Remaining Life Prediction Information-based Maintenance Decision Model for Equipment Under Imperfect Maintenance

-

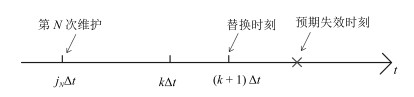

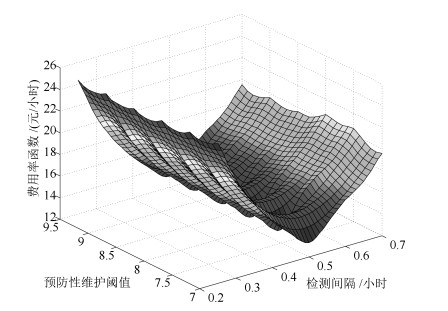

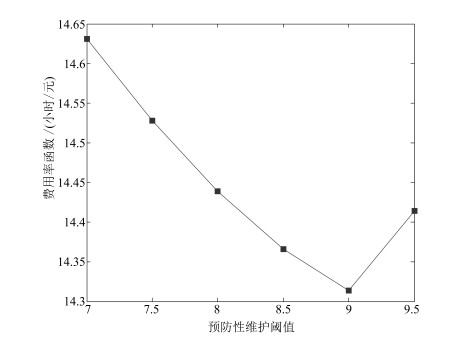

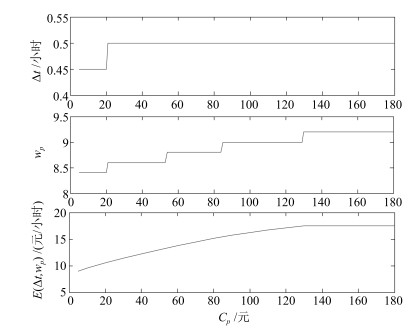

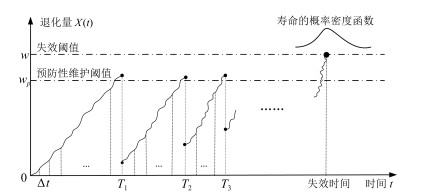

摘要: 基于剩余寿命预测信息进行设备维护决策的研究中,现有方法通常仅考虑不完美维护对退化量或退化率的单一影响,忽略了不完美维护对两者的双重影响.鉴于此,针对随机退化设备,提出一种考虑不完美维护影响的性能退化模型与维护决策模型,融合了维护活动对设备退化量和退化率的双重影响.首先基于Wiener过程分阶段构建存在不完美维护干预的随机退化模型,在首达时间的意义下推导出剩余寿命的解析概率分布;然后基于剩余寿命的预测结果,以检测间隔和预防性维护阈值为决策变量建立维护决策模型;最后数值仿真实验验证了本文模型的有效性,并对费用参数进行了敏感性分析.实验结果表明本文模型具有潜在的工程应用价值.Abstract: In making a maintenance decision for equipment based on remaining life prediction information, current methods normally consider that maintenance activities can only have influence on either the degradation level or the degradation rate, but not on both. In this paper a degradation model and a maintenance decision model considering the influence of imperfect maintenance for stochastic deteriorating equipment are proposed so as to combine the influences of imperfect maintenance activities on both degradation level and degradation rate. A stochastic degradation model subject to the intervention of imperfect maintenance is firstly established based on the multi-phase Wiener process, and the analytical probability distribution of the remaining life is derived in the sense of the first hitting time. Then, a maintenance decision model whose decision variables are the monitoring interval and the preventive maintenance threshold is constructed based on the remaining life prediction information. Finally, a numerical simulation is provided to substantiate the effectiveness of the proposed model and to analyze the sensitiveness of the cost parameters. The experiment result shows that the model has potential to be applied in practice.1) 本文责任编委 文成林

-

表 1 相关费用参数

Table 1 Cost parameters

参数 ${C_i}$ ${C_p}$ ${C_r}$ ${C_f}$ 费用(/元) 5 50 200 500 -

[1] Pecht M G. Prognostics and Health Management of Electronics. New Jersey, USA: John Wiley, 2008. [2] 周东华, 魏慕恒, 司小胜.工业过程异常检测、寿命预测与维修决策的研究进展.自动化学报, 2013, 39(6):711-722 http://www.aas.net.cn/CN/abstract/abstract18097.shtmlZhou Dong-Hua, Wei Mu-Heng, Si Xiao-Sheng. A survey on anomaly detection, life prediction and maintenance decision for industrial processes. Acta Automatica Sinica, 2013, 39(6):711-722 http://www.aas.net.cn/CN/abstract/abstract18097.shtml [3] 程志君, 郭波.基于半Markov决策过程的劣化系统检测与维修优化模型.自动化学报, 2007, 33(10):1101-1104 http://www.aas.net.cn/CN/abstract/abstract13421.shtmlCheng Zhi-Jun, Guo-Bo. Optimization of inspection and maintenance policy for deteriorating system with semi-Markov decision process. Acta Automatica Sinica, 2007, 33(10):1101-1104 http://www.aas.net.cn/CN/abstract/abstract13421.shtml [4] Guo C M, Wang W B, Guo B, Si X S. A maintenance optimization model for mission-oriented systems based on Wiener degradation. Reliability Engineering and System Safety, 2013, 111:183-194 doi: 10.1016/j.ress.2012.10.015 [5] 涂慧玲, 张胜贵, 司书宾, 兑红炎.面向维修过程的多态混联系统综合重要度计算方法.自动化学报, 2014, 40(1):126-134 http://www.aas.net.cn/CN/abstract/abstract18273.shtmlTu Hui-Ling, Zhang Sheng-Gui, Si Shu-Bin, Dui Hong-Yan. The integrated importance measure of multi-state compound systems for maintenance processes. Acta Automatica Sinica, 2014, 40(1):126-134 http://www.aas.net.cn/CN/abstract/abstract18273.shtml [6] Zhang M M, Gaudoin O, Xie M. Degradation-based maintenance decision using stochastic filtering for systems under imperfect maintenance. European Journal of Operational Research, 2015, 245(2):531-541 doi: 10.1016/j.ejor.2015.02.050 [7] Zhang M M, Ye Z S, Xie M. A condition-based maintenance strategy for heterogeneous populations. Computers and Industrial Engineering, 2014, 77:103-114 doi: 10.1016/j.cie.2014.09.001 [8] 徐晓滨, 张镇, 李世宝, 文成林.基于诊断证据静态融合与动态更新的故障诊断方法.自动化学报, 2016, 42(1):107-121 http://www.aas.net.cn/CN/abstract/abstract18800.shtmlXu Xiao-Bin, Zhang Zhen, Li Shi-Bao, Wen Cheng-Lin. Fault diagnosis based on fusion and updating of diagnosis evidence. Acta Automatica Sinica, 2016, 42(1):107-121 http://www.aas.net.cn/CN/abstract/abstract18800.shtml [9] 高文科, 张志胜, 周一帆, 刘飏, 刘祺.存在故障相关及不完备检测的主辅并联系统可靠性建模与维修策略.自动化学报, 2015, 41(12):2100-2114 http://www.aas.net.cn/CN/abstract/abstract18783.shtmlGao Wen-Ke, Zhang Zhi-Sheng, Zhou Yi-Fan, Liu Yang, Liu Qi. Reliability modeling and maintenance policy for main and supplementary parallel system with failure interaction and imperfect detection. Acta Automatica Sinica, 2015, 41(12):2100-2114 http://www.aas.net.cn/CN/abstract/abstract18783.shtml [10] Pham H, Wang H Z. Imperfect maintenance. European Journal of Operational Research, 1996, 94(3):425-438 doi: 10.1016/S0377-2217(96)00099-9 [11] Mercier S, Castro I T. On the modelling of imperfect repairs for a continuously monitored gamma wear process through age reduction. Journal of Applied Probability, 2013, 50(4):1057-1076 doi: 10.1239/jap/1389370099 [12] Van P D, Voisin A, Levrat E, Lung B. Remaining useful life based maintenance decision making for deteriorating systems with both perfect and imperfect maintenance actions. In: Proceedings of the 2013 IEEE Conference on Prognostics and Health Management. Gaithersburg, MD, USA: IEEE, 2013. 1-9 [13] Castro I T. A model of imperfect preventive maintenance with dependent failure modes. European Journal of Operational Research, 2009, 196(1):217-224 doi: 10.1016/j.ejor.2008.02.042 [14] Wang Z Q, Hu C H, Wang W B, Si X S. A simulation-based remaining useful life prediction method considering the influence of maintenance activities. In: Proceedings of the 2014 Prognostics and System Health Management Conference. Zhangjiajie, China: IEEE, 2014. 284-289 [15] Khatab A. Hybrid hazard rate model for imperfect preventive maintenance of systems subject to random deterioration. Journal of Intelligent Manufacturing, 2015, 26(3):601 -608 doi: 10.1007/s10845-013-0819-x [16] Kijima M. Some results for repairable systems with general repair. Journal of Applied Probability, 1989, 26(1):89-102 doi: 10.2307/3214319 [17] Nakagawa T. Sequential imperfect preventive maintenance policies. IEEE Transactions on Reliability, 1988, 37(3):295 -298 doi: 10.1109/24.3758 [18] Zhou X J, Xi L F, Lee J. Reliability-centered predictive maintenance scheduling for a continuously monitored system subject to degradation. Reliability Engineering and System Safety, 2007, 92(4):530-534 doi: 10.1016/j.ress.2006.01.006 [19] Si X S, Wang W B, Hu C H, Zhou D H. Remaining useful life estimation——a review on the statistical data driven approaches. European Journal of Operational Research, 2011, 213(1):1-14 doi: 10.1016/j.ejor.2010.11.018 [20] Van P D, Bérenguer C. Condition-based maintenance with imperfect preventive repairs for a deteriorating production system. Quality and Reliability Engineering International, 2012, 28(6):624-633 doi: 10.1002/qre.v28.6 [21] 司小胜, 胡昌华, 周东华.带测量误差的非线性退化过程建模与剩余寿命估计.自动化学报, 2013, 39(5):530-541 http://www.aas.net.cn/CN/abstract/abstract17879.shtmlSi Xiao-Sheng, Hu Chang-Hua, Zhou Dong-Hua. Nonlinear degradation process modeling and remaining useful life estimation subject to measurement error. Acta Automatica Sinica, 2013, 39(5):530-541 http://www.aas.net.cn/CN/abstract/abstract17879.shtml [22] Huang Z Y, Xu Z G, Ke X J, Wang W H, Sun Y X. Remaining useful life prediction for an adaptive skew-Wiener process model. Mechanical Systems and Signal Processing, 2017, 87:294-306 doi: 10.1016/j.ymssp.2016.10.027 [23] 葛恩顺, 李庆民, 张光宇, 杨美玲.考虑不完全维修的劣化系统最优视情维修策略.航空学报, 2013, 34(2):316-324 http://www.cnki.com.cn/Article/CJFDTOTAL-YCXX201304004.htmGe En-Shun, Li Qing-Min, Zhang Guang-Yu, Yang Mei-Ling. Optimization of condition-based maintenance for degradation systems under imperfect maintenance. Acta Aeronautica et Astronautica Sinica, 2013, 34(2):316-324 http://www.cnki.com.cn/Article/CJFDTOTAL-YCXX201304004.htm -

下载:

下载: