Abnormal Condition Identification Based on Bayesian Network Parameter Transfer Learning for the Electro-fused Magnesia

-

摘要:

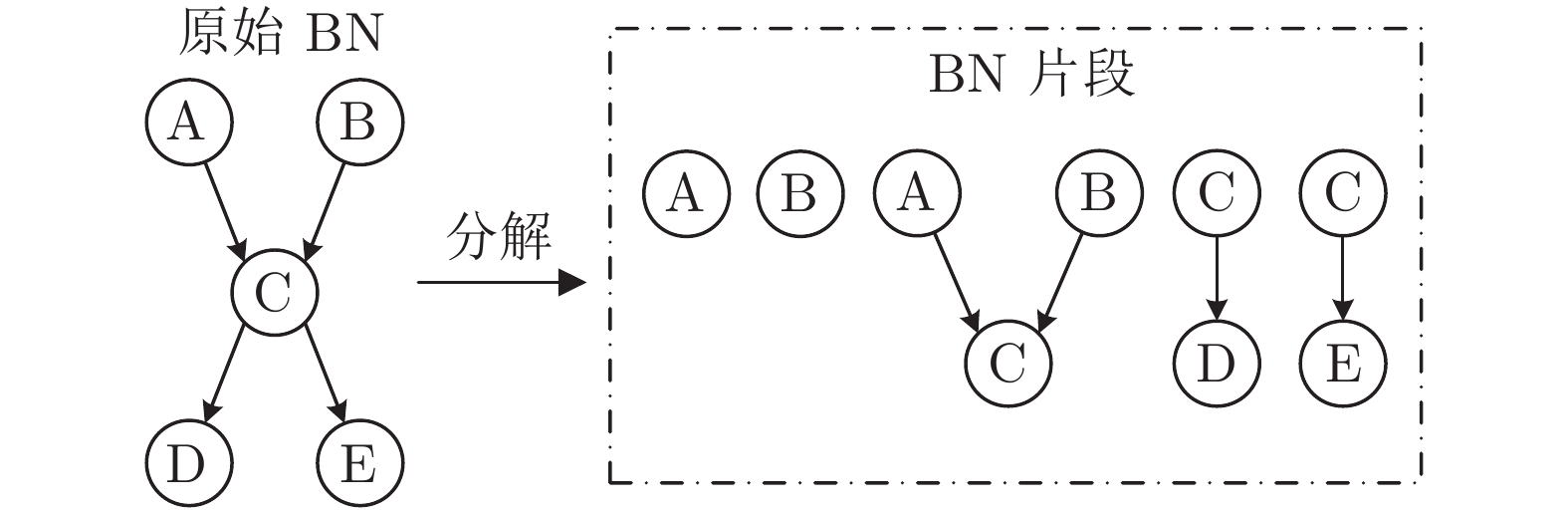

在贝叶斯网络(Bayesian network, BN)参数学习中, 如果数据不够充分, 将无法建立准确的BN模型来分析和解决问题. 针对电熔镁炉熔炼过程的异常工况识别建模, 提出一种新的BN参数迁移学习方法来改进异常工况识别精度. 该方法可以解决源域BN与目标域BN在结构不一致情况下的参数迁移学习问题. 在实验部分, 首先在著名的Asia网络上对该方法进行了验证, 然后将其应用于电熔镁炉熔炼过程排气异常工况识别BN模型的参数学习. 实验结果表明, 与小数据下建立的目标域BN模型相比, 该方法较大地提高了异常工况识别的准确性.

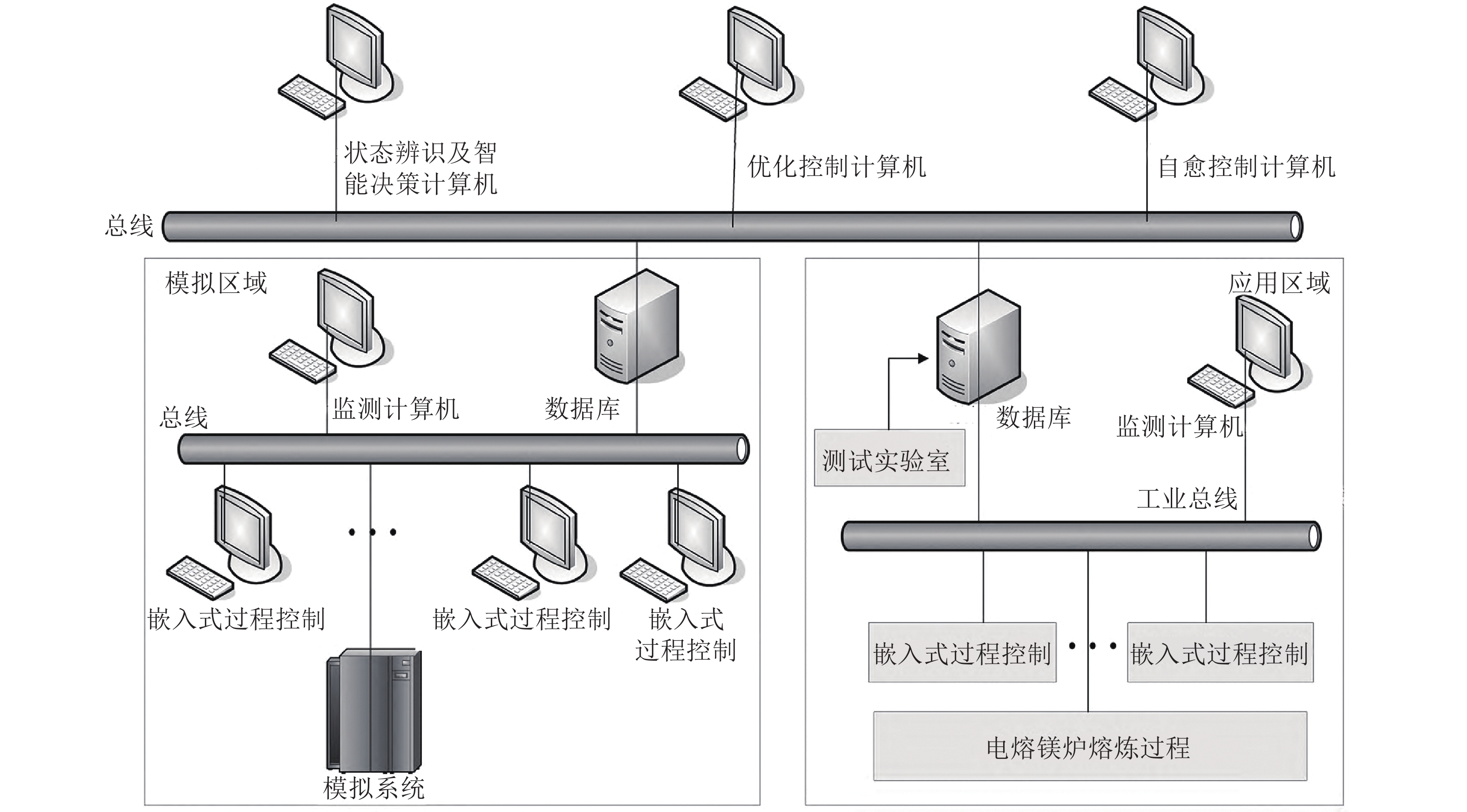

Abstract:In Bayesian network (BN) parameter learning, if the data is not sufficient, an accurate BN model cannot be established to analyze and solve the problem. Aiming at the abnormal condition identification modeling of the electro-fused magnesia, a new BN parameter transfer learning method is proposed in this paper to improve the accuracy of abnormal condition identification. This method can solve the parameter transfer learning problem when the structure of the source domain BN and the target domain BN are inconsistent. In the experimental section, the method is first verified by the well-known Asia network. Then, it is applied to the parameter learning of the BN model for identifying abnormal conditions of exhaust gas in the smelting process of the electro-fused magnesia. Experimental results show that compared with the target domain BN model established under small data, the proposed method greatly improves the accuracy of abnormal condition identification.

-

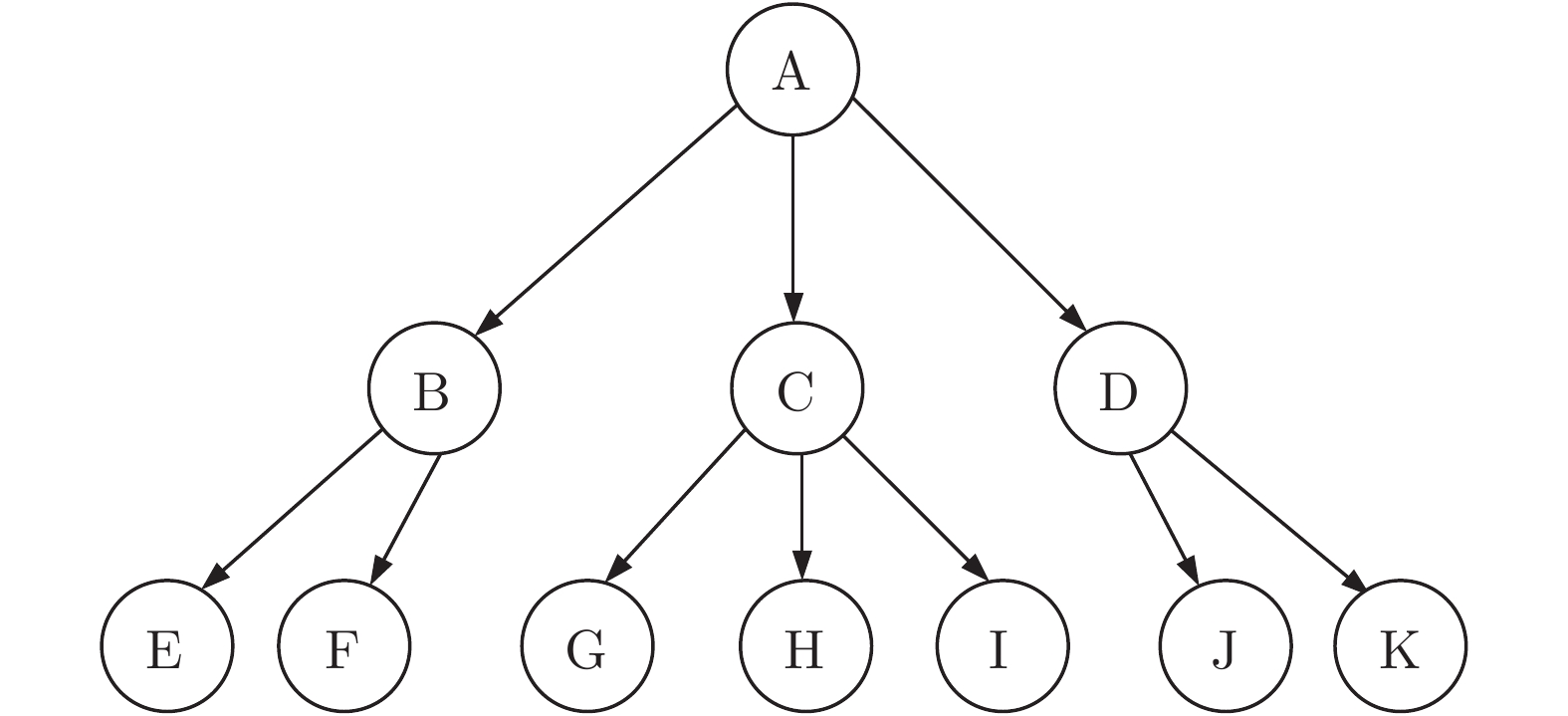

表 1 各节点物理意义

Table 1 Physical meaning of the nodes

节点 物理意义 A 排气异常工况 B 异常声音信息 C 异常图像信息 D 异常电流信息 E 在飞溅特征频率下的短时能量 F 在飞溅特征频率下的幅值 G 平均灰度 H 灰度方差 I 灰度丰度 J 电流变化率 K 电流跟踪误差 表 2 节点

$\underline{\underline {\rm A}} $ 和$\underline{\underline {\rm S}} $ 的CPTsTable 2 The CPTs of nodes

$\underline{\underline {\rm A}}$ and$\underline{\underline {\rm S}} $ $\underline{\underline {\rm A}} $ (i = 1) $\underline{\underline {\rm S}} $ (i = 2) 0 (k = 1) 0.99 0.5 1 (k = 2) 0.01 0.5 表 3 节点

$\underline{\underline {\rm T}} $ 的CPTTable 3 The CPT of node

$\underline{\underline {\rm T}} $ $\underline{\underline {\rm A}} $ 0 (j = 1) 1 (j = 2) $\underline{\underline {\rm T}} $ (i = 3) 0 (k = 1) 0.99 0.95 1 (k = 2) 0.01 0.05 表 4 节点

$\underline{\underline {\rm L}} $ 的CPTTable 4 The CPT of node

$\underline{\underline {\rm L}} $ $\underline{\underline {\rm S}} $ 0 (j = 1) 1 (j = 2) $\underline{\underline {\rm L}} $ (i = 4) 0 (k = 1) 0.99 0.9 1 (k = 2) 0.01 0.1 表 5 节点

$\underline{\underline {\rm B}}$ 的CPTTable 5 The CPT of node

$\underline{\underline {\rm B}} $ $\underline{\underline {\rm S}} $ 0 (j = 1) 1 (j = 2) $\underline{\underline {\rm B}} $ (i = 5) 0 (k = 1) 0.99 0.9 1 (k = 2) 0.01 0.1 表 6 节点

$\underline{\underline {\rm E}} $ 的CPTTable 6 The CPT of node

$\underline{\underline {\rm E}} $ $\underline{\underline {\rm T}} $ 0 1 $\underline{\underline {\rm L}} $ 0 (j = 1) 1 (j = 2) 0 (j = 3) 1 (j = 4) $\underline{\underline {\rm E}} $ (i = 6) 0 (k = 1) 1 0 0 0 1 (k = 2) 0 1 1 1 表 7 节点

$\underline{\underline {\rm X}} $ 的CPTTable 7 The CPT of node

$\underline{\underline {\rm X}}$ $\underline{\underline {\rm E}} $ 0 (j = 1) 1 (j = 2) $\underline{\underline {\rm X}} $ (i = 7) 0 (k = 1) 0.95 0.02 1 (k = 2) 0.05 0.98 表 8 节点

$\underline{\underline {\rm D}} $ 的CPTTable 8 The CPT of node

$\underline{\underline {\rm D}} $ $\underline{\underline {\rm E}} $ 0 1 $\underline{\underline {\rm B}} $ 0 (j = 1) 1 (j = 2) 0 (j = 3) 1 (j = 4) $\underline{\underline {\rm D}} $ (i = 8) 0 (k = 1) 0.9 0.2 0.3 0.1 1 (k = 2) 0.1 0.8 0.7 0.9 表 9 Asia网络专家知识形式二

Table 9 The expert knowledge form two for the Asia network

序号 约束 得分 1 $\theta _{321}^t > 0.8$ 1 2 $0.85 < \theta _{421}^t < 0.95$ 1 3 $0.35 < \theta _{521}^t < 0.45$ 1 4 $0.85 < \theta _{811}^t < 0.95$ 1 5 $\theta _{321}^t > 0.9$ 2 6 $0.88 < \theta _{421}^t < 0.92$ 2 7 $0.38 < \theta _{521}^t < 0.42$ 2 8 $0.88 < \theta _{811}^t < 0.92$ 2 表 10 节点A的参数表达形式

Table 10 The parameters expression of node A

A (i = 1) 1 (k = 1) $\theta _{1\_1}^t$ 2 (k = 2) $\theta _{1\_2}^t$ 3 (k = 3) $\theta _{1\_3}^t$ 4 (k = 4) $\theta _{1\_4}^t$ 表 11 节点B的参数表达形式

Table 11 The parameters expression of node B

A (i = 1) 1 (j = 1) 2 (j = 2) 3 (j = 3) 4 (j = 4) 1 (k = 1) $\theta _{211}^t$ $\theta _{221}^t$ $\theta _{231}^t$ $\theta _{241}^t$ B (i = 2) 2 (k = 2) $\theta _{212}^t$ $\theta _{222}^t$ $\theta _{232}^t$ $\theta _{242}^t$ 3 (k = 3) $\theta _{213}^t$ $\theta _{223}^t$ $\theta _{233}^t$ $\theta _{243}^t$ 表 12 排气异常工况识别模型的专家知识形式一

Table 12 The expert knowledge form one for the abnormal exhausting condition model

序号 约束 1 $\theta _{232}^t < \theta _{233}^t$ 2 $\theta _{333}^t < \theta _{332}^t$ 3 $\theta _{434}^t < \theta _{433}^t$ 4 $\theta _{521}^t < \theta _{522}^t$ 5 $\theta _{831}^t < \theta _{833}^t$ 6 $\theta _{1031}^t < \theta _{1032}^t$ 表 13 排气异常工况识别模型的专家知识形式二

Table 13 The expert knowledge form two for the abnormal exhausting condition model

序号 约束 得分 1 $0.03 < \theta _{341}^t < 0.07$ 1 2 $0.01 < \theta _{512}^t < 0.05$ 1 3 $0.13 < \theta _{923}^t < 0.17$ 1 4 $0.78 < \theta _{1122}^t < 0.82$ 1 5 $0.04 < \theta _{341}^t < 0.06$ 2 6 $0.02 < \theta _{512}^t < 0.04$ 2 7 $0.14 < \theta _{923}^t < 0.16$ 2 8 $0.79 < \theta _{1122}^t < 0.81$ 2 表 14 三种模型描述

Table 14 Descriptions of the three models

模型 建模方法描述 模型一 仅使用目标域的稀缺数据学习目标域 BN 模型参数 模型二 使用本文提出的方法学习目标域 BN 模型参数 模型三 只考虑结构一致下的相关源域来辅助学习目标域 BN 模型参数 表 15 排气异常工况的典型事件

Table 15 The typical scenarios for the abnormal exhausting condition

编号 1 2 3 4 5 6 7 8 9 E 1 2 2 3 3 3 3 2 1 F 1 2 3 2 3 3 2 3 1 G 1 1 1 1 1 1 1 1 3 H 1 1 1 1 1 1 1 1 3 I 1 1 1 1 1 1 1 1 3 J 1 1 1 1 1 2 2 2 3 K 1 1 1 1 1 2 2 2 2 编号 10 11 12 13 14 15 16 17 18 E 1 1 1 1 1 1 1 1 1 F 1 1 1 1 1 1 1 1 1 G 3 3 3 3 2 2 2 2 2 H 3 3 3 3 2 2 2 2 2 I 3 3 3 3 2 2 2 2 2 J 3 2 3 2 3 2 2 3 3 K 4 3 3 4 2 3 4 3 4 表 16 排气异常工况识别模型一的识别结果

Table 16 The identification results of abnormal scenarios for model one

事件编号 1 2 3 4 5 6 7 8 9 节点A的状态 1 0.5167 0.3887 0.3730 0.3721 0.3572 0.3123 0.2964 0.2849 0.0026 2 0.2471 0.3554 0.4089 0.4307 0.4865 0.2547 0.2055 0.1871 0.0182 3 0.2341 0.2546 0.2170 0.1962 0.1555 0.4243 0.4878 0.5174 0.5426 4 0.0021 0.0013 0.0011 0.0010 0.0008 0.0087 0.0103 0.0106 0.4366 事件编号 10 11 12 13 14 15 16 17 18 节点A的状态 1 0.0017 0.0009 0.0009 0.0042 0.1208 0.0429 0.2268 0.0402 0.0815 2 0.0275 0.0457 0.0314 0.0277 0.0282 0.0784 0.0515 0.0483 0.0433 3 0.5241 0.5530 0.4765 0.7157 0.1490 0.1677 0.2354 0.1295 0.1461 4 0.4467 0.4004 0.4912 0.2524 0.7020 0.7110 0.4863 0.7820 0.7291 表 17 排气异常工况识别模型二的识别结果

Table 17 The identification results of abnormal scenarios for model two

事件编号 1 2 3 4 5 6 7 8 9 节点A的状态 1 0.8481 0.0495 0.1105 0.1287 0.1772 0.0433 0.0394 0.0342 0.0075 2 0.1266 0.8739 0.7589 0.7377 0.6344 0.1895 0.2761 0.2878 0.0079 3 0.0234 0.0746 0.1293 0.1323 0.1877 0.7629 0.6738 0.6668 0.1440 4 0.0019 0.0020 0.0013 0.0013 0.0007 0.0043 0.0107 0.0112 0.8406 事件编号 10 11 12 13 14 15 16 17 18 节点A的状态 1 0.0018 0.0017 0.0012 0.0039 0.0245 0.0059 0.0130 0.0039 0.0060 2 0.0046 0.0041 0.0041 0.0058 0.0421 0.0223 0.0313 0.0227 0.0257 3 0.0774 0.0793 0.0713 0.1014 0.1523 0.0873 0.1098 0.0786 0.0851 4 0.9162 0.9149 0.9234 0.8889 0.7811 0.8845 0.8459 0.8948 0.8832 表 18 排气异常工况识别模型三的识别结果

Table 18 The identification results of abnormal scenarios for model three

事件编号 1 2 3 4 5 6 7 8 9 节点A的状态 1 0.7987 0.0412 0.1368 0.1362 0.1259 0.0421 0.0049 0.0052 0.0021 2 0.1881 0.8275 0.7570 0.7498 0.6411 0.1922 0.3574 0.3757 0.0072 3 0.0076 0.1281 0.1034 0.1112 0.2309 0.7593 0.6240 0.6046 0.1293 4 0.0056 0.0032 0.0028 0.0028 0.0021 0.0064 0.0137 0.0145 0.8614 事件编号 10 11 12 13 14 15 16 17 18 节点A的状态 1 0.0003 0.0003 0.0002 0.0006 0.0172 0.0031 0.0063 0.0020 0.0031 2 0.0014 0.0016 0.0011 0.1026 0.1015 0.0278 0.0429 0.0196 0.0250 3 0.1142 0.1168 0.1137 0.5782 0.2461 0.1735 0.1852 0.1473 0.1504 4 0.8841 0.8813 0.8850 0.3186 0.6352 0.7956 0.7656 0.8311 0.8215 -

[1] Fu Y, Wang N H, Wang Z, Wang Z Q, Ji B, Wang X C. Smelting condition identification for a fused magnesium furnace based on an acoustic signal. Journal of Materials Processing Technology, 2017, 244: 231−239 doi: 10.1016/j.jmatprotec.2016.12.017 [2] Fu Y, Wang Z, Wang Z Q, Wang N H, Wang X C. Splattering suppression for a three-phase AC electric arc furnace in fused magnesia production based on acoustic signal. IEEE Transactions on Industrial Electronics, 2017, 64(6): 4772−4780 doi: 10.1109/TIE.2017.2668984 [3] 吴高昌, 刘强, 柴天佑, 秦泗钊. 基于时序图像深度学习的电熔镁炉异常工况诊断. 自动化学报, 2019, 45(8): 1475−1485Wu Gao-Chang, Liu Qiang, Chai Tian-You, Qin Si-Zhao. Abnormal condition diagnosis through deep learning of image sequences for fused magnesium furnaces. Acta Automatica Sinica, 2019, 45(8): 1475−1485 [4] 李鸿儒, 王奕文, 邓靖川. 基于信息融合的电熔镁炉熔炼异常工况等级识别. 东北大学学报 (自然科学版), 2020, 41(2): 153−157Li Hong-Ru, Wang Yi-Wen, Deng Jin-Chuan. Information fusion based abnormal condition levels recognition of smelting in fused magnesium furnace. Journal of Northeastern University (Natural Science), 2020, 41(2): 153−157 [5] Zhang Y W, Fan Y P, Zhang P C. Combining kernel partial least-squares modeling and iterative learning control for the batch-to-batch optimization of constrained nonlinear processes. Industrial & Engineering Chemistry Research, 2010, 49(16): 7470−7477 [6] Zhang Y W, Zhang P C. Optimization of nonlinear process based on sequential extreme learning machine. Chemical Engineering Science, 2011, 66(20): 4702−4710 doi: 10.1016/j.ces.2011.06.030 [7] Zhang Y W, Ma C. Fault diagnosis of nonlinear processes using multiscale KPCA and multiscale KPLS. Chemical Engineering Science, 2011, 66(1): 64−72 doi: 10.1016/j.ces.2010.10.008 [8] Wu Z W, Wu Y J, Chai T Y, Sun J. Data-driven abnormal condition identification and self-healing control system for fused magnesium furnace. IEEE Transactions on Industrial Electronics, 2015, 62(3): 1703−1705 doi: 10.1109/TIE.2014.2349479 [9] Li H, Wang F L, Li H R. Abnormal condition identification and safe control scheme for the electro-fused magnesia smelting process. ISA Transactions, 2018, 76: 178−187 [10] 李荟, 王福利, 李鸿儒. 电熔镁炉熔炼过程异常工况识别及自愈控制方法. 自动化学报, 2020, 46 (7): 1411−1419 Li Hui, Wang Fu-Li, Li Hong-Ru. Abnormal condition identification and self-healing control scheme for the electro-fused magnesia smelting process. Acta Automatica Sinica, 2020, 46 (7): 1411−1419 [11] Yuan P, Sun Y F, Li H, Wang F L, Li H R. Abnormal condition identification modeling method based on Bayesian network parameters transfer learning for the electro-fused magnesia smelting process. IEEE Access, 2019, 7: 149764−149775 doi: 10.1109/ACCESS.2019.2947499 [12] Talo M, Baloglu U B, Yıldırım Ö, Acharya U R. Application of deep transfer learning for automated brain abnormality classification using MR images. Cognitive Systems Research, 2019, 54: 176−188 doi: 10.1016/j.cogsys.2018.12.007 [13] Cai W L, Zheng J B, Pan W K, Lin J, Li L, Chen L, et al. Neighborhood-enhanced transfer learning for one-class collaborative filtering. Neurocomputing, 2019, 341: 80−87 doi: 10.1016/j.neucom.2019.03.016 [14] Zhang L, Liu Y, Deng P L. Odor recognition in multiple e-nose systems with cross-domain discriminative subspace learning. IEEE Transactions on Instrumentation and Measurement, 2017, 66(7): 1679−1692 doi: 10.1109/TIM.2017.2669818 [15] Yang B, Lei Y G, Jia F, Xing S B. An intelligent fault diagnosis approach based on transfer learning from laboratory bearings to locomotive bearings. Mechanical Systems and Signal Processing, 2019, 122: 692−706 doi: 10.1016/j.ymssp.2018.12.051 [16] Liu X, Li Y G, Chen G X. Multimode tool tip dynamics prediction based on transfer learning. Robotics and Computer-Integrated Manufacturing, 2019, 57: 146−154 doi: 10.1016/j.rcim.2018.12.001 [17] Chu F, Zhao X, Yao Y, Chen T, Wang F L. Transfer learning for batch process optimal control using LV-PTM and adaptive control strategy. Journal of Process Control, 2019, 81: 197−208 doi: 10.1016/j.jprocont.2019.06.010 [18] Lu J, Behbood V, Hao P, Zuo H, Xue S, Zhang G Q. Transfer learning using computational intelligence: A survey. Knowledge-Based Systems, 2015, 80: 14−23 doi: 10.1016/j.knosys.2015.01.010 [19] Luis R, Sucar L E, Morales E F. Inductive transfer for learning Bayesian networks. Machine Learning, 2009, 79: 227−255 [20] Niculescu-Mizil A, Caruana R. Inductive transfer for Bayesian network structure learning. In: Proceedings of the 11th International Conference Artificial Intelligence and Statistics. San Juan, Puerto Rico, USA: AISTATS, 2007. 339−346 [21] Oyen D, Lane T. Transfer learning for Bayesian discovery of multiple Bayesian networks. Knowledge and Information Systems, 2015, 43: 1−28 doi: 10.1007/s10115-014-0775-6 [22] Zhou Y, Hospedales T M, Fenton N. When and where to transfer for Bayes net parameter learning. Expert Systems and Applications, 2016, 55: 361−373 doi: 10.1016/j.eswa.2016.02.011 [23] Oyen D, Lane T. Leveraging domain knowledge in multitask Bayesian network structure learning. In: Proceedings of the 26th AAAI Conference on Artificial Intelligence. Toronto, Canada: AAAI, 2012. 1091−1097 [24] Zhou Y, Fenton N, Hospedales T M, Neil M. Probabilistic graphical models parameter learning with transferred prior and constraints. In: Proceedings of the 31st Conference Uncertainty in Artificial Intelligence. Amsterdam, Netherlands: AUAI, 2015. 972–981 [25] Oyen D, Lane T. Bayesian discovery of multiple Bayesian networks via transfer learning. In: Proceedings of the 13th IEEE International Conference on Data Mining. Dallas, TX, USA: IEEE, 2013. 577–586 [26] Fiedler L J, Sucar L E, Morales E F. Transfer learning for temporal nodes Bayesian networks. Applied Intelligence, 2015, 43: 578−597 doi: 10.1007/s10489-015-0662-1 [27] Yang Y, Gao X G, Guo Z G, Chen D Q. Learning Bayesian networks using the constrained maximum a posteriori probability method. Pattern Recognition, 2019, 91: 123−134 doi: 10.1016/j.patcog.2019.02.006 [28] Gao X G, Yang Y, Guo Z G. Learning Bayesian networks by constrained Bayesian estimation. Journal of Systems Engineering and Electronics, 2019, 30: 511−524 doi: 10.21629/JSEE.2019.03.09 [29] Koller D, Friedman N. Probabilistic Graphical Models: Principles and Techniques. USA: MIT Press, 2009 [30] Yan H, Wang F L, He D K, Zhao L P, Wang Q K. Bayesian network-based modeling and operational adjustment of plantwide flotation industrial process. Industrial & Engineering Chemistry Research, 2020, 59(5): 2025−2035 [31] Lin D K. An information-theoretic definition of similarity. In: Proceedings of the 15th International Conference on Machine Learning. Madison, USA: ICML, 1998. 296-304 [32] Larrañaga P, Poza M, Yurramendi Y. Structure learning of Bayesian networks by genetic algorithms: A performance analysis of control parameters. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1996, 18(9): 912−926 doi: 10.1109/34.537345 [33] Yan H, Wang F L, He D K, Wang Q K. An operational adjustment framework for a complex industrial process based on hybrid Bayesian network. IEEE Transactions on Automation Science and Engineering, 2020, 17(4): 1699−1710 -

下载:

下载: