Selective Ensemble Modeling Approach for Mill Load Parameter Forecasting Based on Multi-modal Feature Sub-sets

-

摘要:

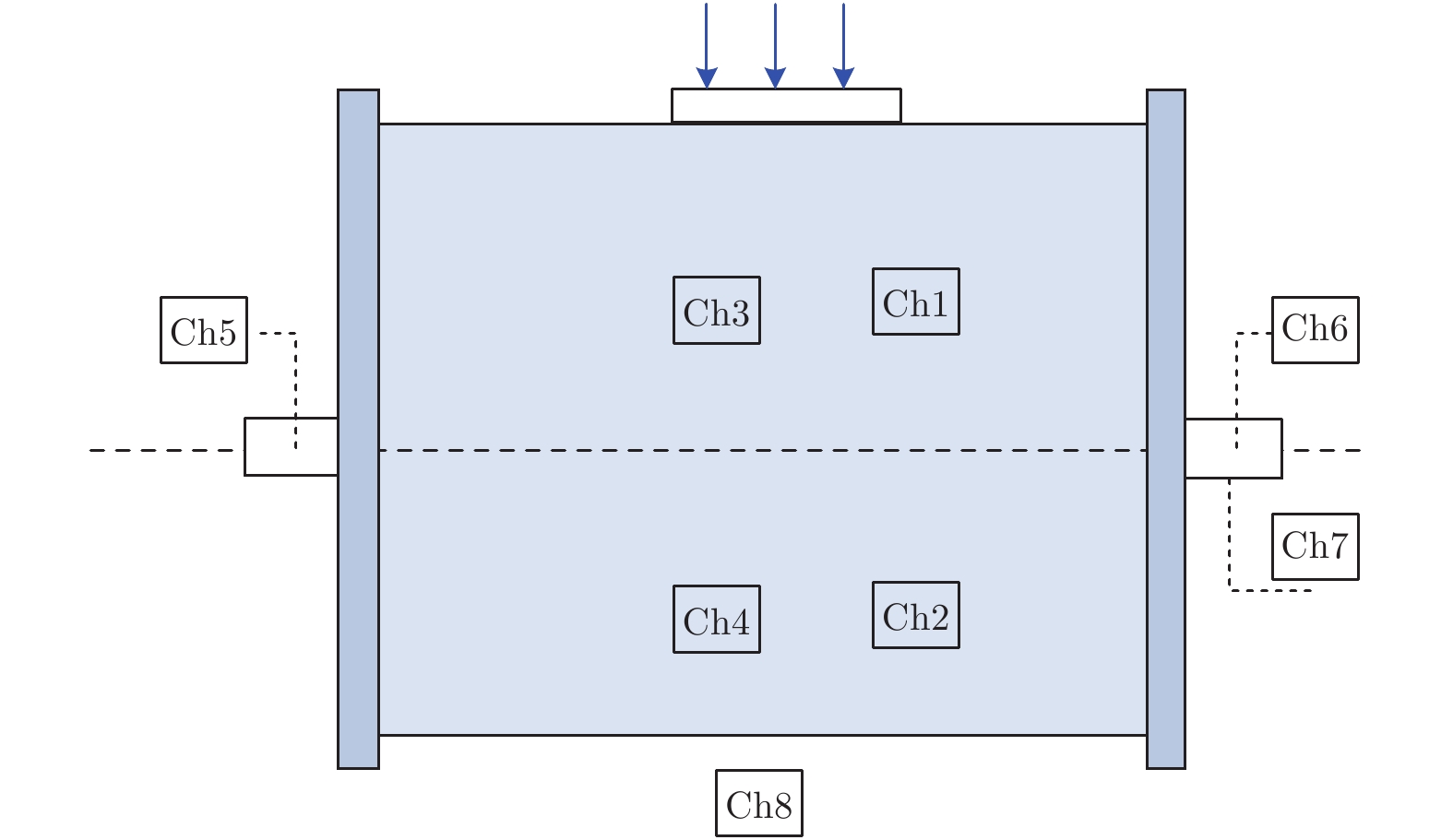

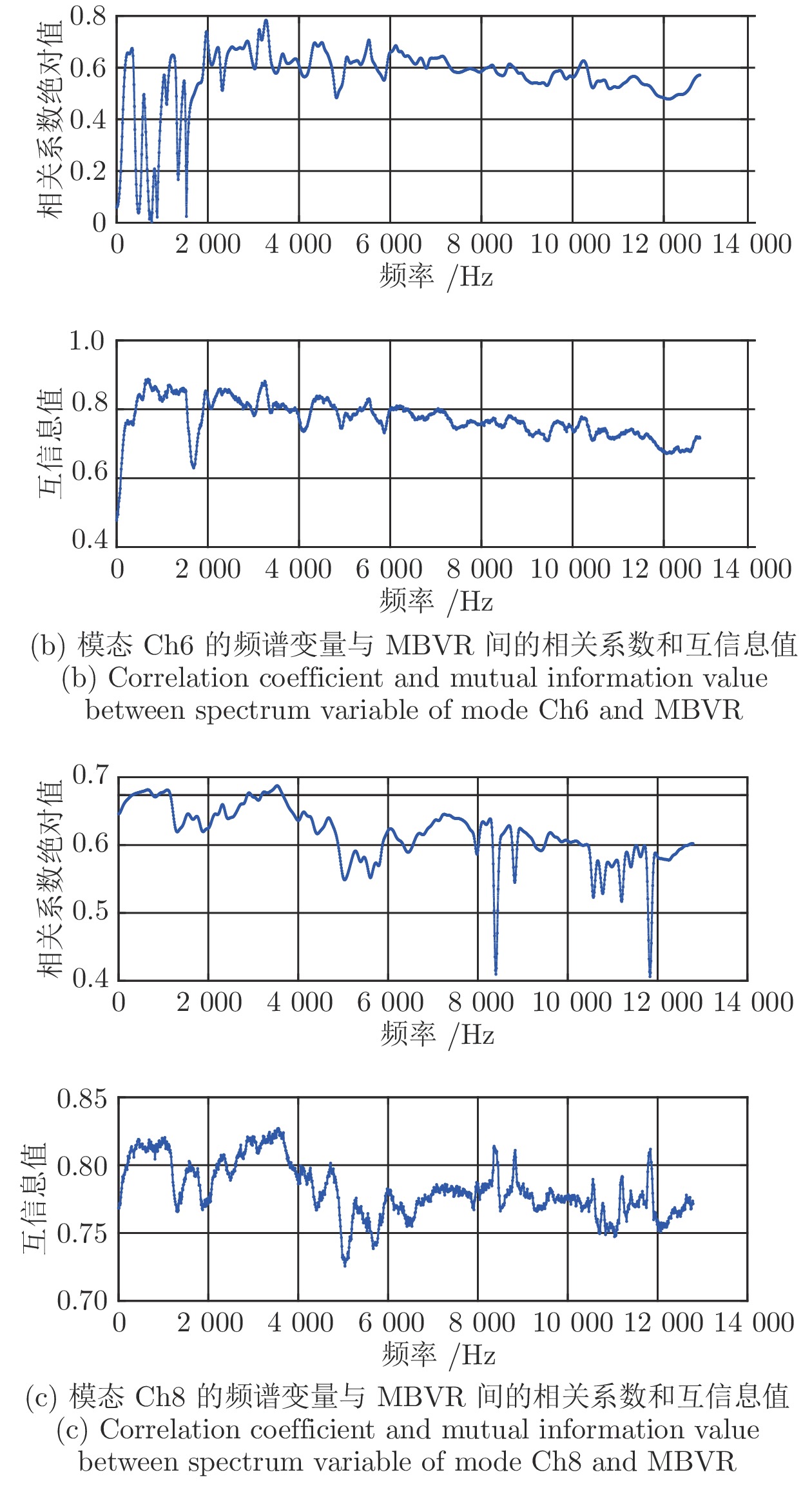

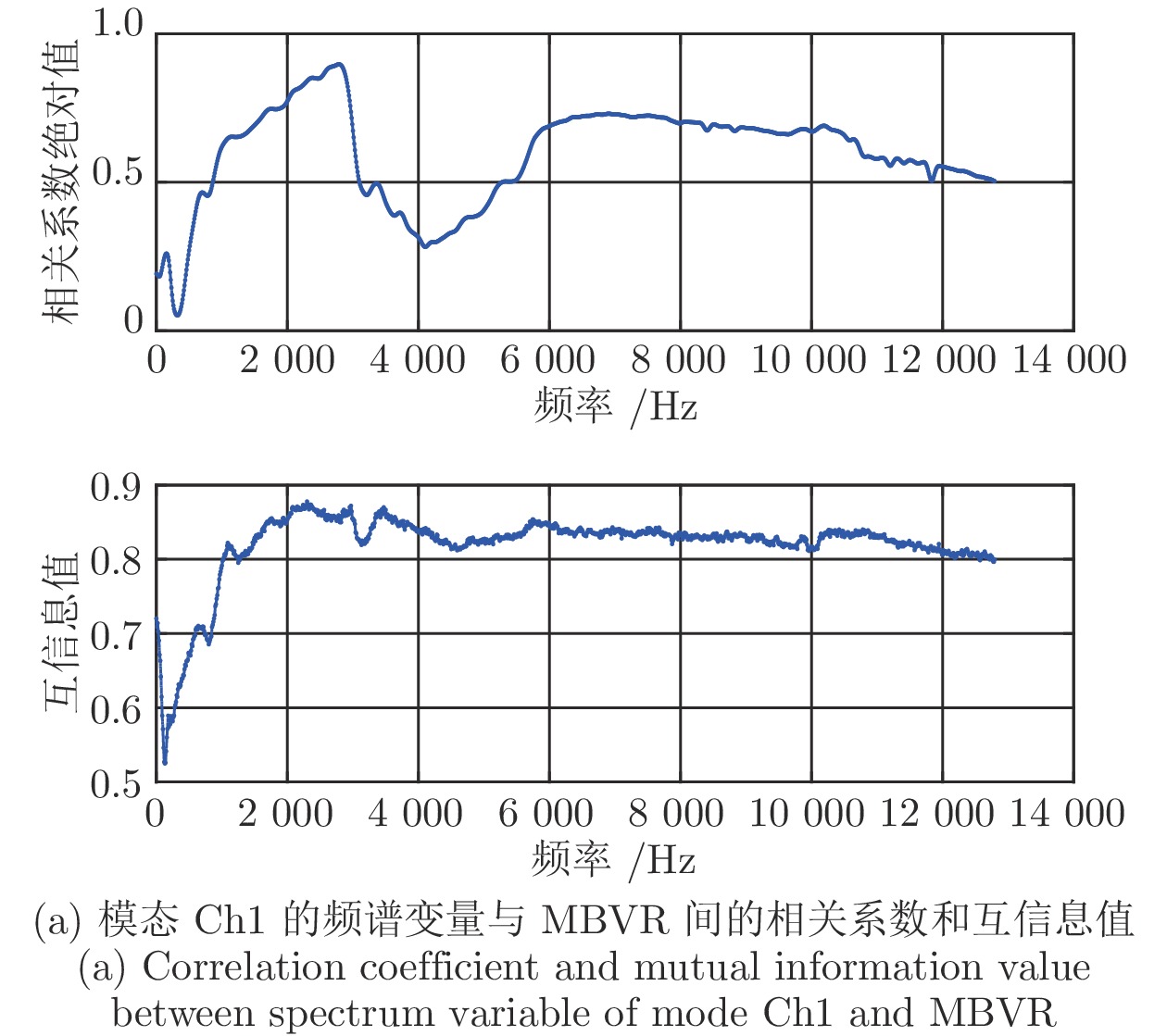

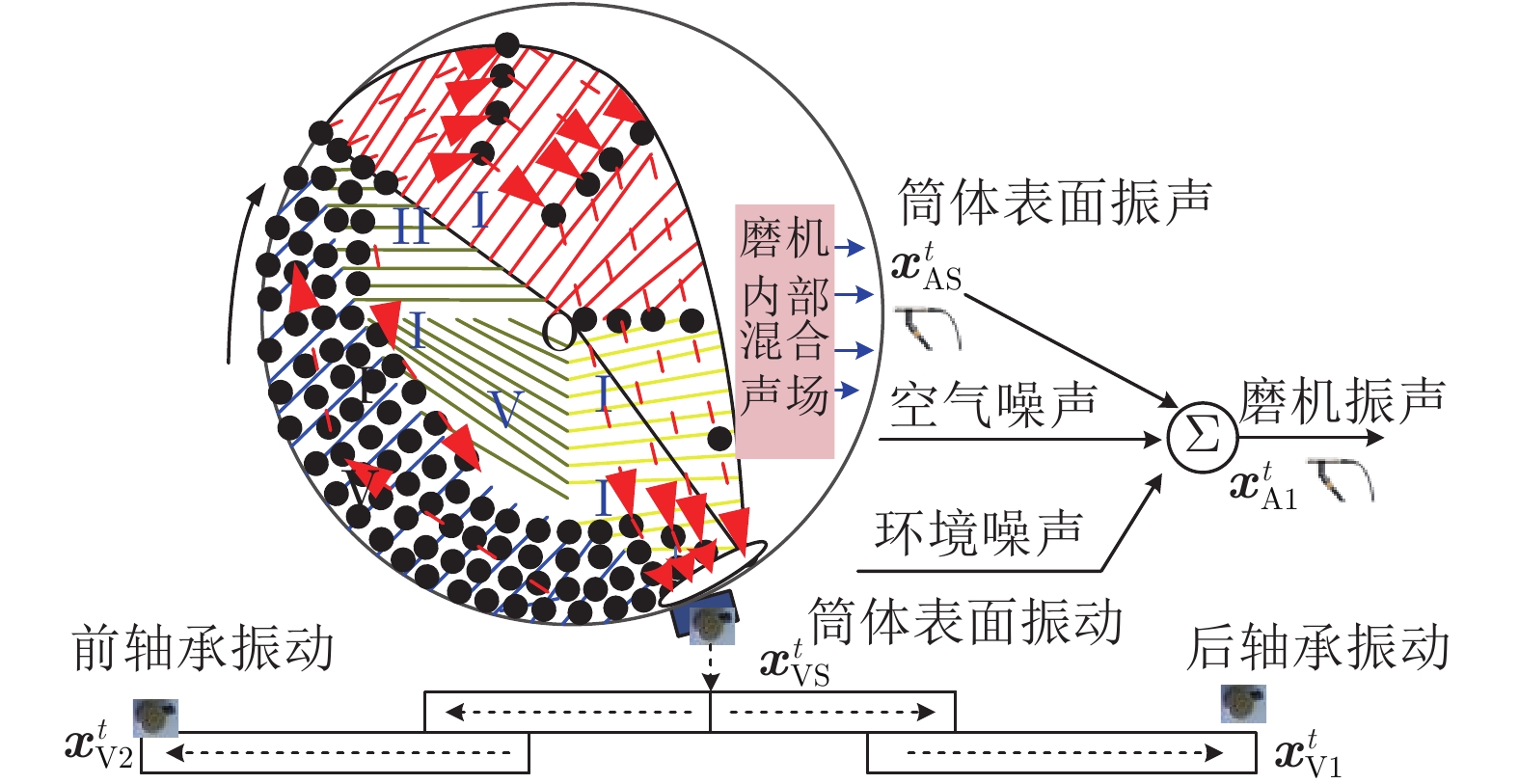

如何融合球磨机系统研磨过程所产生的多模态机械信号构建磨机负荷参数预测(Mill load parameter forecasting, MLPF)模型是当前研究的热点. 针对上述问题, 本文提出一种基于多模态特征子集选择性集成(Selective ensemble, SEN)建模的MLPF方法. 首先, 对多模态机械信号进行时频域变换得到高维频谱数据; 接着, 采用相关系数法和互信息法对多模态频谱进行线性和非线性特征子集的自适应选择; 最后, 采用优化和加权算法对上述特征子集的候选子模型进行自适应地选择与合并, 得到基于SEN机制的MLPF模型. 采用磨矿过程实验球磨机的机械信号仿真验证了所提方法的有效性.

Abstract:How to fuse the multi-modal mechanical signals of the ball mill grinding system to construct mill load parameter forecasting (MLPF) model is a hot issue in current research. Aiming at the above problem, a new selective ensemble (SEN) modeling approach for MLPF based on multi-modal feature sub-sets is proposed. Firstly, time-frequency domain transformation is performed on the multi-modal mechanical signals to obtain high-dimensional spectral data; Then, linear and non-linear feature subsets are adaptively selected from multi-modal frequency spectrum by using feature selection approaches based on correlation coefficient and mutual information method. Finally, linear and non-linear candidate sub-models based on different multi-modal feature sub-sets are constructed, which are adaptively selected and combined by using optimal selection and weighting algorithm jointly. Thus, the final SEN model for MLPF is obtained. Simulation results based on mechanical signals of a laboratory scale ball mill showed the effectiveness of the proposed method.

-

表 1 面向PD的不同模态频谱特征的特征选择系数统计表

Table 1 Coefficients statistical table of different modal spectrum feature for PD

类别 Ch1 Ch2 Ch3 Ch4 Ch5 Ch6 Ch7 Ch8 线性特征选择系数Min 0.09050 0.007868 0.3678 0.005018 0.0001994 0.009596 0.002075 0.8741 线性特征选择系数Max 1.2897 1.7351 1.1913 1.3904 5.2883 1.2649 2.0564 1.0571 非线性特征选择系数Min 0.6644 0.5659 0.8813 0.8403 0.5718 0.7039 0.4860 0.9228 非线性特征选择系数Max 1.0715 1.0885 1.1680 1.1304 1.3556 1.1352 1.623 1.0599 表 2 候选子模型编码

Table 2 Coding of candidate sub-models

序号 子模型特点 子模型名称 子模型编码 多模态通道编号 1 lin_lin Corr-PLS 1-8 1-Ch1, 2-Ch2, 3-Ch3, 4-Ch4, 5-Ch5, 6-Ch6, 7-Ch7, 8-Ch8 2 nonlin_lin Mi-PLS 9-16 9-Ch1, 10-Ch2, 11-Ch3, 12-Ch4, 13-Ch5, 14-Ch6, 15-Ch7, 16-Ch8 3 lin_nonlin Corr-RWNN 17-24 17-Ch1, 18-Ch2, 19-Ch3, 20-Ch4, 21-Ch5, 22-Ch6, 23-Ch7, 24-Ch8 4 nonlin_nonlin Mi-RWNN 25-32 25-Ch1, 26-Ch2, 27-Ch3, 28-Ch4, 29-Ch5, 30-Ch6, 31-Ch7, 32-Ch8 表 3 不同特征选择系数时所构建的SEN模型的预测误差和所选择的子模型编号

Table 3 Prediction error of SEN model with different feature selection coefficients and selected sub-model number

序号 MBVR PD CVR 测试误差 集成子模型编号 测试误差 集成子模型编号 测试误差 集成子模型编号 1 0.05330 { 21 23 27 31 17 32 19 24 30} 0.01579 {26 18 30} 0.01083 {14 19 26 18 30 22} 2 0.06204 {14 31 32 24 27 30} 0.01805 {25 10 31 32 14 19 24 18 30} 0.009697 {27 26 22 30} 3 0.04515 {9 17 26 14 30 27 22 32 19 24} 0.01855 {24 14 18 30 26} 0.01146 {27 14 19 26 31 18 30 22} 4 0.04717 {23 17 27 19 32 24 30} 0.01582 {14 24 26 27 32 30} 0.009544 {19 30 22} 5 0.05231 {27 17 30 23 19 32 24} 0.01843 {24 14 25 22 18 19 30} 0.01093 {20 14 31 27 32 19 26 22 30} 6 0.04433 {31 22 30 32 19 24} 0.01452 {22 14 24 32 26 19 30} 0.009930 {23 25 20 18 32 27 26 19 30 22} 7 0.05697 {31 32 24} 0.01627 {26 22 18 24 32 19 30} 0.009870 {6 20 28 19 32 18 26 27 22 30} 8 0.04459 {27 26 23 22 31 25 30 17 32 24} 0.01687 {27 18 32 19 30} 0.009280 {28 18 26 27 19 22 30} 9 0.04969 {26 32 27 30 25 19 24} 0.01718 {2 18 27 6 26 32 25 30} 0.009650 {18 32 26 25 27 19 30 22} 10 0.04624 {22 17 26 27 30 25 32 19 31 24} 0.01748 {25 26 22 32 27 6 18 19 30} 0.01212 {22 30} 11 0.04404 {25 17 18 27 22 19 30 24} 0.01769 {17 23 22 26 27 6 30 19 18} — — 表 4 磨机负荷参数各通道与多模态特征子集选择性集成模型的测试误差比较

Table 4 Comparison of test errors between various channels of mill load parameters and multi-modal feature subset SEN model

RMSREs 备注 MBVR PD CVR Corr-PLS Mi-PLS Corr-RWNN Mi-RWNN Corr-PLS Mi-PLS Corr-RWNN Mi-RWNN Corr-PLS Mi-PLS Corr-RWNN Mi-RWNN Ch1 0.1924 0.3426 0.1314 0.1503 0.06710 0.05411 0.06910 0.05161 0.05911 0.06622 0.07030 0.04930 筒体振动 Ch2 0.3213 0.7207 0.3103 0.1401 0.04221 0.04430 0.03321 0.03751 0.05650 0.04711 0.03711 0.02620 筒体振动 Ch3 0.4401 0.4431 0.09112 0.09020 0.12012 0.07611 0.03111 0.05210 0.1132 0.07831 0.02922 0.03810 筒体振声 Ch4 0.5125 0.4225 0.2822 0.2001 0.1142 0.08620 0.06460 0.1184 0.07442 0.06910 0.04110 0.04772 筒体振声 Ch5 0.4611 0.3409 0.1911 0.2221 0.1087 0.08122 0.1161 0.09810 0.09711 0.09610 0.04440 0.09911 轴承振动 Ch6 0.3105 0.2141 0.1431 0.1341 0.04410 0.03720 0.03520 0.02431 0.03520 0.03641 0.01630 0.01720 轴承振动 Ch7 0.3802 0.2502 0.1321 0.1101 0.1083 0.06241 0.06121 0.05611 0.09451 0.04811 0.04910 0.04141 轴承振动 Ch8 0.5934 0.6031 0.08090 0.3631 0.0971 0.07910 0.03310 0.03220 0.1421 0.08930 0.06840 0.03730 研磨振声 本文方法 0.04404 0.01452 0.00928 表 5 磨机负荷参数各通道与多模态特征子集选择性集成模型的平均测试误差比较

Table 5 Average test errors comparison of the various channels of mill load parameters and multi-modal feature subset SEN model

通道 MBVR PD CVR 平均预测误差 备注 Ch1 0.1314 0.05161 0.04930 0.07740 筒体振动 Ch2 0.1401 0.03321 0.02620 0.06650 筒体振动 Ch3 0.09020 0.03111 0.02922 0.05020 筒体振声 Ch4 0.2001 0.06460 0.04110 0.1019 筒体振声 Ch5 0.1911 0.08122 0.04440 0.1056 轴承振动 Ch6 0.1341 0.02431 0.01630 0.05820 轴承振动 Ch7 0.1101 0.05611 0.04141 0.06920 轴承振动 Ch8 0.08090 0.03220 0.03730 0.05010 研磨振声 本文方法 0.04404 0.01452 0.00928 0.02260 -

[1] Zhou Ping, Chai Tian-You, Wang Hong. Intelligent optimal-setting control for grinding circuits of mineral processing[J]. IEEE Transactions on Automation Science and Engineering, 2009, 6(4): 730-743. doi: 10.1109/TASE.2008.2011562 [2] 柴天佑. 复杂工业过程运行优化与反馈控制[J]. 自动化学报, 2013, 39(11): 1744-1757. doi: 10.3724/SP.J.1004.2013.01744Chai Tian-You. Operational optimization and feedback control for complex industrial processes. Acta Automatica Sinica, 2013, 39(11): 1744-1757. doi: 10.3724/SP.J.1004.2013.01744 [3] Kano M, Fujiwara K. Virtual sensing technology in process industries: trends & challenges revealed by recent industrial applications[J]. Journal of Chemical Engineering of Japan, 2013, 46(1): 1-17. [4] 汤健, 赵立杰, 岳恒, 柴天佑. 磨机负荷检测方法研究综述[J]. 控制工程, 2010, 17(5): 565-570. doi: 10.3969/j.issn.1671-7848.2010.05.001Tang Jian, Zhao Li-Jie, Yue Heng, Chai Tian-You. Present status and future developments of detection method for mill load[J]. Control Engineering of China, 2010, 17(5): 565-570. doi: 10.3969/j.issn.1671-7848.2010.05.001 [5] 汤健, 乔俊飞, 刘卓, 周晓杰, 余刚, 赵建军. 磨矿过程球磨机研磨机理数值仿真及磨机负荷参数软测量综述[J], 北京工业大学学报, 2018, 44(11): 1459-14Tang Jian, Qiao Jun- Fei, Liu Zhuo, Zhou Xiao-Jie Yu Gang, Zhao Jian-Jun. Review of Ball Mill Grinding Mechanism Numerical Simulation and Mill Load Parameters Soft Measurement for Mineral Grinding Process[J], Journal of Beijing University of Technology, 2018, 44(11): 1459-1470 70 [6] Baltrusaitis T, Ahuja C, Morency L P. Multimodal Machine Learning: A Survey and Taxonomy[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2019, Volume: 41, Issue: 2, Page s: 423- 443 doi: 10.1109/TPAMI.2018.2798607 [7] Huang Peng, Jia Min-Ping, Zhong Bing-Lin. Investigation on measuring the fill level of an industrial ball mill based on the vibration characteristics of the mill shell[J]. Minerals Engineering, 2009, 14: 1200-1208. [8] Das, Sarada Prasad, Das, Debi Prasad, Behera, Santosh Kumar, Mishra, Barada Kanta. Interpretation of mill vibration signal via wireless sensing[J]. Minerals Engineering, 2011, 24: 245-251. doi: 10.1016/j.mineng.2010.08.014 [9] 冯天晶, 王焕钢, 徐文立, 徐宁. 基于筒壁振动信号的磨机工况监测系统[J]. 矿冶, 2010, 19(2): 66-69. doi: 10.3969/j.issn.1005-7854.2010.02.018Feng Tian-Jing, Wang Huan-Gang, Xu Wen Li, Xu Ning. An on-line mill load monitoring system based on shell vibration signals[J]. Mining & Metallurgy, 2010, 19(2): 66-69. doi: 10.3969/j.issn.1005-7854.2010.02.018 [10] 汤健, 乔俊飞, 柴天佑, 刘卓, 吴志伟. 基于虚拟样本生成技术的多组分机械信号建模[J]. 自动化学报, 2018, 44(9): 1569-1589.Tang Jian, Qiao Jun-Fei, Chai Tian-You, Liu Zhuo, Wu Zhi-Wei. Modeling Multiple Components Mechanical Signals by Means of Virtual Sample Generation Technique. Acta Automatica Sinica, 2018, 44(9): 1569-1589. [11] 汤健, 田福庆, 贾美英, 李东. 基于频谱数据驱动的旋转机械设备负荷软测量, 北京: 国防工业出版社, 2015.Tang Jian, Tian Fu-Qing, Jia Mei-Ying, Li Dong. Soft Measurement of Rotating Machinery Equipment Load Based on Spectrum Data Drive. Beijing: National Defense Industry Press, 2015. [12] Hasnat A, Molla A U. Feature selection in cancer microarray data using multi-objective genetic algorithm combined with correlation coefficient. In: Proceedings of Emerging Technological Trends (ICETT), International Conference on. IEEE, 2016: 1−6 [13] Coelho F, Braga A P, Verleysen M. Multi-objective semi-supervised feature selection and model selection based on Pearson's correlation coefficient. In: Proceedings of Iberoamerican Congress Conference on Progress in Pattern Recognition. Springer-Verlag, 2010. [14] Malji P, Sakhare S. Significance of entropy correlation coefficient over symmetric uncertainty on FAST clustering feature selection algorithm. In: Proceedings of 11th International Conference on Intelligent Systems and Control (ISCO). IEEE, 2017: 457−463. [15] Vergara J R, Estévez P A. A review of feature selection methods based on mutual information[J]. Neural computing and applications, 2014, 24(1): 175-186. doi: 10.1007/s00521-013-1368-0 [16] Battiti R. Using mutual information for selecting features in supervised neural net learning[J]. Neural Networks IEEE Transactions on, 1994, 5(4): 537-550. doi: 10.1109/72.298224 [17] Jain A K, Duin R P W, Mao J. Statistical pattern recognition: A review[J]. IEEE Transactions on pattern analysis and machine intelligence, 2000, 22(1): 4-37. doi: 10.1109/34.824819 [18] Fleuret F. Fast binary feature selection with conditional mutual information[J]. Journal of Machine Learning Research, 2004, 5(Nov): 1531-1555. [19] Gavin Brown, Jeremy Wyatt, Rachel Harris, Xin Yao. Diversity creation methods: A survey and categorisation. Information Fusion, 6(2005): 5−20 [20] Tang Jing, Chai Tian-You, Yu Wen, Liu Zhuo, Zhou Xiao-Jie. A Comparative study that measures ball mill load parameters through different single-scale and multi-scale frequency spectra-based approaches[J]. IEEE Transactions on Industrial Informatics, 2016, 12(6): 2008-2019. doi: 10.1109/TII.2016.2586419 [21] 汤健, 柴天佑, 丛秋梅, 刘卓, 余文. 选择性融合多尺度筒体振动频谱的磨机负荷参数建模[J]. 控制理论与应用, 2015, 32(12). doi: 10.7641/CTA.2015.14049Tang Jian, Chai Tian-You, Cong qiu-mei, Liu Zhuo, Yu wen. Modeling mill load parameters based on selective fusion of multi-scale shell vibration frequency spectra[J]. Control theory & Applications, 2015, 32(12). doi: 10.7641/CTA.2015.14049 [22] Tang Jian, Qiao Jun-fei, Wu Zhi-Wei, Chai Tian-You, Zhang Jian, Yu Wen. Vibration and acoustic frequency spectra for industrial process modeling using selective fusion multi-condition samples and multi-source features[J]. Mechanical Systems & Signal Processing, 2018, 99: 142-168. [23] Pao, Y. H., & Takefuji, Y. (1992). Functional-link net computing: theory, system architecture, and functionalities. Computer, 25(5), 76-79. doi: 10.1109/2.144401 [24] Pao, Y. H., Park, G. H., & Sobajic, D. J. (1994). Learning and generalization characteristics of the random vector functional-link net. Neurocomputing, 6(2), 163-180. doi: 10.1016/0925-2312(94)90053-1 [25] 汤健, 赵立杰, 柴天佑, 岳恒. 基于振动频谱的磨机负荷在线软测量建模[J]. 信息与控制, 2012, 41(1): 123-128.Tang Jian, Zhao Li-Jie, Chai Tian-You, Yue Heng. On-line Soft-sensing Modelling of Mill Load Based on Vibration Spectrum[J]. Information and Control, 2012, 41(1): 123-128. [26] 贺敏, 汤健, 郭旭琦, 阎高伟. 基于流形正则化域适应随机权神经网络的湿式球磨机负荷参数软测量[J]. 自动化学报, 2019, 45(2): 398-406.He Min, Tang Jing, Guo Xu-Qi, Yan Gao-Wei. Soft sensor for ball mill load based on DAMRRWNN model[J]. Acta Automatica Sinica, 2019, 45(2): 398-406. [27] 阎高伟, 贺敏, 汤健, 韩东升. 基于最大均值差异多源域迁移学习的湿式球磨机负荷参数软测量[J]. 控制与决策, 2018, 33(10): 1795-1800.Yan Gao-Wei, He Min, Tang Jian, Han Dong-Sheng. Soft sensor of wet ball mill load based on maximum mean discrepancy multi-source domain transfer learning[J]. Control and Decision, 2018, 33(10): 1795-1800. [28] 汤健, 乔俊飞, 刘卓, 周晓杰, 余刚, 赵建军. 面向磨机负荷参数预测的多通道机械信号分析评估与优化组合[J]. 北京工业大学学报, 2019.Tang Jian, Qiao Jun-Fei, Liu Zhuo, Zhou Xiao-Jie, Yu Gang, Zhao Jian-Jun. Multi-channel Mechanical Signal Analytical Estimation and Optimal Combination Method for Mill Load Parameter Forecasting[J]. Journal of Beijing University of Technology, 2019. [29] 赵轩, 郭蔚, 刘京. RGB-D图像中的分步超像素聚合和多模态融合目标检测[J]. 中国图象图形学报, 2018, 23(08): 1231-1241.Zhao Xuan, Guo Wei, Liu Jing. Object detection adopting sub-step merging of super-pixel and multi-modal fusion in RGB-D[J]. Journal of Image and Graphics, 2018, 23(08): 1231-1241. [30] 马江河, 孙颖, 张雪英. 融合语音信号和脑电信号的多模态情感识别[J]. 西安电子科技大学学报, 2019, 46(01): 143-150.Ma Jiang-He, Sun Ying, Zhang Xue-Ying. Multimodal emotion recognition for the fusion of speech and EEG signals[J]. Journal of Xidian University, 2019, 46(01): 143-150. [31] Dahne S, Biebmann F, Samek W, et al. Multivariate Machine Learning Methods for Fusing Multimodal Functional Neuroimaging Data[J]. Proceedings of the IEEE, 2015, 103(9): 1-24. doi: 10.1109/JPROC.2015.2466311 [32] Ramachandram D, Taylor G W. Deep Multimodal Learning: A Survey on Recent Advances and Trends[J]. IEEE Signal Processing Magazine, 2017, 34(6): 96-108. doi: 10.1109/MSP.2017.2738401 [33] Wu D, Pigou L, Kindermans P J, et al. Deep Dynamic Neural Networks for Multimodal Gesture Segmentation and Recognition[J]. IEEE Transactions on Pattern Analysis and Machine I Pattern Analysis and Machine Intelligence, 2016: VOL. 38, NO. 8, 1583-1597. doi: 10.1109/TPAMI.2016.2537340 -

下载:

下载: