 中国钢铁业, 2011, (4): 19−22 doi: 10.3969/j.issn.1672-5115.2011.04.005Wang Wei-Xing. Energy consumption status and energy saving potential analysis of iron and steel industry. China Steel, 2011, (4): 19−22 doi: 10.3969/j.issn.1672-5115.2011.04.005 [3] 张寿荣. 炼铁系统节能——我国钢铁工业21世纪技术进步的重点. 钢铁, 2005, 40(5): 1−4 doi: 10.3321/j.issn:0449-749X.2005.05.001Zhang Shou-Rong. Systematic energy saving in ironmaking-the priority to be paid in technological progress of China′s steel industry in the 21st century. Iron and Steel, 2005, 40(5): 1−4 doi: 10.3321/j.issn:0449-749X.2005.05.001 [4] Soni R, Tanmay D, Twinkle, Bhatia M. Digital twin: Intersection of mind and machine. International Journal of Computational Intelligence and IoT, 2019, 2(3): 667−670 [5] Grieves M W. Product lifecycle management: The new paradigm for enterprises. International Journal of Product Development, 2005, 2(1−2): 71−84 [6] Grieves M. Virtually Perfect: Driving Innovative and Lean Products through Product Lifecycle Management. Space Coast Press, 2011. [7] Glaessgen E H, Stargel D S. The digital twin paradigm for future NASA and U.S. air force vehicles. In: Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Honolulu, USA: AIAA, 2012. 1818−1832 [8] Gockel B T, Tudor A W, Brandyberry M D, Penmetsa R C, Tuegel E J. Challenges with structural life forecasting using realistic mission profiles. In: Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Honolulu, USA: AIAA, 2012. 1813−1817 [9] Shafto M, Conroy M, Doyle R, Glaessgen E, Kemp C, LeMoigne J, et al. Modeling, Simulation, Information Technology and Processing Roadmap. Technical Report, National Aeronautics and Space Administration, Washington, USA, 2012. [10] Tao F, Zhang H, Liu A, Nee A Y C. Digital twin in industry: State-of-the-art. IEEE Transactions on Industrial Informatics, 2018, 15(4): 2405−2415 [11] 陶飞, 刘蔚然, 张萌, 胡天亮, 戚庆林, 张贺, 等. 数字孪生五维模型及十大领域应用. 计算机集成制造系统, 2019, 25(1): 1−18Tao Fei, Liu Wei-Ran, Zhang Meng, Hu Tian-Liang, Qi Qing-Lin, Zhang He, et al. Five-dimension digital twin model and its ten applications. Computer Integrated Manufacturing Systems, 2019, 25(1): 1−18 [12] Kritzinger W, Karner M, Traar G, Henjes J, Sihn W. Digital twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine, 2018, 51(11): 1016−1022 doi: 10.1016/j.ifacol.2018.08.474 [13] Vachálek J, Bartalský L, Rovný O, Šišmišová D, Morháč M, Lokšík M. The digital twin of an industrial production line within the industry 4.0 concept. In: Proceedings of the 21st International Conference on Process Control. Strbske Pleso, Slovakia: IEEE, 2017. 258−262 [14] 王中杰, 谢璐璐. 信息物理融合系统研究综述. 自动化学报, 2011, 37(10): 1157−1166Wang Zhong-Jie, Xie Lu-Lu. Cyber-physical systems: A survey. Acta Automatica Sinica, 2011, 37(10): 1157−1166 [15] Rosen R, Von Wichert G, Lo G, Bettenhausen K D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-PapersOnLine, 2015, 48(3): 567−572 doi: 10.1016/j.ifacol.2015.06.141 [16] 庄存波, 刘检华, 熊辉, 丁晓宇, 刘少丽, 瓮刚. 产品数字孪生体的内涵、体系结构及其发展趋势. 计算机集成制造系统, 2017, 23(4): 753−768Zhuang Cun-Bo, Liu Jian-Hua, Xiong Hui, Ding Xiao-Yu, Liu Shao-Li, Weng Gang. The connotation, architecture and development trend of product digital twin. Computer Integrated Manufacturing Systems, 2017, 23(4): 753−768 [17] Alam K M, El Saddik A. C2PS: A digital twin architecture reference model for the cloud-based cyber-physical systems. IEEE Access, 2017, 5: 2050−2062 doi: 10.1109/ACCESS.2017.2657006 [18] Arnold C, Kiel D, Voigt K-I. Innovative business models for the industrial internet of things: Innovative Geschäftsmodelle für Industrie 4.0. BHM Berg-und Hüttenmännische Monatshefte, 2017, 162(9): 371−381 [19] 孙秋野, 滕菲, 张化光. 能源互联网及其关键控制问题. 自动化学报, 2017, 43(2): 176−194Sun Qiu-Ye, Teng Fei, Zhang Hua-Guang. Energy internet and its key control issues. Acta Automatica Sinica, 2017, 43(2): 176−194 [20] Madni A M, Madni C C, Lucero S D. Leveraging digital twin technology in model-based systems engineering. Systems, 2019, 7(1): Article No. 7 doi: 10.3390/systems7010007 [21] Xu L D, He W, Li S C. Internet of things in industries: A survey. IEEE Transactions on Industrial Informatics, 2014, 10(4): 2233−2243 doi: 10.1109/TII.2014.2300753 [22] Schluse M, Rossmann J. From simulation to experimentable digital twins: Simulation-based development and operation of complex technical systems. In: Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE). Edinburgh, United Kingdom: IEEE, 2016. 1−6 [23] Jin H P, Chen X G, Yang J W, Zhang H, Wang L, Wu L. Multi-model adaptive soft sensor modeling method using local learning and online support vector regression for nonlinear time-variant batch processes. Chemical Engineering Science, 2015, 131: 282−303 doi: 10.1016/j.ces.2015.03.038 [24] Azevedo A, Almeida A. Factory templates for digital factories framework. Robotics and Computer-integrated Manufacturing, 2011, 27(4): 755−771 doi: 10.1016/j.rcim.2011.02.004 [25] Bracht U, Masurat T. The digital factory between vision and reality. Computers in Industry, 2005, 56(4): 325−333 doi: 10.1016/j.compind.2005.01.008 [26] 张睿. 流程工业多层次数据校正研究[博士学位论文], 浙江大学, 中国, 2018.Zhang Rui. Research on Multi-level Data Reconciliation in Process Industry [Ph.D. dissertation], Zhejiang University, China, 2018. [27] Minerva R, Crespi N. Digital twins: Properties, software frameworks, and application scenarios. IT Professional, 2021, 23(1): 51−55 [28] Chakraborty S, Adhikari S, Ganguli R. The role of surrogate models in the development of digital twins of dynamic systems. Applied Mathematical Modelling, 2021, 90: 662−681 [29] Mandolla C, Petruzzelli A M, Percoco G, Urbinati A. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Computers in Industry, 2019, 109: 134−152 doi: 10.1016/j.compind.2019.04.011 [30] 杨林瑶, 陈思远, 王晓, 张俊, 王成红. 数字孪生与平行系统: 发展现状、对比及展望. 自动化学报, 2019, 45(11): 2001−2031Yang Lin-Yao, Chen Si-Yuan, Wang Xiao, Zhang Jun, Wang Cheng-Hong. Digital twins and parallel systems: State of the art, comparisons and prospect. Acta Automatica Sinica, 2019, 45(11): 2001−2031 [31] 刘大同, 郭凯, 王本宽, 彭宇. 数字孪生技术综述与展望. 仪器仪表学报, 2018, 39(11): 1−10Liu Da-Tong, Guo Kai, Wang Ben-Kuan, Peng Yu. Summary and perspective survey on digital twin technology. Chinese Journal of Scientific Instrument, 2018, 39(11): 1−10 [32] Ren S Q, He K M, Girshick R, Sun J. Faster R-CNN: Towards real-time object detection with region proposal networks. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2017, 39(6): 1137−1149 doi: 10.1109/TPAMI.2016.2577031 [33] Alshemali B, Kalita J. Improving the reliability of deep neural networks in NLP: A review. Knowledge-Based Systems, 2020, 191: Article No. 105210 doi: 10.1016/j.knosys.2019.105210 [34] Yang L, Chen M, Zhu Q, Yang T, Wang C, Xie H B. Development of a small-diameter and high-resolution industrial endoscope with CMOS image sensor. Sensors and Actuators A: Physical, 2019, 296: 17−23 doi: 10.1016/j.sna.2019.04.026 [35] Fang L, Wang J N, Xiong R. A coarse-to-fine approach for industrial meter detection and its application. In: Proceedings of the 2016 IEEE Workshop on Advanced Robotics and Its Social Impacts. Shanghai, China: IEEE, 2016. 214−220 [36] Haag S, Anderl R. Digital twin-proof of concept. Manufacturing Letters, 2018, 15: 64−66 doi: 10.1016/j.mfglet.2018.02.006 [37] 何少灵, 郝凤欢, 刘鹏飞, 桑卫兵, 刘瑞, 葛辉良. 温度实时补偿的高精度光纤光栅压力传感器. 中国激光, 2015, 42(6): 166−170He Shao-Ling, Hao Feng-Huan, Liu Peng-Fei, Sang Wei-Bing, Liu Rui, Ge Hui-Liang. High precision fiber Bragg grating pressure sensor with real-time temperature compensation. Chinese Journal of Lasers, 2015, 42(6): 166−170 [38] Guo R, Li B Q, Sun Y T, Han L. A patrol robot for electric power substation. In: Proceedings of the 2009 International Conference on Mechatronics and Automation. Changchun, China: IEEE, 2009. 55−59 [39] 王凯. 数据驱动的动态过程监测方法[博士学位论文], 浙江大学, 中国, 2019.Wang Kai. Data-Driven Dynamic Process Modeling and Monitoring [Ph.D. dissertation], Zhejiang University, China, 2019. [40] Ge Z Q, Song Z H. Mixture Bayesian regularization method of PPCA for multimode process monitoring. AIChE Journal, 2010, 56(11): 2838−2849 doi: 10.1002/aic.12200 [41] Ge Z Q, Song Z H. Maximum-likelihood mixture factor analysis model and its application for process monitoring. Chemometrics and Intelligent Laboratory Systems, 2010, 102(1): 53−61 doi: 10.1016/j.chemolab.2010.04.002 [42] Fatehi A, Huang B. Kalman filtering approach to multi-rate information fusion in the presence of irregular sampling rate and variable measurement delay. Journal of Process Control, 2017, 53: 15−25 doi: 10.1016/j.jprocont.2017.02.010 [43] Zimmermann M, Baumann F W, Falkenthal M, Leymann F, Odefey U. Automating the provisioning and integration of analytics tools with data resources in industrial environments using openTOSCA. In: Proceedings of the 21st IEEE International Enterprise Distributed Object Computing Workshop. Quebec City, Canada: IEEE, 2017. 3−7 [44] 徐兴伟, 穆钢, 王文, 邵广惠, 高德宾, 陶家琪. 基于SCADA和WAMS的电网仿真运行方式. 电网技术, 2006, 30(19): 97−100 doi: 10.3321/j.issn:1000-3673.2006.19.018Xu Xing-Wei, Mu Gang, Wang Wen, Shao Guang-Hui, Gao De-Bin, Tao Jia-Qi. Simulation operation mode of power grid based on SCADA and WAMS. Power System Technology, 2006, 30(19): 97−100 doi: 10.3321/j.issn:1000-3673.2006.19.018 [45] Chang S Y, Han W, Tang J L, Qi G J, Aggarwal C C, Huang T S. Heterogeneous network embedding via deep architectures. In: Proceedings of the 21st ACM SIGKDD International Conference on Knowledge Discovery and Data Mining. Sydney, Australia: ACM, 2015. 119−128 [46] Gao Y P, Lv H Y, Hou Y Z, Liu J H, Xu W T. Real-time modeling and simulation method of digital twin production line. In: Proceedings of the 8th IEEE Joint International Information Technology and Artificial Intelligence Conference (ITAIC). Chongqing, China: IEEE, 2019. 1639−1642 [47] Miller A M, Alvarez R, Hartman N. Towards an extended model-based definition for the digital twin. Computer-Aided Design and Applications, 2018, 15(6): 880−891 doi: 10.1080/16864360.2018.1462569 [48] Gandzha S, Aminov D, Kiessh I, Kosimov B. Application of digital twins technology for analysis of brushless electric machines with axial magnetic flux. In: Proceedings of the 2018 Global Smart Industry Conference (GloSIC). Chelyabinsk, Russia: IEEE, 2018. 1−6 [49] Liu Y, Chen J. Integrated soft sensor using just-in-time support vector regression and probabilistic analysis for quality prediction of multi-grade processes. Journal of Process Control, 2013, 23(6): 793−804 doi: 10.1016/j.jprocont.2013.03.008 [50] Yu J. Online quality prediction of nonlinear and non-Gaussian chemical processes with shifting dynamics using finite mixture model based Gaussian process regression approach. Chemical Engineering Science, 2012, 82: 22−30 doi: 10.1016/j.ces.2012.07.018 [51] Yi B, Li X B, Yang Y. Heterogeneous model integration of complex mechanical parts based on semantic feature fusion. Engineering with Computers, 2017, 33(4): 797−805 doi: 10.1007/s00366-016-0498-2 [52] Feng C, Cui M J, Hodge B M, Zhang J. A data-driven multi-model methodology with deep feature selection for short-term wind forecasting. Applied Energy, 2017, 190: 1245−1257 doi: 10.1016/j.apenergy.2017.01.043 [53] 刘祥官, 曾九孙, 郝志忠, 鹿智勇. 多模型集成的高炉炼铁智能控制专家系统. 浙江大学学报(工学版), 2007, 41(10): 1637−1642 doi: 10.3785/j.issn.1008-973X.2007.10.007Liu Xiang-Guan, Zeng Jiu-Sun, Hao Zhi-Zhong, Lu Zhi-Yong. Multi-model integrated intelligent control expert system for blast furnace ironmaking. Journal of Zhejiang University (Engineering Science), 2007, 41(10): 1637−1642 doi: 10.3785/j.issn.1008-973X.2007.10.007 [54] 李温鹏, 周平. 高炉铁水质量鲁棒正则化随机权神经网络建模. 自动化学报, 2020, 46(4): 721−733Li Wen-Peng, Zhou Ping. Robust regularized RVFLNs modeling of molten iron quality in blast furnace ironmaking. Acta Automatica Sinica, 2020, 46(4): 721−733 [55] Charpentier J C. Perspective on multiscale methodology for product design and engineering. Computers and Chemical Engineering, 2009, 33(5): 936−946 [56] Sengupta D, Abraham J P, Ceja M, Gonzalez M A, Ingwersen W W, Ruiz-Mercado G J, et al. Industrial process system assessment: Bridging process engineering and life cycle assessment through multiscale modeling. Journal of Cleaner Production, 2015, 90: 142−152 doi: 10.1016/j.jclepro.2014.11.073 [57] Stojanovic N, Milenovic D. Data-driven digital twin approach for process optimization: An industry use case. In: Proceedings of the 2018 IEEE International Conference on Big Data (Big Data). Seattle, USA: IEEE, 2018. 4202−4211 [58] Burdea G C, Coiffet P. Virtual Reality Technology. New Jersey: John Wiley & Sons, 2003. [59] 赵沁平. 虚拟现实综述. 中国科学 F辑: 信息科学, 2009, 39(1): 2−46Zhao Qin-Ping. A survey on virtual reality. Science in China Series F: Information Sciences, 2009, 39(1): 2−46 [60] Billinghurst M, Clark A, Lee G. A survey of augmented reality. Foundations and Trends $$ in Human-Computer Interaction, 2015, 8(2−3): 73−272 doi: 10.1561/1100000049[61] Brooks F P. What′s real about virtual reality? IEEE Computer Graphics and Applications, 1999, 19(6): 16−27 doi: 10.1109/38.799723 [62] Fite-Georgel P. Is there a reality in industrial augmented reality? In: Proceedings of the 10th IEEE International Symposium on Mixed and Augmented Reality. Basel, Switzerland: IEEE, 2011. 201−210 [63] Georgel P, Schroeder P, Benhimane S, Hinterstoisser S, Appel M, Navab N. An industrial augmented reality solution for discrepancy check. In: Proceedings of the 6th IEEE and ACM International Symposium on Mixed and Augmented Reality. Nara, Japan: IEEE, 2007. 1−4 [64] Gavish N, Gutiérrez T, Webel S, Rodríguez J, Peveri M, Bockholt U, et al. Evaluating virtual reality and augmented reality training for industrial maintenance and assembly tasks. Interactive Learning Environments, 2015, 23(6): 778−798 doi: 10.1080/10494820.2013.815221 [65] Minos-Stensrud M, Haakstad O H, Sakseid O, Westby B, Alcocer A. Towards automated 3D reconstruction in SME factories and digital twin model generation. In: Proceedings of the 18th International Conference on Control, Automation and Systems (ICCAS). Daegwallyeong, South Korea: IEEE, 2018. 1777−1781 [66] Autiosalo J. Platform for industrial internet and digital twin focused education, research, and innovation: Ilmatar the overhead crane. In: Proceedings of the 4th IEEE World Forum on Internet of Things (WF-IoT). Singapore, Singapore: IEEE, 2018. 241−244 [67] Wang J J, Ye L K, Gao R X, Li C, Zhang L B. Digital twin for rotating machinery fault diagnosis in smart manufacturing. International Journal of Production Research, 2019, 57(12): 3920−3934 doi: 10.1080/00207543.2018.1552032 [68] Lawson D C, Reichard D J, Harkulich J A, Hessmer R, Chand S, Farchmin D W. Industrial Automation App-Store, U.S. Patent 9568908, February 2017. [69] He Y, Guo J C, Zheng X L. From surveillance to digital twin: Challenges and recent advances of signal processing for industrial internet of things. IEEE Signal Processing Magazine, 2018, 35(5): 120−129 doi: 10.1109/MSP.2018.2842228 [70] David J, Lobov A, Lanz M. Attaining learning objectives by ontological reasoning using digital twins. Procedia Manufacturing, 2019, 31: 349−355 doi: 10.1016/j.promfg.2019.03.055 [71] Min Q F, Lu Y G, Liu Z Y, Su C, Wang B. Machine learning based digital twin framework for production optimization in petrochemical industry. International Journal of Information Management, 2019, 49: 502−519 doi: 10.1016/j.ijinfomgt.2019.05.020 [72] Leng J W, Zhang H, Yan D X, Liu Q, Chen X, Zhang D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. Journal of Ambient Intelligence and Humanized Computing, 2019, 10(3): 1155−1166 doi: 10.1007/s12652-018-0881-5 [73] Martínez G S, Sierla S, Karhela T, Vyatkin V. Automatic generation of a simulation-based digital twin of an industrial process plant. In: Proceedings of the 44th Annual Conference of the IEEE Industrial Electronics Society. Washington, USA: IEEE, 2018. 3084−3089 [74] Guo J P, Zhao N, Sun L, Zhang S P. Modular based flexible digital twin for factory design. Journal of Ambient Intelligence and Humanized Computing, 2019, 10(3): 1189−1200 doi: 10.1007/s12652-018-0953-6 [75] Jain P, Poon J, Singh J P, Spanos C, Sanders S R, Panda S K. A digital twin approach for fault diagnosis in distributed photovoltaic systems. IEEE Transactions on Power Electronics, 2020, 35(1): 940−956 doi: 10.1109/TPEL.2019.2911594 [76] Xiang F, Zhang Z, Zuo Y, Tao F. Digital twin driven green material optimal-selection towards sustainable manufacturing. Procedia CIRP, 2019, 81: 1290−1294 doi: 10.1016/j.procir.2019.04.015 [77] Cavalcante I M, Frazzon E M, Forcellini F A, Ivanov D. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. International Journal of Information Management, 2019, 49: 86−97 doi: 10.1016/j.ijinfomgt.2019.03.004 [78] Mohammadi N, Taylor J E. Smart city digital twins. In: Proceedings of the 2017 IEEE Symposium Series on Computational Intelligence (SSCI). Honolulu, USA: IEEE, 2017. 1−5 [79] DebRoy T, Zhang W, Turner J, Babu S S. Building digital twins of 3d printing machines. Scripta Materialia, 2017, 135: 119−124 doi: 10.1016/j.scriptamat.2016.12.005 [80] He R, Chen G M, Dong C, Sun S F, Shen X Y. Data-driven digital twin technology for optimized control in process systems. ISA Transactions, 2019, 95: 221−234 doi: 10.1016/j.isatra.2019.05.011 [81] Laaki H, Miche Y, Tammi K. Prototyping a digital twin for real time remote control over mobile networks: Application of remote surgery. IEEE Access, 2019, 7: 20325−20336 doi: 10.1109/ACCESS.2019.2897018 -

下载:

下载: