Identification of Aero-engine Blade Surface Geometric Defects With Laser Measurement

-

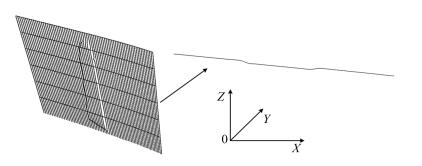

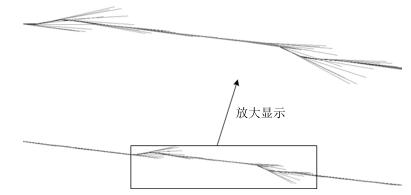

摘要: 针对航发叶片修复检测的应用, 提出了一种基于截面线一阶导矢法的叶片型面缺陷识别方法.该方法是以等高线法处理测量点云中的截面数据, 通过B样条插值函数拟合成光滑曲线; 再由B样条曲线的一阶导矢公式求出每个测点的一阶导数, 然后以点斜公式求出截面曲线上各个测点的切线; 如果曲线光滑, 曲线上测点的斜率变化在两端点斜率值之间, 否则表明曲线上有缺陷存在; 根据k-d树的最近点搜索算法, 遍历整个叶盆(叶背)就可以找到叶盆(叶背)上的缺陷区域.通过与三坐标测量实验比对, 该技术可以实现3 μm精度的缺陷识别.Abstract: Aimed at aero-engine blade repair detection, a method of blade surface defect identification based on the first-order cross-sectional guideline method is proposed. In this method, the cross-section data of the measurement point cloud is processed by the contour line method and the smooth curve is fitted by the B-spline interpolation function. The first-order derivative of each measuring point is obtained by the first-order derivative formula of the B-spline curve. If the curve is smooth, the slope of the measuring point on the curve changes between the slope values of the two endpoints, otherwise it indicates that there are defects in the curve. According to the nearest k-d tree point search algorithm, traversing the entire blade pot (blade back) can find the blade pot (blade back) on the defect area. By comparing with the three-coordinate measurement experiment, the technology can realize the defect identification with a 3 μm precision.

-

Key words:

- Laser displacement sensor /

- aero-engine blade /

- measurement /

- defect identiflcation

1) 本文责任编委 桑农 -

表 1 对叶片表面几何缺陷同一截面进行检测(mm)

Table 1 Detecting the same section of the geometrical defect of the blade surface (mm)

检测装置 最大值 最小值 激光测量系统 0.1337 0.1258 三坐标测量机 0.1369 0.1252 误差 0.0032 0.0006 -

[1] Soares C. Gas turbine major components and modules. Gas Turbines: A Handbook of Air, Land, and Sea Applications. Butterworth: Butterworth-Heinemann, 2008. 119-166 [2] Kauser F B. An overview of gas turbine propulsion technology. In: Proceedings of the 30th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. Indianapolis, IN, USA, 1994. [3] 尹培丽, 王建华, 陈阳泉, 王飞跃.平行测量:复杂测量系统的一个新型理论框架及案例研究.自动化学报, 2018, 44(3): 425-433 doi: 10.16383/j.aas.2018.c170192Yin Pei-Li, Wang Jian-Hua, Chen Yang-Quan, Wang Fei-Yue. Parallel measurements: a new theory and framework for complex measurement system and a case study. Acta Automatica Sinica, 2018, 44(3): 425-433 doi: 10.16383/j.aas.2018.c170192 [4] 孟飙, 曲学军.大尺寸复杂形状组合测量系统的全局标定与多视数据融合.自动化学报, 2017, 43(11): 2051-2060 doi: 10.16383/j.aas.2017.c160273Meng Biao, Qu Xue-Jun. Global calibration and multi-view data fusion for combination measurement system of large complicate shapes. Acta Automatica Sinica, 2017, 43(11): 2051-2060 doi: 10.16383/j.aas.2017.c160273 [5] Wu H D, Gao J, Li S, Zhang Y H, Zheng D T. A review of geometric reconstruction algorithm and repairing methodologies for gas turbine components. TELKOMNIKA, 2013, 11(3): 1609-1618 https://core.ac.uk/display/28429845 [6] Bin S, Bing L. Laser displacement sensor in the application of aero-engine blade measurement. IEEE Sensors Journal, 2016, 16(5): 1377-1384 doi: 10.1109/JSEN.2015.2497363 [7] Mohaghegh K, Sadeghi M H, Abdullah A, Boutorabi R. Improvement of reverse-engineered turbine blades using construction geometry. The International Journal of Advanced Manufacturing Technology, 2009, 49(5-8): 675-687 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dd00017ea594f6a8576de25073e684c3 [8] Giannakoglou K C, Giotis A P, Karakasis M K. Low-cost genetic optimization based on inexact pre-evaluations and the sensitivity analysis of design parameters.Inverse Problems in Engineering, 2001, 9(4): 389-412 doi: 10.1080/174159701088027771 [9] Angelastro A, Campanelli S L, Casalino G. Statistical analysis and optimization of direct metal laser deposition of 227-F Colmonoy nickel alloy. Optics and Laser Technology, 2017, 94: 138-145 doi: 10.1016/j.optlastec.2017.03.027 [10] Blokhina I. Investigation of surfaced press molds made its working resource. Technology Audit and Production Reserves, 2017, 3(1): 34-38 [11] 席平, 孙肖霞.大扭曲度涡轮叶片的三维实体重构与误差检测.工程图学学报, 2009, 30(3): 1-5 doi: 10.3969/j.issn.1003-0158.2009.03.001Xi Ping, Sun Xiao-Xia. 3D solid reconstruction and error inspection of big-twisted turbo blade. Journal of Engineering Graphics, 2009, 30(3): 1-5 doi: 10.3969/j.issn.1003-0158.2009.03.001 [12] 蔺小军, 杨阔, 吴广, 董婷.开式整体叶盘叶片型面数控抛光编程技术.计算机集成制造系统, 2014, 20(2): 379-384 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201402017Lin Xiao-Jun, Yang Kuo, Wu Guang, Dong Ting. NC polishing programming technology of open blisk blade surface. Computer Integrated Manufacturing Systems, 2014, 20(2): 379-384 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201402017 [13] 程云勇, 朱真真, 李维亮, 张定华.面向叶片弯扭变形分析的测量采样方法.计算机集成制造系统, 2013, 19(6): 1329-1335 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201306021Cheng Yun-Yong, Zhu Zhen-Zhen, Li Wei-Liang, Zhang Ding-Hua. Measurement sampling method oriented to blade bending and torsion deformation analysis. Computer Integrated Manufacturing Systems, 2013, 19(6): 1329-1335 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201306021 [14] 张安峰, 李涤尘, 梁少端, 王潭, 严深平, 张连重.高性能金属零件激光增材制造技术研究进展.航空制造技术, 2016, 59(22): 16-22 http://d.old.wanfangdata.com.cn/Periodical/hkgyjs201622001Zhang An-Feng, Li Di-Chen, Liang Shao-Duan, Wang Tan, Yan Shen-Ping, Zhang Lian-Zhong. Development of laser additive manufacturing of high-performance metal parts. Aeronautical Manufacturing Technology, 2016, 59(22): 16- 22 http://d.old.wanfangdata.com.cn/Periodical/hkgyjs201622001 [15] 李文龙, 王刚, 尹周平.闭式叶轮五轴原位检测路径规划与实验验证.航空学报, 2018, 39(3): Article No. 42147Li Wen-Long, Wang Gang, Yin Zhou-Ping. 5-axis onsite inspection path generation and experimental verification of enclosed impeller. Acta Aeronautica et Astronautica Sinica, 2018, 39(3): Article No. 42147 [16] Anoshkin A N, Osokin V M, Tretyakov A A, Potrakhov N N, Bessonov V B. Application of operational radiographic inspection method for flaw detection of blade straightener from polymeric composite materials. Journal of Physics: Conference Series, 2017, 808(1): Article No. 012003 [17] Gao J, Chen X, Yilmaz O, Gindy N. An integrated adaptive repair solution for complex aerospace components through geometry reconstruction. The International Journal of Advanced Manufacturing Technology, 2008, 36(11-12): 1170 -1179 doi: 10.1007/s00170-006-0923-6 [18] 罗菁, 董婷婷, 宋丹, 修春波.表面缺陷检测综述.计算机科学与探索, 2014, 8(9): 1041-1048 http://d.old.wanfangdata.com.cn/Periodical/jsjkxyts201409003Luo Jing, Dong Ting-Ting, Song Dan, Xiu Chun-Bo. A review on surface defect detection. Journal of Frontiers of Computer Science and Technology, 2014, 8(9): 1041-1048 http://d.old.wanfangdata.com.cn/Periodical/jsjkxyts201409003 [19] 上燕燕.逆向工程在发动机叶片重构及检测中的应用研究[硕士学位论文], 陕西科技大学, 中国, 2014.Shang Yan-Yan. The Application Research of Reverse Ngineering in Engine Blade Econstructionand Detection[Master thesis], Shaanxi University of Science and Technology, China, 2014. [20] Ali M H, Kurokawa S, Uesugi K. Application of machine vision in improving safety and reliability for gear profile measurement. Machine Vision and Applications, 2014, 25(6): 1549-1559 doi: 10.1007/s00138-014-0619-0 [21] Mehran P, Demirli K, Surgenor B. Fuzzy machine vision based clip detection. Expert Systems, 2013, 30(4): 352-366 doi: 10.1111/j.1468-0394.2012.00641.x [22] Jung Y S, Park K H. O-ring size measurement based on a small machine vision inspection equipment. Journal of the Korea Industrial Information Systems Research, 2014, 19(4): 41-52 doi: 10.9723/jksiis.2014.19.4.041 [23] 吴庆华.基于线结构光扫描的三维表面缺陷在线检测的理论与应用研究[博士学位论文], 华中科技大学, 中国, 2013.Wu Qing-Hua. Study on Theory and Application of 3D Surface Defect On-line Detecting Based on Line-structured Light Scanning[Ph. D. dissertation], Huazhong University of Science and Technology, China, 2013. [24] 方海燕.非正交系非接触坐标测量机关键技术研究[博士学位论文], 西安理工大学, 中国, 2005.Fang Hai-Yan. Study on Key Technology of Non-orthogonal and Noncontact Coordinate Measuring Machine[Ph. D. dissertation], Xi'an University of Technology, China, 2005. [25] 李文龙, 谢核, 尹周平, 丁汉.基于方差最小化原理的三维匹配数学建模与误差分析.机械工程学报, 2017, 53(16): 190-198 http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201716022Li Wen-Long, Xie He, Yin Zhou-Ping, Ding Han. Mathematical modeling and error analysis of 3d matching based on variance minimization principle. Journal of Mechanical Engineering, 2017, 53(16): 190-198 http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201716022 [26] 李兵, 孙彬, 陈磊, 魏翔.激光位移传感器在自由曲面测量中的应用.光学精密工程, 2015, 23(7): 1939-1947 http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201507017Li Bing, Sun Bin, Chen Lei, Wei Xiang. Application of laser displacement sensor to free-form surface measurement. Optics and Precision Engineering, 2015, 23(7): 1939-1947 http://d.old.wanfangdata.com.cn/Periodical/gxjmgc201507017 [27] Sun B, Li B. A rapid method to achieve aero-engine blade form detection. Sensors, 2015, 15(6): 12782-12801 doi: 10.3390/s150612782 [28] 刘宇, 熊有伦.基于有界k-d树的最近点搜索算法.华中科技大学学报(自然科学版), 2008, 36(7): 73-76 doi: 10.3321/j.issn:1671-4512.2008.07.020Liu Yu, Xiong You-Lun. Algorithm for searching nearest-neighbor based on the bounded k-d tree. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2008, 36(7): 73-76 doi: 10.3321/j.issn:1671-4512.2008.07.020 -

下载:

下载: